All Categories

History

This section provides an overview for carbide ball end mills as well as their applications and principles. Also, please take a look at the list of 35 carbide ball end mill manufacturers and their company rankings. Here are the top-ranked carbide ball end mill companies as of March, 2026: 1.Sichuan Mingtaishun CNC Cutting Tools Co., Ltd, 2.Changzhou Mingtaishun Carbide CO.,LTD, 3.HG TECHNOLOGY CO., LTD..

Table of Contents

Categories Related to Carbide Ball End Mills

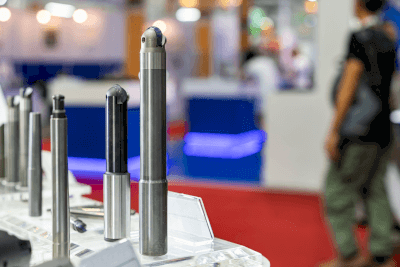

An everloy-cemented-carbide ball end mill is a cutting tool with a spherical cutting edge made of cemented carbide.

Cemented carbide, also called cemented carbide, is an extremely hard alloy. It is manufactured by adding tungsten carbide or titanium carbide to iron and pressing them together by powder sintering at high temperatures.

Ball end mills have cutting edges on the side and one end face, and the end face side is ball-shaped. Complex curved surface machining is possible. Carbide end mills are mainly used for machining center tools.

Ball end mills are suitable for cutting work to form curved surface shapes. In addition, they are also used for fillet sections to prevent parts and debris from accumulating in the bottom corners and for machining curved-shaped grooves as flow paths for liquids.

Specific applications include shape machining of molds, such as injection molds and lens molds, modeling, and small parts. The spherical tip of the cutting tool enables the machining of complex curved surfaces. However, it is not suitable for cutting work that requires sharp edges at the bottom corners.

Cutting with a ball end mill provides higher dimensional accuracy and more complex cutting work than plastic forming, such as press work.

Carbide ball end mills can machine curved surfaces using a ball-shaped cutting edge. Furthermore, when used in conjunction with NC machine tools, it is possible to machine complex three-dimensional curved surfaces.

Ball end mills do not have a large rigidity due to the small cross-sectional area of the cutting edge. Therefore, care must be taken to avoid spilling of the cutting edge. Cemented carbides for cutting tools are classified into three application categories: Class P, Class M, and Class K.

Type P has excellent heat resistance and weldability, and contains a large amount of titanium carbide TiC and tantalum carbide TaC. This alloy is resistant to thermal damage, such as craters and thermal cracks. Its main applications are in the processing of steel, alloy steel, and stainless steel.

Type M contains moderate amounts of titanium carbide TiC, tantalum carbide TaC, etc., and is a strong alloy in terms of both thermal and mechanical damage. Its main applications are in the processing of stainless steel, cast iron, and ductile cast iron.

Class K is a tungsten carbide-WC alloy with excellent strength. It is particularly resistant to mechanical damage, such as crevice wear.

Its main applications are in the machining of cast iron, nonferrous metals, and non-metals. On the other hand, due to its hardness, it has a low stickiness and is easily broken. It is strong in compression, but weak against tensile and lateral forces.

Carbide ball end mills are classified into three types in terms of structure: one-piece type, separate cutting edge type, and brazed type.

The integral type is an end mill in which the shank and cutting edge are integrated into a single unit. Its high rigidity enables high-precision machining. Also, it can be re-grounded and re-coated for use even after wear.

The cutting edge separation type is a type in which the cutting edge, called an insert, is fixed with a screw or a retainer. The price is reduced by partially using cemented carbide material. The feature of this type is that the cutting edge can be replaced with a new one when it is worn out.

Brazed type is an end mill with a carbide blade brazed to the shank. This is a low-cost type.

*Including some distributors, etc.

Sort by Features

Sort by Area

Niagara Cutter, LLC founded in Troy, Michigan, USA, in 1954, is a manufacturer of tools for aircraft, power generation, and general metalworking industry. The company manufactures products including carbide thread mills, cutters, diamond-coated end mills, and grinders. Its aluminum and non-ferrous end mills have an engineered flute shape designed for rigidity and chip space. The company is a subsidiary of Seco Tools, LLC and it also offers services of custom tooling. Its products are ISO-14001 certified.

GARR TOOL, founded in 1944 and headquartered in Alma, Michigan, is a manufacturer of solid carbide cutting tools. The company's broad range of products includes drills, reamers, drill mills, end mills, and rotary files. These cutting tools are used across industries such as manufacturing, aerospace, automotive, metalworking, and woodworking. GARR TOOL's products support precise and efficient material removal, shaping, and machining processes that are used for results in professional and industrial applications. The company is also an ISO 9001:2015-certified company.

Regal Cutting Tools is located in Roscoe, IL, and is a manufacturer of metal cutting tools since 1955. The company's products include thread mills, gages, twist drills, threading taps, and end mills made from materials and coatings such as high speed steel, solid carbide, cobalt steel, Super Tuf particle metal, and carbo-clad carbide tipped. The tools are utilized in aircraft manufacturing, power generation, automotive & transportation, fastener manufacturing, and medical industries. The company has 24-hour special metalworking tap manufacturing services intended purposley for meeting customers' needs.

PCS Co., established in 1960 and based in Fraser, Michigan, United States, is a manufacturer and supplier of mold components for mold-making and die-casting industries. The company caters products in different categories, such as molding supplies, hot runner systems, cutting tools, and mold bases, to customers worldwide. The company also manufactures custom mold bases in different sizes and configurations of up to 35.000” long and thickness to 6.000”. The company maintains ISO-9001 quality certification and the component quality according to these standards.

Conical Cutting Tools was established in 1944 and Michigan, United states as a manufacturer of mills for the metalwork company. The company product portfolio includes diverse line of conical end mills tailored for aerospace, automotive, and mold-making industries. The company serves both small and large organizations, and its distinctive advantage resides in its custom solutions, which enable clients to cut machine time by 20% and boost productivity by 15%. The company position has been strengthened by notable alliances with company's titans, which have resulted in a spectacular 40% increase in sales.

CGS Tool, founded in 1974 and located in Medina, Ohio, United States, is a manufacturer of carbide end mills and cylindrical carbide cutting tools. It offers a wide range of products, including end mills, general-purpose end mills, cylindrical carbide cutting tools, refurbished end mills, and custom-designed profile carbide end mills, for clients in industries such as aerospace, medical, automotive, and manufacturing. The company also provides services such as tool building, troubleshooting, and material data safety sheets.

Guhring, Inc. is an American manufacturer of round shank cutting tools established in 1978 as a subsidiary of German company Guhring KG, which was originally founded in 1898. Headquartered in Brookfield, Wisconsin, the company produces various taps, end mills, drills, and reamers, as well as tool holders and countersinks. These are utilized in the manufacturing and engineering processes of clients in the industrial sector, including tool and mold making, power generation, and construction. Guhring, Inc. owns over 1,000 patents, and produces more than 40,000 different cutting tools that it distributes via other subsidiaries in the Guhring KG network.

TE-CO Workholding was founded in 1926 and is headquartered in Union, Ohio. The company is a manufacturer of work-holding technology and tooling components sold nationally and internationally through distributors. The company’s product segments include Tooling Components, Tooled Vise WOrkholding Systems, Spring Loaded Devices, Clamping Levers, and CMM Picturing & Inspection Components. The Company also offers 2D and 3D CAD models, drawings, and detailed information in various data formats to assist customers in choosing and modifying designs for their needs.

Rohit Industries Group (P) Ltd is a manufacturer of cutting tools since 1963 based in Delhi. The company deals in Drilling, Milling, Lathe, Press, and Tapping tools along with the making of Router Bits these products help machine materials like Alloy Steel, Stainless Steel, Titanium, Cast Iron, Nicker alloys, and other materials. They even make bits with varying HSS material grades for various applications but overall, these tools serve the aerospace, automotive, general manufacturing, and die and cut industry to name a few.

Henan Heygo Tools Co., Ltd, established in 2007, is a manufacturer and supplier of quality diamond tools based in China. The company specializes in the production of diamond saw blades, grinding wheels, and core drill bits for various applications. With a emphasis on precision and durability, Henan Heygo Tools aims to provide tools that enhance cutting, grinding, and drilling processes in industries like construction, stone processing, and metalworking. Their solutions cater to professionals seeking efficient and effective tools for demanding tasks.

Speed Tiger Precision Technology Co., Ltd., established in 1998 and based in Taiwan, is a manufacturer of cutting tools. The company is the first in Taiwan to integrate milling cutter coating technology. It has a good position in the performance CNC tool market. The firm specialises in producing drills, inserts, end mills, and other cutting tools made of tungsten carbide steel with accuracy. The company has more than 100 sets of grinding machines from Germany, Switzerland, Japan, and Taiwan. It is the first producer to combine coating processes with cutting equipment.

Zhuzhou Chuangde Cemented Carbide Co., Ltd., founded in 2009 and based in Zhuzhou City, Hunan, China, is a manufacturer of carbide products such as roller rings, disc cutters, cemented carbide rods, carbide stud hpgr, and more. The company holds the certification of ISO 9001:2015 and exports its products to countries like Japan, Taiwan, the US, the UK, and other parts of Europe. Its carbide-based products serve industries such as automobile, shipbuilding, chemicals, craft carving, and many more.

Karnasch Professional Tools GmbH, founded in 1963 and headquartered in Heddesheim, Germany, is a manufacturer of machining and cutting tools. The company specializes in the manufacturing of optimal-quality cutting tools, including solid carbide drills, end mills, composite tools, and hole saws. These precision-engineered tools offer optimal performance, longevity, and precision, making them ideal for industries requiring premium-precision machining, such as aerospace, automotive, and medical device manufacturing. It is also engaged in manufacturing lubricants, and dental tools and operates in 60 different countries.

HG TECHNOLOGY CO. LTD, established in 2002 and based in Changhua County, Taiwan, is a manufacturer of solid carbide tools including end mills, drills, and reamers. Solid carbide tools can be used to work on a wide range of materials such as stainless steel, aluminum, titanium, graphite, alloy steel, and more. The company’s product portfolio includes various types of carbide end mills such as square, corner radius, and ball nose. These products are commonly used for machining in diverse industries, including electrical, electronics, dental and healthcare equipment, aerospace, and precision molding.

OSG Corporation., founded in 1938 and headquartered in Toyokawa, Japan, is a manufacturer of various cutting tools, including end mills, drills, taps, rolling dies, and gauges. The cutting tools are engineered for an array of industries, including energy, automotive, aerospace, die/mold, and heavy. The company also has an academy that it uses as an innovation hub for researching, designing, and developing new products. It established its first overseas subsidiary in the U.S. in 1968, and since then, it has continued to build a network of manufacturing, sales, and technical support locations spanning 33 countries.

UNION Tool Co., established in 1955 is a manufacturer and retailer of cutting tools, linear motion products, sensor products, and measuring instruments based in Tokyo, Japan. The company offers tungsten carbide-made cutting tools such as MDP drill pointer, OPTECH-M non-contact drill diameter, and ring setting machines. The company also has a rolling dies/ forging tools/ coating rods product segment which includes various products including screw manufacturing dies, rack dies, rolled products, and roll dies & incremental dies. Their products are used in PCB drill development, and machine tools & semiconductor manufacturing applications.

NACHI-FUJIKOSHI CORP. is a Japanese manufacturer of industrial machinery and tools, such as bearings, hydraulic equipment, robots, and cutting tools. They also provide services such as machine maintenance and repair. The company's products are used in automotive, aerospace, construction, and electronics. One of NACHI-FUJIKOSHI's renowned products is their robotic arm, the "MZR series," which is designed for precision assembly and inspection tasks in industries. They received several awards for their technological advancements and contributions to the industry, including the 2021 Japan Society of Mechanical Engineers Medal for new hydraulic equipment technology and the 2020 Nikkan Kogyo Shimbun Grand Technology Award.

DIC TOOLS, established in Patiala, Punjab in 2012 is a manufacturer of cutting tools which include HSS Cutting Tools and Gear Cutting Tools. Their product portfolio includes solid carbide end mills used for precise milling, high-speed steel (HSS) and HSS-Co drills, high-speed steel (HSS) and HSS-Co drills used in turning and milling operations, and boring bars and tool holders for hole machining. The company serves industries such as Electronics and Semiconductors, Metalworking and Fabrication and Precision Engineering.

NS Tool Co., Ltd., founded in 1954 with headquarters in Tokyo City, Japan, is a manufacturer of original coatings and CNC machining tooling under the NS Tool brand. The company's product line includes end mills, original coated toolings, ultra micro end mills, and 2-flute long neck ball end mills for hardened steel. These products are used for precision machining of alloys, hardened steel, and other materials to create components and parts. The company serves markets that include electronics product manufacturing, aerospace, appliance manufacturing, and industrial parts manufacturing.

Xiamen Betalent Carbide Co., Ltd., established in 2008 and based in Dongguan, Ganzhou with its head office and main plant in Xiamen, China, is a manufacturer and supplier of cemented carbide materials and carbide products. The company’s head office and main plant cover an area of 10000-meter square. Cemented carbide is used as cutting tool materials like turning tools, milling cutters, planers, drills, and boring cutters for cutting cast iron, non-ferrous metals, plastics, chemical fiber, and other difficult-to-cut materials. The company has achieved numerous accolades including SGS certification.

Eikosha Co. Ltd., founded in 1950 and headquartered in Ota-ku, Tokyo, is a manufacturer of precision cutting tools. The company specializes in producing reamers, cutters, and end mills with a portfolio of over 40,000 standard tools. It provides customized tool services, creating cutting tools from CAD prints or sketches to meet specific client needs. Its capabilities also include crafting tools from carbide and HSS, ensuring precision and repeatability for every design. Its product lines, such as the Eikosha series, cater to various industrial machining applications. The company exports globally, reaching markets across Europe, Asia, and the Americas.

The Company operates diverse businesses, ranging from nonferrous metals and other fundamental materials to cemented cardide tools/metalworking solutions, the manufacturing of semiconductor-related and electronic components/materials, resource recycling, and renewable energy power generation. In each business, the Company holds the No.1 position in production volume, sales volume, etc.

Fullerton Tool Company, Inc., founded in 1942 with headquarters in the USA, is a manufacturer of solid carbide and cutting tools and equipment. The company's product line includes end mills, drill mills, saws, boring tools, and keyseat cutters. Fullerton Tool Company's tools are utilized for cutting various metals on heavy-duty machines, CNC lathes, engine lathes, and chuckers. The company's equipment is used in numerous industries, including the automotive, construction, general machining, furniture, and oil and gas markets, for cutting, reaming, grooving, and grinding of hard metals. Fullerton Tool Company offers custom tool design and production, as well as refurbishing services.

Li Hsing Precision Tool Co., Ltd. is an award-winning solid carbide end mills manufactruer based in Taichung, Taiwan since 1996. The company's diverse product catalogue includes square ends, ball nose, corner radius end mills, and more. In fact, it also makes reamers, high speed drills and microscope carbide micro boring items. Additionally, the venture counts with multiple standard quotas, including the ISO 9001, TÜV Rheinland, and D-U-N-S certificates. Regarding other accomplishments, the firm was awarded the Taiwan Gold Medal Quality Product Award in 2011 and the 2019 Golden Hand Award for Outstanding SMEs in 2019,

Shenzhen Zhuoluoyu Precision Tool Co., Ltd. (ZLY-TOOLS) is a national high-tech enterprise in China that develops, manufactures, and sells precision cutting tools with its own brand, was established in 2006. The company is located in Shenzhen, specializes in carbide cutting tools, including carbide end mill cutters, carbide drill bits, special tools, slot milling cutters, engraving tools, and more. It provides not only tools but metalworking tool solutions. It has a professional technical team that guarantees all-tool-life service. It has a state-of-the-art production facility and has developed thousands of customized cutting tools.

Ranking as of March 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Sichuan Mingtaishun CNC Cutting Tools Co., Ltd |

9.1%

|

| 2 | Changzhou Mingtaishun Carbide CO.,LTD |

9.1%

|

| 3 | HG TECHNOLOGY CO., LTD. |

9.1%

|

| 4 | DIC TOOLS |

9.1%

|

| 5 | Hwe Der Machinery and Hardware Co Ltd |

6.1%

|

| 6 | Huanatools Co.,Ltd |

6.1%

|

| 7 | Karnasch Professional Tools GmbH |

6.1%

|

| 8 | Fullerton Tool Company, Inc. |

6.1%

|

| 9 | Niagara Cutter, LLC |

3.0%

|

| 10 | ZhuZhou Rivictory New Material Co., Ltd. |

3.0%

|

Derivation Method

The ranking is calculated based on the click share within the carbide ball end mill page as of March 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

10 | 35.7% |

China

China

|

6 | 21.4% |

Taiwan

Taiwan

|

4 | 14.3% |

Japan

Japan

|

4 | 14.3% |

India

India

|

3 | 10.7% |

Germany

Germany

|

1 | 3.6% |

207 products found

207 products

Rinos Co., Ltd.

200+ people viewing

■ Characteristics -It can be used widely from raw material to high rigidity, raw material, toned steel, baked steel (~ 65HRC), titanium and inconel...

10 models listed

Nichia Alloy Co., Ltd.

140+ people viewing

Last viewed: 1 day ago

Solid and edged types available. Compatible with groove machining, contouring machining, etc. We can also provide special tools that match the shap...

10 models listed

Kyowa Seiko Co., Ltd.

320+ people viewing

Last viewed: 19 hours ago

The blade shape is designed for resin processing to improve sharpness. In addition to general drills, end mills, and reamers, we also have a lineu...

Rinos Co., Ltd.

220+ people viewing

Last viewed: 6 hours ago

■ Characteristics -It can be used widely from raw material to high rigidity, raw material, toned steel, baked steel (~ 65HRC), titanium and inconel...

10 models listed

NS TOOL Co., Ltd.

390+ people viewing

Last viewed: 1 hour ago

X-coated 2-flute ball end mill with ball radius less than R1. A versatile type that can process a wide range of work materials from roughing to fin...

Rinos Co., Ltd.

260+ people viewing

Last viewed: 1 day ago

■ Characteristics -It can be used widely from raw material to high rigidity, raw material, toned steel, baked steel (~ 65HRC), titanium and inconel...

10 models listed

Rinos Co., Ltd.

230+ people viewing

■ Characteristics -It can be used widely from raw material to high rigidity, raw material, toned steel, baked steel (~ 65HRC), titanium and inconel...

10 models listed

NS TOOL Co., Ltd.

380+ people viewing

Last viewed: 1 day ago

・2-flute long neck ball end mill for non-ferrous metals ・Flute shape with high cutting performance improves machined surface quality even with de...

Kyoji Co., Ltd.

150+ people viewing

Last viewed: 1 day ago

Overview ■DM series carbide end mill for graphite processing ・CVD diamond coating provides tool stability, long life, and high precision machining...

Rinos Co., Ltd.

250+ people viewing

Last viewed: 1 day ago

■ Characteristics ・ Ideal for precision parts and mold processing from difficult cutting materials such as high -hardware, titanium and stainless ...

10 models listed

NS TOOL Co., Ltd.

290+ people viewing

・2-flute ball end mill for non-ferrous metals ・High cutting performance blade shape improves machined surface quality

Kyoji Co., Ltd.

170+ people viewing

Last viewed: 1 day ago

Overview ■DM series carbide end mill for graphite processing ・CVD diamond coating provides tool stability, long life, and high precision machining...

Kyoji Co., Ltd.

250+ people viewing

Last viewed: 1 day ago

Overview ■TM End mill for titanium alloy - Polishing the front and rear cutting edges improves the surface finish of the tool, reduces wear, and re...

NS TOOL Co., Ltd.

330+ people viewing

Last viewed: 1 day ago

・General-purpose type 2-flute tapered blade ball end mill ・Supports various machining shapes with a wide variety of sizes

Kyowa Seiko Co., Ltd.

400+ people viewing

Last viewed: 1 day ago

Available in a lineup with blade lengths ranging from 3 times the blade diameter to a maximum of 12 times. In addition to general drills, end mill...

Gnet Co., Ltd.

340+ people viewing

Last viewed: 1 day ago

■Features ・Standard ball end mill with 2 flutes and 30 degree twist ・Applicable to processing of high hardness materials up to HRC62 due to TiSi ...

NS TOOL Co., Ltd.

300+ people viewing

・General-purpose 2-flute long neck ball end mill ・Supports various machining depths with a wide variety of sizes

Kyowa Seiko Co., Ltd.

310+ people viewing

Last viewed: 1 day ago

The neck is tapered to increase the effective length. Ideal for deep engraving etc. In addition to general drills, end mills, and reamers, we also...

NS TOOL Co., Ltd.

250+ people viewing

Last viewed: 3 hours ago

・2-flute ball end mill specialized for small diameter sizes with ball radius less than R1 ・A versatile type that can be processed from rough cutt...

Nichia Alloy Co., Ltd.

110+ people viewing

Last viewed: 1 day ago

Solid and edged types available. Compatible with groove machining, contouring machining, etc. We can also provide special tools that match the shap...

10 models listed

Nichia Alloy Co., Ltd.

100+ people viewing

Last viewed: 1 day ago

Solid and edged types available. Compatible with groove machining, contouring machining, etc. We can also provide special tools that match the shap...

10 models listed

NS TOOL Co., Ltd.

240+ people viewing

Last viewed: 1 day ago

・3x blade length, 5x blade length, 10x blade length, ultra-long neck, same diameter type can be selected according to the machining shape. ・Can a...

NS TOOL Co., Ltd.

230+ people viewing

Last viewed: 1 day ago

・Long neck ball end mill specialized for processing copper electrodes. ・High machinability, sharp blade shape, and DLC coating enable long-term, ...

Kyowa Seiko Co., Ltd.

320+ people viewing

Last viewed: 1 day ago

The blade shape is designed for resin processing to improve sharpness. The bottom of the neck is made longer for deep machining. In addition to ge...

NS TOOL Co., Ltd.

260+ people viewing

Last viewed: 1 day ago

NS TOOL's unique blade shape suppresses chatter during corner and side machining.

NS TOOL Co., Ltd.

220+ people viewing

Last viewed: 13 hours ago

・Taper machining and ball machining are possible at the same time ・Sizes range from a minimum R0.1 to a maximum of 15° on one side.

Kyowa Seiko Co., Ltd.

350+ people viewing

Last viewed: 1 day ago

In addition to general drills, end mills, and reamers, we also have a lineup of standard products such as stepped drills, V-shaped end mills, and c...

NS TOOL Co., Ltd.

260+ people viewing

・The lower part of the neck is tapered to improve tool rigidity. ・It is possible to take a larger depth of cut than conventional products.

NS TOOL Co., Ltd.

270+ people viewing

・Neck relief type suitable for narrow and deep machining ・Supports deep precision 3D machining from low speed to high speed

Kyowa Seiko Co., Ltd.

320+ people viewing

Last viewed: 6 hours ago

In addition to general drills, end mills, and reamers, we also have a lineup of standard products such as stepped drills, V-shaped end mills, and c...