All Categories

History

This section provides an overview for brushed dc motors as well as their applications and principles. Also, please take a look at the list of 18 brushed dc motor manufacturers and their company rankings. Here are the top-ranked brushed dc motor companies as of July, 2025: 1.Power Electric, 2.MOOG, 3.Nidec Motors.

Table of Contents

A brushed DC motor is a type of DC motor equipped with brushes that facilitate current flow through the rotor.

These motors are known for their simple control mechanisms, allowing easy manipulation of rotation direction and speed. They offer high starting torque and operate effectively across a wide range of speeds. Brushed DC motors are also favored for their straightforward mechanics, making them ideal for educational purposes and beginners. Additionally, they are cost-effective to produce and purchase.

However, the brushes in these motors are prone to wear due to contact with the rotor, necessitating periodic replacement and limiting the motor's lifespan.

Brushed DC motors are used in diverse applications, including:

These motors are a popular choice for power tools due to their high starting torque and compact design, making them suitable for drills and vibratory tools used in construction and repair work.

Used in radio-controlled cars, helicopters, model airplanes, and more, brushed DC motors are preferred for their affordability and ease of control, enhancing the enjoyment of various toys.

Handheld fans, especially useful in hot conditions, often rely on brushed DC motors for efficient air movement at low power.

Common in electric toothbrushes, hand mixers, and hair dryers, these motors serve as a reliable power source in many small household appliances.

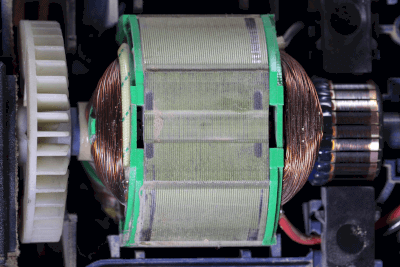

Brushed DC motors operate by the interaction between an electric current and a magnetic field. Key components include the rotor, stator, and brushes.

The stator, typically a permanent magnet or electromagnet, surrounds the motor's rotation axis. The rotor, attached to the motor shaft, contains coils. Brushes supply power to the rotor while maintaining contact.

Upon powering the motor, current flows through the rotor coils, turning them into electromagnets. This creates a magnetic field that interacts with the stator's magnet, generating torque and causing the rotor to spin. The brushes ensure continuous current supply and direction variation, maintaining the rotor's rotation.

Key considerations when selecting a brushed DC motor include:

Ensure the motor's voltage rating matches the intended power supply. Using the correct voltage is crucial, as overvoltage can damage the motor.

Select a motor with sufficient power capacity to handle your required torque and load. Higher power capacity usually translates to more robust performance under larger loads.

Choose a mounting method, such as shaft-mounted or flange-mounted, that suits your application. Consider the available space and connection requirements.

*Including some distributors, etc.

Sort by Features

Sort by Area

Dunkermotoren, established in 1950 and headquartered in Bonndorf, Germany, is a manufacturer specializing in complete motor solutions. We're more than just motor suppliers – we're your trusted partner for comprehensive drive solutions. We take pride in leading diverse industries such as industrial automation, building automation, laboratory and medical technology, and motive applications. Products include brushed DC motors, brushless DC motors, PMDC motors, AC motor, Venetian Blind Drives, Planetary Gearboxes, Angular Gears , Wheel Hub Gear , Controllers, Brakes, Linear Systems, Encoders.

Moog Inc. was incorporated in 1951 and is headquartered in East Aurora, New York. The company designs manufactures and integrates precision motion and fluid controls and control systems for customers including OEMS in industries such as aerospace, defense, industrial machinery, motorsports, and construction. The company’s product offerings include both systems and components. Examples of systems include actuation systems, naval systems, turreted weapon systems, and space vehicles. Examples of components include manifolds, slip rings, actuators, and servo actuators.

Power Electric is a manufacturer and distributor of custom electric and gear motors that was established in 1986 and is headquartered in Plymouth, Minnesota, USA. Power Electric’s products include AC and DC motors, gear motors, and other custom gearing options. Its products are used by several industries, as diverse as food and beverage, packaging, and material handling in Food and Beverage Equipment, Automatic Door Operators, Medical Equipment, and Commercial Equipment. The company also offers many of services, including design, engineering, manufacturing, and testing. The company specializes in the designing and manufacture of custom motors such as to customer’s specifications.

Nidec Corporation traces its roots all the way back to 1908. The company has established itself as an international conglomerate that handles virtually everything that spins and moves. Through its over 300 subsidiaries across the globe, the company manufactures motors that run the spectrum from tiny precision motors in cell phones to motors powering heavy commercial and industrial equipment. The company and its subsidiary's power devices and machines are used in many industrial and personal sectors including agriculture, exercise equipment, HVAC, and refrigeration. Products and services include many varieties of motors, drives, and generators.

MOON’s is headquartered in Shanghai, China. MOON’s is a manufacturer or motion control products. Among these products are stepper drives and motors, brushed and brushless DC motors, servo drives and motors, integrated motors, BLDC drives, lighting drivers and control products, and condition monitoring products. MOON’s has achieved ISO 14001 and ISO 9001 certification.

Nidec Corporation was founded in Kyoto, Japan in 1973 and is a conglomerate with over 200 subsidiaries. Primary products are hard-disk drive motors and automotive parts, and specializes motors ranging from miniature to gigantic. Nidec’s products are used in robotics, automotive, home appliances, agriculturel equipments well as molding, cutting, and machining equipment and sensors.

MinebeaMitsumi Inc. was incorporated in 1951in Japan and manufactures and supplies machined components, and electronic devices and components globally. It operates through four segments: machined components, electronic devices and components, MITSUMI Business, and the U-Shin business segment. MinebeaMitsumi specializes in bearing products including spherical, roller, rod end, and ball bearings for aerospace. MinebeaMitsumi also produces products including precision mechanical assemblies, fasteners, other special components including clutches and brakes, motors, blowers, sensors and lighting devices. Additionally, MinebeaMitsumi offers its products for use in PCs and peripheral equipment, information and telecommunications equipment, household electrical appliances, automobiles, and aerospace.

Greensky Power Company Limited, founded in Hangzhou, China in 2011, is a manufacturer of micro electric motor and controller The company's product portfolio includes Micro AC Motors, Brushed DC Motors, Brushless DC Motors, and Gearboxes. Its products find application in E-bike, Electric kayaks, lawn mowers, pellet boilers, and transmission machines. The company is working closely with clients to develop customized micro solutions that align with their unique requirements and offer product guidance.

VOLCANO ELECTRIC, founded in Ningbo, China, is a manufacturer of motors and motor drives. The company's product portfolio includes brushed (from 80w to 540w for consistent power) and brushless (from 150w to 15kw for consistent power ) permanent magnet DC motors in metric & NEMA frames, as well as gear motors, controllers, and generators. Its products contribute to sustainability with energy-efficient motor and drive solutions and enhance automation processes, productivity, and overall system performance.

Ningbo Leison Motor Co. Ltd, founded in Ningbo, China in 2006, is a manufacturer of electric motors. The company's product portfolio includes AC motors for a wide range of industrial applications, DC motors suitable for various commercial and industrial uses, precision-engineered servo motors for applications demanding accuracy, speed, and control, and customized motor solutions. It exports its products to more than 93 countries and also offers services including after sales support and on time delivery.

Assun Motor is based in Shenzhen China, founded in 2003, an innovative manufacturer for advanced DC drive system. Products including DC Coreless Brushed Motor, DC Slot-less Brushless Motor, Planetary Gearbox, Servo Motor and Controller, Encoder and Brake. Assun Motor provide high precision, reliability and efficiency DC drive systems for critical applications.

Portescap originated in Switzerland in 1931 as a manufacturer of miniature motors and precision motor control solutions. The company assists its customers in selecting the optimal motion technology for a specific application. The extensive range of products includes linear actuators, gearheads, encoders, miniature DC motors (both brush and brushless), and miniature stepper motors. The miniature stepper motors and DC motor technologies are designed to reduce size and weight while enhancing efficiency. They fulfill the need for precise control in medical devices. robotics, surgical, and industrial power tools, automation and other applications.

Gems Motor Limited, founded in Ningbo, China, is a manufacturer of small AC and DC motors and related parts. The company's product portfolio includes stepper, brushless DC, brushed DC, permanent split capacitor (PSC) motors, and shaded pole motors. It has contracted manufacturing partners specializing in motor components, gearboxes, assemblies, and castings. Its products are used in automotive applications, facilitating precise and controlled movements in robotic systems. The company also offers engineering and design services for OEM customers to develop custom small electric motors, as well as custom connectors, controllers, and assemblies based on specific application requirements.

Founded in New York in 1916, Kollmorgen designs and manufactures motion system, drives, motors, actuators, gear heads, automated guided vehicle (AVG) systems, and accessories across a number of implementations and industries. These include aerospace, AGV, food&beverage, machine tools, metal forming, medical automation and imaging, energy, packaging, pharmaceutical, postal sorting, printing, robotics, smart warehouses, and tire and rubber production. Kollmorgen assists customers both in custom designs and in allowing customers to design their own devices based on individual needs.

Ametek PDS, headquartered in Woodstock, NY. is an OEM supplier of components and systems used for power generation and distribution, motion control, data acquisition, and cockpit instruments for the aerospace and defense industry. Products consist of custom power supplies, programmable power supplies, and AC/DC power supplies. The company also offers a range of services, such as repair and calibration, to ensure power supply operation. AMETEK PDS is a part of AMETEK Inc., a publicly traded global manufacturer of electronic instruments and electromechanical devices.

Hansen Corporation was founded in 1907 in Princeton, Indiana, and is now an ElectroCraft Company. The company specializes in synchron motor and DC motor production as part of ElectroCraft. ElectroCraft provides motion control solutions in industrial, commercial, and consumer product markets. ElectroCraft and Hansen product models include asynchronous drives, stepper motors, DC brush motors and brushless motors, and actuators. The company’s tech center includes a CAD library of Hansen and ElectroCraft products, a conversions calculator, and whitepapers.

Retek Motion Co., Limited., founded in Suzhou, China in 2012, is a supplier of motor solutions. The company's product portfolio includes Motors, Die-Casting, and CNC manufacturing, and wire harnesses. Its products are widely supplied for residential fans, air planes, medical facilities, laboratory facilities, and other automotive machines. The company has offices in North America, the Middle East, and Tanzania. It also provides expert guidance to help clients choose the right motor solutions for their specific applications.

Ranking as of July 2025

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Power Electric |

15.7%

|

| 2 | MOOG |

11.6%

|

| 3 | Nidec Motors |

9.5%

|

| 4 | Shanghai MOONS' Electric Co., Ltd. |

7.3%

|

| 5 | MinebeaMitsumi Inc. |

5.7%

|

| 6 | Kollmorgen Corporation |

4.8%

|

| 7 | Ningbo Leison Motor Co. Ltd |

4.5%

|

| 8 | Greensky Power Company Limited |

4.4%

|

| 9 | ebm-papst |

4.1%

|

| 10 | GEMS MOTOR LIMITED |

4.0%

|

Derivation Method

The ranking is calculated based on the click share within the brushed dc motor page as of July 2025. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

China

China

|

4 | 40.0% |

United States of America

United States of America

|

3 | 30.0% |

Japan

Japan

|

2 | 20.0% |

| United States | 1 | 10.0% |

100 products found

100 products

Tokushu Denso Co., Ltd.

430+ people viewing

Last viewed: 1 day ago

■Summary D.C. motors with special electrical equipment for various industrial machines. Small and lightweight, high performance, high quality, many...

Tokushu Denso Co., Ltd.

390+ people viewing

Last viewed: 8 hours ago

■Summary D.C. motors with special electrical equipment for various industrial machines. Small and lightweight, high performance, high quality, many...

Widework Co., Ltd.

1080+ people viewing

Last viewed: 1 hour ago

It can be used for various purposes such as hobby, radio control, plastic model, model work, etc.

2 models listed

Tokushu Denso Co., Ltd.

390+ people viewing

Last viewed: 13 hours ago

■Summary D.C. motors with special electrical equipment for various industrial machines. Small and lightweight, high performance, high quality, many...

Unitec Co., Ltd.

210+ people viewing

Last viewed: 16 hours ago

■Thin and easily replaceable pump. Can be used for multiple purposes by replacing the tube Due to the direct motor connection structure, it is thin...

Tokushu Denso Co., Ltd.

520+ people viewing

Last viewed: 5 hours ago

■Summary D.C. motors with special electrical equipment for various industrial machines. Small and lightweight, high performance, high quality, many...

Tokushu Denso Co., Ltd.

370+ people viewing

Last viewed: 40 minutes ago

■Summary D.C. motors with special electrical equipment for various industrial machines. Small and lightweight, high performance, high quality, many...

TSUKASA ELECTRIC CO.,LTD

570+ people viewing

Motors are used in a wide range of equipment, from financial institutions to homes and medical equipment. Compact design. ■Main usage examples AT...

2 models listed

Unitec Co., Ltd.

380+ people viewing

Last viewed: 11 hours ago

A brushed DC motor is an electric motor that operates using a direct current power source. The main features are that it has a simple structure, ma...

TSUKASA ELECTRIC CO.,LTD

1440+ people viewing

Last viewed: 2 hours ago

Motors are used in a wide range of equipment, from financial institutions to homes and medical equipment. Compact design. ■Features φ16 planetary...

10 models listed

Tokushu Denso Co., Ltd.

330+ people viewing

Last viewed: 1 day ago

■Summary D.C. motors with special electrical equipment for various industrial machines. Small and lightweight, high performance, high quality, many...

Tokushu Denso Co., Ltd.

380+ people viewing

Last viewed: 10 hours ago

■Summary D.C. motors with special electrical equipment for various industrial machines. Small and lightweight, high performance, high quality, many...

TSUKASA ELECTRIC CO.,LTD

380+ people viewing

Last viewed: 15 hours ago

Motors are used in a wide range of equipment, from financial institutions to homes and medical equipment. Compact design. ■Main usage examples AT...

Tokushu Denso Co., Ltd.

320+ people viewing

Last viewed: 1 hour ago

■Summary D.C. motors with special electrical equipment for various industrial machines. Small and lightweight, high performance, high quality, many...

TSUKASA ELECTRIC CO.,LTD

1870+ people viewing

Last viewed: 2 hours ago

Motors are used in a wide range of equipment, from financial institutions to homes and medical equipment. Compact design. ■Features φ16 planetary...

10 models listed

Nerve Motor Co., Ltd.

230+ people viewing

Last viewed: 13 hours ago

■Summary - Reduction gears and intermediate reduction gears can be purchased separately. ・When displayed in red, the reducer rotates in the same d...

Kazumomotion Tech Co., Ltd.

530+ people viewing

Last viewed: 10 hours ago

■ Characteristics Taiwanese TS16949 certification maker SHA YANG YE (Shiki Company Jin Cortical) A gearbox that boasts high robustness is possible ...

TSUKASA ELECTRIC CO.,LTD

660+ people viewing

Last viewed: 17 hours ago

Motors are used in a wide range of equipment, from financial institutions to homes and medical equipment. Compact design. ■Main usage examples AT...

3 models listed

Tokushu Denso Co., Ltd.

340+ people viewing

Last viewed: 3 hours ago

■Summary D.C. motors with special electrical equipment for various industrial machines. Small and lightweight, high performance, high quality, many...

Nerve Motor Co., Ltd.

210+ people viewing

Last viewed: 19 hours ago

TSUKASA ELECTRIC CO.,LTD

1370+ people viewing

Last viewed: 3 hours ago

Motors are used in a wide range of equipment, from financial institutions to homes and medical equipment. Compact design. ■Features □22 planetary...

10 models listed

TSUKASA ELECTRIC CO.,LTD

1630+ people viewing

Last viewed: 4 hours ago

Motors are used in a wide range of equipment, from financial institutions to homes and medical equipment. Compact design. ■Features φ22 planetary...

10 models listed

Keisei Co., Ltd.

170+ people viewing

Last viewed: 18 hours ago

■Features ・With gear head ・Output 1.5W, voltage DC12V, permanent magnet ・Rating Intermittent ・Reduction ratio 1:78.9

TOAMEC Co., Ltd.

160+ people viewing

Last viewed: 1 day ago

DC motors are widely used in a variety of equipment, from financial institutions to homes and medical equipment. Output ranges from about 1W to 46W...

FEW Co., Ltd.

220+ people viewing

Last viewed: 10 hours ago

■Summary We meet a wide range of needs, including general industrial and battery-powered DC power transmitters, and small DC motors for actuators. ...

TSUKASA ELECTRIC CO.,LTD

1360+ people viewing

Last viewed: 1 hour ago

Motors are used in a wide range of equipment, from financial institutions to homes and medical equipment. Compact design. ■Features φ22 planetary...

10 models listed

FEW Co., Ltd.

220+ people viewing

Last viewed: 4 hours ago

■Summary We meet a wide range of needs, including general industrial and battery-powered DC power transmitters, and small DC motors for actuators. ...

TSUKASA ELECTRIC CO.,LTD

480+ people viewing

Last viewed: 13 hours ago

Motors are used in a wide range of equipment, from financial institutions to homes and medical equipment. High output compact design. ■Main usage...

2 models listed

FEW Co., Ltd.

290+ people viewing

Last viewed: 14 hours ago

■Summary Our brushless DC motors can handle power from several tens of W to several kW. Even when using battery power, we manufacture brushless DC ...

TSUKASA ELECTRIC CO.,LTD

1420+ people viewing

Last viewed: 4 hours ago

Motors are used in a wide range of equipment, from financial institutions to homes and medical equipment. High output compact design. ■Features □...

10 models listed