All Categories

History

This section provides an overview for welding robots as well as their applications and principles. Also, please take a look at the list of 37 welding robot manufacturers and their company rankings. Here are the top-ranked welding robot companies as of February, 2026: 1.OTC DAIHEN, 2.Miller Electric Mfg. LLC, 3.Wolf Robotics.

Table of Contents

Categories Related to Welding Robots

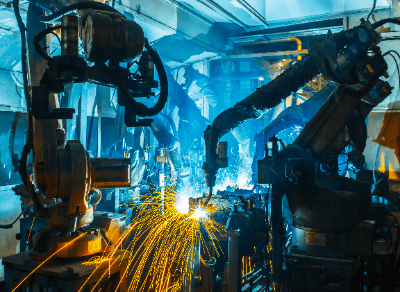

A welding robot is an industrial robot that can perform welding processes automatically. They are mainly used in factories that manufacture automobiles, airplanes, etc.

Welding robots can save labor and improve productivity. They can repeat the same operation quickly and accurately, increasing work efficiency through short and stable operations. Additionally, they can reduce the risk of occupational accidents, such as burns from welding processes and health hazards due to inhaling toxic gases during welding, as well as errors caused by human factors.

In the welding process, achieving consistent weld appearance and density is challenging when done manually, as the quality of welding processes significantly depends on the skills of individual workers. While welding robots are industrial products and may have minimal play in their operating axes, individual differences between robots are controlled meticulously, ensuring exceptional work reproducibility.

Welding robots can minimize quality variations without relying on operators' skills, consistently producing uniform products, thus enhancing quality reliability.

Welding robots automate and optimize welding processes, reducing the need for human intervention and enhancing efficiency. They can be programmed to execute a series of work procedures and processes, reducing labor costs and preventing a decrease in work efficiency due to a lack of manpower.

Furthermore, in manual welding processes, workers are exposed to high-temperature areas where metal melts, increasing the risk of burns from welding spatter, eye damage from intense light, and health hazards from harmful gases. Welding robots contribute to improving the safety of the work environment.

Welding robots have an arm structure resembling a human hand with multiple joints for smooth movement. The most common type is the 6-axis robot, but robots with fewer joints can handle heavier objects with a more limited range of motion, while those with more joints can perform more intricate movements.

Attached to the end of the robot's arm is a welding torch, and by changing the torch part, various welding processes can be performed. Additionally, by replacing the welding torch with a fixture for holding parts, the robot can function as a transfer/handling robot, enabling automation of tasks beyond welding.

Teaching involves instructing welding robots on welding operations and procedures, programming them for automatic operation. Robots can only perform tasks defined in the program. Teaching is crucial because the accuracy of welding processes depends on factors beyond the welding robot, such as workpiece alignment during part setup and the surface quality of the welding surface.

Teaching programming typically uses a microcontroller called a PLC (programmable logic controller) or a sequencer. The most common programming language is the "ladder diagram," which uses an intuitive "ladder-like" graphical representation. There are two primary teaching methods:

Offline Teaching

Offline teaching involves using 3D data on a computer to obtain coordinates for welding process points, simulating them, and transferring the data to the welding robot. Alternatively, welding motion can be programmed directly into the robot. Depending on the accuracy of the product or fixture, strict adherence to 3D data may not always be possible. Combining online teaching, as described in the next section, can improve teaching accuracy.

Online Teaching

In online teaching, a teaching operator uses a remote control to move the welding robot directly, performing a sequence of welding operations. The robot memorizes these actions and reproduces them precisely. However, this teaching method has the drawback that the robot cannot be used for production during the teaching process. It is time-consuming because the operator must set up each welding operation by moving the robot. Consequently, offline teaching has become more common in recent years. Nevertheless, fine adjustments may still be necessary based on the product's machining accuracy or fixture, so it's essential to switch teaching methods flexibly as needed.

Teaching welding robots requires special training, as mandated by Article 59 of the Occupational Safety and Health Law. Violations can result in penalties for both the operator and the company. Operators can qualify for the job with just two days of specialized training and must acquire the skills and knowledge to perform teaching immediately.

Teaching involves programming and simulation using 3D data, as well as knowledge of welding operations. In many cases, optimizing the welding process order and adjusting the welding robot's posture can significantly enhance welding process efficiency. The skill of the operator conducting the teaching is crucial, so training from an experienced person within or outside the company is essential.

For large parts, processing and assembly errors in preceding processes often lead to misalignment in the welding area. In recent years, sensor technology has gained attention for its ability to automatically compensate for welding robot misalignment by attaching sensors to the robot. Sensing technologies include wire touch sensors and laser displacement sensors for pre-sensing before welding and arc sensors and visual sensors for real-time sensing during welding.

Sensing technology continues to advance, allowing welding robots to automatically compensate for misalignment. This eliminates the need for detailed manual teaching corrections, ensuring more stable product quality.

*Including some distributors, etc.

Sort by Features

Sort by Area

ARC Specialties, founded in the United States in 1983, is a manufacturer of automated manufacturing systems. It specializes in metal welding and cutting applications, material handling, pick-and-place machinery, and test equipment for various industries, including consumer, defense, oil and gas, and research. The company also provides installation, training, and communication support, even for clients located in remote areas, to walk operators through the latest techniques and updates for their equipment.

Kobe Steel USA Inc. serves as the US headquarters for Kobe Steel, Ltd. (KOBELCO), a Japanese manufacturer established in 1905. The company specializes in steel, aluminum, and copper products, as well as welding, industrial, and construction machinery. KOBELCO offers a wide range of products for the automotive industry, construction sites, civil engineering projects, energy infrastructure, and transportation systems. The company also develops technologies for environmental cleanup and recycling, including water treatment. Notably, KOBELCO implements strategies to reduce carbon dioxide emissions during production, such as generating electricity from steam and warm water discharge.

Miller Electric Mfg. LLC (MEM) is an American manufacturer of arc welding and cutting equipment originally founded in 1929 before its acquisition by Illinois Tool Works (ITW) in 1993. Headquartered in Appleton, Wisconsin, the company produces various welders such as tungsten inert gas (TIG) and engine-driven models, wire feeders, and plasma cutters. It also offers related consumables and accessories, such as connector kits, spot welding tongs, safety equipment, and flux-cored wires. MEM products are commonly used in metal fabrication, manufacturing, and construction, as well as in the aviation industry.

Lincoln Electric, is a manufacturer and supplier of welding and cutting solutions that was founded in 1895 and is headquartered in Cleveland, Ohio, USA. The company’s core activities include providing a wide range of welding and cutting equipment and consumables, catering to sectors such as automotive, construction, and manufacturing. It offers a suite of services, including technical support, training, and customized welding solutions, tailored to the specific needs of its clients.

Nachi Robotic Systems, Inc. is a subsidiary of Nachi-Fujikoshi Corp., a Japanese manufacturer of industrial robots. It is headquartered in Novi, Michigan, and was established in 1925. The company offers a wide range of robot products, controllers and software, and robot information. Its popular products include arc welding robots, spot welding robots, and assembly robots. Nachi Robotic Systems also offers robot accessories, such as grippers, sensors, and software. The company's products find application in many industries including arc welding, collaborative, dispensing, food grade and material handling.

Kawasaki Robotics (U.S.A.), Inc., founded in 1989 as a subsidiary of Kawasaki Heavy Industries, Ltd., is a manufacturer headquartered in Wixom, Michigan, specializing in industrial robots and robotic automation systems. The company offers robotic solutions, including pick and place robots, general-purpose robots with payloads spanning 3 to 1,500 kg, as well as palletizing robots, capable of handling payloads from 80 to 700 kg, Additionally, the company develops the duAro series, featuring dual-arm Selective Compliance Assembly Robot Arm (SCARA) collaborative robots. Furthermore, the company provides robots for specific functions, such as arc welding robots, explosion-proof paint robots, sealing robots, and water transfer robots.

THG Automation, LLC is a manufacturer of welding robotic system of robotic automation solutions, founded in 2020 and headquartered in Indianapolis, Indiana, USA. The company offers a wide range of products and services, including MIG welding, TIG welding, Oxy-Fuel cutting, and collaborative robots. The company also provides engineering design support, prototyping, and project management services. These products and services are being utilized by OEM industries for wire assemblies and cable harnesses.

Innovation Technology Machinery, Inc., since 1929, has been a turn-key designer and manufacturer facility with extensive manufacturing capabilities in Schertz, Texas. The firm develops, manufactures, and integrates industrial automation, robotics, material handling, visual inspection, tooling, and precision machining systems. The company provides reverse design examination of current systems and equipment to improve supportability and performance. The company provides worldwide installation, onsite support, and training on utilizing the systems and equipment for the printing, oil and gas, chemical, pharmaceutical, and photography industries.

INPRO Technologies was founded in 1987 and is headquartered in Frederick, Maryland. The company is a manufacturer of automation and robotic machinery to market segments including medical devices, automotive, electronics, plastics, and coating of wood and laminate flooring. The company provides process technologies including UV curing and control, web cleaning, plasma treatment, surface cleaning, and electrostatic charging. The company’s services include system integration, consulting, diagnostics, repair, and robotics & automation integration.

AMADA WELD TECH is a subsidiary of AMADA WELD TECH Co., LTD, which was founded in 1972. AMADA is based in Southern California and is a manufacturer of equipment and systems for resistance welding, hot bar bonding, laser marking, and other laser cutting services for industries such as aerospace, automotive, electronics, medical, and photonics. AMADA is ISO 9001:2015 certified. Examples of AMADA products include machines and systems for resistance welding, laser cutting, hermetic steam sealing, laser micromachining, and more.

Force Design, Inc., founded in 1998, and headquartered in Troy, Ohio, is a manufacturer of custom robotic automation equipment. The companys's offerings include robotic machine tending, robotic welding, robotic assembly, robotic painting, and robotic packaging, which are used in industries such as automotive, food and beverages, heavy equipment, industrial, and medical. Motion control and mechanical engineering, machine language programming and automation consultation services are also offered. Its products are used to automate and enhance various manufacturing processes, increasing efficiency and precision across industries.

Ergonomic Partners is a branch of Tri-State Overhead Crane, located in St. Louis, Missouri. Ergonomic Partners has a 50-year history as a turnkey solution manufacturer for material handling applications. Ergonomic Partners provides customer solutions for repetitive lifting application, precise product placement, and awkward load handling. Additionally, Ergonomic Partners provides off-the-shelf ergonomic material handling and workstation equipment with custom designed and engineered handling devices and special equipment solutions. Custom lifting devices include ergonomic lift assists, easy arms, manipulator arms, vacuum lifters, tool balancers and more

Rice Automation, situated Missouri, United States, is a manufacturing company that specializes in the production of personalized welding stations. The company produces various kinds of welding cells, including manual turntable robotic welding cells, dual-zone, dual-zone HSTS, and dual-zone servo turntable robotic welding cells. It also offers fiber lasers, 5-axis waterjets, and milling & turning centers, and provides various services such as education on robot welding, setting up welding stations, as well as maintenance.

Spotwelding Consultants, Inc. was established in 1983 and based in Rowlett, Texas. The company is a welding consultant and distributor of new and used resistance welders to customers across the United States and many countries overseas. The company also provides rebuilding, tooling, and customization services for customers’ welding equipment and machinery. The company’s primary lines are spot welding equipment which includes maintenance and quality control devices, and resistance soldiering products including soldering irons and resistance soldering systems.

Sutton Garten Co.’s history dates back to1916 in Indianapolis, Indiana. Sutton Garten is an independent welding distributor, providing products and services. Sutton Garten’s product offerings include welding abrasives, dry ice & blast equipment, electric welding equipment & supplies, filler metals, flux and chemicals, fume extraction equipment, gases, cylinders, dewars, gas equipment for welding, welding hand tools, plasma cutting equipment, metal cutting sawing grinding tools, welding safety equipment, and weld accessories. Sutton Garten’s service offerings include bulk gas installations, carbon dioxide gas fill service, rental welding & cutting equipment as well as repairs.

ARO Welding Technologies, founded in 1949 and headquartered in Chateau-du-Loir, Le Mans, France, is a manufacturer of welding systems. The company offers a comprehensive product portfolio, including stationary welding machines, welding measuring tools, robotic welding guns, stationary welding tools, and welding controls and software. These products are used in automotive, aerospace, and general industrial applications. It also provides services such as project management, welder training, parameter optimization in the laboratory, and rectifying existing faults.

FANUC Corporation, established in 1972 and headquartered in Yamanashi Prefecture, Japan, is a manufacturer of factory automation, robomachine, IoT, and robotics. The company offers an extensive and diversified product portfolio including, servomotor, robodrill small cutting machine, roboshot electric injection molding machine, robocut wire electrical discharge machine, and lasers. These cutting-edge products cater to a wide range of industries, spanning from automotive, health care, and aerospace to electronics. The aim of the company is to provide efficient and low-cost products to customers.

Guangzhou Heron Intelligent Equipment Co. Ltd., founded in 1991 and headquartered in Guangzhou, China, is a developer and manufacturer of industrial metal connection technologies, machines, and systems. The company's products include spot and press welders, servo-actuated robotic resistance welding guns, and universal clinching machines. It also offers special-purpose industrial metal joining process lines for the home appliance, hardware, and motor manufacturing sectors. The company's services include the custom production of turnkey automated welding and clinching process lines and plants, with on-ground support available from its partners across the Americas, Europe, and Asia.

ESAB, founded in 1904 and headquartered in Maryland, United States, is a manufacturer of welding as well as cutting equipment and consumables. It manufactures accessories and consumables, arc welding equipment, cutting automation, filler metals, and gas equipment. Moreover, it offers manual plasma cutting, PPE/Safety, robotics, torches, and welding automation. For arc welding, Fabricator EM 400i, for instance, is ideal for heavy industries due to the use of solid and flux-cored wires together with fabricator feed. ESAB has earned ISO 9001, ISO 14001, and the Occupational Health and Safety Advisory Services 18001 certifications.

KUKA AG was founded in 1898 in Augsburg, Germany. The company is a subsidiary of GD Midea Holding Co., Ltd. and is an automation developer, designing and manufacturing robot-based automation solutions for medical, automotive, warehousing, and distribution industries. The company’s product segments include robot systems, production machines, and systems, mobility as a driver of Industry 4.0, and process technologies that provide special welding processes to factories. The company’s services include repair and servicing for robots and machines and engineering services for designing and programming robotic systems.

ABICOR BINZEL USA, Inc., a company established in 1945, based in Frederick, Maryland, USA, is a manufacturer and supplier of welding and cutting technology and related products. The company provides various products such as MIG welding guns, robotic welding torches, laser welding optics, fume extraction systems, and consumables. These products are designed to be dependable, efficient, and cost-effective. It plays a pivotal role in welding and cutting processes across various industries, ensuring precise and efficient metalwork. From automotive manufacturing to construction, its solutions are integral to achieving quality welds and cuts.

Spectrum Design, LLC, established in 1995, and located in Franklinville, New Jersey, is a manufacturer of custom industrial machinery and automation equipment. Its range of custom products, include industrial machinery, automation, web handling and converting, automated inspection, and tooling and fixturing in which their products are used in industries such as manufacturing, pharmaceuticals, and electronics. Its products improve productivity, accuracy, and safety in industrial applications, giving customers the tools they need to improve workflow and productivity.

Standard Resistance Welder Company was founded in 1973 and headquartered in Winston, Georgia as a division of Jim Dally & Associates, inc. The company is a developer, engineer, and manufacturer of resistance welding equipment. The company offers custom design and manufacture of all types of standard and special resistance welding equipment and systems as well as electrodes, special tooling, and fixtures. The company’s products include resistance welders and other welding products including gun welders, seam welders, press-type welding machines, and automated welding systems bench welders.

Legacy Industries, established in 1993 in Los Angeles, California, USA, is a manufacturer and supplier of custom metal and plastic components. The company offers a wide range of products including precision metal stampings, custom plastic injection moldings, and enriched assemblies. These components are used in diverse industries such as automotive, electronics, and consumer goods. Legacy Industries' components are integral to the creation of quality products, ensuring durability and functionality. Additionally, the company continues to provide tailor-made solutions that meet the unique requirements of its clients and enhance the success of various industries.

Weldlogic was started in 1978 and is headquartered in Newbury Park, California. The company serves both domestic and international customers globally in the medical, sensor, aircraft, military, and oil industries as an engineer and manufacturer of welding systems and roll-forming systems. In addition to welding systems and roll forming systems, the company offers various custom systems, tube manufacturing cells, welding power supplies, and laser welding systems. The company offers process validation via pretesting systems and guarantees that the quality and specifications of every system delivered meet or exceed customer requirements.

Shenzhen JASIC Technology Co. Ltd. (JASIC Technology), founded in 2005 and headquartered in Shenzhen, Guangdong, China, is a developer, manufacturer, and supplier of welding and cutting equipment. The company's products range from hobby-grade welding machines to advanced industrial-grade solutions and include inverter welding machines, welding accessories, and air plasma cutters. The company exports its products to over 80 countries, and its products were chosen for the construction of the Beijing Bird's Nest Stadium and the Shenzhen Metro.

Migatronic A/S is a Danish manufacturer of welding machines and equipment that is headquartered in Fjerritslev, Denmark, and was established in 1974. The company's core expertise lies in designing and producing a diverse range of welding machines and accessories, including MIG welders, TIG welders, plasma cutters, and robotic welding systems. Migatronic also offers other welding consumables, such as welding rods, wire, and gas. Migatronic offers services such as customization warranties, automation and machine refurbishment. The company's customers include various welding processes and industries, including manufacturers, distributors, automotive, industrial, and shipbuilding.

Acieta is an American contract manufacturer specializing in robotic automation solutions that was originally founded in 1983 as Automated Concepts Incorporated before its rebrand in 2014. Based in Waukesha, Wisconsin, the company primarily offers design, development, and engineering services including concept development, layout planning and simulation. They also provide project management as well as onsite installation and training. Acieta manufactures robotic automation products such as Fuji automatic numerical control (FANUC) robots, electrical cabinets, and FastARC weld cells for their clients in the industrial sector. The company is a subsidiary of North American machine tool distributor Ellison Technologies.

SybotX is a robotics engineering and industrial automation firm based in Lyon, specialized in customized industrial solutions. Active nationally and internationally, we offer comprehensive services: consulting, auditing, expertise, integration, technical support, and training for various sectors including automotive, aerospace, and pharmaceutical industries.

Yaskawa Motoman, founded in 1989, is a manufacturing company which offers industrial automation and robotics solutions in the Americas. With more than 540,000 industrial robots, 18 million servos and 30 million inverter drives installed globally, the company provides automation products and solutions for virtually every industry and robotic application including arc welding, assembly, packaging, dispensing and more. Their product line includes more than 150 distinct industrial arm, a full-line of pre-engineered "World" solutions that are complete application-specific robotic systems that include robot, process and safety equipment. They are backed by a powerful parent, Yaskawa Electric Corporation of Japan.

Novarc Technologies Inc. is a supplier of collaborative robots specializing in the design and commercialization of industrial applications. The company has been in operation since 2017 and is headquartered in North Vancouver, Canada. The company offers a wide range of collaborative robots, including the Spool Welding Robot (SWR) and SWR + HyperFill, using its NovEye and NovSync technologies. Novarc Technologies' services include system design, engineering, and installation. The company's products find application in mechanical contracting, oil and gas, shipbuilding and engineering procurement construction.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | OTC DAIHEN |

17.7%

|

| 2 | Miller Electric Mfg. LLC |

5.8%

|

| 3 | Wolf Robotics |

4.8%

|

| 4 | Kobe Steel USA Inc. |

4.1%

|

| 5 | INPRO Technologies, Inc. |

4.0%

|

| 6 | Arc Specialties |

3.8%

|

| 7 | AMADA WELD TECH INC. |

3.5%

|

| 8 | THG Automation, LLC |

3.2%

|

| 9 | Innovation Technology Machinery |

3.1%

|

| 10 | Nachi Robotic Systems, Inc. |

2.9%

|

Derivation Method

The ranking is calculated based on the click share within the welding robot page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

18 | 66.7% |

France

France

|

2 | 7.4% |

Japan

Japan

|

2 | 7.4% |

Denmark

Denmark

|

2 | 7.4% |

China

China

|

1 | 3.7% |

United Kingdom

United Kingdom

|

1 | 3.7% |

Canada

Canada

|

1 | 3.7% |

89 products found

89 products

Tokuden Co., Ltd.

680+ people viewing

Last viewed: 11 hours ago

■Issues that can be solved ・Improve productivity ・Quality improvement ・Labor saving ■Recommended industries ・Metal products ・Cars/motorcycles...

Linkwith Co., Ltd.

550+ people viewing

Last viewed: 21 hours ago

We have packaged automated equipment for sheet metal TIG welding by combining "L-ROBOT" and collaborative robots. The "L-ROBOT Sheet Metal Welding ...

Japan MDA Robo Co., Ltd.

370+ people viewing

Last viewed: 15 hours ago

The most suitable type of robot and hand can be selected depending on the workpiece mass, operating range, and transfer speed. Hard ones, square on...

7 models listed

Makitec Co., Ltd.

930+ people viewing

Last viewed: 1 day ago

We offer total solutions for production factories, including the introduction of robots and pre- and post-processes. ■Features 1. Labor saving: Au...

Asia Giken Co., Ltd.

750+ people viewing

Last viewed: 1 day ago

The stud welding robot is a dedicated welding system based on our CD stud welding machine. By inputting a program according to the welding conditio...

Asia Giken Co., Ltd.

710+ people viewing

Last viewed: 2 hours ago

The stud welding robot is a dedicated welding system based on our CD stud welding machine. By inputting a program according to the welding conditio...

Asia Giken Co., Ltd.

550+ people viewing

Last viewed: 21 hours ago

The stud welding robot is a dedicated welding system based on our CD stud welding machine. By inputting a program according to the welding conditio...

Hatashige Shoten Co., Ltd.

290+ people viewing

Last viewed: 19 hours ago

■Product introduction Elfin series can be used in automated production lines, assembly, picking, welding, polishing, painting and other application...

6 models listed

DOBOT JAPAN Co., Ltd.

540+ people viewing

Last viewed: 8 hours ago

Fuji Kiko Co., Ltd.

510+ people viewing

Last viewed: 1 day ago

■Product features ・Stud welding robot is a dedicated welding system based on CD stud welding machine. By inputting a program according to the weld...

Dahching Electric Industrual Co,. Ltd.

690+ people viewing

Last viewed: 1 day ago

■Projection welding machine Projection welding uses the heat generated by pressurizing the protrusion and passing an electric current through the p...

Maruka Corporation

300+ people viewing

Last viewed: 1 day ago

■Features The definitive spot welding robot. In pursuit of acceleration and vibration damping, we have achieved a 30% reduction in cycle time (comp...

FURUKAWA ELECTRIC POWER SYSTEMS CO., LTD

480+ people viewing

Last viewed: 1 day ago

A robot gun driven by a servo motor that contributes to improving welding quality, improving the working environment, and simplifying equipment. ■...

FURUKAWA ELECTRIC POWER SYSTEMS CO., LTD

380+ people viewing

Last viewed: 1 day ago

A robot gun driven by a servo motor that contributes to improving welding quality, improving the working environment, and simplifying equipment. ■...

Maruka Corporation

340+ people viewing

Last viewed: 1 day ago

■Features This is a next-generation spot welding robot with a hollow arm structure. The cables used for the welding gun are built-in, increasing th...