All Categories

History

This section provides an overview for laser sensors as well as their applications and principles. Also, please take a look at the list of 29 laser sensor manufacturers and their company rankings. Here are the top-ranked laser sensor companies as of July, 2025: 1.ifm efector, inc., 2.Acuity Laser, 3.Banner Engineering Corporation.

Table of Contents

Categories Related to Laser Sensors

Engaged in research on nitride semiconductor growth using the MBE method at Waseda University Graduate School. After graduating from graduate school in 2016, he joined a non-ferrous metal manufacturer.

Engaged in equipment maintenance and engineering work at metal smelting plants. Moved to a chemical manufacturer in 2022. Engaging in similar tasks.

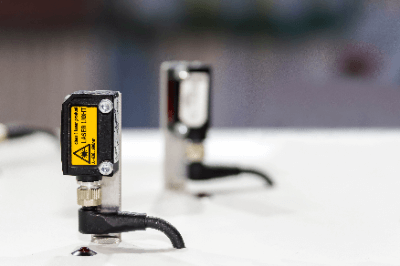

A laser sensor is a non-contact type of sensing device that uses a laser to measure the distance between the object to be measured and the sensor, as well as the thickness and height of the object itself.

A laser sensor is a non-contact type of sensing device that uses a laser to measure the distance between the object to be measured and the sensor, as well as the thickness and height of the object itself.

Since they are commonly used sensing devices, there are a variety of measurement methods and accuracies.

Laser sensors can be used to measure the distance between a processing or conveying device and the object to be measured when the distance to the object needs to be accurately determined. They are also used in situations where thickness information of the object to be measured is required, such as in product appearance inspections.

Thickness measurement can be performed with contact-type calipers, but if the object has a complicated shape or is inconvenient to touch, a non-contact type laser sensor can be used for non-destructive inspection.

In principle, laser sensors allow non-contact measurement, but there are several types of methods. When measuring the distance to a certain object to be measured, either a diffuse-reflective or a normal-reflective laser sensor is used.

In both cases, light from the laser source is reflected off the surface of the object to be measured, and the distance is determined by detecting the reflected light at the photosensitive area. The photosensitive area has a certain area width, and the photosensitive area varies depending on the angle of the reflected light. When the photosensitive area changes, a corresponding electric current is detected, and this information is used to convert it into a distance value.

Due to its structure, if the light source is incident to the surface of the object to be measured that is inclined beyond a certain angle, the reflected light will not be returned to the photosensitive area and, therefore, cannot be detected. This allowable tilt depends on the design of the displacement sensor, and in general, Laser Sensors with the diffuse reflection method have a wider detection angle.

First, check whether the application is distance detection or acquiring shape information, such as thickness and height. If it is for distance detection, select a product that can measure at or above that angle from among those that match that measurement range, assuming how much the surface of the object to be measured is inclined. For thickness measurement, check the detection range.

Then, depending on how accurate you want the measurement itself to be, select the specifications for resolution, detection accuracy, and linearity. All of these factors affect measurement accuracy, and in general, the higher the accuracy, the more expensive the product, so be careful not to over-specify.

In addition to measurement accuracy, it is also a good idea to note whether the unit itself can be installed. If there is not enough space for the mounting area, it may be necessary to select a smaller Laser Sensor.

A security sensor is a system to prevent the intrusion of suspicious persons. They are utilized in all kinds of places, such as condominiums, offices, and factories, and they are designed to sound an alarm when an intruder touches the sensor. Laser Sensors are currently widely used as security sensors.

There are two types of laser sensors: horizontal detection type and vertical detection type.

Horizontal Detection Type

The laser beam is emitted horizontally at 180 °C and covers a wide area. This type of monitoring system is suitable for open areas such as outdoors and detects moving objects. The monitoring range can be set to define areas to be excluded in advance.

Vertical Detection Type

This is a security sensor in which a laser beam is emitted vertically, covering a surface perpendicular to a wall or ceiling. This type of monitoring system is suitable for localized areas such as a passageway or in front of a door and detects objects that pass in front of the surface on which the sensor is working. The height of the object to be detected can also be set.

Laser Sensors are convenient non-contact sensors that use light rays, but they may malfunction under some conditions.

Unevenness of the Surface of the Object to Be Detected

Laser sensors with a small spot may malfunction due to fluctuations in the amount of light received due to reflections caused by the unevenness of the surface of the object to be detected. If the surface of the object to be detected is uneven, use a sensor with a large spot.

Vibration

Vibration applied to the laser sensor may cause the optical axis to shift, resulting in a malfunction. Review the installation of the laser sensor and fix it with screws or auxiliary fittings, and install it as close to the object to be detected as possible to minimize the effects of optical axis misalignment.

Pulsed Light

Pulse lighting is a lighting method that repeatedly turns on and off. Since the light is turned on at a high frequency, it appears to the human eye as if the light is continuously turned on, although it is actually blinking.

Most laser sensors use pulsed light emitting lasers, which may malfunction against surrounding LEDs that pulse light as well as themselves. If there is a pulsing light nearby, it is important to install a shield between the sensor and the light receiving part or adjust the angle of the light receiving part so that the light does not hit the sensor.

*Including some distributors, etc.

Sort by Features

Sort by Area

Ono Sokki is a measuring instrument manufacturer focused on the tasks of applying digital technology to measurement applications, and has a proud history in that field, including development of Japan's first digital counter in 1954, and myriad products using digital technology. Our taste for innovation, however, is not limited to hardware; we provide not only measurement solutions but also to offer intuitive and integrated analysis software that matches the sophistication of modern technology.

Banner Engineering Corporation, established in 1966 and headquartered in Minneapolis, Minnesota, is a manufacturer and supplier of industrial automation products. They offer an extensive range of sensors, including proximity sensors, photoelectric sensors, and limit switches, for detecting object presence, position, and speed. Additionally, Banner provides a different types of switches, such as pushbuttons, toggle switches, and rotary switches, to control electricity flow and offer system feedback. Their wide array of controls includes PLCs, HMIs, and motion controllers, enabling automation of industrial processes.

ifm efector (ifm) is a subsidiary of ifm electronic, founded in Germany in 1969. ifm has developed, manufactured and marketed sensors and controls technology to industries that include assembly and robotics, automotive, material handling, metal forming, mobile equipment, plastics, and food and beverage. Ifm produces sensors, condition monitoring equipment, image processing, safety technology, industrial communication, IO-link, systems for mobile machines, displays, software, connection technology, voltage supplies, as well as other accessories.

Pepperl+Fuchs, Inc. was founded in Mannheim, Germany in 1945 developing the forerunner of the proximity switch. Pepperl+Fuchs continues to develop proximity sensors as well as other industrial sensors including ultrasonic sensors, rotary encoders, positioning systems, display and signal processing, vibration monitoring, industrial communication, and signal processing as well as related accessories and software. Explosive protection products include safety barriers, surge protection, wireless solutions, HMI systems, power supplies, electrical explosion protection equipment, level measurement, and related software.

Diamond Technologies was founded in 1997 and is based in Hudson, Massachusetts and is a custom designer and engineer for data collection automation, and industrial communications. Diamond Technologies’s automation solutions segment offers OEMs and other customers system configuration, component selection, verification of compatibility, review of power requirements, software development, and other services. Data collection includes integration of data collection equipmpent, maintained OEM delivery, pre-programmed barcode, RFID, or embedded data collection components, OEM labeling, and others.

Acuity Laser is a U.S.-based laser sensor company. It was founded in 1992 to develop laser distance sensors and laser measurement systems for industrial and OEM use. Today, their lasers are used in many industries in order to improve quality control, improve fuel efficiency, reduce environmental impact, improve material management, and reduce overall business cost. Acuity serves a wide range of customers, including clients in production industries, system integrators, and OEM customers. Their lasers and sensors all operate based off non-contact measurement. Non-contact measurement ensures the ability to provide extremely high-speed measurements and precise accuracy, without the drawbacks of touching the material. Acuity has worked with small and large volume customers to provide customized sensors and small solutions. They leverage their laser sensor expertise to provide answers to challenging applications. Acuity has sales engineers located throughout the United States. They offer local onsite visits to better understand how to help solve challenging measurement applications. Their sensors are used in a wide range of industrial applications including manufacturing, lumber production, steel casting, glass and paper production, medical imaging, crane control and micron-level part and surface inspection.

El.En. S.p.A, a company founded in 1981 and based in Florence, Italy, is a manufacturer and supplier specializing in technological laser solutions. The company's product portfolio includes CO2 lasers, laser scanning heads, and G-Series galvanometers. These products find applications in various industries, including food processing, packaging, and the printing and labeling sector. The company offers services including technical support, spare parts supply, and customization options for specific customer requirements, all while being ISO 9001 certified.

ASTECH Angewandte Sensortechnik GmbH, a company founded in 1990, and based in Rostock, Germany, is a manufacturer of non-contact measurement and automation equipment. The company’s products include the standard VLM, LDM, CROMLAVIEW series, and OEM products manufactured according to customer requirements. More items from the company include microcontroller, FPGAs, and CCD sensors. The company earned its ISO 9001 certification in 2015 and is a member of IHK zu Rostock and BG ETEM.

Captron Electronic GmbH, established in 1983, is based in Olching, Germany, as a manufacturer of automation machinery. It manufactures capacitive, level, and optical sensors and LED signal lamps. It also manufactures peripheral equipment, such as connect cable, mounting support, plumb for level sensors, and disassembly tools. The company obtained several ISO, including ISO 9001:2015 and ISO 14001:2015 certifications. It also received several awards, such as the Bavarian State Government Award in 2017, Olchinger Agenda 21 in 2010, and Git Safety Award in 2010. Its manufactured products are utilized for Automotive, Aviation, Robotics, and medical industries across China, North America, and Poland.

Panasonic Industry Europe is the European branch of Panasonic, a global manufacturer of electronics and houseware, originally founded in 1918. Panasonic Industry Europe manufactures in 4 categories: components, devices, energy & building, and automation devices & solutions. Components include relays, capacitors, resistors, sensors, switches, connectors, couplers. Devices include wireless connectivity, e-bike systems, motors, compressors, thermal solutions, GPS antennas, as well as electronic materials. Energy & building includes batteries, fuel cells, solar sells, power tools, and home IoT. Automation devices & solutions include sensors for factory automation, industrial motors, laser welding, and more.

Azbil Europe NV is based in Germany and was founded in 1906 as a manufacturer and supplier of automation products and solutions. The company designs Industrial Control Communication devices like Digital Controllers, and Flame Safeguard Systems, along with Electromagnetic, Differential Pressure, Vortex Gas, and Thermal Flowmeters. They also deal in sensors and switches and their list of Industrial Automation products includes Field Instruments and Control Valves. Together these components serve the Oil and Gas market, the Pharmaceutical industry, and the Electronics and Electrical equipment industry.

Pulsotronic GmbH & Co. KG, headquartered in Niederdorf, Germany, is a manufacturer and supplier of sensors and sensor systems for the automotive, industrial, and medical sectors. Their ISO 9001:2015 certified products include distance sensors for measuring object distance in parking assist systems and robotics, speed sensors for applications like engine control and cruise control systems, pressure sensors for tire pressure monitoring and medical devices, temperature sensors for thermostats and climate control, and Hall sensors for proximity switches and automotive ignition systems.

Proxitron GmbH, founded in 1979, and based in Elmshorn, Germany, is a manufacturer of optoelectronic systems for industrial color detection and measurement. Its product line includes inductive sensors, optical sensors, path and distance measurement systems, pyrometers, and flow sensors. These products are used for various applications like metal object detection, distance measurement, temperature measurement, and flow monitoring. The company maintains ISO 9001 certification, ensuring industry standards in its manufacturing processes and product quality.

Optex Fee Co., Ltd., was established in 2002 and based in Kyoto, Japan, is a manufacturer and supplier of factory automation sensors and solutions. The company offers an extensive and diversified product portfolio including photoelectric sensors, fiber-optic sensors, displacement sensors, non-contact thermometers, vision sensors, and other industrial automation products. These sensors and solutions play a pivotal role in enhancing manufacturing processes across a spectrum of industries, including automotive, electronics, and packaging.

Hypersen Technologies Co. Ltd. is a manufacturer of precision sensors established in 2015 and based in Shenzhen, China. The company produces standard and custom mechanical or optical sensing devices. These include 6-axis force torque sensors, laser cross beam sensors for edge detection or alignment, and 3D solid-state LiDAR for 3D environment scanning or mapping. The company primarily serves clients in the medical device production, industrial automation, and security sectors. Some of its notable clients include Bosch, Foxconn, and Apple.

BinMaster is based in Lincoln, Nebraska, USA, and is a manufacturer of inventory management systems and level indicators that was established in 1965 as a brand line of Garner Industries. The company produces continuous and point level indicators, organizational software, and wireless communication devices. These include RL acoustic sensors that measure and map material volume, software for monitoring facility-wide level sensors, and vibrating rod switches for low or high level detection. The company mainly serves clients in the mining, energy production, and pharmaceutical industries.

Omron Corporation, started in 1933 and headquartered in Kyoto, Japan, is a manufacturer of automation components, equipment, and systems, and it developed the first contactless proximity switch in 1960. It has four domains, including industrial automation, electronic components, healthcare, and social systems, and it provides products and services in around 120 countries and regions. Some of its products include microsensing devices, access control systems, industrial robots, surveillance cameras, and blood pressure monitors. In 1971, it developed the first online cash machine, and in 1972, it established Japan’s first welfare factory.

Baumer Electric AG was founded in 1952 and is headquartered in the city of Frauenfeld, Switzerland. The ISO 9001 and ISO 14001 certified company provides sensor solutions for digitalization, packaging, railway, food and beverage, and pharmaceutical industries. A sample of the company’s sensor product listings includes object detection, distance measurement, force sensors, accessories, and connectivity devices. The company offers product support for setup and installation, product functionality, and optimized product usage.

Balluff was founded in 1921 and is headquartered in Neuhausen, near Stuttgart, Germany. Balluff is a manufacturer of sensor and automation solutions for customers globally. Balluff serves many industries including life sciences, semiconductors, metalworking, fluid power, and mobile equipment. Balluff’s product line consists of sensors and connectivity components, accessories, complete systems, and software. Balluff offers services to assist customers across the range of finding solutions, deploying solutions, training, as well as support.

ALTHEN, established in 1978, headquartered in Kelkheim, Germany, is a manufacturer and supplier that specializes in providing precision sensors and measurement solutions. Their product range includes strain gauges, load cells, pressure transducers, and displacement sensors, catering to industries such as aerospace, automotive, renewable energy, and robotics. ALTHEN's sensors enable accurate data collection, testing, and monitoring of various parameters critical to the performance and safety of industrial processes and structures. They maintain ISO 9001 and ISO 14001 certifications, ensuring the quality of their products for precise measurements across diverse industrial applications.

SensoPart, Inc. was founded in 1994 and headquartered in Germany with US operations based out of Bingham Farms, Michigan. The ISO 9001:2015 certified manufacturing company serves the automotive, robotics, plastics, solar, and other industries with photoelectric sensors and image processing products. The company’s products include optical sensors, vision sensors, ultrasonic sensors, inductive sensors, and accessories. Together they are used in manufacturing detection & inspection, product identification, a diverse array of measuring tasks, product positioning, and color detection.

Micro-Epsilon was originally founded in Osaka and Micro-Epsilon America was founded in 1998, headquartered in Raleigh, North Carolina. Micro-Epsilon develops, manufactures, and distributes sensors to aerospace, battery production, glass production, wind power, precision optics, medical technology, transportation, semiconductor, and other industries. Micro-Epsilon’s sensor product categories include inductive, capacitive, laser, confocal, laser distance, magneto-inductive, draw-wire, rotation speed, color, paint thickness measurement, and fiber optic sensors in addition to interferometers and other sensor equipment.

Schlüter Automation und Sensorik GmbH, established in 1967 and headquartered in Todtnau, Germany, serves as a manufacturer and supplier specializing in automation and sensor solutions. The company's primary product categories include industrial sensors, control systems, and automation equipment. It caters to a wide range of industries, including manufacturing, automotive, food processing, and pharmaceuticals. Its products catalog includes optical sensors, safety light curtains, magnetic field switches, inductive detectors, laser distance sensors, among others.

PMC-STS Inc., founded in 1963 and based in Danbury, Connecticut, is a manufacturer of pressure, vacuum, and level sensor instruments for aerospace, motorsports, and water applications, among others. The company also provides customized solutions and products to meet challenging customer requirements. It is the first manufacturer offering flush-mounted transmitters for measuring in-process pulp in wastewater, paper, and other difficult fluid level and pressure measurements. In 2022, the company was acquired by Sensor Technik Sirnach AG to help penetrate the North American market further and benefit from both application and product expertise.

OMRON Industrial Automation is the UK branch of OMRON, originally founded in Japan in 1933. OMRON Industrial Automation serves food and beverage industry, panel board design, automotive manufacturing industries among others. OMRON Industrial Automation products categories include automation systems such as industrial PCs and human machine interfaces (HMI), safety such as safety switches and safety logic control systems, switching components such as solid state relays, motion & drives such as motion controllers, sensing such as photoelectric sensors, software, robotics, quality control & inspection systems, as well as control components including power supplies and digital panel indicators.

Ramco Innovations, founded in the United States in 1972, is an automation supplier. It offers a wide range of products, including motion control, safety products, a complete line of precision displacement laser measurement sensors, background (BGS) and foreground (FGS) LED and laser sensors, and Panasonic fiber optic cables. The company also offers a range of value-added services, including application engineering, kitting and assembly, connectorizing and cabling, panel building, and shipping and receiving services.

Ranking as of July 2025

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | ifm efector, inc. |

21.0%

|

| 2 | Banner Engineering Corporation |

4.9%

|

| 3 | Panasonic Industry Europe GmbH |

4.7%

|

| 4 | Acuity Laser |

4.3%

|

| 5 | Diamond Technologies, Inc. |

4.3%

|

| 6 | Angewandte Sensortechnik GmbH |

4.2%

|

| 7 | El.En. S.p.A |

3.8%

|

| 8 | Proxitron GmbH |

3.8%

|

| 9 | CAPTRON ELECTRONIC GMBH |

3.8%

|

| 10 | ALTHEN |

3.7%

|

Derivation Method

The ranking is calculated based on the click share within the laser sensor page as of July 2025. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

6 | 37.5% |

Germany

Germany

|

6 | 37.5% |

Italy

Italy

|

1 | 6.3% |

Belgium

Belgium

|

1 | 6.3% |

Japan

Japan

|

1 | 6.3% |

China

China

|

1 | 6.3% |

109 products found

109 products

Tokyo Optoelectronic Industry Co., Ltd.

4310+ people viewing

Last viewed: 17 minutes ago

■Features ・Instantly measure outer diameter and gap without contact using laser light ・Equipped with simultaneous display of two types of measure...

8 models listed

Mt Precision Co., Ltd.

1590+ people viewing

Last viewed: 4 hours ago

Dimetix's D Series Laser Distance Sensors are at the forefront of the industry thanks to continuous development and innovation. Measure long distan...

8 models listed

Takenaka Optonic Co., Ltd.

380+ people viewing

Last viewed: 3 hours ago

■Features - Equipped with a function to detect laser pattern deviation and readjust to the normal laser projection position. - Built-in sensor that...

Takenaka Optonic Co., Ltd.

380+ people viewing

Last viewed: 1 hour ago

■Features ・Standard lineup of red, green, and blue colors with the same external shape using visible light semiconductor lasers ・1:1 wide pattern...

ALT Co., Ltd.

250+ people viewing

Last viewed: 19 hours ago

■Features Scan beam timing detection sensor unit

ALT Co., Ltd.

340+ people viewing

Last viewed: 1 day ago

■Features Measures the distance to the object using the TOF (Time of Flight) method.

Eureka Co., Ltd.

270+ people viewing

Last viewed: 48 minutes ago

◾️Obstacle detection alarm system Reducing risks in risk assessments of cargo handling work environments and preventing damage to cargo and work s...

Irie Co., Ltd.

210+ people viewing

Last viewed: 2 hours ago

■BLINK FR (Fast response laser sensor) ・Operation speed tens of times faster than "conventional sensors" ・Power density performance: 1.5Kw/cm2 ・...

Irie Co., Ltd.

200+ people viewing

Last viewed: 1 hour ago

■BLINK FR (with OEM amplifier) ・Operation speed tens of times faster than "conventional sensors" ・Power density performance: 1.5Kw/cm2 ・Active a...

Irie Co., Ltd.

200+ people viewing

Last viewed: 1 day ago

■BLINK HS (High-speed response laser sensor) ・Repetition frequency up to 1MHz ・Electronic sampling speed: max. 500Msample/s ・Active area: 14x14m...

Soki Co., Ltd.

470+ people viewing

Last viewed: 6 hours ago

Ideal for traffic safety measures near entrances and exits of work sites. Notify pedestrians of vehicle entry and exit. Installation of the device ...

Techno Electronics Co., Ltd.

230+ people viewing

Last viewed: 1 hour ago

This is a high-performance laser measuring device. A sensor is inserted into the pipe to measure the inner diameter and shape. This is a laser devi...

Ars Co., Ltd.

150+ people viewing

Last viewed: 2 hours ago

This product is a device that measures the plate thickness of products.

Opcell Co., Ltd.

220+ people viewing

Last viewed: 22 hours ago

It is possible to detect defects inside glass, transparent ceramics, sapphire, quartz, etc. A laser sheet is projected onto the object, and a camer...

ifm efector, inc.

340+ people viewing

Last viewed: 1 day ago

It is a compact laser sensor that does not depend on the standard M18 screw cut and IO-Link. Io -Link -Metal exterior type M18 CUBE Distance senso...

ALT Co., Ltd.

220+ people viewing

Last viewed: 1 day ago

■Features Detect smoke particles using high-power laser light

Panasonic Industry Co., Ltd.

130+ people viewing

Last viewed: 15 hours ago

basic information ■Make high-precision displacement sensors easier Obtained UL, CE, CSA, Korean KC, FDA, UKCA. (UL, CSA: certified by TÜV SÜD Ameri...

Panasonic Industry Co., Ltd.

130+ people viewing

Last viewed: 11 hours ago

basic information ■Standard for CMOS laser displacement sensors with excellent cost performance Obtained CE, FDA, UKCA certification. Features ■Ac...

Panasonic Industry Co., Ltd.

160+ people viewing

Last viewed: 6 hours ago

basic information ■Intelligent controller pursuing ultra-compact sensor head and high functionality Obtained CE, FDA, UKCA certification. (FDA: HL-...

Panasonic Industry Co., Ltd.

180+ people viewing

Last viewed: 5 hours ago

basic information ■TOF sensor module is built into an aluminum die-cast case that is both light and strong. Distance is measured by the time it tak...

Panasonic Industry Co., Ltd.

160+ people viewing

Last viewed: 36 minutes ago

basic information ■Line up of limited reflective type spot type and line spot type Obtained CE, FDA, GB, UKCA. (GB: 7247.1 compatible) Features ■T...

Panasonic Industry Co., Ltd.

150+ people viewing

Last viewed: 2 hours ago

basic information ■The birth of a CMOS laser sensor that provides stable detection with a repeatability of 10μm*. *For HG-C1030 (-P) Obtained UL/C-...

Panasonic Industry Co., Ltd.

130+ people viewing

Last viewed: 4 hours ago

basic information ■High-level self-diagnosis function informs superiors of one's "status" Obtained UL/C-UL, CE, FDA, UKCA. Features ■Reducing the ...

Panasonic Industry Co., Ltd.

120+ people viewing

Last viewed: 1 day ago

basic information ■Industry's smallest* laser sensor head LASER CLASS 1 Obtained CE, FDA, UKCA certification. *As of March 2024, according to our r...

Panasonic Industry Co., Ltd.

120+ people viewing

Last viewed: 8 minutes ago

basic information ■Make high-precision laser sensing more accessible and easier to use Obtained UL/C-UL, CE, FDA, UKCA. (UL/C-UL: Recognition certi...

Panasonic Industry Co., Ltd.

120+ people viewing

Last viewed: 1 day ago

basic information ■3LED mark sensor introduced Obtained UL, CE, UKCA. (UL: Recognition certified) Features ■Supports detection of various marks su...

Panasonic Industry Co., Ltd.

120+ people viewing

basic information ■World-class smallness* Obtained UL/C-UL, CE, UKCA. (UL: Recognition certified) *As of March 2024, according to our research as a...

Panasonic Industry Co., Ltd.

130+ people viewing

Last viewed: 4 hours ago

basic information ■Upgrade to a sensor that is more earth- and people-friendly Obtained UL, CE, UKCA. (UL: Recognition certified) Features of CX-4...

Panasonic Industry Co., Ltd.

140+ people viewing

basic information ■Built-in amplifier/ultra-thin size Obtained UL, CE, UKCA. (CE: Excluding EX-15□/17□ UKCA: Excluding EX-15□/17□ UL: Recognition c...