All Categories

History

This section provides an overview for palletizing & depalletizing robots as well as their applications and principles. Also, please take a look at the list of 20 palletizing & depalletizing robot manufacturers and their company rankings. Here are the top-ranked palletizing & depalletizing robot companies as of July, 2025: 1.RMH Systems, 2.Simplimatic, 3.Robopac USA.

Table of Contents

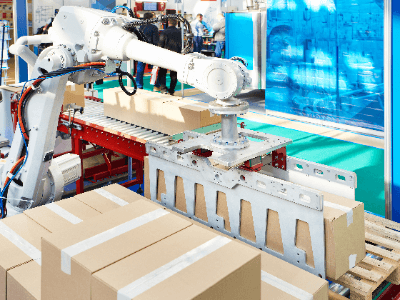

A palletizing robot is an industrial robot that stacks boxes packed with products in a predetermined position on a pallet.

It is sometimes also called a palletizer. Palletizing robots feature a highly automated robot arm that handles the task of transporting and loading heavy loads. Because of its many advantages, such as enabling high-mix low-volume production, improving food product freshness, and reducing shipping time, palletizing robots are attracting attention in a variety of industries.

A similar type of equipment is the depalletizing robot, which automatically unloads boxes mounted on pallets. Depalletizing robots have similar benefits.

Palletizing robots are used in a wide range of industries, including many manufacturing and logistics industries that handle food, chemical, and machine parts. In manufacturing and logistics, boxes packed with products are stacked in specific arrangements on pallets, and then lifted by forklifts to efficiently transport the pallets.

Manually lifting boxes one by one after packing and stacking them on pallets in multiple layers is extremely burdensome work. Onsite, the risk of back pain is a major problem.

By introducing palletizing robots, the work of loading pallets can be automated, which is expected to save labor, reduce the risk of work-related injuries, and streamline the production process.

Palletizing Robot has a gripping mechanism that grips the box in which the product is packed and an arm to which the gripping mechanism is attached. If the processes before and after the palletizing robot are also automated to some extent, the position of the pallet can be the same every time as the position of the boxes sent from the previous process.

Therefore, if the robot repeatedly performs the pre-teached grasping, carrying, and loading operations, it can load the boxes at the exact position. One side of the jaws that make up the gripping mechanism is thinner than the other side, allowing adjacent boxes to be loaded in close contact. Safety principles are specified to prevent workers from entering the robot's range of motion, since workers may be injured if the robot arm collides with them.

Therefore, in addition to automation of product transfer from the previous process using conveyor belts, etc., worker safety is ensured by installing fences to prevent entry into the robot's movable range and by installing ancillary equipment such as doors with interlocks that stop operation when opened.

Palletizing robots include vertically articulated robots and Cartesian coordinate robots.

Vertically articulated robots have a structure similar to a human arm. Vertically articulated palletizing robots, for example, consist of 4, 5 or 6 axes.

An orthogonal robot is a robot with a simple structure consisting of a single-axis linear motion unit. An orthogonal palletizing robot consists of 3 or 4 axes, for example.

Palletizing robots performs the task of repositioning an item from its initial position to a specific position. For example, if the Palletizing Robot performs the task of placing a pallet of 30 boxes (30 long x 20 wide) on a pallet, a total of 600 boxes will be loaded on the pallet.

If we assume that we need to define 5 teaching points for the palletizing robot to reposition one box, then to program this palletizing operation, we need to teach 600 x 5 = 3,000 positional information to the palletizing robot. The palletizing robot must be taught 3,000 positional information.

Teaching 3,000 position data manually to the palletizing robot is a very difficult task. Therefore, teaching is generally simplified by taking advantage of the features of palletizing.

In the case of a pallet with 30 boxes lined up in a regular pattern (30 boxes vertically and 20 boxes horizontally), if the positional relationship of adjacent boxes is known, the positions of all boxes can be calculated by offsetting them by the difference of their positions. Teaching the robot the calculated positions of all the boxes completes the robot teaching.

Depalletizing is the process of moving goods on a pallet to a predetermined position. In other words, it is the reverse of palletizing. Since palletizing and depalletizing involve almost the same work, similar robots can be used.

Depalletizing is part of the process of transporting goods delivered by an outside manufacturer to various locations within the company. Because the palletizing of goods is done externally, it can be difficult to maintain a certain level of palletizing accuracy quality. In this case, it is generally more difficult to develop a depalletizing process than to develop a palletizing process because it may not be possible to accurately perform the depalletizing operation within the company.

*Including some distributors, etc.

Sort by Features

Sort by Area

Micmachinery is a top manufacturer of food and beverage processing packing machinery, specializing in filling, capping, labeling, and mixing equipment. We cater to various industries, including food, cosmetics, pharmaceuticals, and chemicals. Our machines are designed for packaging liquids, pastes, granules, and powders into bottles, jars, cans, sachets, barrels, IBC tanks and tubes. Micmachinery supports packaging for diverse materials like beverages, oils, cosmetics, creams, sauces, and even pharmaceutical products. Our solutions accommodate different packaging types, such as PET bottles, glass bottles, aluminum tubes, soft tubes, and pouches. Known for precision, automation, and durability, our equipment enhances production efficiency and quality. Learn more about our offerings by accessing our website.

Zhangjiagang Micmachinery is a leading manufacturer of high-quality filling, packaging and labeling machines, specializing in innovative solutions for a variety of industries. With a focus on automation and precision engineering, we offer a wide range of products including beer filling machine, carbonated filling machine,non-carbonated filling machine, labeling machine, packing machine and more. Our advanced technologies ensure reliable, efficient and affordable solutions to meet our customers' unique needs. Committed to excellence, Zhangjiagang Micachinery strives to provide outstanding customer service and customize its machines for optimal performance and durability. Visit www.micmachine.com to explore our complete product line and learn more about how we can support your business with state-of-the-art machines.

Honeywell International Inc. was founded in 1885 and headquartered in Charlotte, North Carolina. Honeywell is a diversified technology and manufacturing company to global customers in many industries such as aerospace, building technologies, performance materials, manufacturing, and safety. Honeywell produces hardware and software solutions for each industry it serves. In building technologies, Honeywell designs access controls, electrical and wiring, fire life safety, and employee training services. In aerospace, Honeywell designs cockpit systems and displays, engines, cabin management and cleaning, and health and usage monitoring.

Simplimatic is a Forest, Virginia-based American manufacturer of automation systems and components originally founded in 1965 as Simplimatic Engineering Corp. before being acquired by Signode in 2021 and rebranding in 2022. The company's specialized product lineup includes laser systems for cutting, scanning or welding, packaging and lab automation systems, conveyors for semiconductors or pharmaceutical applications, and robotic palletizing equipment. The company also offers design and engineering, installation, personnel training, and maintenance services for customers in need of additional support.

RMH Systems was established in 1938 and is based in Waukee, Iowa as a provider and integrator of material handling, packaging, and robotic automation solutions. The company’s product portfolio includes conveyor systems, overhead cranes, end-of-line packaging, inkjet coding, racking, ergonomics, and industrial robots, among others. The solutions and accessories offered by the company are vital components in production and distribution systems, enabling safe and efficient operations. The products are used in various industries such as aerospace, automotive, industrial, medical, and motorsport. It is suitable for multiple purposes, from manual operation to computerized control.

Zhangjiagang Micmachinery Co., Ltd., established in 1999, is a professional enterprise specializing in machine design, sales, and turnkey projects across various industries. With decades of production and installation experience, we have become a trusted and quality-assured manufacturer in Zhangjiagang. Our products include filling machines, capping machines, labeling machines, sealing machines, mixers, and water treatment systems, all certified with CE and ISO 9001:2000. Located in Jiangsu, China, our 10,000+ square meter facility serves both domestic and international markets. We prioritize customer satisfaction with innovative, high-quality solutions, combining advanced foreign technologies and durable, reliable equipment to meet industry needs. Mic Machinery aims to be your most trusted partner.

Changzhou Mic Machinery Co., LTD., established in 1999 and based in Changzhou, China, is initially a chemical and agrochemical packaging machine manufacturer. The company develops and manufactures filling machines, capping machines, labeling machines, and pretreatment equipment for liquid, cream, and paste. It also offers vacuum emulsifier mixers, water treatment, and mixing tanks. It is CE and ISO 9001 certified, exporting to over 90 countries, and serves chemical, pharmaceutical, cosmetic, food, and agricultural industries.

Chain We Machinery Co., Ltd was established in 1988 and is headquartered in Taichung City, Taiwan. The company is a designer and producer of customized factory automation conveying equipment to customers in Asia, Europe, and the United States. Customers are generally in the semiconductor equipment, electronics, logistics, and food industries. The company’s products include roller and belt conveyors, linear tracks, pallet dispensers, aluminum framework, and other components designed to improve efficiency in Industry 4.0 environments.

OCME Srl is an Italian manufacturer of integrated systems for industrial packaging that was established in Parma in 1954. The company’s product portfolio includes filling machines for bottling viscous or liquid goods, as well as packing, stretch wrapping, palletizing, and depalletizing machines. It also offers internal logistics solutions such as conveyors, elevators, and laser-guided vehicles (LGVs) for onsite material handling or transport operations. The company’s products are commonly used by clients in the food and beverage, personal care, paper goods, and lubricants industries.

FANUC Corporation, established in 1972 and headquartered in Yamanashi Prefecture, Japan, is a manufacturer of factory automation, robomachine, IoT, and robotics. The company offers an extensive and diversified product portfolio including, servomotor, robodrill small cutting machine, roboshot electric injection molding machine, robocut wire electrical discharge machine, and lasers. These cutting-edge products cater to a wide range of industries, spanning from automotive, health care, and aerospace to electronics. The aim of the company is to provide efficient and low-cost products to customers.

Okura Yusoki Co., Ltd. established in 1960 and based in Hyogo, Japan, is a manufacturer specializing in material handling equipment. The company offers an extensive and diversified product portfolio including conveyor equipment, advanced 3D robot picking systems, efficient automated storage systems, precise picking and sorting equipment, and palletizing equipment picking equipment among others. In addition, the company also provides end-to-end support, from system consultation and design to manufacturing and after-sales service to engineers.

YUSHIN PRECISION EQUIPMENT CO., LTD. established in 1973 and based in Kuzetonoshiro-cho, Minami-ku, Kyoto, JAPAN, is a manufacturer and distributor of Cartesian robots and other industrial automation equipment. The company's product range includes Take-out Robots, Palletizing Robots, End-of-arm tools, Stock System, and Downstream Equipment. These products are designed for tasks like extraction of injection-molded plastic products, enhancing labor efficiency, and supporting factory automation processes. Industries relying on manufacturing, factory automation, and broader industrial operations benefit from its offerings. Beyond product manufacturing, YUSHIN provides services such as product development, and comprehensive sales support.

KUKA AG was founded in 1898 in Augsburg, Germany. The company is a subsidiary of GD Midea Holding Co., Ltd. and is an automation developer, designing and manufacturing robot-based automation solutions for medical, automotive, warehousing, and distribution industries. The company’s product segments include robot systems, production machines, and systems, mobility as a driver of Industry 4.0, and process technologies that provide special welding processes to factories. The company’s services include repair and servicing for robots and machines and engineering services for designing and programming robotic systems.

Mech-Mind Robotics Technologies Ltd. is a Chinese manufacturer and supplier of 3D cameras and AI robotics software that was established in Beijing in 2016. The company primarily produces MECH-EYE branded high-resolution, high-detail industrial 3D cameras for various imaging applications. It also offers MECH- brand series deep learning, machine vision, and robotics programming software. The company’s products are used mainly in the construction, automotive, and logistics industries, including by companies such as Schneider Electric and Siemens.

Robopac USA was established in 1982 as a manufacturer of secondary packaging solutions with its headquarters in Italy. The company deals in Automatic and Semi-Automatic Wrappers with various configurations for different applications. They also provide Case Packer Machines, Horizontal Bagging Machines, Stretch Bundlers, Shrink Bundling Equipment, and Wrap Around Case Packers along with Palletizers and Laser-Guided Vehicle Systems (LGV). This equipment and machines have applications in the food and beverage, paper goods, personal care products, metal, and woodworking industries.

TGW SYSTEMS INC., established in 1976 and headquartered in Marchtrenk, Austria, is a manufacturer and supplier of automated warehouse solutions. The company's product range entails automated storage and retrieval systems (AS/RS), picking systems, conveyor systems, robotic systems, and warehouse management software, serving industries such as fashion and apparel, grocery, industrial and consumer goods, and e-commerce. The company’s comprehensive services include design and engineering, installation, maintenance, and repair, as well as technical support. It also holds an ISO 9001:2015 certification, reflecting its devotion to delivering quality automated warehouse solutions.

SybotX is a robotics engineering and industrial automation firm based in Lyon, specialized in customized industrial solutions. Active nationally and internationally, we offer comprehensive services: consulting, auditing, expertise, integration, technical support, and training for various sectors including automotive, aerospace, and pharmaceutical industries.

Yaskawa Motoman, founded in 1989, is a manufacturing company which offers industrial automation and robotics solutions in the Americas. With more than 540,000 industrial robots, 18 million servos and 30 million inverter drives installed globally, the company provides automation products and solutions for virtually every industry and robotic application including arc welding, assembly, packaging, dispensing and more. Their product line includes more than 150 distinct industrial arm, a full-line of pre-engineered "World" solutions that are complete application-specific robotic systems that include robot, process and safety equipment. They are backed by a powerful parent, Yaskawa Electric Corporation of Japan.

Ranking as of July 2025

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | RMH Systems |

44.6%

|

| 2 | Simplimatic |

6.9%

|

| 3 | Robopac USA |

5.3%

|

| 4 | KUKA AG |

5.1%

|

| 5 | OCME |

4.9%

|

| 6 | TGW SYSTEMS INC. |

4.4%

|

| 7 | Greif Velox |

4.0%

|

| 8 | Honeywell International Inc |

4.0%

|

| 9 | Mech-Mind Robotics Technologies Ltd. |

3.3%

|

| 10 | Star Seiki Co., Ltd. |

2.9%

|

Derivation Method

The ranking is calculated based on the click share within the palletizing & depalletizing robot page as of July 2025. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

China

China

|

4 | 28.6% |

United States of America

United States of America

|

3 | 21.4% |

Japan

Japan

|

3 | 21.4% |

Taiwan

Taiwan

|

1 | 7.1% |

Italy

Italy

|

1 | 7.1% |

Austria

Austria

|

1 | 7.1% |

France

France

|

1 | 7.1% |

56 products found

56 products

Daiki Sangyo Co., Ltd.

420+ people viewing

Last viewed: 4 hours ago

[Food industry] [Cosmetics manufacturing industry] No safety fence required. Palletizing realizes space saving and relocation, which is impossible ...

Closer Co., Ltd.

380+ people viewing

Last viewed: 3 hours ago

A palletizer that anyone can easily use, even without system knowledge. Both hardware and software (developed in-house) are developed in Japan. It ...

Japan MDA Robo Co., Ltd.

560+ people viewing

Last viewed: 13 hours ago

The most suitable type of robot and hand can be selected depending on the workpiece mass, operating range, and transfer speed. Hard ones, square on...

6 models listed

Japan MDA Robo Co., Ltd.

370+ people viewing

Last viewed: 13 hours ago

The most suitable type of robot and hand can be selected depending on the workpiece mass, operating range, and transfer speed. Hard ones, square on...

Sanmei Co., Ltd.

240+ people viewing

Last viewed: 5 hours ago

■High productivity With high payload capacity and the highest operating speed in its class, it is possible to transport and pack many boxes per hou...

Makitec Co., Ltd.

1000+ people viewing

Last viewed: 2 hours ago

Can be delivered immediately. Robotic palletizing system. Based on our track record in a wide range of industries, we will propose robots that are ...

4 models listed

Makitec Co., Ltd.

880+ people viewing

Based on our extensive experience, we will propose the most suitable hand according to the customer's request.

6 models listed

DOBOT JAPAN Co., Ltd.

370+ people viewing

Last viewed: 1 day ago

■Strong performance, palletizing expert The smart palletizing workstation is equipped with the latest generation DOBOT CR20A collaborative robot wi...

DOBOT JAPAN Co., Ltd.

380+ people viewing

■Strong performance, palletizing expert The smart palletizing workstation is equipped with the latest generation DOBOT CR20A collaborative robot wi...

MUTUAL CORPORATION

280+ people viewing

Last viewed: 1 day ago

■Features This is a mobile collaborative robot palletizer that does not require disassembly or installation work when moving because all controller...

MUTUAL CORPORATION

260+ people viewing

Last viewed: 20 hours ago

■Features ・Achieved a width of 1,650 mm using an articulated robot, allowing automatic palletizing without disrupting the flow of people even if t...

DOBOT JAPAN Co., Ltd.

330+ people viewing

Last viewed: 1 day ago

Easy to use and rich in features ■High efficiency with two vacuum cups It supports "two vacuum cup modes" that allow you to pick and palletize two ...

Baro Electric Industry Co., Ltd.

230+ people viewing

Last viewed: 5 minutes ago

It has multiple joints and can reproduce the high degree of freedom of movement like a human arm. Therefore, it can handle palletizing work that re...

Baro Electric Industry Co., Ltd.

220+ people viewing

Last viewed: 11 hours ago

Consists of 2 and 3 orthogonal sliding axes. It is used in a wide range of applications such as assembly, conveyance, transportation, and processin...

Baro Electric Industry Co., Ltd.

220+ people viewing

Last viewed: 21 hours ago

It is used to arrange multiple layers of packages of the same size and shape and stack them on pallets.

Baro Electric Industry Co., Ltd.

190+ people viewing

Last viewed: 1 day ago

Capable of handling products of various sizes and shapes individually and stacking them on pallets.

Baro Electric Industry Co., Ltd.

260+ people viewing

Last viewed: 1 day ago

They are generally specialized for linear movement and are suitable for palletizing products of specific shapes and sizes.

Baro Electric Industry Co., Ltd.

190+ people viewing

Last viewed: 1 day ago

A method of moving goods using a conveyor or transfer mechanism.

Sanmei Co., Ltd.

270+ people viewing

Last viewed: 1 day ago

Features/benefits ■The industry's best processing capacity It boasts the highest transport capacity in the industry, with a maximum of 500 cases/ho...