47 Cam Manufacturers in 2024

This section provides an overview for cams as well as their applications and principles. Also, please take a look at the list of 47 cam manufacturers and their company rankings. Here are the top-ranked cam companies as of July, 2024: 1.Isky Racing Cams, 2.HOWARDS CAMS & RACING COMPONENTS, 3.TIMKEN.

Table of Contents

What Is a Cam?

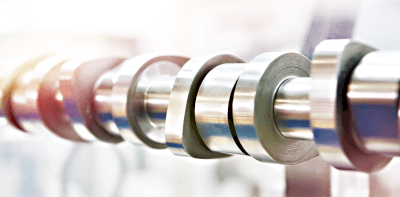

A cam is a mechanical component designed to change the type and direction of motion. It achieves this by transmitting motion to a driven section via a contactor. For instance, the rotational motion of a circular cam can be transformed into the vertical movement of a rod-shaped driven section. Known for its simple structure, a cam offers a long service life and requires low maintenance. It is also efficient and minimizes force transmission to other parts. Cams come in various shapes and sizes, each suited for specific applications.

Uses of Cams

Cams are widely used in machinery and devices where a change in motion direction is needed, such as in an engine exhaust valve. In gasoline-powered vehicles, cams facilitate the smooth expulsion of exhaust gases. They transform the rotational motion of the engine into the reciprocating motion of valves, controlling the opening and closing of the valves in a timely manner.

Principles of Cams

Cams, which come in various shapes, efficiently change the motion direction. The two primary types are flat cams and three-dimensional cams.

- Flat cams, such as straight plate cams and rotating plate cams, use a simple, flat structure. Straight plate cams transfer reciprocating motion to the driven section via a contoured surface, while rotating plate cams use an irregularly shaped plate to create vertical movement in the driven node.

- Three-dimensional cams, including cylindrical, spherical, and swash plate cams, have more complex structures. These cams use grooves or inclined surfaces to enable complex motion changes in the driven section.

Designing Cams

Designing cams involves selecting the appropriate type and mechanism. Key considerations include the cam type (plane or three-dimensional), the kind of driven installation (linear or oscillating), and the details of the output motion. Creating a timing diagram and considering factors like pressure angle and lever length are crucial. The pressure angle influences the load on the contact surface, and the cam's diameter is determined based on the maximum pressure angle. Calculations for pressure angle, radius of curvature, and other parameters ensure the cam's shape is optimal for its function. Finally, the design must account for surface pressure, mechanical strength, rolling contact fatigue life, and rigidity.

Confirmatory Cams

Positive-acting cams ensure reliable transmission of motion to the driven section. High-speed rotation may hinder the driven section from following the cam's movement, so a spring is often used for constraint. Examples of positive cams include frontal, cylindrical, tapered, and spherical cams.

List of 47 Cam Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- United States of America

- Australia

- Germany

- Italy

- Japan

- New Zealand

- United Kingdom

-

-

-

DESTACO, A Dover Company

Cams

Manufacturer Overview

DESTACO, a Dover Company was founded in 1915, is a global manufacturer of automation, workholding, and containment solutions, headquartered in the United States. The company's product portfolio includes clamps, grippers, end effectors, and robotic tool changers. They are a worldwide supplier in the design, manufacture and support of clamping, gripping, linear/rotary transferring and robotic tooling solutions for workplace and flexible automation needs. Their customer base covers a wide range of industries requiring a global customer service network offering consistent solutions and program support.

-

-

-

-

-

Wire Tech EDM, Inc.

Cams

Manufacturer Overview

Wire Tech EDM, Inc., headquartered in California, is a manufacturer specializing in precision wire EDM machining and small hole drilling services. Established in 1986, the company's technical expertise and advanced equipment are used in industries where micrometer-level precision is essential, such as aerospace, medical, and electronics, amongst others. The company crafts intricate components with exacting tolerances, ensuring the utmost efficiency in critical applications. Its products enhance overall system performance, safety, and technological advancement, making them a partner for precision manufacturing needs across industries.

-

-

-

-

-

Wire Cut Co., Inc.

Cams

Manufacturer Overview

Wire Cut Co., headquartered in Buena Park, California has been a manufacturer of high-precision EDM parts since 1978. They use wire EDM machines to cut complex shapes in conductive materials, such as metal, plastic, and composites. Some of the products they have manufactured include landing gears for aircraft, pacemakers for medical implants, engine components for automobiles, and prototypes for medical devices. The company is found to be compliant with AS9100D industry standards.

-

-

-

-

-

TIMKEN

Cams

Manufacturer Overview

The Timken Company (Timken) was founded in 1899 and is headquartered in North Canton, Ohio. Timken designs, manufactures, and manages engineered bearings and industrial motion products worldwide. Timken operates in two segments, Mobile Industries and Process Industries. The Mobile Industries segment’s portfolio includes bearings, seals, and lubrication devices and systems. The Process Industries segment provides industrial bearings and assemblies; industrial motion components, such as gears and gearboxes; and linear motion products, couplings, seals, lubricants, chains, belts, and related products and services to OEMs and end users in various industries.

-

-

-

-

-

Stock Drive Products/Sterling Instrument - SDP/SI

Cams

Manufacturer Overview

SDP/SI was founded in 1950 and is situated in New Hyde Park, New York. SDPP/SI is a manufacturer of precision gears and high-quality mechanical components used in the aerospace, industrial manufacturing, medical technology, and robotics fields. The company manufactures parts in a variety of materials including alloy steel, stainless steel, bronze, brass, nylon, and titanium. The company also provides coating services such as heat treating, zinc plating, and painting. Additional custom options are available including manufacturing to customer drawings and specifications.

-

-

-

-

-

Sterling Sintered Technologies, Inc.

Cams

Manufacturer Overview

Sterling Sintered Technologies, Inc. is the manufacturer of sintered metal parts since 1955 based in Connecticut. The company also produces fabricating powder metal parts for complex mechanical components creating various components, from simple miniature pieces to complex structures used in specialized applications. They work with sintered metal alloys, as well as providing services such as tool making and secondary operations. With the facilities they cater to a wide range of powder metallurgy applications, ensuring that clients receive products tailored to their specific needs.

-

-

-

-

-

STD Precision Gear & Instrument, Inc.

Cams

Manufacturer Overview

STD Precision Gear & Instrument, Inc., since 1986, is a manufacturer of high precision, tight tolerance, configured gears, splines and other mechanical transfer components such as pulleys and sprockets, ratchets, universal joints, cranks and jackscrews used in aerospace, medical, commercial, and military industries. The company in West Bridgewater, MA, has capabilities such as CNC turning & milling, surface & cylindrical grinding, isotropic superfinishing, heat treating, and tool making. The company’s products qualified for applications such as NASA’S Space Station and Hubble Telescope and are certified by ISO 9001 and AS 9100 and Nadcap accredited.

-

-

-

-

-

Ready Technology, Inc.

Cams

Manufacturer Overview

READY Technology is the North American operation of a worldwide network of factories and branch offices and is based in Dayton, Ohio. The company manufactures and distributes components to the global metal stamping, plastic mold, and automation industries. The company is ISO 9001 certified and operates through the READY brand as well as Acrotech, Amcor, Associated Raymond Spring, and other brand names. The company’s product categories include Ready Benders, Ready SuperSprings, Nitrogen Gas Springs, Cam Units, and Guiding Elements. The company offers custom machining services for die sets, raw plates, and everything up to finished products.

-

-

-

-

-

PSM Industries, Inc.

Cams

Manufacturer Overview

PSM Industries is a family business founded in 1956 and is based in Los Angeles, California. PSM provides solutions in parts fabrication through powder metal technology. Through this, PSM serves industries including medical, sporting goods, food service, and aerospace. PSM Industries consists of 4 categories of divisions throughout the United States. High-Performance PM includes Pacific Sintered Metals, PM Engineered Solutions, and BestMetal. High Wear Carbides Includes PM Krupp High-Speed Steels and Yilik Precision Carbides. The other two categories are metal injection molding featuring PolyAlloys and engineered plastics featuring W.M. Guliksen.

-

-

-

-

-

Mallory Industries, Inc.

Cams

Manufacturer Overview

Mallory Industries, founded in 1956 and based in Farmington, CT, U.S., is a manufacturer of precision components and assemblies for the aerospace, energy, and commercial markets. The company provides machining of aluminum, titanium, high-temperature alloys, and stainless steel with an emphasis on 2D & 3D cams for aerospace and commercial applications. They offer adapters, housings, sleeves, and rings along with valves, flanges, pistons, shafts, and actuators. They deliver services including multi-axis turning, CNC vertical milling, CNC turning, wire electrical discharge machining, and gearing that find uses in the military, automobile, aerospace, and oil & gas industries.

-

-

-

-

-

KLH Industries, Inc.

Cams

Manufacturer Overview

KLH Industries, Inc. is a manufacturing company of precision machining that is headquartered in Germantown, Wisconsin and was founded in 1987. The company manufactures custom parts per print that includes EDM, CNC, waterjet, and CMM inspection. Moreover, the company also offers small hole EDM drilling services, dimensional CMM inspection, sinker EDM services, and CNC surface grinding services. The industries served by the company includes machining in aerospace, automotive, contract, defense, and electronics.

-

-

-

-

-

Jerpbak-Bayless Company

Cams

Manufacturer Overview

Jerpbak-Bayless Company (JBC) is an American contract manufacturer specializing in precision machining services that was established in Solon, Ohio in 1945. The company produces various OEM components for heavy industry via its inhouse capabilities, which include CNC milling and turning, specialty machining, and custom threading. These allow them to work with materials that are typically difficult to handle in precision fabrication processes, such as inconel and titanium. JBC commonly produces items like flanges, gears, and shafts for use in steel mills, bridge construction projects, and oil and gas exploration.

-

-

-

-

-

J.W. Winco, Inc.

Cams

Manufacturer Overview

J.W. Winco was originally founded as Ganter in 1894 in Germany. Winco specializes in parts manufacturing. Parts offerings the operating parts segment including handles, adjusting, and positioning parts; clamping parts segment featuring tensioning, clamping, switching, and levers; and finally the machine parts segment with indexing, locking, mounting, connecting elements, guides, spindles, rollers, magnets, casters, and wheels. Winco’s complete catalog contains over 75,000 standard parts. Winco is also ISO 9001 certified. Winco offers free CAD downloads and technical documentation for many arts.

-

-

-

-

-

B&B Precision Wire EDM, Inc.

Cams

Manufacturer Overview

B&B Precision Wire EDM, Inc., founded in 1994, and located in Forest Hill, Maryland, is an ITAR registered custom manufacturer of wire electrical discharge machining (EDM). Its product line includes wire EDM, ram EDM, and small hole EDM. CNC milling, laser cutting, and waterjet cutting are also offered, in which it caters to industries such as medical, aerospace, energy, defense, and industrial. Its products are used for precise and intricate metal cutting, shaping, and drilling processes.

-

-

-

-

-

Allied Sinterings, Inc.

Cams

Manufacturer Overview

Allied Sinterings, Inc. (ASI) is an American contract manufacturer of miniature powdered metal products that was established in Danbury, Connecticut in 1959. The company offers various fabrication capabilities for miniature metal parts or components, including design engineering, prototyping, heat treating, tooling, and plating services. It also offers quality assurance and secondary operations (e.g. assembly, packaging) for customers requiring additional assistance. ASI primarily produces switches and implantable devices, as well as small gears for planetary drives. These are used by its clients in the aftermarket automotive, aerospace, consumer goods, and medical device manufacturing industries.

-

-

-

-

-

ALLCAMS Machine Co.

Cams

Manufacturer Overview

ALLCAMS Machine Co., established in Folsom, PA in 1960 is a manufacturer of CAMs for automated industrial machinery and CNC machines for general machining. Their product portfolio includes Barrell CAMs, Face CAMs, Geneva CAMs, Index CAMs, and Linear CAMs. The company's products are used in industries such as Packaging, Pharmaceutical, Canning , and Ammunition. They also provide national customer services including product selection, installation, custom design for industry needs, preventative maintenance, troubleshooting, and repair.

-

-

-

-

-

Roller Bearing Company Inc.

Cam Followers

Manufacturer Overview

Roller Bearings Incorporated was founded in 1919 and is headquartered in Oxford, Connecticut. RBC manufactures and markets precision bearings and related components globally, mainly to the aerospace, agricultural, automotive, industrial, and semiconductor manufacturing sectors. The company’s products are primarily divided into two market segments: aerospace and industrial. Both segments include basic components such as airframe control ball bearings, needle track rollers, ball bearing rod ends, and thin-section ball bearings. The Aerospace Segment also includes special machine components while the Industrial Segment also includes heavy-duty needles roller bearings and self-lubricating bearings subsegments.

-

-

-

-

-

Isky Racing Cams

CAM AND COMPLETE KIT

Company Overview

Isky Racing Cams, established in 1939 and based in Gardena, California, USA, is a manufacturer and supplier of great-performance camshafts and related components. The company's product lineup includes 4130 chrome moly light weight steel valve spring retainer, adjustable checking push rod, aluminum bronze distributor gear, aluminum valve spring retainer, and anti-walk cam tool kit. These products are essential for automotive enthusiasts, racers, and mechanics, ensuring optimal performance and durability in racing conditions. Serving industries such as motorsports, automotive manufacturing, and aftermarket modifications, the company continues to be active in the field of great-performance engine components.

-

-

-

-

-

Vi-Cas Mfg. Co., Inc.

Cams

Company Overview

Vi-Cas Manufacturing Company is headquartered in Cincinnati, Ohio. The company is a manufacturer and distributor of rollers and parts made for product movement for industries such as manufacturing, material handling, packaging & conveying, and printing. The company can custom produce vacuum cups, adapters, and rollers to customer specifications for size, shape, function, and material, in both small and high volumes. The company’s product lineup includes vacuum cups, capper tightening discs, rollers, depanneur cups, and other rubberized materials.

-

-

-

-

-

OneMonroe (Monroe Engineering Products)

Cams

Company Overview

OneMonroe was founded in the 1920s and is located in Rochester Hills, Michigan. OneMonroe is an ISO 9001:2015 and AS9100D certified global industrial manufacturing company serving several types of customers including manufacturers, distributors and catalog-houses across several vertical markets including aerospace/defense, automotive, medical, and transportation. Product lines include adjustable handles, bearings, casters, gaskets, hydraulic clamping, military spec hinges, molded rubber, piano hinges, pins, pull handles, quick release pins, seals, springs, toggle clamps, and various harnesses. Custom manufacturing is also available to meet specific customer needs.

-

-

-

-

-

Morton Machine Works

Cams

Company Overview

Morton Machine Works was founded in 1939 and is headquartered in Millersburg, Pennsylvania. The company is a manufacturer of tooling components supplying to industrial distributors, catalog houses, and OEMs throughout the world. The company offers custom manufacturing capabilities in an ISO 9001-certified facility for customers in industries such as metalworking, OEM, automotive, aerospace, and medical industries. The company’s product categories include various fasteners, plungers, leveling pads, locating components, and work holding components.

-

-

-

-

-

Cook-Leitch Inc.

Cams

Company Overview

Cook-Leitch Inc. was incorporated in 1964 and serves as a distributor for engineered components and metal finishing solutions. Cook-Leitch serves a number of industries including home & commercial appliances, aerospace & defense, automotive, agriculture, fluid power & hydraulics, distribution, and heavy truck & construction equipment. Some of Cook-Leitch’s product categories include powdered metal featuring Eastern Sintered Alloys, screw machine/complex shafts featuring Precision Capital LTD, springs/wire forms/stampings featuring Wire products company, split seam tubes featuring Baker Stamping, fasteners featuring Vasco Inc, and metal finishing featuring Decal Metal Finishing, Hale Performance Coatings, and Whitaker Finishing.

-

-

-

-

-

Budgit Hoist

Cams

Company Overview

BudgitHoist.com is headquartered in Forest Lawn, Illinois and is owned and operated by Sievert Electric Service and Sales Company. Sievert Electric is a distributor for Budgit Hoist who is the producer. BudgitHoist produces 1/4 to 3t electric chain hoists, air chain hoists, trolleys, repair parts, and other accessories. BudgitHoist offers additional services such overhead crane design sales, service, and repair, as well as electrical repairs and new construction. Additionally, BudgitHoist offers communication installations, repairs, and maintenance, as well as scoreboard installation repair and construction.

-

-

-

-

-

-

-

-

-

Supply Solutions, Inc.

Cams

Distributor Overview

Supply Solutions was founded in the early 2000s and operates out of Stonewood, West Virginia. Supply Solutions is a wholesale distributor serving the telecommunications industry, including traditional CATV operators, independent telephone companies and FTTX providers, as well as the contractors that support these operations. Supply Solutions offers hardware including aerial hardware including sub-components and parts,, cables, conduits, fiber optics, power supplies, sealants, test equipment, drop & instillation products, FTTX equipment including optical enclosures, headend products, underground equipment, wireless equipment, poles, as well as test equipment.

-

-

-

-

-

Orr & Orr, Inc.

Cams

Distributor Overview

Orr & Orr, Inc. has been offering wholesale distribution services since 1934 out of Bedford Park, IL. Orr & Orr emphasizes speed of order processing, shipping, and both customer and distributor satisfaction. Product categories that Orr & Orr offers include air conditioners, brake controls, cargo restraint equipment, door tracks, lighting equipment, fans, gas springs, heating equipment, hinges, plumbing supplies, seat belts, steps, toolboxes, hitch and towing products, various truck hardware, cables, battery products, safety equipment, and spring latches.

-

-

-

-

-

Northeast Lock Co.

Cams

Distributor Overview

Northeast Lock Co., founded in 1968 and headquartered in Clifton, New Jersey, is a distributor of custom and specialized lock products. The company provides a wide range of locks, including padlocks, deadbolts, mortise locks, electronic locks, and keysets, in any quantity. Their specialty lies in the elevator, OEM, vending, marine, casino, Kiosk, and aerospace industries, where access control and security are of utmost importance. They also offer custom stamping keys or locks, which involves imprinting the desired information directly onto the metal surface for easier tracking and identification of the parts.

-

-

-

-

-

METRO INDUSTRIAL SUPPLY, INC

Cams

Distributor Overview

Metro Industrial Supply, Inc. is headquartered in Garfield, New Jersey. The company is a distributor of power transmission equipment factory & mill supply original European replacements parts, portable gas detection systems, proximity & photoelectric sensors. A few of the brands for which the company is a United States distributor include Balluff, Bosch, Garlock, Goodyear, Siemans, and ZKL. Many brands and products not listed online can be ordered by contacting the company directly by email or by phone call.

-

-

-

-

-

Atlas Bronze

Cams

Distributor Overview

Atlas Bronze was established in 1994 in Trenton, New Jersey. The company is a US brass bronze supplier that is operated by Maranatha Now, Inc. Its products are bronze, copper, iron, self-lubricated bushings, and wear plates. They are available in custom and standard sizes, including solid diameters, cored bars, plates, and rectangle blocks. Atlas Bronze’s products are applied in multiple areas, such as the aerospace, architectural, manufacturing, energy, and defense industries. Commonly, they’re found as gear bearings, joints, marine equipment, pipes, and railroad parts.

-

-

-

-

-

Riken Corporation

Camshafts

Manufacturer Overview

Riken Corporation, established in 1927 and headquartered in Tokyo, Japan, is a manufacturer known for producing engine and vehicular components. Its product range includes piston rings, brake parts, camshafts, steering knuckles, valve lifters, and valve seats. Piston rings help seal combustion chambers, manage engine oil consumption, and facilitate heat transfer. Brake parts are integral to vehicle braking systems, while camshafts control fuel intake and exhaust. Steering knuckles are vital for steering and suspension. Valve lifters and seats are key components of engine valve trains. The company has been honored with internal research awards, and its supercomputer, Fugaku.

-

-

-

-

-

Crown Connections Australia

Cams

Manufacturer Overview

Crown Connections Australia, established in 2016 and based in Dandenong South, Australia, is a supplier of rail, mining, electrical, data and fixed fire fighting equipment. The company supplies commercial grade switchboards, meter panels, fixed fire fighting equipment , UPS, data and other enclosures to Australian manufacturers and resellers. It sources products for various applications including water treatment facilities, sheet metal processing, architecture and maintenance companies. The company complies with AS/NZS64139 quality standard and offers resources such as data sheets and catalogs with IP(ingress protection) rating system to provide detailed product information to the customers.

-

-

-

-

-

CDC ELETTROMECCANICA

Cam Timers

Manufacturer Overview

CDC ELETTROMECCANICA is a manufacturer of electromagnetic clutches and brakes. Established in 1960, the company is based in Brignano Gera d’Adda (BG), Italy. The company specializes in designing and producing products such as electromagnetic clutches and brakes for various applications. Its product range includes cam programmers, engines, gearboxes, gear motors and, electronic and electromechanical timers, serving industries such as professional dishwashers, glass washers, ice machines, ovens, refrigeration counters and, incubators for eggs. CDC ELETTROMECCANICA offers services like technical support and customized solutions.

-

-

-

-

-

ITALPLANT S.r.l.

CYLINDRICAL CAM INDEXERS

Manufacturer Overview

ITALPLANT S.r.l. an engineering company, founded in 1981 and based in Torino, Italy, is the designer and manufacturer of handling and automation systems. It offers a wide range of products, including conveyors, elevators, and custom automation solutions. The company caters to various sectors, including automotive, pharmaceutical and medical, packing, food and more. The company aims to ensure premium solutions and the highest performance in the world to sectors that rely on them, working to increase every day the performance provided by its indexers and conveyors.

-

-

-

-

-

ZZ-DriveTech GmbH

Globoidal, Cylindrical and Radial Cams

Manufacturer Overview

ZZ -DriveTech GmbH was founded in 1912, based in Baden-Wuerttemberg, Germany, and is a manufacturer of high-performing mechanical gears for mechanical engineering. It has a wide range of products including Bevel Gearbox ZZ-Universal-Line for accuracy, Servogearbox ZZ-Servoline for high gear ratios, Indexing Gearboxes for precise movements, Indexing Tables with customizable features, and Spiral Bevel Gears for efficiency. The company's products are used worldwide in mechanical and plant engineering, with a priority on uniform drives and irregular drives. The company aims for customer satisfaction, constant improvement, and secure partnerships.

-

-

-

-

-

norelem Normelemente GmbH & Co. KG

Cams

Manufacturer Overview

Normelemente KG, established in 1958 and based in Markgroningen, Baden-Wuerttemberg, is a German manufacturer and supplier that specializes in standard parts and machine components. Norelem offers an extensive catalog of more than 70,000 products, catering to the needs of engineers and designers in various projects. Their product range includes clamping technology, measuring and testing components, electromechanics, systems and components for machine and plant construction, and material handling and transport solutions. These products find applications in diverse engineering fields, such as automotive, aerospace, machinery, and robotics sectors.

-

-

-

-

-

Colombo Filippetti S.p.A.

Cams

Manufacturer Overview

Colombo Filippetti Spa founded in 1953, is an international company that serves as a designer and manufacturer of computer-aided mechanisms. The company offers a wide range of products, including oscillating drives, tandem mechanisms, tool changers, fret saw machines, and CAM driven pallet changers, serving diverse range of industries, including manufacturing, robotics, woodworking, and metalworking. These products enhance automation, precision, and efficiency in various processes and machinery. The company offers customer service, prompt support and technical expertise.

-

-

-

-

-

Atlas Pressed Metals

Cams

Manufacturer Overview

Atlas Pressed Metals, established in 1976 and headquartered in DuBois, Pennsylvania, is a manufacturer of precision powdered metal parts. They specialize in producing complex and simple structural components using materials like iron, sinter-hardened steel, stainless steel, copper, brass, and bronze. Serving diverse industries such as automotive, industrial, medical, energy, and more, their product range includes bushings, bearings, gears, structural components, wear plates, and other custom parts. These components find applications in load-bearing, wear resistance, and corrosion resistance scenarios. relaible

-

-

-

-

-

Titus Group

Cam5000

Manufacturer Overview

Titus Group, founded in 1973 and based in Dekani, Slovenia, is the developer, manufacturer, and seller of cabinet hardware solutions. It offers a wide range of products including cabinet hardware, hydraulic dampers, automated assembly systems, tooling, custom die-cast components, as well as die-casting, ultrasound fastening, and others. The company’s modern product design, engineering expertise, and effective service help business partners improve productivity, quality, and reduce costs. Providing global solutions and embracing the versatility of Its teams worldwide, the company became a global brand.

-

-

-

-

-

W.M. Berg

Cams

Manufacturer Overview

W M Berg, founded in 1967 and based in Cudahy, Wisconsin, is a manufacturer and supplier of precision industrial parts. The company delivers ISO 9001:2015 certified products and services, including assemblies, bearings, belts & chains, couplings & shafts, gears, fasteners & hardware, pulleys & sprockets and more. W M Berg provides designing, developing, manufacturing and testing facilities to its clients in the aerospace, medical and motion control industries. Its distributors include Applied Industrial Technology and Motion Industries.

-

-

-

-

-

Tank Truck Service & Sales, Inc.

Cams

Company Overview

Tank Truck Service & Sales, Inc. has been designing and building tank trucks since 1948 and is based in Warren, Michigan. The company is a manufacturer, assembler, and distributor of tank trucks and trailers. The company's product offerings include parts and components including tank truck equipment, bulk plant and storage tank equipment, dry break or dry disconnect fittings, valves, hose, hose reels, meters, swivel joints, gaskets, and pipe sealants. Tank truck offerings include refined fuel trucks and trailers, LGP trucks, and specialty tank trucks. Additionally, The company offers metalwork, equipment work, dot testing, paintwork, and sensor repairs.

-

-

-

-

-

Strybuc Industries

Cams

Company Overview

Strybuc Industries was founded in 1982 and is a wholesale distributor of window and door replacement hardware.They are an American, family-run company with three main locations in Philadelphia, Miami, and Reno. Their product line includes sash locks, window repair parts, door rollers, handles, and other items that can be customized to meet the demands of the customer. Their inventory encompasses over 80,000 hardware parts, and they serve enterprises all around the world.

-

-

-

-

-

Proponent

Cams

Company Overview

Proponent grew out of the partnership between Kapco Global, founded in 1972, and Avio-Diepen, founded in 1946. The company is an aerospace distributor with a product portfolio of over 500,000 aircraft parts available for delivery to customers based around the world. The company’s product lineup has four categories: interior, engine, airframe, and cockpit. The company’s services and solutions include resources for manufacturers, suppliers, and end users. The company also offers water jet machining, turnkey design, fabrication, finishing, and assembly customizations according to customer preferences.

-

-

-

-

-

-

-

Essentra plc

Cams

Company Overview

Essentra Components is a producer of plastic injection moulded, vinyl dip moulded, and metal components, operating in 29 countries across 4 continents. Essentra Component has a catalog of over 45,000 products. These range from caps, plugs, wire & cable management, flange protection, knobs, handles & grips, access hardware, PCB, and electronics hardware. Essentra Component offers free samples of CADs of standard parts for assist customers in creating custom-manufacture red solutions, including prototyping and 3D printing.

-

-

-

-

-

-

-

Allegis Corporation

Cams

Distributor Overview

Allegis Corporation is headquartered in Minneapolis, Minnesota. The company is a supply chain management consultant and distributor of heavy-duty machinery and parts for markets including internal enclosures, HVAC, agriculture, and transportation to customers across the United States. The company’s products include moving parts such as latches, handles, and casters, as well as mirrors, lights, and other non-moving parts. The company’s services include custom engineering and supply chain services. Custom engineering solutions assist customers in designing necessary hardware, while supply chain services streamline product acquisition, reducing costs and risk while improving efficiency.

-

-

Cam Manufacturer Ranking

*Including some distributors, etc.Ranking as of July 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Isky Racing Cams |

11.3%

|

| 2 | HOWARDS CAMS & RACING COMPONENTS |

11.0%

|

| 3 | TIMKEN |

5.7%

|

| 4 | DESTACO, A Dover Company |

5.3%

|

| 5 | Mallory Industries, Inc. |

3.1%

|

| 6 | Riken Corporation |

2.8%

|

| 7 | KELFORD CAMS |

2.5%

|

| 8 | Wire Tech EDM, Inc. |

2.5%

|

| 9 | KLH Industries, Inc. |

2.5%

|

| 10 | ZZ-DriveTech GmbH |

2.5%

|

Derivation Method

The ranking is calculated based on the click share within the cam page as of July 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

- Riken Corporation: 4,153

- EMKA Beschlagteile GmbH & Co. KG: 2,100

- Titus Group: 900

Newly Established Company

- Crown Connections Australia: 2016 (8 years ago)

- KLH Industries, Inc.: 1987 (37 years ago)

- METRO INDUSTRIAL SUPPLY, INC: 1983 (41 years ago)

Company with a History

- DESTACO, A Dover Company: 1915 (109 years ago)

- Roller Bearing Company Inc.: 1919 (105 years ago)

- EMKA Beschlagteile GmbH & Co. KG: 1932 (92 years ago)

Cam Manufacturers in United States

*Including some distributors, etc.

- DESTACO, A Dover Company

- Wire Tech EDM, Inc.

- Wire Cut Co., Inc.

- TIMKEN

- Stock Drive Products/Sterling Instrument - SDP/SI

- Sterling Sintered Technologies, Inc.

- STD Precision Gear & Instrument, Inc.

- Ready Technology, Inc.

- PSM Industries, Inc.

- Mallory Industries, Inc.

- KLH Industries, Inc.

- Jerpbak-Bayless Company

- J.W. Winco, Inc.

- B&B Precision Wire EDM, Inc.

- Allied Sinterings, Inc.

- ALLCAMS Machine Co.

- Roller Bearing Company Inc.

- Isky Racing Cams

- Vi-Cas Mfg. Co., Inc.

- OneMonroe (Monroe Engineering Products)

- Morton Machine Works

- Cook-Leitch Inc.

- Budgit Hoist

- Delta Camshaft

- HOWARDS CAMS & RACING COMPONENTS

- Supply Solutions, Inc.

- Orr & Orr, Inc.

- Northeast Lock Co.

- METRO INDUSTRIAL SUPPLY, INC

- Atlas Bronze

Global Distribution of Cam Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

30 | 75.0% |

Italy

Italy

|

3 | 7.5% |

Germany

Germany

|

3 | 7.5% |

Japan

Japan

|

1 | 2.5% |

Australia

Australia

|

1 | 2.5% |

New Zealand

New Zealand

|

1 | 2.5% |

United Kingdom

United Kingdom

|

1 | 2.5% |