All Categories

History

This section provides an overview for cartesian robots as well as their applications and principles. Also, please take a look at the list of 31 cartesian robot manufacturers and their company rankings. Here are the top-ranked cartesian robot companies as of March, 2026: 1.Festo, 2.Cerebrus, 3.Henkel Corporation.

Table of Contents

Categories Related to Cartesian Robots

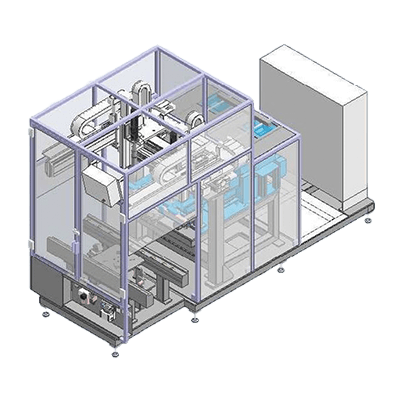

Cartesian Robots, also known as gantry robots, operate by moving along two or three orthogonal axes. Their straightforward structure makes industrial robots a common choice for automating various tasks across a wide range of industries.

Since they have at most three Cartesian coordinates, they can be made by hand and can be easily modified. Another feature is that the program that performs the work can be easily modified.

Therefore, if the work does not require complicated motions and involves monotonous movements, Cartesian Robots can be used to mechanize the work relatively easily.

Cartesian Robots are mainly used in the manufacturing industry for simple tasks such as assembling and transporting parts. In this field, Cartesian Robots are often introduced because linear motion is sufficient to perform these tasks.

First, the line along which the parts will flow is determined. Then, by using a camera or other means, the work from assembly to transport is broken down and replaced by Cartesian Robots. The introduction of the system enables stabilization of productivity.

Specifically, Cartesian Robots are used for small precision mechanical parts, automotive parts, electronic parts for board mounting, as well as in the medical and pharmaceutical fields. In the food field, for example, specially processed arms can precisely grip and move delicate foods, such as tofu, which is fragile and difficult to handle.

The operating range of Cartesian Robots is simple and easy to understand compared to, for example, robots with 6-axis motion, and the price is favorable. Cartesian Coordinate Robots can be used stably even under severe conditions, such as in humid places or semiconductor factories where corrosive gases are used.

The basic operation of Cartesian Robots is to slide a work arm along a linear guide to perform tasks such as assembly, transportation, and positioning.

Multiple units that move on a single axis are combined to perform work in a Cartesian coordinate system. In this case, since each axis of the robot can be moved simultaneously, many operations can be performed efficiently by superimposing linear movements.

Cartesian Robots have a relatively narrow operating range, but they can be combined with a high degree of freedom and can be easily adapted to the required specifications. Since their movements are simpler than those of other robots, they are easier to control, and it is possible to combine multiple Cartesian Robots.

By combining and coordinating with other robots, it is possible to perform many tasks, such as making some complex movements or incorporating processes such as material cutting

Cartesian Robots can only perform simple linear movements, but the accuracy is higher. In particular, those using linear guides with ball screws and linear encoders can achieve highly accurate positioning.

Cartesian Robots have fewer parts, which makes them more rigid. As a result, gaps and deformation are minimized, motion blur is reduced, and work is stabilized. In addition, the simple structure of the Cartesian coordinate robot allows for faster speeds and shorter cycle times.

Cartesian Robots, which can be manufactured with a simple structure and a small number of parts, are less expensive than articulated robots.

Cartesian Robots have disadvantages as well as advantages.

Complex work is impossible

It is difficult to perform complex tasks other than the combination of linear motion.

Large footprint

The disadvantage of Cartesian Robots is that they tend to have a large footprint because they can only move in a straight line and cannot be folded because they have no joints.

Difficult to enlarge

It is difficult to make Cartesian Robots larger in size while maintaining their accuracy and strength, due to cost.

Manpower saving in conveyance work

Although an articulated robot was used to automate the conveyance of change after packaging, a durability problem arose. Cartesian Robots were adopted for this improvement, and good results were obtained. The risk of breakdowns was reduced and labor productivity increased by 1.4 times.

Automation of Nail Brush Manufacturing Process

Nail brushes were mostly handmade due to the complexity of the production process. In order to reduce the aging of workers and costs, six Cartesian Robots were introduced, and the cutting, temporary attaching, and gluing processes were performed by the robots. As a result, six workers were reduced to two, and labor productivity has increased 30 times compared to before the introduction of the robots.

Reduction of Burden and Efficiency of Hazardous Work

Cartesian Robots were used to replace heavy and potentially hazardous tasks that were being handled by humans. As a result, hazards were eliminated, efficiency was improved, and labor productivity was increased 1.4 times compared to the previous system.

*Including some distributors, etc.

Sort by Features

Sort by Area

Henkel Corporation is an American manufacturer specializing in sealants, adhesives, and coatings since its establishment as a subsidiary of German multinational company Henkel AG & Co. KGaA in 1974. Based in Rocky Hill, Connecticut, the company produces various oleochemicals, surfactants, and chemical intermediates used in the production of brand name industrial adhesives, skincare, and surface treatment products. Some of these include Technomelt, Purex, Bonderite, and Loctite. Henkel Corporation is divided into separate Adhesive Technologies, Beauty Care, and Laundry & Home Care business units. The company primarily supplies the product formulation needs of clients in the consumer goods and industrial sectors.

Nordson Corporation, established in 1954 and headquartered in Westlake, Ohio, USA, is a global manufacturer and marketer of differentiated products for precision dispensing and processing. They cater to diverse end markets, including packaging, electronics, medical, energy, and transportation. With over 6,800 employees across more than 35 countries, Nordson offers solutions for bonding, adhesive dispensing, fluid management, test and inspection, and UV curing. Their product line includes dispense tips, syringe barrels, dispensers, srapy valves, fluids, and syringe systems among others. Comprised of eight divisions, they are ISO 9001:2015 certified and provide systems, precision technology, and after market parts.

Absolute Robot Inc., established in 2013 and based in Worcester, Massachusetts, United States is a manufacturer specializing in complete automation solutions for injection molding machines. The company provides a comprehensive product portfolio that includes full servo robots, and pneumatic sprue pickers, and holds the distinction of being a FANUC-authorized system integrator. Beyond manufacturing, it also offers valuable services such as application design and testing, robust aftermarket support, as well as in-person training sessions both before and after the delivery of robots. These automation solutions find applications in diverse industries, including industrial automation, automotive manufacturing, and the broader field of robotics.

Yamaha Motor Corporation, founded in 1955 with their Head Quarters in Iwata, Japan is a manufacturer of motorcycles, marine products, and other motorized products. Yamaha Motor Robotics, founded in 1955 is a subdivision of Yamaha Motor Corporation, and they produce machines that are used in the surface mounter industry. The company offers servo-motor control and image recognition technology for vision systems to develop solder-paste printers, printed circuit board inspection machines, flip-chip hybrid placers, and dispensers. They also provide SMD storage systems and software solutions, and they produce articulated robots, and cartesian robots that have applications in robotics.

Cerebrus, founded in 2008 and headquartered in Hillsborough, United States, is a manufacturer for automation and mechatronic solutions. It specializes in developing cutting-edge software that combines artificial intelligence and cybersecurity expertise to protect critical data from breaches and unauthorized access. These products cater to the medical, defense, automotive, and education industries and are designed to proactively identify and mitigate potential threats. The company's partnerships with cybersecurity organizations and its recognition through awards validate its prowess in the field. It holds an ISO 9001:2015 certification and is recognized as a UL 508A-listed electrical panel shop for maintaining quality in their products.

Festo Corp., originally established in 1925 in Germany, has offices worldwide and is a manufacturer and direct supplier of automation solutions for OEMs. The company produces and sells pneumatic and electrical control systems, drive technology for factories, and process automation. Examples include fittings, actuators, sensors, vacuum technology, pneumatic power modules, electrical control technology, integrated systems, and accessories. They have also expanded into robot control systems. Their custom services include the design, engineering, and production of partial and complete automation control process lines for OEM clients.

Isotech was founded in 182 and is headquartered in Hatfield, Pennsylvania. Isotech is a manufacturer’s representative and distributor of proprietary mechanical and electromechanical products to the industrial, medical, and military OEM and in-plant markets. Some of Isotech’s products include linear slide assemblies & rail sets, shock/vibration mounts & pads, linear bushings & shafting, telescoping lifting columns, positioning stages, air bearings, gas springs/air cylinders, motorized positioning tables, laser marking cutting systems, foamed aluminum/metal/composites, stamped metal, noise control products, and belt driven actuators.

Newmark Systems, founded in 1995, with their Head Quarters at Rancho Santa Margarita, U.S.A, manufacture precision positioning systems and motion control products for OEM applications and optical technologies. The company produces rotary positioners, linear positioners, vacuum-compatible stages, and gantry stages. They manufacture gimbal mounts, motion controllers, and accessories and also offer services to research organizations such as Google, JPL, UCLA, TRW, Lawrence Livermore, and Cornell University. Their products have applications in semiconductor inspection, gimbals for satellite tracking, and robotic systems for component manipulation and inspection. They manufacture products that are used in the semiconductor manufacturing industry and fiber optic communications.

Wuxi Lingood Machinery Technology Corp., established in 1994 and headquartered in Jiangsu Province, China, is a digitally intelligent conveying technology designer, manufacturer, and supplier. The company's products include loss-in-weight feeders, pelletizers, and feeding and conveying equipment. It offers system engineering services for precision metering and batching systems, automatic metering, mixing, and conveying systems, and lithium battery twin-screw continuous pulping systems. The company has installed over 1,000 systems, including in applications for wood plastic composite materials, cable material, and biodegradable plastics.

TECHNAX S.A.S., founded in 1989 as Technax Industrie S.A.S., is a French manufacturer based in Saint-Priest, Lyon, providing brazing and welding services for various equipment and machines. The company’s services include laser, resistance, and refill friction stir spot welding. It also engages in induction brazing and combrazing, a combination of resistance brazing and compacting processes. It offers tool design and fabrication, catering to functions like bending, punching, and screwing, along with precise feeding and positioning of small components. The company serves various industries, primarily the transportation and energy sectors.

Imanpack Packaging and Eco Solutions SPA, established in 1975 and headquartered in Schio, Vicenza, Italy, is a manufacturer of automated packing systems with over 70 partners and 50 agents worldwide. The company's primary products include a range of horizontal packing, vertical wrapping, and carton-forming machines. It also produces feeding systems, shipping-ready end-of-line KLT container packages, and robotic palletizing systems. The company serves the food, automotive, and pharmaceutical industries with customized bag, box, and wet wipe packaging solutions and provides client services that include machine servicing and spare parts supply.

Musashi Engineering, Inc. is a Japanese manufacturer specializing in fully-automated dispensing systems and equipment established in 1978 and based in Tokyo. The company produces various valve types, pneumatic and manual dispensers, and pumps that facilitate fluid transport, as well as robots and controllers that can be customized to work with different interfaces. These are primarily used in the cosmetics, automotive, electronics, and medical markets. Musashi Engineering also offers additional services like consultation, training, installation, and product maintenance to customers with demanding requirements.

Initially established in 1938, Shibaura Machine has three-quarters of a century providing Comprehensive technology and supporting the “monozukuri” of the world. With the technical and development capabilities of the Shibaura Machine Group, various machines and services create rich value and contribute to the creation of an industrial base. Working on the eight technical platforms, they develop and manufacture a wide range of production devices that meet the needs of the times, delivering the best solutions by combining our accumulated excellent know-how and the latest technology. Shibaura Machine uses its knowledge of modern global standards of advanced technology to support Japan and the world.

Janome was founded in 1984 and headquartered in Japan is a manufacturer of sewing machine motors and other precision parts. The company offers an extensive and diversified product portfolio including, servo presses, Cartesian robots, SCARA robots, automatic screw presenters, and computer robots. These products are integral to various industries, particularly textile and apparel manufacturing; and are used for press fitting, powder compression and shaping, perforation cutting, press molding, and caulking, among other essential applications.

Kondo Seisakusho Co., Ltd. based in Gamagori-city, Aichi-prefecture, is a manufacturer and supplier of specialized industrial equipment. The company's product range includes Parallel Hand, Fulcrum Hand, Chuck, Rotary Joint, and Autohand Changer Aligning Device. These tools play a role in various industrial processes, aiding in operations such as precision alignment, material handling, component installation, and machinery synchronization. They serve industries that require precision equipment and alignment. Additionally, the company offers services in quality assurance, design, manufacturing, and customer support.

ENGEL, headquartered in Schwertberg, Austria, is one of the globally leading companies in plastics processing machines. From individual injection moulding machines to integrated and automated production cells, ENGEL offers customised solutions for thermoplastic, thermoset and elastomer processing from a single source. ENGEL injection moulding solutions are used, for example, to manufacture automotive components, housings and other parts for electrical and electronic products, household goods, toys and leisure articles, packaging, and products for medical technology and health care. ENGEL's leading market position is founded on two cornerstones: on the one hand, high-technology business that initiates permanent further development and on the other hand, large-scale production to make our cost-intensive development work financially affordable. With nine production plants in Europe, North America and Asia, as well as subsidiaries and representatives in more than 85 countries, ENGEL has a global presence. From its foundation in 1945 to the present day, ENGEL has always been 100 percent family-owned.

PreciFluid System Corporation, established in 1998 and based in France, is a manufacturer of fluid dispensing technology. The company offers a range of dispensers, cartesian robots, and accessories tailored to optimize production lines. These solutions cater to many industries, including aerospace, automotive, and renewable energy. Its fluid treatment technologies offer precision up to 0.06 microliters with outstanding repeatability. The company's expertise in micro-motors and drive systems enables it to facilitate efficient and sustainable optimization and fluid utilization for its clients. It also provides comprehensive engineering, procurement, and maintenance services.

IntelLiDrives Inc., founded in 1999 and headquartered in Pennsylvania, United States, is a manufacturer of linear actuators, XY tables, and rotary tables. The company offers a diverse product lineup, including multi-axis motion and automation controllers with visual programming, four-axe XY-Z-rotary stages for precision applications, and integrated two-axe rotary assemblies. These products have applications in various industries, including semiconductor manufacturing, automated accurate positioning in microscopy, and electronic assembly manufacturing. Its research center has published that aperture Planar ServoRing Series rotary tables can be used to develop medical devices.

igus GmbH, established in 1964 and based in Cologne, Germany, is a manufacturer and distributor of technical products made using polymers for movement. Its products include injection molding frames, motor control systems, and plain bearings, and it has over 240,000 products in over 1,000,000 variations. It serves 188,000 companies from over 80 countries worldwide in 50 different industries, including packaging, automotive, and renewable energy. The company is ISO 9001, ISO 14001, and ISO 50001 certified, and in 2023, it recorded €1.115 billion in sales. Since 2021, the company has purchased 380 new injection-molding machines and has replaced 275 old ones.

KUKA AG was founded in 1898 in Augsburg, Germany. The company is a subsidiary of GD Midea Holding Co., Ltd. and is an automation developer, designing and manufacturing robot-based automation solutions for medical, automotive, warehousing, and distribution industries. The company’s product segments include robot systems, production machines, and systems, mobility as a driver of Industry 4.0, and process technologies that provide special welding processes to factories. The company’s services include repair and servicing for robots and machines and engineering services for designing and programming robotic systems.

MITA Cooling Technologies, founded in Italy in 1960, is a manufacturer and supplier of cooling systems. It offers a range of cooling products, including adiabatic dry coolers and adiabatic condenders, open-circuit cooling towers, closed-circuit cooling towers, and evaporative condensers. It also provides services like cooling water maintenance, remote management, and cooling advisory services, as well as software programs and technical advice to help customers select water-efficient and sustainable cooling technologies.

Hirata Corporation is a manufacturer and distributor of industrial robotic and logistics equipment based in Kumamoto, Japan. Established in 1951, the company first dabbled in manufacturing and marketing industrial vehicles. In 1958, they turned to manufacturing agricultural-related products. By 1959, they started their first conveyor belt line, and in May 1964, their television assembly line was launched. In 1977, they developed their first robot-controlled machine, and from there, they shifted towards robotic logistical equipment. The company is present in eight countries, namely Japan, Taiwan, the United States, Mexico, China, Singapore, Malaysia, and Thailand.

FUYU Technology Co., Ltd, established in 2011 in Chengdu, Sichuan Province, China, is a manufacturer and supplier of linear motion system intelligent products. The company's product range includes Ball Screw Linear Guides, Belt Driven Linear Guide, Miniature Series, High Precision Series, and Linear Motor Module. These products find vital applications across industries such as medical, automation, and electronics. The company also offers services such as electric actuator development, multi-axis positioning stage design, Cartesian robot motion control, and OEM solutions.

Sepro Group was founded in 1973 and is located in La Roche sur Yon, France, is a manufacturer of cartesian CNC robots for injection molding machines. The company offers a diverse product portfolio, including 3-axis robots, 5-axis robots, and 6-axis robots controlled by the same visual control system. These robots are utilized in various applications such as managing a small peripheral for simple inserts distributor, picking parts and placing them on a conveyor, and stacking on a conveyor system with boxes and interleaves.

OMRON Corporation is a Kyoto based electrical equipment manufacturing company founded by Kazuma Tateisi in 1933. OMRON’s product portfolio includes medical equipment like nebulizers and digital thermometers, automated teller machines for the finance industry to AC, DC and custom control systems for the oil and gas industries. The company has over 30,000 employees and offers its products and services in 120 countries. It primarily serves the healthcare, energy, casino, and automated test equipment industries.

Dopag, founded in 1976 and headquartered in Mannheim, Germany, is an ISO 9001-certified supplier of metering, mixing, and dispensing solutions and a member of the Hilger & Kern Group. Its products include metering components, pumps, and automated dispensing systems, which can be partially or fully automated or be integrated into production lines. The company also sells mixing as well as one-component and multi-component metering systems for sealing, gasketing, and bonding processes. It serves industries such as wind power, automotive, and aerospace and can configure and produce unique systems according to customer’s requirements.

TM Robotics is an American authorized distributor of industrial robots manufactured by the Japanese company Shibaura Machine (formerly known as Toshiba Machine) that was established in the year 2000. Based in Elk Grove Village, Illinois, the company offers various industrial robots, including Selective Compliance Articulated Robot Arm (SCARA), Cartesian, and 6-axis model category robots. These are used in a wide range of industrial facility applications, including loading or unloading, machine tending, and assembling. TM Robotics operates internationally, with a European headquarters in Hertfordshire, United Kingdom and a network of distributors across North and South America, Africa, Asia, and Europe.

Ranking as of March 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Festo |

9.2%

|

| 2 | Cerebrus |

8.5%

|

| 3 | Henkel Corporation |

7.0%

|

| 4 | Nordson Corporation |

6.7%

|

| 5 | Yamaha Motor Corporation, USA |

6.6%

|

| 6 | Absolute Robot Inc. |

6.1%

|

| 7 | Isotech, Inc. |

5.6%

|

| 8 | KUKA AG |

3.7%

|

| 9 | ROSH Electroptics |

3.1%

|

| 10 | ENGEL |

3.1%

|

Derivation Method

The ranking is calculated based on the click share within the cartesian robot page as of March 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

8 | 36.4% |

Japan

Japan

|

7 | 31.8% |

Italy

Italy

|

3 | 13.6% |

China

China

|

1 | 4.5% |

France

France

|

1 | 4.5% |

Switzerland

Switzerland

|

1 | 4.5% |

Germany

Germany

|

1 | 4.5% |

129 products found

129 products

Janome

920+ people viewing

Last viewed: 10 hours ago

It is a orthogonatic robot that inherits the high functionality and ease of use of multifunctional desktop robots. The orthogonal robot "JC-3 Seri...

Oriental Motor Co., Ltd.

360+ people viewing

Last viewed: 10 hours ago

■Summary ・Delivered with 3 axes of electric slider assembled. ・Moving range 300mm x 300mm x 100mm (X-Y-Z), payload 2.5kg ・Easy operation with de...

Sailor Fountain Pen Co., Ltd. Robot Equipment Division

220+ people viewing

Last viewed: 10 hours ago

A new standard model of Sailor's robot extractor. It is equipped with a variety of functions that respond to user feedback. WVGA (800x480), 7-inch...

5 models listed

Janome

1670+ people viewing

Last viewed: 10 hours ago

It is a orthogonatic robot that inherits the high functionality and ease of use of multifunctional desktop robots. The orthogonal robot "JC-3 Seri...

Oriental Motor Co., Ltd.

460+ people viewing

Last viewed: 10 hours ago

■Summary ・Delivered with 3 axes of electric slider assembled. ・Moving range 300mm x 300mm x 100mm (X-Y-Z), payload 2.5kg ・Easy operation with de...

MPS Co., Ltd.

450+ people viewing

Last viewed: 10 hours ago

■Components of automatic equipment Pro-beam supplies nearly 20 automatic electron beam welding lines to Europe and Asia, including automotive parts...

Janome

1290+ people viewing

Last viewed: 5 hours ago

It is a orthogonatic robot that inherits the high functionality and ease of use of multifunctional desktop robots. The orthogonal robot "JC-3 Seri...

Sailor Fountain Pen Co., Ltd. Robot Equipment Division

300+ people viewing

Last viewed: 10 hours ago

A new standard model of Sailor's robot extractor. It is equipped with a variety of functions that respond to user feedback. WVGA (800x480), 7-inch...

5 models listed

Data Design Co., Ltd.

260+ people viewing

Last viewed: 8 hours ago

■Make the most of multiple 3D printers Form Auto automatically removes printed parts from Build Platform 2, starts the next print without any manua...

Janome

1410+ people viewing

Last viewed: 6 hours ago

It is a orthogonatic robot that inherits the high functionality and ease of use of multifunctional desktop robots. <Main features> ・ Maximum strok...