All Categories

History

This section provides an overview for tabs as well as their applications and principles. Also, please take a look at the list of 7 tab manufacturers and their company rankings. Here are the top-ranked tab companies as of July, 2025: 1.RHYTHM CO.,LTD., 2.FUJICON CO.,LTD..

Table of Contents

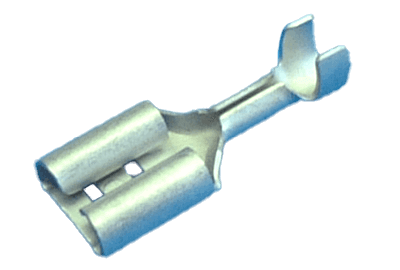

Tab terminals are connectors used for joining wires and harnesses. They consist of a male tab terminal and female receptacle, connecting by fitting the tab into the receptacle. To simplify design processes, terminal standards, including tab terminals, are standardized among manufacturers.

Tab terminals facilitate the connection of cables by inserting the tab into a receptacle. This setup is ideal for situations requiring maintenance, such as cable replacement, since it allows easy disconnection and reconnection. They are commonly used as cost-effective connectors in assembly processes where direct cable routing is challenging.

Tab terminals connect cables by inserting a flat metal tab into a receptacle's groove. The receptacle's slightly narrower groove width than the tab's thickness ensures a secure fit due to metal elasticity. While the standard design provides a robust connection, some models include claws to prevent disconnection. Cables are attached to tab terminals via crimping, requiring careful handling to avoid loosening the connection.

Common types include the 110, 187, and 250 series, known as fastons. Manufacturers may introduce proprietary series like the 205, with products available in various packaging forms for board mounting. The wide range of manufacturers underscores the importance of choosing reliable tab terminals for electrical safety.

As tab terminals expose metal, it's crucial to cover them with an insulator to prevent electric shock and leakage. Only the receptacle side should be insulated, hiding the tab inside the cover upon connection. Proper terminal selection requires special tools and adherence to wire thickness and connector dimensions, guided by industrial standards.

Crimping flat terminals correctly involves using dedicated crimping tools, although some may use pliers for bending and attachment. The crimp's reliability hinges on the secure fastening of the wire barrel, the terminal part crimped to the wire core. Ensuring the crimp's strength is neither too weak nor too strong prevents wire pullout or breakage, highlighting the importance of using manufacturer-recommended crimping tools for a reliable connection.

*Including some distributors, etc.

Sort by Features

Sort by Area

FUJICON CO., LTD. is a company established on April 23, 1996, headquartered in Kugahara, Ota Ward, Tokyo, Japan, a manufacturer of terminal blocks and accessories The company products provide a wide range of terminal blocks, connectors, board terminals, and insulating bushings, catering to various industries and sectors. These products are designed to establish electrical connections between wires and devices. They provide a secure and organized way to terminate, route, and distribute electrical signals in various applications. The company also provides customer services including document requests, web interviews, and inquiry responses.

Established in 1950 in Tokyo, Japan, Rhythm Inc. is an environmentally conscious manufacturer and supplier of watches. Since then, their product catalog has expanded to include Thermo-hygrometers, humidifiers, fan circulators, stopwatches, pedometers, and more. The company believes in contributing to society through sustainable growth and continuous creation. They sponsor professional sports teams and conduct local cleaning activities. They hold alarm clock assembly classes and donate timepieces to commemorate special occasions.

TE Connectivity Ltd., started in 2007 and headquartered in Schaffhausen, Switzerland, is a designer and manufacturer of sensor and connectivity solutions for harsh conditions. It operates three primary segments, namely transport, industrial, and communication solutions, and its product portfolio includes automotive connectors, fiber optic connectors, analog power meters, RTD sensors, and circuit breakers. It serves customers in approximately 140 countries and several industries, including aerospace, automotive, rail, IoT connectivity, and E-mobility. The company manufactures 192 billion products annually and has invested over 610 million USD in research development and engineering.

Keystone Electronics Corp. has a 70 year history and is headquartered in New Hyde Park, New York. Keystone is a global manufacturer of precision electronic components and hardware. Keystone is ISO 9001:2015 certified. Keystone offers several types of products including battery & coin cell holders, contacts, && clips, fuse clips & fuse holders, handles for instrumentation, metal key-pad dome switches, multi-purpose hardware, PC board hardware, plugs, pins, jacks, sockets, quick-fit terminals, screw terminals, terminal blocks, screws, spacers, standoffs, terminals, terminal boards, test points, tips, probes, jumpers, and clips. Keystone also offers custom manufacturing capabilities including stamping, machining, assembly, tool room, and quality assurance.

Ranking as of July 2025

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | RHYTHM CO.,LTD. |

50.0%

|

| 2 | FUJICON CO.,LTD. |

50.0%

|

Derivation Method

The ranking is calculated based on the click share within the tab page as of July 2025. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

Japan

Japan

|

2 | 100.0% |

81 products found

81 products

e431 Co., Ltd.

420+ people viewing

Last viewed: 9 hours ago

Insulated closed end connector (CE type) CE-2 ■Features ・Insulator: Nylon ・Standard color: Milky white ・Rated voltage (V): 300 ・Flame retardan...

Furukawa Electric Manufacturing Co., Ltd.

290+ people viewing

Last viewed: 10 hours ago

It is used to connect copper strips and electric wires, and the connection on the wire side is not compressed but tightened. When changing equipmen...

Morimatsu Co., Ltd.

300+ people viewing

Last viewed: 20 hours ago

Muromoto Iron Works Co., Ltd.

250+ people viewing

Last viewed: 1 day ago

2 models listed

Daido terminal manufacturing

1250+ people viewing

Last viewed: 1 day ago

■ Ingredients JIS H3100, C1020 or equivalent or higher copper specified in H3300. The material of the insulator is vinyl or nylon. ■ With dowel We...

10 models listed

Daido terminal manufacturing

590+ people viewing

Last viewed: 4 hours ago

■ Ingredients JIS H3100 or equivalent or higher copper. ■ With dowel We use materials that can withstand the strength such as stretching during cr...

2 models listed

Daido terminal manufacturing

1320+ people viewing

Last viewed: 8 hours ago

■ Ingredients The connection is the brass of the JIS H3100, and the material of the insulator is vinyl. The surface treatment is performed by elect...

6 models listed

Daido terminal manufacturing

940+ people viewing

Last viewed: 1 day ago

■ Ingredients JIS H3100, C1020 or equivalent or higher copper specified in H3300. The material of the insulator is vinyl or nylon. ■ With dowel We...

10 models listed

Daido terminal manufacturing

860+ people viewing

Last viewed: 15 hours ago

■ Ingredients The connection is the brass of the JIS H3100, and the material of the insulator is vinyl. The surface treatment is performed by elect...

6 models listed

Daido terminal manufacturing

1040+ people viewing

Last viewed: 3 hours ago

■ Ingredients JIS H3100 or equivalent or higher copper. ■ With dowel We use materials that can withstand the strength such as stretching during cr...

10 models listed

Nippon Tanshi Co., Ltd.

320+ people viewing

Last viewed: 6 hours ago

Compatible with RoHS and ELV directives

Nippon Tanshi Co., Ltd.

280+ people viewing

Last viewed: 1 day ago

Compatible with RoHS and ELV directives

Nippon Tanshi Co., Ltd.

240+ people viewing

Last viewed: 1 day ago

Compatible with RoHS and ELV directives

Nippon Tanshi Co., Ltd.

330+ people viewing

Last viewed: 4 hours ago

Compatible with RoHS and ELV directives

Nippon Weidmuller Co., Ltd.

190+ people viewing

Last viewed: 23 hours ago

■Interface to device Are you looking for an interface from electrical engineering to electronics? Solder connections or standard plug-in solutions ...