All Categories

History

This section provides an overview for board terminal blocks as well as their applications and principles. Also, please take a look at the list of 34 board terminal block manufacturers and their company rankings. Here are the top-ranked board terminal block companies as of July, 2025: 1.Gluefast Co., Inc., 2.Curtis Industries, 3.Automation Systems Interconnect.

Table of Contents

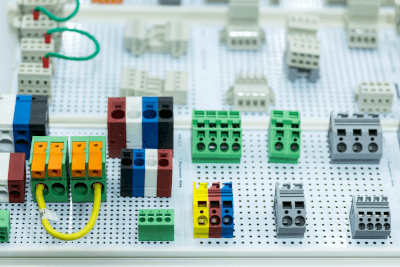

A board terminal block is a component designed for installation on a printed circuit board (PCB) and for electrical connection to other boards or components via wires or cables.

A board terminal block is a component designed for installation on a printed circuit board (PCB) and for electrical connection to other boards or components via wires or cables.

There are various methods to connect a board terminal block to wires and cables. For example, some types use screws to fasten wires via crimp terminals attached to the wire ends. Others incorporate a spring in each terminal of the block, allowing wires to be fastened by inserting them while pressing down on specific parts of the terminal.

In both types, soldering to connect wires or cables to the board terminal block is not necessary, enabling use by individuals without soldering expertise.

Board terminal blocks facilitate the connection of multiple PCBs or between PCBs and components. This modular approach allows for separation of boards or components into functional units. For instance, a circuit design might be divided into three types of boards: A, B, and C. The A board handles basic functions, while the B and C boards provide additional features.

By using board terminal blocks, different products can be created through various combinations of these boards, such as a product with only board A, a product with both boards A and B, a product with boards A and C, or a product with all three boards.

When selecting board terminal blocks, consider factors like material, insulation resistance, operating temperature range, applicable PCB thickness, and compliance with various laws and regulations. For sale in Japan, products must adhere to domestic regulations, while exports to Europe require compliance with the ROHS directive (Restriction of Hazardous Substances).

The ROHS directive mandates that electrical and electronic equipment contain less than 0.1% of specific hazardous chemical substances, including lead, mercury, hexavalent chromium, cadmium, polybrominated biphenyls, polybrominated diphenyl ethers, di-2-ethylhexyl phthalate, butyl benzyl phthalate, di-n-butyl phthalate, and diisobutyl phthalate. This regulation aims to facilitate recycling and minimize health risks associated with electronic waste.

*Including some distributors, etc.

Sort by Features

Sort by Area

Automation Systems Interconnect (ASI), founded in 1999, is a manufacturer and supplier of electrical and electronic components, universal printing systems, and custom-assembled products based in Mechanicsburg, Pennsylvania. The company’s product portfolio includes cables, cords and connectors, CAM and disconnect switches, and more. Their wide range of industrial components cater to various applications such as automation and control, power distribution and generation, and printed board assembly. The company’s suppliers and partners hold ISO, UL and ATEX certifications to ensure their industrial electrical and electronic components meet industry standards.

Sealevel Systems Inc. is a designer and manufacturer of communications products and industrial computers founded in 1986 and located in Liberty, South Carolina, USA. The company’s products include ethernet serial servers for connecting serial devices to ethernet networks, input-output (I/O) modules for data control and acquisition applications, and embedded computers for integrated systems. It also offers PCI express cards and USB serial adapters, and ruggedized computers for industrial environments. The company is ISO 9001: 2015-certified, and serves clients in the military and defense, aerospace, and industrial automation sectors.

Curtis Industries, founded in 1933, is a specialized electrical component manufacturer and supplier based in Wisconsin, Milwaukee. The company manufactures custom and standard terminal blocks, EMI/RFI power line filters, printed circuit board blocks, and other custom plastic molded electrical and electronic components for industrial applications. Their products cater to various industries including aerospace, communications, medical, military, and more. With ISO 9001:2015 certification and adherence to UL and ITAR standards, Curtis Industries is a global company with component centers in both North America and Asia.

Gluefast Co., Inc. is a manufacturer of gluing equipment, glues, and adhesives that was established in 1939 in Neptune, New Jersey, USA. The company’s products include water based adhesives, hot melt adhesives that activate when heated, and pressure sensitive adhesives that bond optimally under weight or mechanical pressure. It also offers glue guns, as well as manual adhesive applicators such as films, sprays, and beads. The company’s products are commonly used in custom graphics applications, industrial packaging operations, and woodworking processes.

Excel Cell Electronic, founded in 1981 is a manufacturer and supplier of electromechanical components and stamping products headquartered in Taiwan. The company offers electromechanical components including industrial control switches, stepping motors, terminal blocks, resettable fuses, and relays. Their stamping products include heat spreaders for BGA, high-precision electronic components, and lead frames of semiconductors for discrete devices / integrated circuit & photoelectric products. The company is ISO/TS 16949:2009, CNS15506: 2011, TOSHMS: 2007, ISO 14001, and ISO 9001-certified, and their products are used in various applications in optoelectronic, security systems, power energy, network, and communication industries.

SATO PARTS CO., LTD. is a Japanese-based company founded on March 1, 1948, and headquartered in Sotokanda, Chiyoda-ku, Tokyo, and has established itself as a supplier and manufacturer of terminal blocks and electrical components. The company offers a wide range of products, including screwless terminal blocks, screw-type terminal blocks, fuse holders, and indicator lights. These products are utilized in industries such as automotive, electronics, and machinery manufacturing. The company also offers customer services such as customer consultation and email accommodation.

Toyogiken Co. Ltd (TOGI) is a manufacturer in electrical machinery and accessories. They design, develop and sell terminal blocks, transformers, cables, box terminals, PC board terminals and related accessories. TOGI headquartered in Nagano, Japan has set up their global operations in China, Taiwan, Korea, Thailand, Indonesia, Malaysia and Vietnam. The company is ISO:9001 2015 certified. In addition they are also involved in solar power business operations. TOGI holds 7 patents, 5 trademark patents and 48 utility model patents.

Wieland, established in 1910 and based in Bamberg, Germany, is a manufacturer and supplier of electrical connection technology. Their product range includes pluggable connections for seamless plug-and-play electrical device connections, insulated connectors that provide electrical insulation in device connections, cable glands for safeguarding cables and ensuring a watertight seal, terminal blocks used for connecting electrical wires, and contact systems facilitating connections between electrical components. Wieland's products find applications in diverse industries, such as building construction, electrical engineering, and automation.

Founded in 1984, Xiamen Hongfa Electroacoustic Co., Ltd. is a manufacturer specializing in relays, connectors, precision manufacturing parts, and automation equipment. Headquartered in Xiamen, China, the company has established 30 subsidiaries worldwide, serving over 120 countries and regions. HONGFA offers customized solutions utilizing its electrical appliances and complete equipment. Its wide range of products finds applications in various industries such as smart homes, smart grids, industrial control, automotive and railway transportation, and the Internet of Things. The company has received multiple awards, including the 2023 National Enterprise Culture Outstanding Achievement by China Enterprise Confederation and China Entrepreneurs Association.

IMO Precision Controls, a company founded in 1972 and headquartered in Hertfordshire, United Kingdom, is a manufacturer and supplier of industrial automation and control products. The company offers a wide range of products and solutions, including automation products, circuit protection, control and switch gears, and solar products. Their products find application in diverse industries such as manufacturing, energy, and transportation. The company also offers customer services that include technical support, value-added assembly, training courses, and tailored solutions to meet clients’ requirements.

Degson Electronics, established in 1990, and based in Shanghai, China, is a manufacturer and supplier of industrial products. The product portfolio of the company includes terminal blocks, circular connectors, electronic products, electric vehicle chargers, e-bike connectors, and energy storage connectors. The company offers ISO-certified products with services such as customized solutions and automation development. The products are used in various industries which include electric energy, wind power generation, rail traffic, and intelligent systems.

CamdenBoss Ltd is a manufacturer of electromechanical components and enclosures established in 1986 and headquartered in Edmunds, Suffolk, United Kingdom. The company offers electromechanical components such as switches, protects, lights, and connects including PCB terminal blocks, circular connectors, interface modules, relay bases, and terminal strips. It also offers enclosures such as plastic, metal, din rail, and wall cabinets & 19” enclosures. The company also offers customized enclosures with their in-house processes including designing, prototyping, and manufacturing to meet the customer’s specific requirements.

WAGO was founded in Minden in 1951 in then West Germany. WAGO manufacturers components for the automotive, digital lant, elevator and escalator, energy, intralogistics, lighting, marine & offshore, mechanical engineering, and railway systems industries. WAGO produces, electrical interconnections such as rail mount terminal blocks, wire connectors, PCB interconnects, pluggable connection systems, panel feedthrough connections, and EMC shielding. Other types of products include relays, protection devices, fieldbus couplers, ethernet switches, touch panels, edge devices, and wireless devices.

Ningbo Best Group Co. Ltd. is a manufacturer of RoHS certified electronic and acoustic components that was established in 1997 in Ningbo, Zhejiang, China. The company fuses switches for protecting circuits, programmable buzzers for producing alarm signals, and terminal blocks for connecting wire or cable assemblies. It also offers battery holders and DC motors for converting or providing power, and custom engineering services for unique projects. The company’s products are used mainly by clients in the consumer electronics, telecommunications, and automotive industries.

Keystone Electronics Corp. has a 70 year history and is headquartered in New Hyde Park, New York. Keystone is a global manufacturer of precision electronic components and hardware. Keystone is ISO 9001:2015 certified. Keystone offers several types of products including battery & coin cell holders, contacts, && clips, fuse clips & fuse holders, handles for instrumentation, metal key-pad dome switches, multi-purpose hardware, PC board hardware, plugs, pins, jacks, sockets, quick-fit terminals, screw terminals, terminal blocks, screws, spacers, standoffs, terminals, terminal boards, test points, tips, probes, jumpers, and clips. Keystone also offers custom manufacturing capabilities including stamping, machining, assembly, tool room, and quality assurance.

ShenZhen Antenk Electronics Co., Ltd. is a manufacturer and supplier of connectors and cable assemblies that was established in 2007 and is headquartered in Shenzhen, Guangdong, China. The company produces a wide range of connectors, including board-to-board connectors, wire-to-board connectors, and cable assemblies. Its products, such as USB connectors, HDMI connectors, SATA connectors, FPC/FFC cable connectors and RJ45 connectors, are used by a number of industries, as diverse as electronics, telecommunications, and automotive industries. The company also provides a range of services, including custom design, manufacturing, and testing.

TE Connectivity Ltd., started in 2007 and headquartered in Schaffhausen, Switzerland, is a designer and manufacturer of sensor and connectivity solutions for harsh conditions. It operates three primary segments, namely transport, industrial, and communication solutions, and its product portfolio includes automotive connectors, fiber optic connectors, analog power meters, RTD sensors, and circuit breakers. It serves customers in approximately 140 countries and several industries, including aerospace, automotive, rail, IoT connectivity, and E-mobility. The company manufactures 192 billion products annually and has invested over 610 million USD in research development and engineering.

Omron Corporation, started in 1933 and headquartered in Kyoto, Japan, is a manufacturer of automation components, equipment, and systems, and it developed the first contactless proximity switch in 1960. It has four domains, including industrial automation, electronic components, healthcare, and social systems, and it provides products and services in around 120 countries and regions. Some of its products include microsensing devices, access control systems, industrial robots, surveillance cameras, and blood pressure monitors. In 1971, it developed the first online cash machine, and in 1972, it established Japan’s first welfare factory.

Connectwell, established in 1978 in Mumbai, India, is a manufacturer and supplier of terminal blocks, interface modules, professional tools, and switching power supplies. The company holds ISO 9001 certification, and its product range offers flexible solutions for electrical and electronics applications, including connecting and routing electrical wires and components efficiently. Its products are designed to simplify wiring processes, reduce installation times, and enhance the overall performance of electrical connections. It serves a wide range of industries, including automation, control systems, energy, and industrial manufacturing, where the products play a vital role in streamlining electrical connections and ensuring stable performance.

Dinkle Group was established in 1983 and is headquartered in Taipei, Taiwan. Dinkle is a multi-national, ISO 9001-certified manufacturer and distributor of electronics and equipment for industrial sectors such as factory automation, transportation, new energy, telematics, and equipment manufacturing. Dinkle has 4 product lines: terminal blocks, electronics & interface, electronic housings, and tools. Terminal blocks include PCB terminal blocks, barrier terminal blocks, and NEMA terminal blocks. Electronics & interface include interface modules, surge protection devices, and industrial relays. Electronic housings include enclosures for bus systems, DMEB component housing, and PCB carriers. Tools include drivers, marking systems, ferrules, and others.

METZ CONNEct was founded in 1976 in Blumberg, Germany. The company is a global manufacturer of electronics used in semiconductor, manufacturing, consumer electronics, and other industries. The company has 3 primary product lines: P-cabling, U-Contact, and C-Logline. P-Cabling provides cabling solutions for networks and includes DIN rail housing, patch panels, and fiber optic wall distributors and housings. U-Contact for connection technology includes PC board terminal blocks and board-to-board connectors. C-Logline for intelligent system components includes I/O components, energy controlling, and telecommunication products.

Phoenix Contact is headquartered in Blomberg, Germany, originally founded in 1923. Phoenix Contact’s Israeli subsidiary was founded in 2006 and located in Quadima Tzoran. Phoenix Contact provides tools and components for e-mobility, power, infrastructure, process industry, production manufacturing, system manufacturing, and others. Phoenix Contact’s product lines include automate including cloud computing, connect including PCB terminal blocks, “mark, assemble, and install” including hand tools, “supply, charge, and protect” including power distributors, and “switch, measure, and monitor” including relays and optocouplers.

Widmuller Group, established in 1946 in Waldshut, Germany, is a manufacturer and supplier of industrial automation components. Its product range includes switches, communication modules, sensors, and connectors, encompassing industrial connectors, panel mount connectors, and DIN rail connectors. The company's offerings cater to diverse industries, spanning automotive, machine tools, building automation, and energy sectors. Devoted to delivering quality industrial automation components, the company provides additional services like technical support, training, and customization. As a certified ISO 9001:2015 company, it emphasizes furnishing customers with quality products and services.

Weidmüller is a manufacturer and distributor of electronic components and devices and a supplier of electronic solutions, that was established in 1850 in Germany. The company produces connectivity components and devices namely terminals, connectors, distribution boxes, and other products like cable entry systems and cables. In the Electronic solutions department, they design and supply relays, power supplies, housings, and modules. Their automation and software department consists of Controls & Edge, I/O systems, Industrial Ethernet, and Measuring & monitoring systems and these products and systems provide Energy management, Industrial IoT, Industrial Analytics, and Water & Wastewater Solutions to name a few.

Rockwell Automation, Inc. was founded in 1903 and is headquartered in Milwakee, WI. Rockwell Automation provides industrial automation and digital transformation solutions around the world. Rockwell Automation operates through their intelligent devices, software & control, and lifecycle services segments with both hardware and software products and services. The Intelligent Devices segment offers drives, motion, safety, sensing, industrial components, and configured-to-order products. The Software & Control segment provides control and visualization software and hardware, information software, and network and security infrastructure solutions. The Lifecycle Services segment provides consulting, professional services and solutions, and connected and maintenance services through independent distributors.

American Electrical was founded in 1997 and is based out of Richmond, Virginia. The company is a distributor of DIN rail-mounted components and electrical equipment to customers in the US as well as overseas. The company offers 3 product segments: Connection, Protection, and Wire Preparation. The connection segment includes terminal blocks, PCB terminal blocks, IR modules, and DIN rails. The Protection segment includes products such as circuit breakers and surge arrestors. Wire Preparation offerings include wiring ducts, wire ferrules, and tools.

Altech Corporation, founded in 1984 and headquartered in Flemington, New Jersey, is a supplier and distributor of electronic and control components and is ISO 9001 certified. The company provides a broad line of products, including programmable controllers, monitoring relays, and terminal blocks, used in instrumentation, industrial control, and automation applications. The company’s enclosed disconnect switches are available in different materials like stainless steel, plastic, and aluminum and have a use rating of 16A to 150A/600V AC. The products are all RoHS and REACH compliant and meet diverse national and international standards like IEC, CSA, and UL.

LEIPOLE Electric, established in 2001, is a manufacturing company specializing in the production of end-of-barrel products for injection molding machines, based in China. The company produces plastic parts of electrical products for ABB, Siemens, and Schneider. It also engages in the design and sale of terminal blocks, fan filters, and transformers, which provide interconnection of electrical systems. Its global network includes distribution offices in 34 cities in China and 10 cities or countries worldwide such as Singapore, Ho Chi Minh, Kuala Lumpur, Hong Kong, Johannesburg, Istanbul, Dubai, Ecuador, Sao Paulo, Poland and Denmark, continuing to evolve its product offerings.

PTR Hartman is a German supplier of test plugs for PCB and cable harness testing, test probes for industrial applications, PCB connectors, and custom inductors. All of these are manufactured in-house with competencies in Rotary Code Switches, Micro Switches, PCB Terminal Blocks, Test Probes, and Inductors. They have been certified since 1999 according to the environmental management standard DIN EN ISO 14001. They continuously set new environmental targets and undergo annual TÜV audits to ensure compliance.

Ranking as of July 2025

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Gluefast Co., Inc. |

6.5%

|

| 2 | Curtis Industries |

6.5%

|

| 3 | Automation Systems Interconnect |

6.5%

|

| 4 | SAKAZUME ELECTRIC IN. CO., LTD |

6.5%

|

| 5 | Altech Corporation |

5.2%

|

| 6 | Wieland ELECTRIC GMBH |

5.2%

|

| 7 | TOYOGIKEN CO.,LTD. |

5.2%

|

| 8 | BlockMaster Electronics |

3.9%

|

| 9 | LEIPOLE ELECTRIC. |

3.9%

|

| 10 | American Electrical, Inc. |

3.9%

|

Derivation Method

The ranking is calculated based on the click share within the board terminal block page as of July 2025. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

Germany

Germany

|

5 | 25.0% |

United States of America

United States of America

|

4 | 20.0% |

Japan

Japan

|

3 | 15.0% |

Taiwan

Taiwan

|

2 | 10.0% |

China

China

|

2 | 10.0% |

United Kingdom

United Kingdom

|

2 | 10.0% |

India

India

|

1 | 5.0% |

Canada

Canada

|

1 | 5.0% |

128 products found

128 products

Takachi Electric Industry Co., Ltd.

180+ people viewing

Last viewed: 7 hours ago

This is a screw type terminal block for printed circuit boards for the H53 series. Can be used by connecting terminal blocks. In addition to the H5...

2 models listed

Mibu Electric Manufacturing Co., Ltd.

210+ people viewing

Last viewed: 7 hours ago

We also have PCB terminal block connectors for circuit boards. ■Made by Wieland, Germany ・Highly reliable and secure connection method ・Easy con...

Nippon Weidmuller Co., Ltd.

170+ people viewing

Last viewed: 7 hours ago

■Highly efficient power electronics compatible printed circuit board connectors and printed circuit board terminal blocks With each new generation,...

Nippon Weidmuller Co., Ltd.

190+ people viewing

Last viewed: 7 hours ago

■Highly efficient power electronics compatible printed circuit board connectors and printed circuit board terminal blocks With each new generation,...

Nippon Weidmuller Co., Ltd.

180+ people viewing

Last viewed: 7 hours ago

■Highly efficient power electronics compatible printed circuit board connectors and printed circuit board terminal blocks With each new generation,...

Mibu Electric Manufacturing Co., Ltd.

350+ people viewing

Last viewed: 7 hours ago

14mm 19mm pitch ■Features - A terminal block for circuit boards that can effectively utilize narrow spaces. - Two types with rated current of 50A/...

Nippon Weidmuller Co., Ltd.

170+ people viewing

Last viewed: 7 hours ago

■Highly efficient power electronics compatible printed circuit board connectors and printed circuit board terminal blocks With each new generation,...

Mibu Electric Manufacturing Co., Ltd.

250+ people viewing

Last viewed: 3 hours ago

7.62mm 8.5mm pitch ■Features This is a terminal block for circuit boards that can effectively utilize narrow spaces.

Nippon Weidmuller Co., Ltd.

190+ people viewing

Last viewed: 1 day ago

■Highly efficient power electronics compatible printed circuit board connectors and printed circuit board terminal blocks With each new generation,...

Mibu Electric Manufacturing Co., Ltd.

270+ people viewing

Last viewed: 7 hours ago

6.5mm 7.62mm pitch ■Features This is a terminal block for circuit boards that can effectively utilize narrow spaces.

Nippon Weidmuller Co., Ltd.

190+ people viewing

Last viewed: 7 hours ago

■Highly efficient power electronics compatible printed circuit board connectors and printed circuit board terminal blocks With each new generation,...

Mibu Electric Manufacturing Co., Ltd.

260+ people viewing

Last viewed: 7 hours ago

7.62mm pitch ■Features - A terminal block for circuit boards that can effectively utilize narrow spaces. ・Up to 30 pins can be selected. ■Rating...

Nippon Weidmuller Co., Ltd.

180+ people viewing

Last viewed: 7 hours ago

■Highly efficient power electronics compatible printed circuit board connectors and printed circuit board terminal blocks With each new generation,...

Nippon Weidmuller Co., Ltd.

170+ people viewing

Last viewed: 7 hours ago

■Highly efficient power electronics compatible printed circuit board connectors and printed circuit board terminal blocks With each new generation,...

Nippon Weidmuller Co., Ltd.

190+ people viewing

Last viewed: 7 hours ago

■Highly efficient power electronics compatible printed circuit board connectors and printed circuit board terminal blocks With each new generation,...

Toho Technology Co., Ltd.

200+ people viewing

Last viewed: 7 hours ago

■Features ・Push-in method for single wires and wires with ferrules, where the work is completed just by plugging them in. ・By arranging the wire ...

Würth Elektronik

130+ people viewing

Last viewed: 1 day ago

Toho Technology Co., Ltd.

380+ people viewing

Last viewed: 2 hours ago

■Features - Space-saving 2-tier terminal block with a pitch between terminals of 7.62 mm. Convenient when installation space is limited. ・A wide v...

Toho Technology Co., Ltd.

250+ people viewing

Last viewed: 13 hours ago

■Features ・This is a terminal block with an emphasis on ease of maintenance, as the socket (terminal block side) and header (board side) can be se...

Toho Technology Co., Ltd.

220+ people viewing

Last viewed: 9 hours ago

■Features - We have a wide variety of models, two types of terminal block shapes: closed end type and open end type, four types of terminal pitch: ...

Toho Technology Co., Ltd.

170+ people viewing

■Features - Ideal for common terminals, this is a 3-tier terminal block where the upper or lower tier of the terminal block can be used as a common...

Toho Technology Co., Ltd.

270+ people viewing

Last viewed: 10 hours ago

■Features ・This is a terminal block with an emphasis on ease of maintenance, as the socket (terminal block side) and header (board side) can be se...

Aoyama Industrial Research Institute Co., Ltd.

150+ people viewing

Last viewed: 20 hours ago