All Categories

History

This section provides an overview for eda tools as well as their applications and principles. Also, please take a look at the list of 5 eda tool manufacturers and their company rankings. Here are the top-ranked eda tool companies as of July, 2025: 1.Xilinx, 2.Siemens EDA, 3.Synopsys, Inc..

Table of Contents

An EDA (Electronic Design Automation) tool is a set of software and hardware tools used to streamline and automate the electrical design process.

It can be thought of as the electrical design counterparts to the CAD and CAM tools commonly used in mechanical design.

For instance, in the design of household appliances, the product design journey typically begins with system (conceptual) design, followed by circuit design, assembly, iterative prototyping, and final product completion. Throughout this process, EDA tools play a crucial role in facilitating product design.

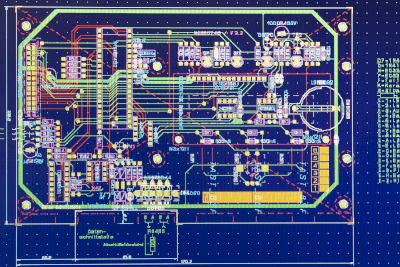

EDA tools cater to various stages of the design process. In the context of product design, including household appliances, they encompass tools for system (conceptual) design and simulation, which represents the initial design phase. Additionally, they encompass tools for circuit design and simulation, tools for printed circuit board layout, and tools for mitigating unwanted emissions.

In the semiconductor design field, EDA tools encompass tools for semiconductor device design and their simulation, logic and timing design tools and simulation tools, as well as layout design tools and simulation tools.

It is technically possible to proceed with product design without employing EDA tools or by using only a subset of these tools.

However, in today's competitive landscape, where manufacturers of various products, including household appliances and semiconductor devices, vie on a global scale, the notion of "build it, and it will sell" no longer applies. Success hinges on the ability to swiftly and cost-effectively deliver high-functionality, high-performance products. Consequently, circuits are becoming increasingly compact, smaller in size, lighter, and more power-efficient.

Remaining competitive necessitates an unmatched blend of development prowess and speed in this environment, and EDA tools serve as invaluable aids in achieving this.

The initial step in designing a product entails defining the product's nature. What functions should it encompass? What should the production cost be? Subsequently, one must devise a system configuration that aligns with this cost target.

System design tools prove to be invaluable in this process. The simulation functionality of system design tools enables the evaluation of whether the virtual system configuration, conceived on a computer, is optimal. This involves assessing whether the performance, functionalities, and costs meet predefined expectations.

If simulation results prove unsatisfactory, the system can be reconfigured, and simulations rerun, iterating the trial-and-error process until an optimal system configuration is attained. Conducting this process by physically building a product would entail significant time and resources, but EDA tools empower users to conduct such verifications swiftly on a computer.

A similar approach can be employed in subsequent design phases, effectively shortening the overall design timeline.

*Including some distributors, etc.

Sort by Features

Sort by Area

Intel PSG, founded in Santa Clara, California in 1968 is a manufacturer of processors, chipsets and wireless products. The company's product portfolio includes Graphics Processing Units, Systems & Devices, programmable devices, and non-volatile memory solutions. their products are used in laptops, desktops, mobile phones, AI analytics and self-driving cars. The company serves markets including Automotive and Electric Vehicles, Renewable Energy and Energy Storage and Electronics and IT Infrastructure. The company has operations all around the world and provides global technical and customer support.

Synopsys, founded in Sunnyvale, California, in 1986 is a manufacturer of electronic equipment such as Smart medical devices, wearables, and autonomous cars. The company's product portfolio includes silicon chips, Semiconductor IP, RSoft Photonic Device Tools, Virtual Prototyping and Signal & Power Integrity. The company serves markets including Automotive and Electric Vehicles, Renewable Energy and Energy Storage and Electronics and IT Infrastructure. They also provide services including Open-Source Audits, Open Source Risk Management, RF Design, Silicon Lifecycle Management and Software Supply Chain Security.

Keysight Technologies, Inc. was founded in 1939 and headquartered in Santa Rosa, California. Keysight is a global developer and manufacturer of electronic design and test solutions to communications, networking, aerospace, defense, and government, automotive, energy, semiconductor, electronic, and education industries. Keysight’s communications solutions group solutions include electronic design automation software; radio frequency and microwave test solutions, hardware and virtual network test platforms and software applications, as well as optical laser source solutions. Keysight’s electronic industrial solutions group offers various design tools and verification tools. Keysight offers product support, technical support, and training and consulting services. It sells its products through direct sales force, distributors, resellers, and manufacturer's representatives.

Xilinx founded in 1959, is a manufacturer of technology components and semiconductors which invested in the FPGA and Adaptive SoCs. The products include accelerators, graphic cards, processors, computer platforms, and servers. The company is behind the production of Alveo X3 Series, NIC X2 Series Offload, KV260 Vision AI Starter Kit and KR260 Robotics Starter Kit, and many others The company in San Jose, California a researcher, developer, and designer of software, apps, and tools, including virtualization, cloud computing, green IT, and energy efficiency.

Siemens EDA is an American distributor of integrated circuit (IC) as well as printed circuit board (PCB) design and verification software that was established in 1981 as a subsidiary of the German company Siemens AG. Based in Wilsonville, Oregon, the company offers emulation, simulation, layout, wire harness, and design-for-manufacturing software tools for use in conceptualizing and testing various IC or PCB mockups. This saves time in the prototyping and troubleshooting stages of their production processes, increasing efficiency while reducing risk of cost overages. Siemens EDA chiefly serves clients in the semiconductor, aerospace, defense, and consumer electronics sectors.

Ranking as of July 2025

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Xilinx |

34.2%

|

| 2 | Siemens EDA |

22.2%

|

| 3 | Synopsys, Inc. |

15.6%

|

| 4 | Keysight Technologies |

14.2%

|

| 5 | Intel PSG |

13.8%

|

Derivation Method

The ranking is calculated based on the click share within the eda tool page as of July 2025. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

3 | 100.0% |

57 products found

57 products

ECAD Solutions Co., Ltd.

350+ people viewing

Last viewed: 7 hours ago

The ECAD series is a 2D CAD system equipped with functions for control design and power distribution board design. We have been developing this pro...

Electro System Co., Ltd.

460+ people viewing

Last viewed: 7 hours ago

esCAD-sch is a circuit diagram creation CAD software. Great effects can be achieved by linking with the printed circuit board pattern design CAD so...

Altium

580+ people viewing

Last viewed: 10 hours ago

■Electronic design that provides both an intuitive interface and high quality With ever-increasing electronic design requirements and ever-shorteni...

3 models listed

CSi Global Alliance, inc.

360+ people viewing

Last viewed: 7 hours ago

■Point1 Design For Manufacture/Improvement of manufacturability design function Designers need to understand the requirements for the manufacturing...

Intersoft Co., Ltd.

300+ people viewing

Last viewed: 1 day ago

■Advanced SPICE circuit design simulator. Best convergence in its class SIMetrix is a digital/analog mixed simulation package designed for use by...

natural up Co., Ltd.

200+ people viewing

Last viewed: 1 day ago

■Easy operation ・Estimates can be created using automatic aggregation from CAD data. - Anyone can easily create drawings using a mouse. - Once you...

Electro System Co., Ltd.

520+ people viewing

Last viewed: 1 day ago

esCAD pcb is a printed circuit board design tool (software). ■Product features It is equipped with convenient functions not found in existing prin...

4 models listed

CSi Global Alliance, inc.

350+ people viewing

Last viewed: 1 day ago

■An easy-to-use circuit diagram editor for busy circuit designers. We provide a complete circuit design environment. ・Edit attributes in the parts...

Electro System Co., Ltd.

260+ people viewing

Last viewed: 1 day ago

Setup Meijin is a tool that automatically and efficiently performs tasks such as creating mounting diagrams and finding mounting positions for each...

CSi Global Alliance, inc.

230+ people viewing

Last viewed: 15 hours ago

Analysis compatible with AC/DC, transient analysis, operating analysis, sensitivity analysis, and digital/analog mixed circuits is possible. Monte ...

CSi Global Alliance, inc.

250+ people viewing

Last viewed: 8 hours ago

Equipped with a wealth of functions that support all designs from analog/power supply/flexible boards to multilayer boards. [Parts] Automatic crea...

Electro System Co., Ltd.

190+ people viewing

Last viewed: 1 day ago

EsCAD pcb is a printed circuit board design tool (software). It is available for free for a limited time. ■Product features esCAD PCB is equipped ...

CSi Global Alliance, inc.

240+ people viewing

Last viewed: 1 day ago

Capable of high-density, high-clock propagation delay, impedance, reflection, and crosstalk analysis. Verify EMI and high-frequency design issues b...

CSi Global Alliance, inc.

240+ people viewing

Last viewed: 1 day ago

■Restore Gerber data to PCB Manufacturing data output from other companies' CAD systems can be easily edited, and it is equipped with a variety of ...

KB Consulting Co., Ltd.

350+ people viewing

Last viewed: 1 day ago

■Features of BJ-Electrical Design efficiency is greatly improved with excellent operability and high cost performance. It is compatible with Zuken ...

CSi Global Alliance, inc.

280+ people viewing

Last viewed: 1 hour ago

■ Significantly reduces wasted design time. The collaboration between electric and mechanical is realized. It is possible to check for interference...

KB Consulting Co., Ltd.

440+ people viewing

Last viewed: 14 hours ago

■Characteristics of ACAD-DENKI ACAD-DENKI is an electrical/control design CAD system provided by Zuken Alphatech. ACAD-DENKI is an electrical CAD w...

3 models listed

CSi Global Alliance, inc.

200+ people viewing

Last viewed: 10 hours ago

We sell KONEKT's automatic wiring tool "Electra Route" on an OEM basis. ``Electra Route'' is an auto-routing software for printed circuit boards. W...

CSi Global Alliance, inc.

290+ people viewing

Last viewed: 1 hour ago

You can open circuit diagram data, PCB (printed circuit board), and project files created with CSiEDA6. Output such as printing is possible from th...

IDAJ Co., Ltd.

560+ people viewing

Last viewed: 21 minutes ago

Semiconductor package "Simcenter ™ Flotherm ™ XT", which can analyze from the single to the entire device, is a thermal design support tool that ca...

IDAJ Co., Ltd.

500+ people viewing

Last viewed: 6 hours ago

The Simcenter ™ Flotherm ™, which can analyze from the semiconductor package alone to the entire device, is a thermal design support tool that can ...

4 models listed

CSi Global Alliance, inc.

260+ people viewing

Last viewed: 1 day ago

■LMS (Library Management System) Library management system By having the administrator register the libraries created by each individual, the same ...

Cross light software ink

290+ people viewing

Last viewed: 1 day ago

■ Overview of apsys APSYS is a general -purpose 2D/3D finite element analysis and design software for semiconductor devices. In addition to the fle...

Cybernet System Co., Ltd.

150+ people viewing

Last viewed: 1 day ago

■DEMITASNX Overview DEMITASNX is an "EMI suppression design support tool" developed by NEC. It is designed to be easy to use even for beginners, wi...

Zuken Alphatech Co., Ltd.

310+ people viewing

Last viewed: 10 hours ago

This is a CAD system for electrical and control design that can meet customer needs, not only for design work but also for manufacturing support. ...

2 models listed

CSi Global Alliance, inc.

240+ people viewing

Last viewed: 1 day ago

■High-quality heat dissipation design including highly integrated LSI and LED In recent years, a major issue has become how to efficiently dissipat...

Argo Japan ES Co., Ltd.

450+ people viewing

Last viewed: 20 hours ago

*Annual maintenance requires two years' worth of maintenance fees in the first year. *Other product numbers are available.

10 models listed

Zuken Alphatech Co., Ltd.

390+ people viewing

Last viewed: 12 hours ago

■BJ-Electrical .dwg based electrical CAD application. Design efficiency can be greatly improved with excellent operability and high cost performanc...

5 models listed

IDAJ Co., Ltd.

440+ people viewing

Last viewed: 20 minutes ago

DEMITASNX is a design check tool for applying known standards and algorithms from information such as wiring patterns of boards in the upstream pro...

2 models listed

HPC Systems Co., Ltd.

170+ people viewing

Last viewed: 1 day ago

■Product overview JMAG is a domestic simulation program for electrical equipment design and development developed by JSOL Corporation in 1983. It i...