All Categories

History

This section provides an overview for machining as well as their applications and principles. Also, please take a look at the list of 25 machining companies and their company rankings. Here are the top-ranked machining companies as of March, 2026: 1.Paulson Manufacturing Corp., 2.South Shore Manufacturing, 3.Ardel Engineering & Manufacturing Co., Inc..

Table of Contents

Categories Related to Machining

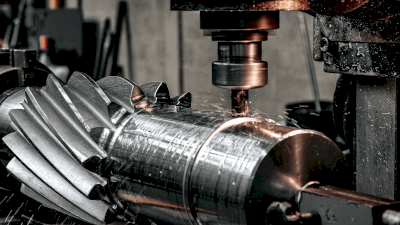

Machining is a processing method in which a blade is used to cut a material.

The product is formed by shaving off unnecessary parts of the material with a tool. Usually, machine tools are used to cut metals and plastics. The machine tools commonly used include lathes, milling machines, and machining centers, which must be selected according to the shape and size required for the process.

The machining methods include turning, milling, drilling, grinding, and scraping, and the machining method must be selected according to the application. For example, drilling is selected for drilling threaded holes.

Machining is characterized by high accuracy but is time-consuming. Therefore, it is important to consider the time required for the manufacturing process when introducing this process.

Machining is used in all kinds of fields, including parts for electrical products, machinery, and automobiles. Workpieces can be made from a variety of materials, including metal, resin, and wood.

There are also various uses for processing methods. For example, lathe turning is used to cut materials to form round shapes, and drilling is used to form threaded holes. Depending on the application, a processing method should be selected.

The principle of machining consists of removing unnecessary parts of the material. For example, if you want to form a round shape, unnecessary parts are removed by lathe turning.

The following five types of machining are typical. The principle of each is as follows:

Lathe turning is a machining process that utilizes a machine tool called a lathe to perform grinding, drilling, and cutting services. To finish parts neatly and efficiently in lathe turning, it is necessary to adjust the speed of material rotation, the speed of blade movement, and the amount of depth of cut.

These settings will vary depending on the dimensions, shape, and material of the material, as well as the type of cutter, and cannot be determined until actual cutting is performed. Appropriate conditions must be selected by observing the noise and shavings during cutting.

Milling is a process to cut an object by rotating a tool. There are vertical milling machines with the rotation axis in the vertical direction and horizontal milling machines with the rotation axis in the horizontal direction.

The tool is moved in three directions, horizontally and vertically, to make a hole at the required position or cut the surface of the material. Tools called drills and end mills are used as cutting tools. End mills are cutters for flat surface machining. The automatic feed function of the milling machine can be used to produce a clean finish on the machined surface.

Drilling is a process of drilling a cylindrical hole in a workpiece with a rotary tool, such as a drill. In addition to general drilling using a drill, the following drilling methods are also available.

There are many other processing methods, in addition to those listed above. The machine used for drilling also varies, and different drilling machines, lathes, milling machines, machining centers, and turning centers must be used for different purposes depending on the intended workpiece.

Grinding is a process for finishing the surface of a material with a grinding wheel. A familiar example of a grinding tool is the whetstone used to sharpen a kitchen knife. It consists of grinding the material with fine and hard abrasive grains.

The kisage process is used to form the material into a perfectly flat surface. This process is characterized by the fact that flat surfaces are processed by hand. The material is removed by rubbing face to face.

In addition to machining, other machining methods include molding, joining, special machining, heat treatment, and surface treatment. Machining is characterized by higher precision than other machining methods.

However, in exchange for the higher precision, it takes more time than other processing methods because of the cutting process. When machining is used in the manufacturing process, it is necessary to manage the process to allow enough time for machining.

*Including some distributors, etc.

Sort by Features

Sort by Area

South Shore Manufacturing Inc., established in 1985 as Jack’s Machine Company, is an American manufacturer based in Hanson, Massachusetts, specializing in precision wire electrical discharge machining (EDM). The company's capabilities include wire and small hole EDM for producing industrial components used in various industries such as aerospace, medical devices, and prototype manufacturing. Its service offerings also include wire jet and fiber laser cutting for materials like metal and rubber, suited for industries like automotive and lighting. Additionally, the company provides a range of computer numerical control (CNC) machining, including boring, milling, and threading, as well as laser marking and engraving services.

Paulson Manufacturing Corp. is a manufacturer of protective clothing that is headquartered in Temecula, California and was founded in The company provides transparent face and eye protection meant for industrial workers and front line responders. The product catalog includes Arc Flash PPE, Industrial PPE, Tactical PPE, Firefighter PPE, and Medical PPE. Electrical, industrial, tactical, fire and rescue, and medical industries are catered by the company. They also offer engineering solutions to applications of their product catalog to the catered industries.

Astro Machine Works is a manufacturer of custom machinery and precision parts. Established in 1984 and has it headquarter in USA. The company specialize in superb design, fabrication, and assembly solutions tailored to diverse industries. They are known for their precision, reliability, and innovation. The company combines advanced technology with skilled craftsmanship to provide unparalleled solutions that meet the demands of our global clientele. They empower businesses to enhance their operations and achieve new levels of efficiency and productivity.

Ardel Engineering & Manufacturing Co., Inc. (AEM) is a contract manufacturer specializing in precision CNC machining, Swiss screw turning, and wire EDM cutting. Founded in 1978 and based in New Hope, Minnesota, the company produces parts and components for use in commercial, medical, defense and industrial applications. The company offers inspection and assembly of components or subassemblies from its ISO 9001:2015 certified and ITAR registered facility. AEM also provides various value-added services to its clients, including design and prototyping assistance, packaging, shipping and inventory management.

GrovTec Machining was founded in 2006 and is headquartered in Wood Village, Oregon, as a small parts manufacturer for several industries. The company possesses advanced machinery and a proficient team of machinists capable of undertaking projects of varying sizes and complexities. The company specializes in delivering items of superior quality within short timeframes, ensuring prompt delivery of parts to meet customer demands. The company places great emphasis on delivering unique customer service and assuring the greatest satisfaction of clients throughout the entire process, starting from the design phase and extending to the final product delivery.

Valworx is a leading supplier of actuated valves and accessories. Valworx can provide you with Stainless, brass, PVC, sanitary ball and butterfly valves. Electric, pneumatic and manual actuation.

In-Place Machining Co., established in 1976, is a supplier of on-site machining and precision machining services based in Wisconsin, USA. The company specializes in on-site machining solutions, performing machining operations directly at the location of the machinery or equipment, eliminating the need for disassembly and transport to a machine shop. This approach reduces downtime, transportation costs, and the complexities of moving large machinery. The company offers machining services, including milling, grinding, welding, and disintegrating. Field machining, emergency repairs, and custom solutions are offered and serve industries like power generation, manufacturing, petrochemicals, and construction.

ISO-TECH Kunststoff GmbH, established in 1990 and headquartered in Ahaus, Germany, is a semi-finished plastic goods and finished plastic parts manufacturer. The company's products include ultra-high-molecular-weight polyethylene interpressed plastic sheets, sliding profiles, and conveyor stars. Its products are available as single pieces or as assembled components. The company has produced products with applications such as marine fenders in shipping ports, cutting boards for the food industry, and bumper guards for airports, hospitals, and supermarkets.

M-Plus Group, established in 1987 and headquartered in France, is a manufacturer of complex parts and sub-assemblies. The company provides complex parts and sub-assemblies using superalloys and stainless steels, serving the energy and aerospace sectors. Its capabilities include machining, sheet metal working, and production of components for gas turbines and combustion systems. It specializes in machining complex 5-axis parts and producing small to medium runs of superalloy components. The company's operations encompass laser cutting, CNC machining, and thermal treatments. It also offers design and assembly services, ensuring end-to-end production capabilities for specialized components and assemblies.

Blisk Casting, established in 1985 and headquartered in Slovenia, is a manufacturer of high-pressure aluminum die-casting components and related components. The company specializes in aluminum parts and offers tooling design, production, and mechanical and surface treatment services. It employs AlSi9Cu3 DIN 226 and AlSi12Cu3 DIN 231 alloys to meet industrial requirements in the automotive, electronics, and mechanical engineering sectors. It incorporates management systems and sustainable development practices into its operations and produces ready-to-use components using CNC machining technology delivered directly to assembly lines. The company also provides technical support, R&D services, and prototyping, utilizing die-casting mold techniques.

HLC Metal Parts Co. Ltd. is an IATF 16949-certified manufacturer of precision metal parts and components founded in 2003 and based in Dongguan City, Guangdong, China. The company primarily produces custom precision metal parts using a range of in-house capabilities, such as metal stamping, CNC machining, and in-mold welding. It also offers assembly and fitting services for metal and plastic accessories. The company operates internationally, with additional locations in Mexico, Taiwan, and Bulgaria.

Schwanog Siegfried Güntert GmbH, founded in 1946 and headquartered in Villingen-Schwenningen, is a specialist manufacturer of tool-changing systems. Since 1990, the company has specialized in the design and manufacture of a range of tool quick-change insert systems that allow continued machining without having to reset tools. Its products include drill forms with inserts, thrust rings as broaching tools for manufacturing gears in one stroke, and tool holders with internal coolant driven straight to the cutting edge. The company's services include complete tool design support for turning parts on single and multi-spindle machines.

Proto Labs Inc. is a custom manufacturer of parts and components for prototyping operations founded in 1999 and located in Maple Plain, Minnesota, USA. The company produces CNC machined parts for on-demand production orders, 3D printed parts for rapid prototyping of test concepts, and injection-molded parts for short-run production of trial or limited edition items. It also offers custom fabrication of sheet metal parts according to client specifications. The company mainly serves client manufacturers of medical devices, consumer appliances, and automotive parts.

AGC Industrial Solutions, founded in 2000 and headquartered in Namur, Belgium, is a contract manufacturer of plastic, metal, and electronic components. Its operational offices are in Shanghai and Qingdao, and it helps small and medium enterprises worldwide to manage and maintain projects in China through subcontracting and purchasing support. The company has over 70 active and audited suppliers and provides services such as casting, stamping, and precision machining. It offers four industrial solutions for manufacturing plastic components, including plastic injection, machining, and 3D printing.

HeBei Matson Metal Tech Co. Ltd., founded in 2014 and based in Shijiazhuang, China, is a supplier of custom metal parts made using various methods like casting, machining, and fabrication. The company has been in the industry for over 20 years and provides die-casting, machining, and 3D print prototyping services, among others. It uses several materials, including stainless steel, aluminum, and Carbon steel, to supply various metal parts like pipe fittings, valves, and pumps. Its CNC machining operation has over 120 machines to provide the full spectrum of machining services, including drilling, turning, and milling.

Thyssenkrupp Materials France, established in 1975 and headquartered in Maurepas, France, is a steel and non-ferrous materials distributor. The company's products include mechanical steel, stainless steel, and non-ferrous metals. It also offers a range of specialty steels manufactured to meet application requirements. From blanks to semi-blanks, it provides processing services to meet customer specifications and supplies parts that integrate into clients processing and manufacturing systems. It serves clients in the automotive, construction, and railway industries.

Ranking as of March 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Paulson Manufacturing Corp. |

11.3%

|

| 2 | South Shore Manufacturing |

11.3%

|

| 3 | Ardel Engineering & Manufacturing Co., Inc. |

9.3%

|

| 4 | MCT Fonderie-Matriçage |

8.2%

|

| 5 | Mecanizados y Acabados Torres, S.L. |

8.2%

|

| 6 | Astro Machine Works |

8.2%

|

| 7 | GrovTec Machining |

6.2%

|

| 8 | Blisk Casting |

5.2%

|

| 9 | AGC Industrial Solutions |

4.1%

|

| 10 | Schwanog Siegfried Güntert GmbH |

3.1%

|

Derivation Method

The ranking is calculated based on the click share within the machining page as of March 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

7 | 36.8% |

China

China

|

6 | 31.6% |

France

France

|

2 | 10.5% |

Germany

Germany

|

1 | 5.3% |

Slovenia

Slovenia

|

1 | 5.3% |

Belgium

Belgium

|

1 | 5.3% |

Spain

Spain

|

1 | 5.3% |