All Categories

History

This section provides an overview for safety light curtains as well as their applications and principles. Also, please take a look at the list of 34 safety light curtain manufacturers and their company rankings. Here are the top-ranked safety light curtain companies as of July, 2025: 1.Edmund Optics Inc.,, 2.Engineering Technology Corporation, 3.Ferndale Safety.

Table of Contents

Categories Related to Safety Light Curtains

Engaged in research on nitride semiconductor growth using the MBE method at Waseda University Graduate School. After graduating from graduate school in 2016, he joined a non-ferrous metal manufacturer.

Engaged in equipment maintenance and engineering work at metal smelting plants. Moved to a chemical manufacturer in 2022. Engaging in similar tasks.

Safety light curtains are light sensors that monitor the intrusion of people into a facility.

They are mainly installed at entrances to facilities, and in hazardous areas to provide safety measures for workers. Due to their safety-critical nature, many products are designed and evaluated in accordance with the international standard IEC61496-1/2, General Safety Standard for Sensors, and are certified as safety equipment by a third-party certification body.

Safety light curtains are one of the main safety devices used in industry.

The following are examples of where safety light curtains are used:

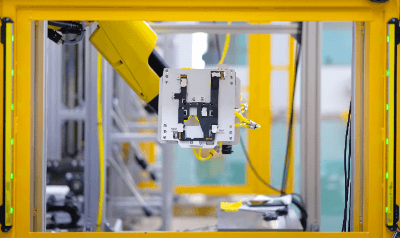

They are often used to detect human intrusion in the vicinity of large drive machines. Also, safety light curtains prevent accidents caused by being caught or entangled in machinery.

In general, large drive machines are covered with fences or railings to make them physically impenetrable. However, it is inconvenient to cover areas completely that are frequently accessed by people or require regular maintenance. In such areas, safety light curtains are installed to shut down the equipment in case of human intrusion.

In addition to industrial applications, safety light curtains are sometimes used in museums where people frequently enter and leave the building and security is required at night.

Safety light curtains consist of a light sensor, an enclosure, and lead wires.

Light sensors are generally composed of a pair of light-emitting and light-receiving units. The mechanism is similar to that of photoelectric sensors and laser sensors, where the light-receiving device detects an object by blocking the projected light and transmits a signal. The optical axes must be aligned, so that multiple projected parallel beams of light are received.

The light source of the floodlight is specified to use a wavelength range of 400 nm to 1,500 nm. LEDs that output infrared rays with a wavelength of about 900 nm are mainly used.

In the case whereby the sensor of safety light curtain malfunctions, the safety device will operate to shut down the equipment if it detects an abnormality. The health signal is mixed with the light sensor, and if it is not received within the response time, a failure signal is sent out as a circuit failure.

The enclosure is an outer shell which is to protect the optical sensor and internal circuit boards. Generally, hard synthetic resin or metal is used. It may be painted with a tiger stripe pattern to indicate that it is a safety measure product.

Lead wires are components used to connect sensors to external control devices. Generally, a multi-core Moving-cable or the like is used. It is often a connector cable.

Selection criteria for safety light curtains include detection height, optical axis pitch, and detection distance.

The detection height is the width of the safety light curtain from which the light beam is emitted. It is selected according to the size of the opening.

The larger the detection height, the wider the area to be detected; but the more expensive and the larger the device, the more uneconomical it becomes. Generally, the size of the aperture should be kept to a minimum and the size of the safety light curtain should be reduced.

The optical axis pitch is the distance between the emission of the optical axis. Also referred to as the minimum detectable object, the shorter the value, the more likely it is to detect even small material intrusions. However, the shorter the optical axis pitch, the more expensive it is.

In order to detect hand intrusion, a 20 mm to 40 mm width is select while 40 mm or more is selected for the detection of arm or human body intrusion.

Detection distance is the distance between the projector and receiver. It is selected according to the size of the opening. Generally, the longer the detection distance, the more expensive the product tends to be.

There are products with short detection distances of 5 m or less. Products capable of detecting over 50 m at the maximum are also available. In general, the shorter the detection pitch, the shorter the detection distance tends to be.

Safety light curtains ensure safety, but there are muting and blanking functions that can be partially disabled. However, care must be taken when using these functions, as incorrect use can lead to fatal accidents.

The muting function temporarily deactivates the safety light curtain. This is done for a portion of the detection area. For example, if a product or part is being manufactured and passes through the safety light curtain, only the part that passes through the safety light curtain will be made non-detectable.

Blanking function is a function that disables a portion of the safety light curtain at any time. It is used in equipment where the optical axis is constantly blocked by a fixed object such as a workbench.

*Including some distributors, etc.

Sort by Features

Sort by Area

Edmund Optics Inc., established in 1942 with headquarters in Seattle, is a manufacturer of optics and optical components for industry, mostly in research and development, pharmaceutical, biotech, security, automation, and defense. The company is responsible for designing and manufacturing a wide array of multi-element lenses, lens coatings, imaging systems, and opto-mechanical equipment. The company offers two types of products: components and assemblies. Edmund Optics Inc. also provides custom engineering, troubleshooting, and manufacturing services to its customers.

Engineering Technology Corporation, founded in 1962 and headquartered in Salt Lake City, Utah, USA, is a manufacturer of equipment like filament winding and tape wrapping processes. The company provides equipment for a complete production line, such as resin baths, tensioning creels, pipe curing ovens, hydraulic testers, and more. It delivers products and services to customers from various sectors, including aerospace, automotive, marine, and energy. The company has been a member of the Zoltec and Toray groups since 2014.

Pepperl+Fuchs, Inc. was founded in Mannheim, Germany in 1945 developing the forerunner of the proximity switch. Pepperl+Fuchs continues to develop proximity sensors as well as other industrial sensors including ultrasonic sensors, rotary encoders, positioning systems, display and signal processing, vibration monitoring, industrial communication, and signal processing as well as related accessories and software. Explosive protection products include safety barriers, surge protection, wireless solutions, HMI systems, power supplies, electrical explosion protection equipment, level measurement, and related software.

ifm efector (ifm) is a subsidiary of ifm electronic, founded in Germany in 1969. ifm has developed, manufactured and marketed sensors and controls technology to industries that include assembly and robotics, automotive, material handling, metal forming, mobile equipment, plastics, and food and beverage. Ifm produces sensors, condition monitoring equipment, image processing, safety technology, industrial communication, IO-link, systems for mobile machines, displays, software, connection technology, voltage supplies, as well as other accessories.

Sick AG, founded in 1946 and headquartered in Waldkirch, Germany, is a manufacturer of sensor and sensor solutions that aid in in production, logistics, and processes automation. The company’s expansive product portfolio includes industrial sensors, encoders, and analyzers. It has over 50 subsidiaries and equity investments as well as several agencies worldwide, and in the 2022 fiscal year, it generated around €2.2 billion. The company established the first subsidiary in France in 1972 and opened another subsidiary in USA in 1975. It changed to a joint stock company in 1996 and the first employee shares were issued in 1999.

HTM Sensors, established in 2007 and headquartered in Niagara Falls, USA, is a manufacturer of industrial sensors and automation products. The product range includes proximity sensors, photoelectric sensors, temperature sensors, and level sensors. These products offer precise detection, stability, and automation control for industrial processes. The benefits of the products include increased production efficiency, reduced downtime, and improved quality control. The company serves industries such as manufacturing, automotive, packaging, and process automation, providing essential sensor solutions that optimize production, enhance safety, and support efficient industrial operations across multiple industries.

Pinnacle Systems Inc., located in Batavia, IL has been a manufacturer of safety products for industrial machine guarding applications for many decades. The company’s products include safety light curtains, safety mats, ergonomic palm buttons, safety relays, and safety controls, among others. The company also provides risk assessment services for industries. Another flagship product of the company is safety relay hubs which provide a complete safety solution for machines and are programmable as per the requirement of the customer.

Banner Engineering Corporation, established in 1966 and headquartered in Minneapolis, Minnesota, is a manufacturer and supplier of industrial automation products. They offer an extensive range of sensors, including proximity sensors, photoelectric sensors, and limit switches, for detecting object presence, position, and speed. Additionally, Banner provides a different types of switches, such as pushbuttons, toggle switches, and rotary switches, to control electricity flow and offer system feedback. Their wide array of controls includes PLCs, HMIs, and motion controllers, enabling automation of industrial processes.

Euchner-USA, Inc. is based in East Syracuse, New York, USA, and is a manufacturer of industrial safety equipment that was established in 1989 as a subsidiary of Germany’s Euchner GmbH + Co. KG. The company produces magnetically coded and transponder-coded safety switches, emergency stop devices, and safety relays for control systems. It also offers light curtains, handheld pendant stations for controlling machinery or processes, and read heads with external evaluation functionality. The company’s products are commonly used in industrial manufacturing operations, including within the automotive, robotics, and machine tool industries.

Dongguan Dadi Electronic Technology Co., Ltd., established in 2006, based in Dongguan, China, is a manufacturer and supplier of infrared sensors and safety light curtains. The safety light curtains include measurement & automation light curtains, multi-area safety light curtains, and accessories such as support columns, deflection mirrors, curtain controllers, adjustable brackets, and customizable cables. The sensors are ultrasonic sensors, color sensors, laser displacement sensors, photoelectric sensors, and slot-type sensors. The company also offers vehicle separators, safety laser scanners, mechanical bolts for safety switches, as well as safety relays. The company is certified by CE, TUC, RoHS, and ISO 9001.

Euchner was established in 1953 as a manufacturer of industrial safety products and is based in Germany. The products designed and manufactured by the company are used by industries that want to minimize risks and hazards. One example of their equipment is a Transponder with Coded Key Systems EKS and CKS which is used for controlling machine functions, storing process parameters, maintaining different access rights, and much more and it helps with procedures like automatic logging on and off for safe and controlled access. There are also safety switches, relays, identification systems, emergency stop devices, and similar items.

Intellisense Microelectronics Xiamen Ltd. is a manufacturer of various industrial sensors that was founded in 2010 in Fujian, China. The company produces sensors with a wide range of applications such as in automation, smart home operations, and industrial processes. Its products include liquid level sensors, photoelectric sensors for object detection, and CMOS integrated sensors that can be programmed for various applications. The company also offers product design as well as customization services for clients with unique projects. Its products are primarily used in industrial automation, healthcare, and defense R&D.

Hans Turck GmbH & Co. KG, established in 1965 with headquarters in Mülheim, Germany, is a manufacturer of industrial automation equipment and systems. The company's product portfolio includes around 15,000 products from the fields of sensor and connection technology as well as fieldbus and interface technology. In addition to individual components such as sensors, remote I/O stations, and quick connectors, it offers systems for image processing, RFID, and pick-to-light applications. The company serves the process manufacturing, mining, agriculture, automotive, semiconductor, and medical industries, among others.

Dongguan Dadi Electronic Technology Co. Ltd., established in 2003 and headquartered in Dongguan City, Guangdong, is a manufacturer of safety light curtains and infrared sensors. The company offers an extensive range of measurement and automation light curtains, multi-area safety light curtains, and industrial safety mats. It also manufactures a range of proximity, photoelectric, and ultrasonic sensors. These products are used in industrial, commercial, and retail applications where it is necessary to detect, measure, and recognize objects. The company offers OEM part and component production services and also accepts wholesale orders.

SCHLEICH, established in 1935, is headquartered in Schwäbisch Gmünd, Germany, as a manufacturer of toy figurines and playsets. The company's product includes a diverse range of meticulously designed figurines spanning various themes such as wildlife, dinosaurs, farm animals, and mythical creatures. The company has won awards such as the Toy of the Year Award in 2018 for its detailed Horse Club sets. In addition, the company's diverse target market encompasses children, parents, educators, and enthusiasts, while international collaborations extend to partnerships with retailers and educational institutions.

Wick Electronic Company Limited is situated in Zhongshan City, China and was founded in 1998 is a manufacturer of sensor projects in the wide industrial automatic field. The company offers an array of products, including extended inductive proximity sensors, weld field immune proximity sensors, and capacitive proximity sensors DC. These products find applications in non-contact detection of metallic objects at greater sensing distances, detect levels of liquids, and operate reliably in environments with strong electromagnetic fields, such as welding applications.

ReeR S.p.A., founded in 1959 in Turin, Italy, is a manufacturer of optoelectronic sensors and controllers for industrial safety. Its products, including laser scanners, contactless interlocks, and photocells, are essential in manufacturing, robotics, automotive, and packaging industries. The company's innovation culture and adherence to ISO9001 specifications lead to the highest level of protection for workers and equipment and make products appealing to global clients. ReeR S.p.A provides technical support and know-how for clients to select, install, and maintain safety solutions.

Eickmann Elektronik, established in 1947 and headquartered in Iserlohn, Germany, is a global cable manufacturer and supplier. Specializing in cable assemblies, temperature measurement technology, and more, their offerings include temperature sensors for various industries, high-temperature thermocouples, and fiber optic sensors for challenging environments. The company also provides efficient fieldbuses like KNX and OPC UA for building and analog automation solutions. Additionally, the company provides light barriers as part of their offerings.

VITECTOR was established in 1918 and is a manufacturer of sensor products and solutions based in North Rhine-Westphalia, Germany. The company manufactures various products such as airwave switches, rubber profile, reflective photo eye, safety light curtain, and pull-in protection. The products have been used in various applications such as sectional doors, rolling doors, and high speed doors. The company has obtained the certification of ISO 9001:2015 for the production of the optic sensor systems.

Redinfra Systems Private Ltd, established in 2021 in Nashik, Maharastra, is a manufacturer of process and automation control equipment, including safety curtains. The company manufactures a comprehensive line of products, including safety curtains, inductive proximity switches, laser marking machines, and infrared sensors, for use in multiple industries. These are frequently utilized for non-contact sensing, switching, and regulating different automatic processes, safety, & security applications, as well as to increase product quality and output. The ISO 9001:2015 organization specializes in magnetic reed switches and its products are used in automotive, electronics, workshop, packaging, and plastics manufacturing industries.

Jining KeLi Photoelectronic Industrial Co, Ltd, established in 1997 in Jining, Shandong, China, is a manufacturer of photoelectronic protection products and equipment. The company specializes in manufacturing safety light curtains that protect against various photoelectronic machines such as lasers, and infrared devices. The comprehensive product line includes safety light curtains, automation light curtains, laser markers, and safety controllers, to name a few, for application in multiple industries. The products are used in hazardous machine industries such as electronics, rubber, plastics, automotive, and packaging industries for their efficient protection, enhanced productivity, and longer durability.

Sai Control System, established in 1997, headquartered in Pune, Maharashtra, is a manufacturer of industrial automation and control products. The product range includes PLC (Programmable Logic Controller) systems, HMI (Human-Machine Interface) panels, SCADA (Supervisory Control and Data Acquisition) systems, proximity sensors, and customized automation products. These products offer efficient process control, increased productivity, and real-time monitoring for industrial applications. The benefits include improved production quality, reduced downtime, and enhanced operational efficiency. The company serves industries such as manufacturing, process control, energy, and pharmaceuticals, providing essential automation solutions that optimize production, ensure precise control, and result in cost-effective and optimal operations.

Ferndale Safety, established in 1971 in Quebec, Canada, is a manufacturer of safety and industrial hygiene products. The product line covers personal protective equipment (PPE), desk shields, Ironworkers, and various industrial hygiene equipment. These products improve worker safety, regulatory compliance, and risk management across various industries. The products' advantages include fewer accidents at work, optimal employee health, and regulatory compliance. The company provides vital safety solutions that safeguard employees, improve workplace safety cultures, and aid in increased operational efficiency across multiple industries, comprising manufacturing, construction, healthcare, and energy.

Takex Europe Ltd. is based in Basingstoke, England, UK, and is a manufacturer of anti-intruder sensors and photo sensors that was established in 1999 as the European subsidiary of Japan’s Takenaka Sensor Group. The company’s product lineup includes passive infrared (IR) sensors for motion detection applications, IR beams for detecting gasses that absorb IR light, and beam towers for disguising the position and number of beams in a space. The company mainly serves clients in the security, transportation, and automation industries.

Schmersal GmbH & Co. KG, founded in 1945, by Heinz and Philip Schmersal, is a name in safety technology, is a manufacturer of safety technology solutions, specializing in switchgear and control devices for various industries. With a diverse range of mechanical and electro-sensitive switching devices, they offer an extensive collection of safety switching systems and devices for safeguarding both humans and machinery. The company looks after three key domains: lift technology, automation technology, and safety technology. Their substantial approach position them as a global supplier of safety switching devices, catering to the safety and automation needs of various industries.

Telco Sensors, established in 1975 and headquartered in Brovst, Jammerbugt, is a designer, developer, and manufacturer of industrial automation and sensing products. Some of its products include photoelectric sensors, photoelectric amplifiers, light curtains, and optical fork sensors. These products find application in various industrial processes and machinery for object detection, safety, and automation. The company is ISO 9001:2015 certified, and all of its products carry a 3-year warranty. The company's network spans six continents and provides around-the-clock service.

Autonics Corporation, established in 1977 and based in Busan, South Korea, is a developer and manufacturer of automation products, which are marketed worldwide. Some of its products include sensors, peripheral connection equipment, motion devices, control devices, and process automation instruments. The automation products are used in various industries, including automotive, packaging, machine tools, metal, and marine. The company has 12 international offices spanning over 100 countries, a fully automated warehouse system, and various international quality certifications, including RoHS, CE, UL, and EAC. Its safety products meet the functional safety standards IEC 61508 and mechanical safety standards ISO 13849.

Omron Corporation, started in 1933 and headquartered in Kyoto, Japan, is a manufacturer of automation components, equipment, and systems, and it developed the first contactless proximity switch in 1960. It has four domains, including industrial automation, electronic components, healthcare, and social systems, and it provides products and services in around 120 countries and regions. Some of its products include microsensing devices, access control systems, industrial robots, surveillance cameras, and blood pressure monitors. In 1971, it developed the first online cash machine, and in 1972, it established Japan’s first welfare factory.

FIESSLER Elektronik, founded in 1956 in Bretten, Germany, is a manufacturer and supplier of safety and control systems. The company offers a range of safety switches, sensors, and control devices used in industrial automation, ensuring operational safety and efficiency. FIESSLER's products find applications in various industries including automotive, packaging, and material handling, where they enhance the safe and seamless operation of machines and equipment. Courtesy of its user-friendly and optoelectronic safety solutions of great quality, the company is always at customers’ disposal for word and deed. The company is also ISO 9001 Certified, an assurance of the customer's constant quality of products.

Telemecanique Sensors, established in 1924 and headquartered in Rueil-Malmaison, France, is a manufacturer and supplier of sensors and sensor-related technology. With a global reach encompassing over 100 subsidiaries and distributors across 50 countries, its offerings which include inductive proximity sensors for object detection, photoelectric sensors, ultrasonic sensors for measurements like level and thickness, capacitive proximity sensors for liquid level detection, and limit switches for object position sensing find applications in diverse industries such as manufacturing, food and beverage, transportation, medical, and utilities. Its facilities are also all compliant with ISO 14 001 global standard.

OMRON Corporation is a Kyoto based electrical equipment manufacturing company founded by Kazuma Tateisi in 1933. OMRON’s product portfolio includes medical equipment like nebulizers and digital thermometers, automated teller machines for the finance industry to AC, DC and custom control systems for the oil and gas industries. The company has over 30,000 employees and offers its products and services in 120 countries. It primarily serves the healthcare, energy, casino, and automated test equipment industries.

Ranking as of July 2025

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Edmund Optics Inc., |

6.9%

|

| 2 | Engineering Technology Corporation |

5.5%

|

| 3 | Ferndale Safety |

4.0%

|

| 4 | HTM Sensors |

4.0%

|

| 5 | Eickmann Elektronik |

4.0%

|

| 6 | Pinnacle Systems Inc. |

3.7%

|

| 7 | SICK AG |

3.7%

|

| 8 | Intellisense Microelectronics Xiamen Ltd |

3.4%

|

| 9 | VITECTOR |

3.4%

|

| 10 | ReeR S.p.A. |

3.4%

|

Derivation Method

The ranking is calculated based on the click share within the safety light curtain page as of July 2025. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

9 | 33.3% |

China

China

|

6 | 22.2% |

Germany

Germany

|

5 | 18.5% |

Italy

Italy

|

2 | 7.4% |

India

India

|

2 | 7.4% |

Switzerland

Switzerland

|

1 | 3.7% |

Canada

Canada

|

1 | 3.7% |

Japan

Japan

|

1 | 3.7% |

459 products found

459 products

TOAMEC Co., Ltd.

280+ people viewing

Last viewed: 3 hours ago

It is slim yet highly rigid, and has a high-power optical system. The SF4D series was introduced as a safety light curtain whose body shuts out liq...

ifm efector, inc.

8070+ people viewing

Last viewed: 3 hours ago

Safety light curtains are used when they need to protect dangerous areas. It is a photoelectric safety device consisting of one floodle and one lig...

129 models listed

ifm efector, inc.

1090+ people viewing

Last viewed: 2 hours ago

Safety light curtains are used when they need to protect dangerous areas. It is a photoelectric safety device consisting of one floodle and one lig...

3 models listed

ifm efector, inc.

1950+ people viewing

Last viewed: 7 hours ago

Safety light curtains are used when they need to protect dangerous areas. It is a photoelectric safety device consisting of one floodle and one lig...

21 models listed

ifm efector, inc.

1190+ people viewing

Last viewed: 1 day ago

Safety light curtains are used when they need to protect dangerous areas. It is a photoelectric safety device consisting of one floodle and one lig...

16 models listed

ifm efector, inc.

720+ people viewing

Last viewed: 2 minutes ago

Safety light grid is used when dangerous areas need to be protected. It is a photoelectric safety device consisting of one floodle and one light re...

3 models listed

ifm efector, inc.

660+ people viewing

Last viewed: 19 hours ago

Safety light grid is used when dangerous areas need to be protected. It is a photoelectric safety device consisting of one floodle and one light re...

3 models listed

ifm efector, inc.

560+ people viewing

Last viewed: 14 hours ago

Safety light grid is used when dangerous areas need to be protected. It is a photoelectric safety device consisting of one floodle and one light re...

3 models listed

ifm efector, inc.

530+ people viewing

Last viewed: 9 hours ago

Safety light grid is used when dangerous areas need to be protected. It is a photoelectric safety device consisting of one floodle and one light re...

3 models listed

ifm efector, inc.

650+ people viewing

Last viewed: 7 hours ago

Safety light grid is used when dangerous areas need to be protected. It is a photoelectric safety device consisting of one floodle and one light re...

6 models listed

Panasonic Industry Co., Ltd.

190+ people viewing

Last viewed: 8 hours ago

basic information ■Globally compatible/flame-proof structure - Obtained UL, CE, CSA, TUV, FM, NEPSI. (CE: ATEX Directive, Machinery Directive, EMC ...

Panasonic Industry Co., Ltd.

210+ people viewing

Last viewed: 14 hours ago

basic information ■Feel "easy to use". Slim & highly rigid body, high power new optical system, functional design - Obtained UL, CE, CSA, TUV, GB, ...

Panasonic Industry Co., Ltd.

170+ people viewing

Last viewed: 14 hours ago

basic information ■Compact safety light curtain Type4 is now available. Perfect fit for aluminum frame Obtained UL, CE, CSA, TUV, UKCA. (CE: Machin...

Panasonic Industry Co., Ltd.

190+ people viewing

Last viewed: 14 hours ago

basic information ■Type 2 is now available as an ultra-thin safety light curtain. Easy installation and reduced wiring Obtained UL, CE, CSA, TUV, U...

Panasonic Industry Co., Ltd.

190+ people viewing

Last viewed: 14 hours ago

basic information ■This one piece is the ultimate in safety and productivity. Ultra-thin safety light curtain Obtained UL, CE, CSA, TUV, UKCA. (CE:...