All Categories

History

This section provides an overview for eccentricity measuring instrument as well as their applications and principles. Also, please take a look at the list of 17 eccentricity measuring instrument manufacturers and their company rankings. Here are the top-ranked eccentricity measuring instrument companies as of February, 2026: 1.SIKORA International Corp., 2.Novatechrus Ltd., 3.Proton Products.

Table of Contents

Categories Related to Eccentricity Measuring Instrument

An eccentricity measuring instrument is used to measure the eccentricity, bending, or runout of a shaft or other object.

Eccentricity is defined as the misalignment of the center of a workpiece compared to the center point where it should be. In addition to workpiece eccentricity, runout, bending, concentricity, and coaxiality can also be measured.

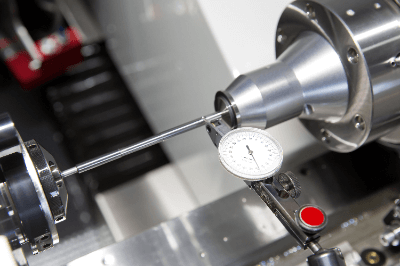

Eccentricity is usually measured using a dial gauge. Center holes machined on both sides of the workpiece are clamped at both centers of the measuring instrument. The dial gage is set at the point to be measured and the workpiece is rotated for measurement.

In addition to the dial gauge method, there are other measurement methods such as reflective and transmissive methods using lasers and optics.

Eccentricity measuring instruments are used to measure the eccentricity of rotating cutting tools, various arbors, crankshafts, gears, piston heads, etc. Eccentricity measuring instruments are also used to measure the eccentricity of lenses.

Parallelism between the top of the eccentricity measuring instrument table and both centers is assured. The structure is rigid to prevent errors caused by the weight of the workpiece or deviations over time.

The purpose of using eccentricity measuring instruments is usually to check accuracy after machining, such as cutting or grinding. In the case of bending measurement, it is used to check distortion after heat treatment.

By placing the dial gauge on the end face of a workpiece with a multi-stage shaft shape, it is also possible to measure the squareness of the end face with respect to both centers.

Measurement of Center Standards

The centers of eccentricity measuring instruments are usually made of hardened steel. When used on hard workpieces or for frequent measurements, a carbide center with a carbide brazed tip may be used.

For workpieces with an inside diameter machined instead of a center hole at the edge of the workpiece, an umbrella type center is used. A center with the same bevel angle as the chamfer angle of the bore machining part is required.

A dial gauge is applied to the outer surface of the workpiece and the change in position of the workpiece outer surface is read while the workpiece is rotated slightly. This is the center-based eccentricity measurement.

Measurement of Outer Diameter Standard

Instead of clamping by both centers of eccentricity measuring instruments, the outer diameter of a workpiece is placed on two sets of rollers and supported by two sets of rollers at both ends of the workpiece, for a total of four rollers. Eccentricity can be measured by rotating the workpiece. The measurement value is based on the outside diameter.

There is also an eccentricity measuring instrument that can measure eccentricity by placing one side of the workpiece on a set of two rollers and attaching a roller for clamping to the top of the roller, thereby enabling single-handed measurement. For cylindrical shapes with inside diameter processing, where the coaxiality of the inside diameter with respect to the outside diameter is to be measured, a dial gage can be placed on the inside diameter and rotated to make the measurement.

In either case, the span of the two rollers must be adjusted according to the size of the workpiece diameter.

Laser Eccentricity Measuring Instrument

Runout of the outer diameter during rotation can be measured. Using a reflective laser displacement meter, a laser is shone on the outer surface of the rotating object and the reflected wave is detected to measure the distance variation. A sampling rate of at least 10 times the rotational speed is required.

Transmission-type laser dimensional measuring instruments can also be used for measurement. The laser is applied to the circumferential direction of the outer surface of the rotating body, and the p-p value of the runout is measured by the receiver. A sampling speed of at least 10 times the rotational speed is required.

In addition, using a transmission-type 2-D laser dimensional measuring instrument, positional variations at multiple points can be measured. Runout of V-grooves and protrusions cut on the circumference can be measured.

Optical Eccentricity Measuring Instrument

This method measures the eccentricity of convex and concave lenses. There are two types: reflective and transmissive. The reflective eccentricity measuring instrument measures the eccentricity between the outer diameter of the lens under test and the spherical center of the lens using the reflective method.

The transmission eccentricity measuring instrument measures the transmission eccentricity of a lens. Transmission eccentricity is the amount by which transmitted light deviates from the optical axis. The optical axis is the line connecting the spherical centers of both sides of the lens.

First, on the table of the eccentricity measuring instrument, set the left and right centers at the desired positions according to the length of the workpiece and lock each of them. One of the left and right centers is designed to move in and out by operating a lever.

By operating this lever, the workpiece is set with the center retracted, and the workpiece is clamped by returning the lever. The force of the spring enables the workpiece to be supported with constant holding force.

The dial gauge is placed on the outer surface of the workpiece, and the workpiece is rotated. The change in the pointer obtained at that time is the eccentricity.

*Including some distributors, etc.

Sort by Features

Sort by Area

Magnetic Analysis Corp., founded in 1928 and located in Elmsford, New York, is an American manufacturer providing instruments, solutions, and systems for nondestructive testing (NDT). The company offers eddy current testing (ECT) and multichannel ultrasonic testing (UT) instruments, designed for bars, tubes, and pipes, as well as eddy current and ultrasonic rotaries for testing round bars and tubular products. It also provides ultrasonic velocity measurement equipment, used for testing automotive parts, along with rail wheel testers. The company further offers flux leakage testing instruments for defect detection in hot rolled black steel bars and flaw identification in heavy wall magnetic tubing.

Zumbach Electronics Corp., founded in 1957, is a manufacturer of on-the-line measuring, monitoring and control systems. The company in Hauptstrasse, Orpund Schweiz, offers maintenance, repair and calibration, training, support & consultation, and spare part delivery. They have 11 international subsidiaries and representatives in 40+ countries. Their products include a Laser surface velocimeter, KW fault detector, MSD led device, Steelmaster, and calibrator. These are used in wire & cable, rubber, steel cold or hot, optical fibre, non-ferrous and plastic industries.

Marposs S.p.A. is headquartered in Bentivoglio, Italy. The company serves industries such asa aerospace, semiconductors, machine tooling, and biomedical as a manufacturer and as a service provider. The company’s products vary by industry but include tools for gauging, profiling, and monitoring, as well as data management systems and machines for testing and automation. The company’s services include after sales service, customer training, original spare parts, retrofit and upgrade of existing machinery, and project management consulting services.

Teclock, founded in 1950 and based in Okaya, Nagano, Japan, is a distinguished manufacturer of precision measuring instruments. Its instruments has a high dimensional accuracy with a smallest scale of 0.0005mm. Its product lineup includes dial indicators, lever testers, thickness gauges, depth gauges, and calipers. The company also offers height gauges, stands, handy durometers, and micrometers. The company also provides a Cloud-based IoT measurement solution, enabling the seamless digitization and analysis of measurement data.

SEIKOH GIKEN Co., Ltd., a company founded on June 7, 1972, and headquartered in Chiba, Japan, is a manufacturer and supplier of optical components and equipment. The company specializes in the development and production of fiber optic connectors, fusion splicers, and related products for the telecommunications and data communication industries. Their products are used for fiber optic connections in various applications, including telecommunication networks, data centers, and optical sensing systems. The company also offers customer services including prompt and responsive communication to address inquiries and technical assistance.

SIKORA International Corp., established in 1973, is a manufacturer of measuring and control technology in Bremen, Germany. The company's products and services ensure quality and optimize production processes in various industries. The company's measuring control technology measures and controls parameters such as diameter, eccentricity, ovality, and thickness. Its inspection systems detect defects such as cracks, inclusions, and voids. Its analysis and sorting systems classify and sort products based on quality characteristics.

S.A.M.A. Italia S.r.l., established in 1994 and located in Viareggio, Italy, is a manufacturer of measuring and control instruments through its brand SAMA Tools. The company offers a wide range of products, including climate chambers, salt spray cabinets, calipers, micrometers, weighing systems, and more. It also offers instruments for environmental and workplace safety monitoring and control. Its products can help in monitoring and controlling environmental and safety conditions. The company has achieved ISO 9001 and ISO/IEC 17025 certification. It serves industries such as manufacturing, quality control, and more.

Tosei America Inc., founded in 2009 and located in Cincinnati, Ohio, is a manufacturer of automatic measuring equipment for production lines of precision automotive parts, bearings, and electronic products. The company provides a range of products, including gages, micrometers, digital measuring instruments, laser interferometers, and automatic measuring systems. Their products cater to diverse industries such as automotive, bearings, and the electronics industry. These products are used to ensure adherence to industry standards, detect defects or variations, and verify the reliability and precision of the produced components.

Proton Products, established in 2000 and headquartered in Buckinghamshire, England, is a manufacturer of instrumentation and process control products. The company offers a wide range of products such as speed and length measurement systems, spark testers, laser gauging systems, and more. It also offers tension measurement systems, extrusion control, wire preheating, lump and neck detection, and more. Its product helps manufacturers maintain consistent tension levels in their production processes, ensuring good quality output. The company has achieved ISO 9001:2015 certification for its quality management systems. It serves various industries, including wire and cable, web converting, and more.

MABUCHI S&T Inc. founded in 1950 and based in Tatsuno, Kamiina, Nagano, Japan, is a manufacturer and supplier of products in the optical, electronic, and life science fields. The company's product range includes spherical lens, aspherical lens, prisms, equipment, related materials, health products, and agitation products. These products find applications in optical instrumentation and health and wellness solutions. They primarily serve industries such as optics, electronics, and life sciences. Beyond its product manufacturing, the company offers consultation services, technical support, and product customization.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | SIKORA International Corp. |

11.6%

|

| 2 | Novatechrus Ltd. |

8.0%

|

| 3 | Proton Products |

7.6%

|

| 4 | Zumbach Electronics Corp. |

7.2%

|

| 5 | Teclock |

7.2%

|

| 6 | Sci-Mach Industrial |

6.8%

|

| 7 | Marposs |

6.8%

|

| 8 | Magnetic Analysis Corp. |

6.4%

|

| 9 | SEIKOH GIKEN Co., Ltd. |

6.4%

|

| 10 | Handan Nihao Welding Material Production Equipment Co.,Ltd. |

5.6%

|

Derivation Method

The ranking is calculated based on the click share within the eccentricity measuring instrument page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

Japan

Japan

|

5 | 38.5% |

Italy

Italy

|

2 | 15.4% |

United States of America

United States of America

|

1 | 7.7% |

Switzerland

Switzerland

|

1 | 7.7% |

Germany

Germany

|

1 | 7.7% |

India

India

|

1 | 7.7% |

China

China

|

1 | 7.7% |

Russia

Russia

|

1 | 7.7% |

51 products found

51 products

Osaka Precision Machinery Co., Ltd.

820+ people viewing

Last viewed: 1 day ago

Speedy and fully automatic measurement of tooth profile, tooth lead, pitch, eccentricity, etc. of sintered metal and resin gears used in electronic...

Osaka Precision Machinery Co., Ltd.

1000+ people viewing

Last viewed: 5 hours ago

Speedy and fully automatic measurement of tooth profile, tooth lead, pitch, and eccentricity of gears used in high-load power transmission devices ...

Osaka Precision Machinery Co., Ltd.

550+ people viewing

Last viewed: 1 day ago

Speedy and fully automatic measurement of tooth profile, tooth lead, pitch, and eccentricity of gears used in high-load power transmission devices ...

Osaka Precision Machinery Co., Ltd.

450+ people viewing

Last viewed: 1 day ago

The continuous shape of the tooth profile and tooth trace of hypoid gears and spiral bevel gears with module 1 or higher is measured in the same wa...

Osaka Precision Machinery Co., Ltd.

400+ people viewing

Last viewed: 1 day ago

The continuous shape of the tooth profile and tooth trace of hypoid gears and spiral bevel gears with module 1 or higher is measured in the same wa...

Opto Device Corporation Co., Ltd.

320+ people viewing

Last viewed: 5 hours ago

This device is a reflection eccentricity measurement device that uses a Laser Auto Collimator. This is a reflection eccentricity measurement to imp...

4 models listed

Osaka Precision Machinery Co., Ltd.

750+ people viewing

Last viewed: 1 day ago

This is the most widely used 2-tooth surface mesh tester for fine pitch or small gears, and is widely used in Japan and overseas to measure gears f...

Osaka Precision Machinery Co., Ltd.

530+ people viewing

Last viewed: 1 day ago

Measures total meshing error, meshing error of all pitches, etc. We have a wide range of accessories such as master gears, internal gears, bevel ge...

Osaka Precision Machinery Co., Ltd.

730+ people viewing

Last viewed: 7 hours ago

Measures total meshing error, meshing error of all pitches, etc. We have a wide range of accessories such as master gears, internal gears, bevel ge...

Osaka Precision Machinery Co., Ltd.

840+ people viewing

Last viewed: 44 minutes ago

Measures total meshing error, meshing error of all pitches, etc. We have a wide range of accessories such as master gears, internal gears, bevel ge...

Osaka Precision Machinery Co., Ltd.

600+ people viewing

Last viewed: 7 hours ago

Measures total meshing error, meshing error of all pitches, etc. We have a wide range of accessories such as master gears, internal gears, bevel ge...

Star Micro Co., Ltd.

400+ people viewing

Last viewed: 20 hours ago

■The definitive high-performance eccentricity measuring machine that can be used on-site. The device introduced here is a transmission type eccentr...

Riken Measuring Instruments Manufacturing Co., Ltd.

400+ people viewing

Last viewed: 5 hours ago

■Product overview ・Hold the workpiece to be measured at both centers, rotate it little by little, and read it with the dial gauge. - Can be used t...

3 models listed

Osaka Precision Machinery Co., Ltd.

530+ people viewing

Last viewed: 21 hours ago

2 By connecting to a tooth surface mesh tester GTR-4, GTR-30, GTR-40, etc., you can not only record conventional analog recording diagrams, but als...

Riken Measuring Instruments Manufacturing Co., Ltd.

330+ people viewing

Last viewed: 1 day ago

■Product overview ・Hold the workpiece to be measured at both centers, rotate it little by little, and read it with the dial gauge. - Can be used t...

3 models listed

Osaka Precision Machinery Co., Ltd.

460+ people viewing

Last viewed: 1 day ago

This is a 2-tooth surface mesh tester GTR-30 with an automatic selection counter connected. By replacing the test result with a digital quantity, a...

Riken Measuring Instruments Manufacturing Co., Ltd.

610+ people viewing

Last viewed: 7 hours ago

■Product overview ・The dial stand part of standard model No. 1 can be moved forward, backward, left and right. - It can be easily moved to the mea...

Osaka Precision Machinery Co., Ltd.

310+ people viewing

Last viewed: 1 hour ago

The AG-230 type is a versatile manual type gear sorting machine. The structure allows each sensor to be changed freely, making it possible to sort ...

Riken Measuring Instruments Manufacturing Co., Ltd.

280+ people viewing

Last viewed: 7 hours ago

■Product overview ・The workpiece does not have a center hole and can be used to inspect circularity, runout, bending, etc. ・The V groove has a ca...

3 models listed

Riken Measuring Instruments Manufacturing Co., Ltd.

640+ people viewing

Last viewed: 1 day ago

■Product overview - A small, highly accurate eccentricity tester that can be used both vertically and horizontally. ・By removing the center and us...

Zensei Co., Ltd.

390+ people viewing

Last viewed: 21 hours ago

This measuring tool is suitable for measuring concentricity and eccentricity of cylindrical parts that do not have a hole in the center. It is poss...

Riken Measuring Instruments Manufacturing Co., Ltd.

510+ people viewing

Last viewed: 5 hours ago

■Product overview - Can be used to measure small workpieces. ・By removing the center and using the V groove, you can measure workpieces without a ...

Zensei Co., Ltd.

380+ people viewing

Last viewed: 1 day ago

This measuring tool is suitable for measuring concentricity and eccentricity of cylindrical parts that do not have a hole in the center. It is poss...

Zensei Co., Ltd.

380+ people viewing

Last viewed: 1 day ago

This measuring tool is suitable for measuring concentricity and eccentricity of cylindrical parts that do not have a hole in the center. It is poss...

Zensei Co., Ltd.

290+ people viewing

Last viewed: 1 day ago

This measuring tool is suitable for measuring concentricity and eccentricity of cylindrical parts that do not have a hole in the center. It is poss...

Zensei Co., Ltd.

440+ people viewing

Last viewed: 12 hours ago

This measuring tool is suitable for measuring concentricity and eccentricity of cylindrical parts that do not have a hole in the center. It is poss...

Zensei Co., Ltd.

290+ people viewing

Last viewed: 1 day ago

This measuring tool is suitable for measuring concentricity and eccentricity of cylindrical parts that do not have a hole in the center. It is poss...

Zensei Co., Ltd.

360+ people viewing

Last viewed: 1 day ago

This measuring tool is suitable for measuring concentricity and eccentricity of cylindrical parts that do not have a hole in the center. It is poss...

Zensei Co., Ltd.

410+ people viewing

Last viewed: 14 hours ago

This measuring tool is suitable for measuring concentricity and eccentricity of cylindrical parts that do not have a hole in the center. It is poss...

Zensei Co., Ltd.

340+ people viewing

Last viewed: 1 day ago

If the outer diameter surface of a screw is uneven, you can use this probe to measure concentricity.