All Categories

History

This section provides an overview for ultrasonic flaw detectors as well as their applications and principles. Also, please take a look at the list of 47 ultrasonic flaw detector manufacturers and their company rankings. Here are the top-ranked ultrasonic flaw detector companies as of March, 2026: 1.Advanced Test Equipment Corporation (ATEC), 2.Hocker Inc., 3.S.A.M.A. Italia S.r.l..

Table of Contents

Categories Related to Ultrasonic Flaw Detectors

An ultrasonic flaw detector is a device that can measure internal flaws using ultrasonic waves.

It is used in various places as a nondestructive inspection device because it can check internal flaws without having to make an incision in the object. Ultrasonic waves are applied from the surface of the object to detect damage, and the sound waves reflected through the interior of the object are detected. It is possible to check not only the presence or absence of scratches, but also their location and size, and is used to inspect for defects in the manufacturing process of various products.

Ultrasonic flaw detectors can measure flaws that occur in various locations.

An example is the measurement of defects during welding. Welding is a method of joining parts by melting metal, and while it is an essential process for manufacturing industrial products, it is often performed by hand and is prone to human error and defects. To prevent serious accidents from occurring, quality inspections are conducted using ultrasonic flaw detectors.

It is also used to check the bonding condition: when two identical materials are bonded, ultrasonic waves penetrate the boundary surface and do not bounce back, but if there is delamination, they will be reflected in that area. By detecting this, the state of adhesion can be checked.

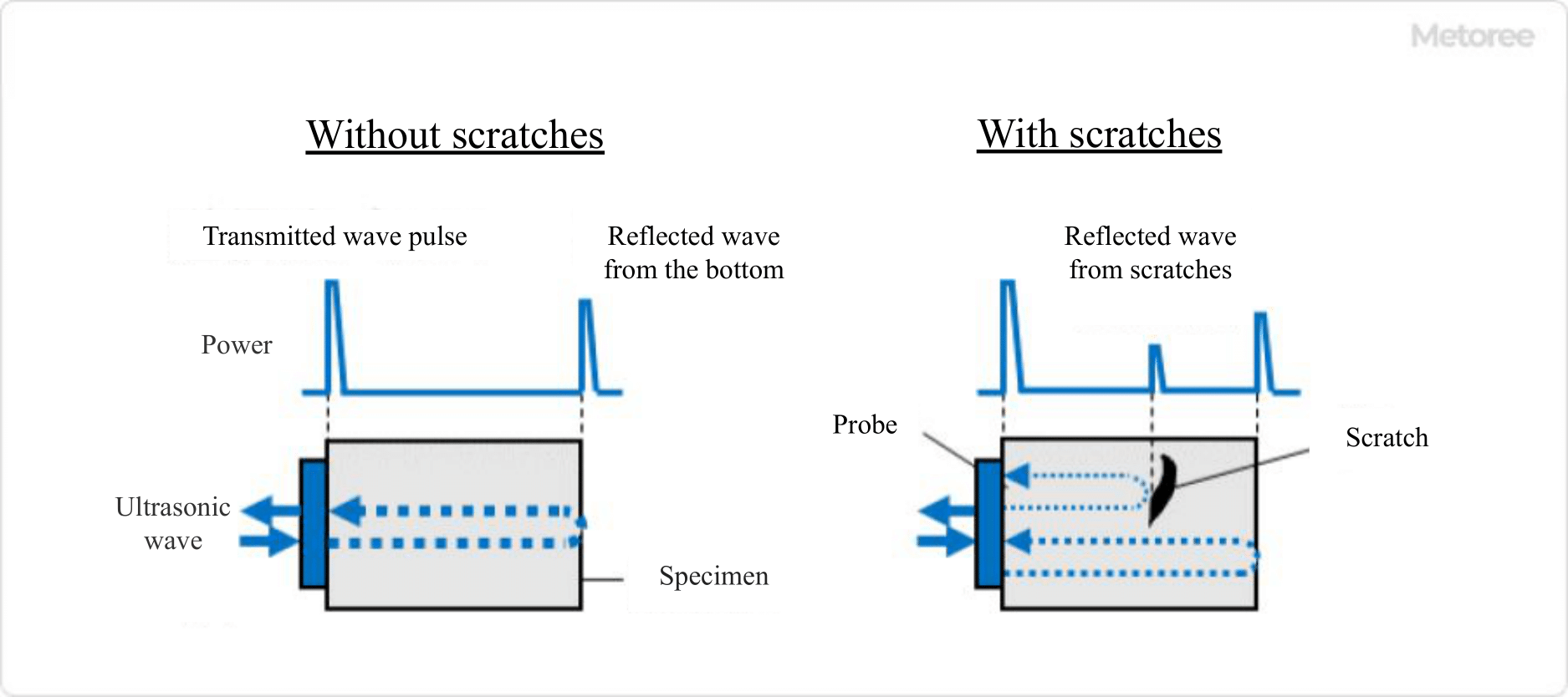

Figure 1. Principle of ultrasonic flaw detector

The ultrasonic flaw detectors use the reflection of ultrasonic waves to identify the presence, position, size, etc. of flaws, and the principle is called the pulse reflection method.

A probe capable of transmitting and receiving ultrasonic waves is placed on the surface to be inspected. The ultrasonic waves incident on the object from the probe are reflected by the bottom surface or internal flaws and then returned to the probe. By observing this reflected wave, the condition of the inside of the inspection object can be estimated.

If there is a flaw inside, the received waves are observed in the order of the transmitted wave pulse, the reflected wave from the flaw, and the reflected wave from the bottom surface. The position and size of the flaw are estimated from the time it takes for the waves to be observed and the strength of the waves.

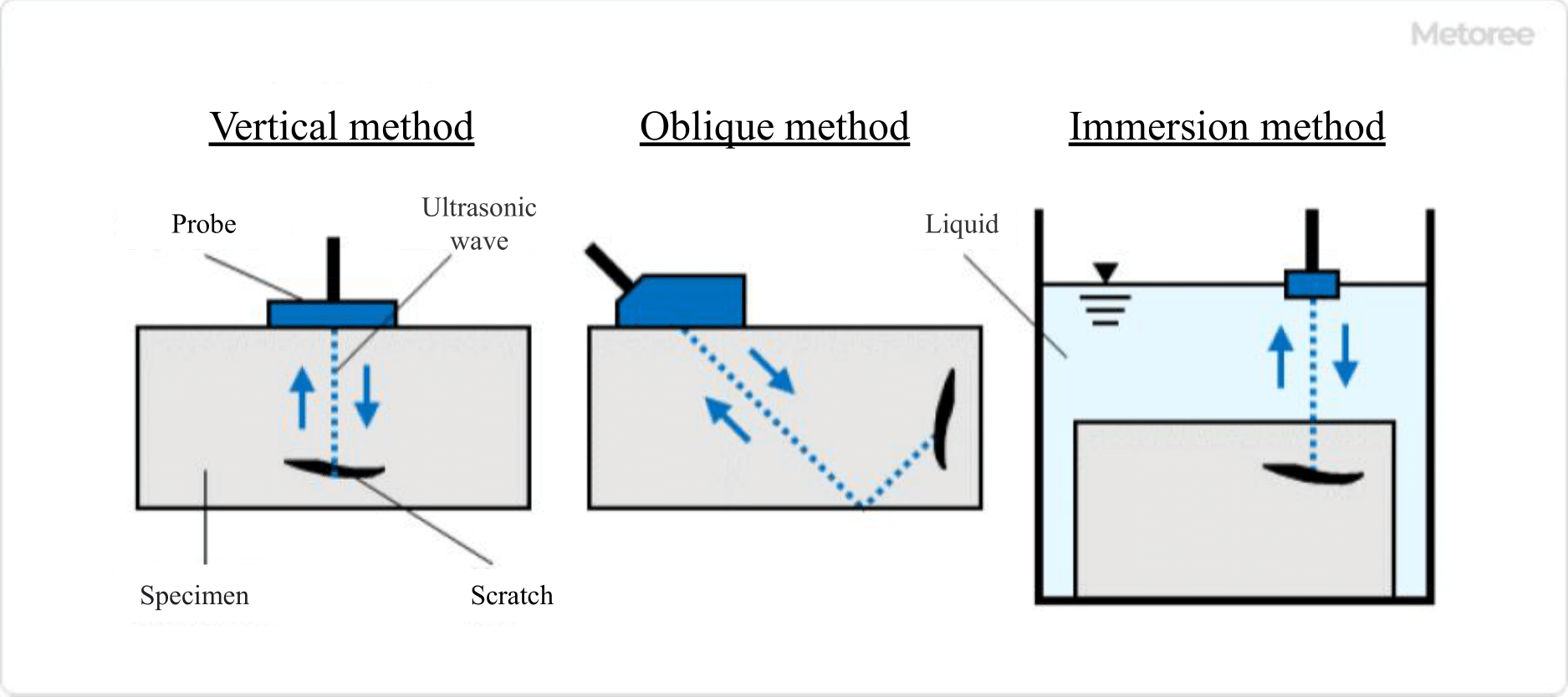

Figure 2. Classification of ultrasonic flaw detector

There are several types of ultrasonic flaw detectors.

Depending on the angle of incidence of the waves, they can be classified into two methods: the vertical method, in which the waves are incident perpendicular to the object to be inspected, and the oblique method, in which the transverse waves are incident obliquely to the object to be inspected. The oblique method is especially used for inspecting welds.

Depending on whether the probe is applied directly to the inspection object or not, the two methods can be classified into two types: the direct contact method, in which the probe is directly applied to the inspection object, and the water immersion method, in which the inspection object is submerged in a liquid and ultrasonic waves are injected through the liquid. The water immersion method can be further classified into the full immersion method and the partial immersion method.

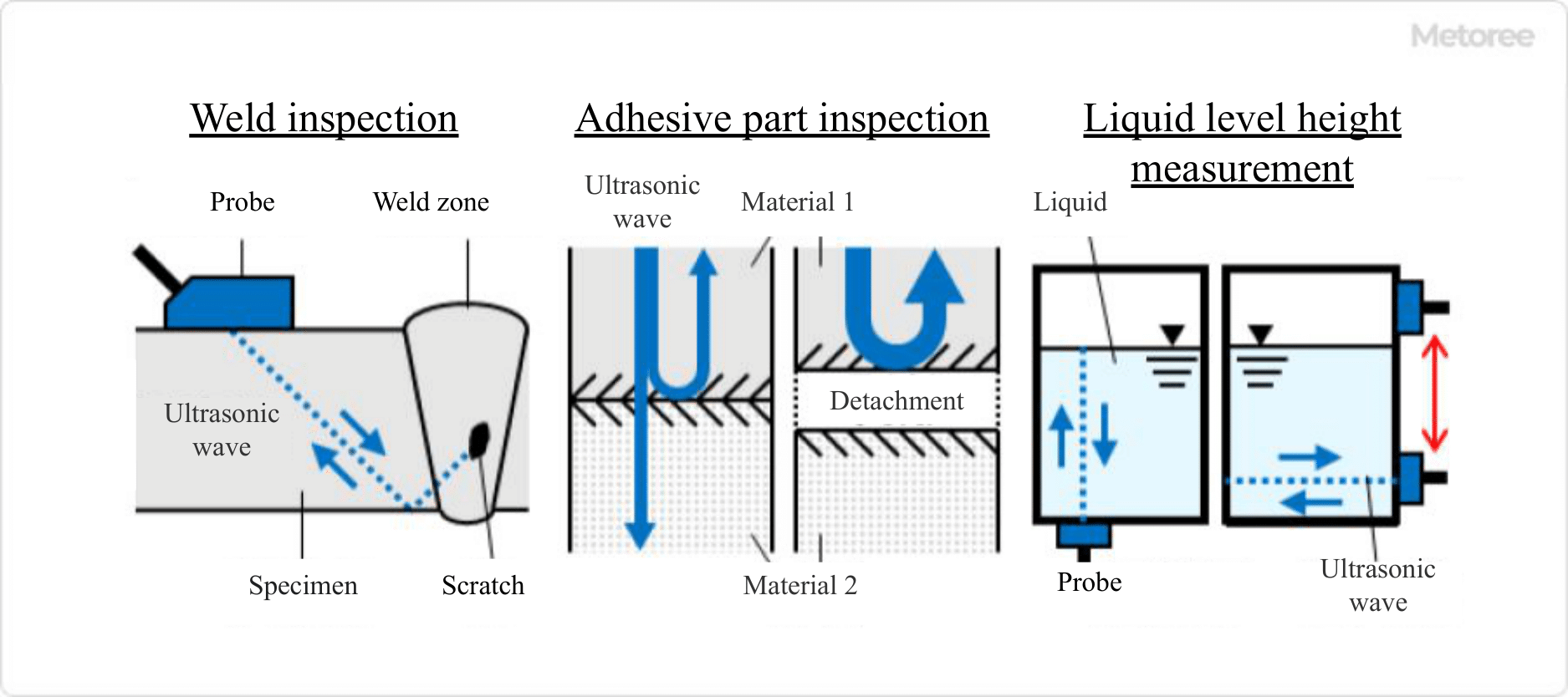

Figure 3. Example of inspection using an ultrasonic flaw detector

Ultrasonic flaw detectors can be used in various ways depending on its intended use. Typical uses are as follows

1. Inspection during welding

Ultrasonic flaw detectors are used to inspect defects such as shape defects and metal cracks that occur during welding. When applying ultrasonic waves, the ultrasonic waves are applied to the weld area from an angle to check for defects. To avoid missing any defects by applying ultrasonic waves at an angle, the ultrasonic waves are reflected once on the backside of the object and then applied to the object.

2. Inspection of bonded area

When two materials are bonded, ultrasonic waves are applied to them to check whether the bonding is sufficient. If the same materials are sufficiently bonded, ultrasonic waves will not be reflected, but if there is a gap due to peeling in the bonded area, ultrasonic waves will be reflected, allowing the accuracy of the bond to be checked.

In the case of different materials, reflection always occurs at the boundary surface, and if delamination occurs, the phase of reflection is shifted or reversed, which can be confirmed as a defect.

3. measurement of the liquid level height of liquid sealed in a container

For liquids that easily vaporize or hazardous chemicals, it is necessary to measure the presence or absence and quantity of the contents in a sealed container without opening it.

The ultrasonic testing device is used to apply ultrasonic waves from the bottom of the container. The ultrasonic waves travel through the liquid and are reflected at the liquid surface, so the volume can be measured from the height of the solution's water surface.

*Including some distributors, etc.

Sort by Features

Sort by Area

Dakota Ultrasonics is an American manufacturer of industrial ultrasonic testing equipment, based in Scotts Valley, California. The company's product line includes corrosion gauges for measuring the effects of corrosion on structures, precision gauges for measuring material thickness, racing gauges to measure parts of race cars, and specialty gauges for measuring the thickness of materials that are difficult to penetrate with sound, all of which can be controlled using software and wireless applications. The company also offers flaw detectors, bolt tension monitors, and related accessories Dakota Ultrasonics' products find usage across diverse sectors, including petrochemical, aerospace, power generation, and automotive.

Advanced Test Equipment Corporation is a service company established in 1981 and is involved in the rent, sale, calibration, and service of test and measurement instruments. The company which is based in San Diego, California, offers electronic, electrical, and environmental test equipment solutions. These are used for the analysis, inspection, measurement, monitoring, and commissioning of products and electrical infrastructure. ATEC also offers services for the 5G, communications, defense, electrical, and hydropower industries.

OKOndt was established in 1993 and is headquartered in Rockville, Maryland, USA, as a manufacturer of non-destructive testing (NDT) equipment. The product list of the company consists of Eddy Current Double Rail Flaw Detector, Portable Eddy Current Flaw Detector, and Right angle surface probe, among others. The products are used for various inspection purposes, including detecting hidden sub-surface flaws and surface defects, monitoring railway track defects, and performing visual, penetrant, and ultrasonic testing. The company caters to the railroad, aircraft, oil and gas, metallurgy, machine engineering, and power industries.

NDT Systems, headquartered in Huntington Beach, California, established in 1971, is a manufacturer and distributor of advanced ultrasonic testing equipment for the non-destructive testing marketplace. The company's product range includes ultrasonic thickness gauges, bond testers, portable flaw detectors, precision ultrasonic transducers, and manual/automated scanners. NDT Systems' customized solutions, including fully automated robotic inspection systems and specialized transducers, cater to industries such as airfoil manufacturing, aerospace, oil and gas, power generation, and transportation.

Nishiyama Corporation of America, a company founded in 1916 and headquartered in Tokyo, Japan, is a manufacturer and supplier of textile machinery and equipment. The company specializes in providing solutions for the textile industry. They offer a wide range of products, including spinning frames, winding machines, and other textile manufacturing equipment. Their machinery is utilized in textile mills and factories worldwide to achieve precise production processes. The company also offers technical support, maintenance, and training programs to meet customers’ requirements.

Hocker Inc., established in 1973 and based in Houston, US, is a supplier of industrial equipment. The company provides services to a wide range of sectors, such as drilling, forensics and CSI, testing labs, aerospace, and petroleum-chemical. It also repairs automatic film processors, magnetic particle equipment, black lights, and many other products used in NDT inspections. The company’s QMS is in accordance with ISO 9001-2015 and ISO 17025-2017 and it also supplies Labino CSI Forensic Crime Kits.

Papworths Construction Testing Equipment - PCTE is a supplier of instruments and sensors based in Australia. The company supplies field testing equipment which includes non-destructive testing (NDT) equipment to test concrete strength, quality, defects, and cracking and for various other surveys and analyses. There are also Ground Penetrating Radars for concrete and utility scanning along with Lab equipment for different material testing like aggregates, asphalt, rock, soil, etc. and there are geotechnical and structural monitoring sensors among other instruments that serve the Construction industry.

NOMO Group, Inc., founded in 2009, and based in South America, is a distributor of nondestructive testing, heat treatments, welding equipment, and consumables. The company offerings include instruments like the sentinel model 880 delta, finder testing equipment, and Labino line products. Nondestructive testing inspects materials for defects without altering their original structure, ensuring their safety in everyday use. These products and services cater to industries ranging from aerospace, petrochemical, manufacturing, and automotive to consumer products. The company supports its customers' growth by providing timely supply and strong vendor relationships.

Qualitest International Inc., founded in 1999, is a supplier of testing equipment such as hardness testers, material testing equipment, universal testing machines, and instruments for testing rubber, metals, paper, plastic, paint, and packaging materials used in the gold and jewelry, mining, oil and gas, surveying, and ultrasonic industries. The Lauderdale, Florida-based business offers technical support, calibration, and repair either directly or through the global QualiService authorized network. The company has an online store with international shipping.

NDT Supply is a supplier of non-destructive testing (NDT) equipment and consumables. With a founding year in 1981, the company operates from its headquarters in Lenexa, Kansas, USA. The company's main activities involve offering a comprehensive range of NDT equipment and supplies such as Barkhausen Noise - Stress Measurement, Blacklights / UV Lamps / Meters, Bond Testing and Borescopes / Remote Visual Inspection. NDT Supply's product range includes penetrant testers, ultrasonic flaw detectors, and radiography equipment that serves various industries like aerospace, automotive, and construction. Its main services encompass delivering multiple NDT solutions including equipment, accessories, and training.

MARKTEC Corporation, founded in 1955 as Tokushu Toryo Co. Ltd., and based in Tokyo, Japan, is a manufacturer and seller of fluorescent paint and metal testing materials. The company offers a wide range of products for Penetrant Testing such as Dye Penetrant Flaw Detection Material, Magnetic Particle Testing, Eddy Current Testing, Ultraviolet Light Testers, and many more. The company’s products serve various industries such as automobile, construction, steel, and heavy industries among others. It holds the ISO 9001:2015 and ISO 14001: 2015 certifications.

S.A.M.A. Italia S.r.l., established in 1974 and headquartered in Viareggio, Italy, is a manufacturer of precision measuring and control instruments and calibration solutions. The product line includes an extensive range of options, such as flow meters, temperature sensors, pressure gauges, and calibration tools. These optimal-precision devices make it possible to precisely measure and regulate vital characteristics across an array of sectors, including petrochemical, manufacturing, automotive, and aerospace. The products' stability, accuracy, and longevity are essential to quality control and industry compliance in measuring and control solutions for organizations all over the world.

Heation, established in 2019, and located in Norrköping, Sweden, is a manufacturer of industrial water filter in stainless steel. Its product line includes bag filter housing, strainer filter, cyclone filter, inline basket filter, and automatic self-cleaning brush filter, in which these products cater to industries such as water treatment, oil and gas, manufacturing, agriculture, and pharmaceutical. The company's products are used to remove impurities and contaminants from fluids and gases, ensuring product quality, equipment protection, and process efficiency in various industrial applications.

Jinan Hensgrand Instrument Co. Ltd., established in 2001 and based in Jinan, China, is a manufacturer of testing equipment used in performance testing of metal, non-metal, and composite materials. Some of the equipment it stocks include spring, impact, and torsion testing machines used in several industries, including military, aviation, and auto manufacturing. The company sells to all cities and provinces around China and exports to several locations, including North America, Europe, and Australia. It has obtained CE and ISO 19001 certifications and welcomes OEM and ODM orders.

HV Hipot Electric Co., Ltd., established in 2003 and based in Wuhan, China, is a manufacturer of electrical safety testing equipment. The company specializes in high voltage testing equipment and tests various kinds of electrical products, such as transformers, circuit breakers, surge arresters, generators and insulators. It also produces products like transformer, switch-gear, electric energy and battery test equipment, partial discharge measurement device and relay protection tester. The company provides OEM and customization services as well as inspection, maintenance and calibration services for its test equipment.

Beijing TIME High Technology Ltd., founded in 1984 in Beijing, China, is a manufacturer of precision measuring instruments. The company manufactures Leeb hardness testers, thickness gauges, ultrasonic flaw detectors, metallurgy equipment, and roughness testers. These advanced instruments are important for obtaining robust accuracy and stability, making them indispensable tools for quality control and material testing across various industries. The Leeb hardness testers are used for assessing the hardness of metals, while their thickness gauges and roughness testers maintain quality standards. The wholly owned company of Time Group with ISO9001, ISO14001, OHSAS18001, CE, Gost Certificates, operates in 60 countries.

RTUL was founded in 1982 as a manufacturer of Ultrasonic instrumentation having its setup in India. The company designs various welding machines for different applications like Ultrasonic plastic welding equipment for plastic molded parts, Ultrasonic metal welding equipment for joining non-ferrous metal parts together, cleaning machines and equipment along with manufacturing and supplying portable Ultrasonic Non-Destructive Testing Equipment. The ultrasonic energy is also utilized to provide cutting of textiles, woven sacks/plastic, etc., and the powder screening machine is used for dry materials like polymers, pigments, oxides, etc. to help industries such as medical, plastic, metal, textile, and more.

Laboao Equipment and Instruments Co., Ltd., based in China, is a manufacturer and supplier of laboratory equipment and instruments. The company specializes in providing a range of laboratory equipment and instruments including rotary evaporators, glass reactors, heating and cooling equipment, and more. Their products cater to diverse research and industrial applications including pharmaceuticals, biotechnology, chemical engineering, and academic institutions. The company employs GMP-style process management with batch-by-batch quality inspection from raw materials to finished products to ensure they deliver quality products to their clients worldwide.

Gain Express Holdings Ltd., established in 2002 and headquartered in Hong Kong, operates as a manufacturer and supplier specializing in measuring instruments and testing equipment. The company core product range encompasses digital multimeters, oscilloscopes, environmental testers, and industrial meters. Gain Express plays a crucial role in various industries, providing accurate measurement solutions for professionals in fields such as electronics, engineering, and environmental monitoring. For their quality and dependability, Gain Express instruments subsidize to particular data collection and analysis, supporting advancements in technology and scientific research.

NDT-KITS (Honesdom International HK Limited), established in 1973, is a Hong Kong-based manufacturer of non-destructive testing (NDT) instruments that are used to evaluate materials’ non-conformity with specifications as well as surface and internal defects without causing any damages. The instruments developed include the company’s first digital ultrasonic flaw detector, which garnered recognition from the Chinese Academy of Science (CAS) and a patent from the State Intellectual Property Office (SIPO). Other instruments developed are time-of-flight diffraction (TOFD) and phased array ultrasonic testing (PAUT) flaw detectors. NDT-KITS has achieved ISO 9001:2000 certification and adheres to the CE mark and EU EN-12668 standards.

Screening Eagle Technologies is based in Zurich, Switzerland, and is a developer and manufacturer of inspection software and sensors for the industrial sector established in 2019 before merging with Dreamlab and Proceq. The company specializes in software technology products for building environment inspection. These include full-stack inspection solution platforms, portable sensors, and data collection devices used to inform construction and asset maintenance decisions. The company chiefly serves clients in logistics, construction, and engineering operations.

SONOTEC GmbH, established in 1991, is a German manufacturer based in Halle (Saale), Saxony-Anhalt, specializing in ultrasonic measurement technology solutions. The company offers non-invasive flow meters and air bubble detectors for fluid monitoring in medical technologies, bioprocessing, and the semiconductor industry. It also supplies ultrasonic testing devices used for condition monitoring, inspections, predictive maintenance, tightness testing, and ultrasonic leak detection. Additionally, the company engages in non-destructive testing (NDT) using ultrasound, primarily for flaw detection, thickness measurements, and weld seam testing, commonly applied in industries like aerospace, aviation, power plants, as well as other sectors including pipelines, railways, and sheet metal inspections.

Sonatest, established in 1958 in Wolverton, UK, is a manufacturer of cutting-edge UT inspection equipment and ultrasonic NDT products. The company is present globally and has a clientele comprising Boeing, Airbus, Shell, Eon, and Network Rail offering tools that assist in NDT testing in harsh environments. The products consist of Ultrasonic Testing, Phased Array Flaw Detectors, WheelProbes, Scanners, and Couplants. These equipment are widely used in various industries such as aerospace, automotive, chemical, infrastructure, and manufacturing for their simplicity, reliability as well as capability. They offer service & repair, application evaluation and training associated with NDT applications, MPT and ECT uses.

Gilardoni S.p.A., a Socio Unico, was established in 1947 and is headquartered in Mandello del Lario, Italy as a manufacturer and designer of X-ray and ultrasound equipment. The company offers various products, including portable X-ray machines, explosive trace detectors, anti-explosive containers, ultrasound devices, shearography equipment, and radtag systems. These equipment have applications in various fields, such as the manufacturing of X-ray irradiators for preventing TA-GvHD, a fatal disease associated with blood transfusion, as well as the detection of weapons and drugs contained in hand luggage. The company also produces millimeter-wave machines for scanning people and detecting traces of solid explosives.

LabGeni is a manufacturer and supplier of laboratory equipment and consumables that was established in 2004 and is headquartered in Wuhan, China. LabGeni's main activity is the design, development, and manufacturing of laboratory equipment, including microplate readers, centrifuges, and incubators. The company also offers a wide range of laboratory consumables, such as pipette tips, microcentrifuge tubes, and cell culture media. Its products are used by a wide range of customers, including academic institutions, research laboratories, and pharmaceutical companies. LabGeni has over 200 employees and operates in more than 20 countries.

Elcometer Limited, established in 1947, has a global network of facilities and is a manufacturer in the UK and the USA of inspection equipment for the coatings, concrete, and NDT industries. The company's core portfolio of products covers four divisions: Blast, spray, coating inspections, and NDT equipment. Example products include industrial and commercial spray equipment used for protective coatings to meet OEM requirements, bodyshop spray equipment, and components used primarily to provide repair and customized work to the interior and body of passenger cars, trucks, vans, and trailers by their clients, including commercial, industrial, and OEMs.

Baker Hughes Co. (BHC) is an American service provider and manufacturer of industrial oilfield equipment that was established in 1987 following the merger of Baker International and Hughes Tool Company. Based in Houston, Texas, the company produces several categories of oilfield products including drilling equipment, pipe and subsea production systems, generators, and storage systems. It also offers process control components and actuators such as pumps, valves and regulators. BHC provides various services for oilfield and liquefied natural gas (LNG) operations, including regasification, well construction, transportation, and storage.

Ryoden Shonan Electronics Corporation is a company established in 2004 and based in Kanagawa, Japan, as a manufacturer of ultrasonic inspection equipment. The company is part of Mitsubishi Electric Group and has acquired the ISO 9001 certification. It specializes in manufacturing ultrasonic flaw detectors, bolt axial force gauges, and ultrasonic transducers. Its products are utilized for maintenance inspection equipment, traffic-related systems, construction, petroleum chemical plants, and thermal power generation across Japan and the USA.

TMTeck Instrument Co., Ltd founded in Beijing, China, in 2007, is a manufacturer and supplier of inspection and measuring equipment. Products offered by the company are coating thickness gauges, ultrasonic flaw detectors, leeb hardness testers, and darkroom accessories. Its Leeb hardness tester is a portable, non-destructive testing device used to measure the hardness of materials, primarily metals. The company has a 300 square meters factory workshop and its products are EU and Russian GOST certified.

Modsonic Instruments Mfg. Co.Ltd. founded in Ahmedabad, India, in 1987, is a manufacturer and distributor of portable ultrasonic testing equipment. The company’s product catalog includes ultrasonic flaw detectors, ultrasonic thickness gauges, velocity meters, and dual rail testers. Its products are ISO-9001 certified. The company has a manufacturing facility and calibration unit in an area of 32,000 square feet. It also has service stations in all major cities of India to provide calibration and repair services.

KARL DEUTSCH Prüf- und Messgerätebau GmbH, established in 1949 and based in Wuppertal, Germany, is a manufacturer of equipment for non-destructive material testing. The company provides mobile testing and measuring devices, stationary testing systems, sensors and chemical crack detection equipment mainly for the metal producing and processing industry. These equipment are used by steelworks and automotive industry suppliers such as forges, foundries and ball bearings manufacturers. The company also performs test tasks such as weld seam inspection and the detection of casting cavities with ultrasound and surface crack testing on forged parts using magnetic particles and the dye penetrant method.

Russell Technologies India Pvt. Ltd, established in 2009 in New Delhi, India, is a manufacturer and supplier of NDT equipment and accessories. The company specializes in the design and manufacture of NDT equipment, offering ultrasonic flaw detectors, magnetic particle testing equipment, radiographic testing instruments, and eddy current testers. It holds ISO 9001:2015 certification, and its products benefit customers by allowing precise and stable testing and inspection of materials without causing damage. These NDT solutions find applications in aerospace, automotive, construction, and manufacturing, where non-invasive testing methods are essential for ensuring the safety and quality of materials.

ACS-Solutions GmbH, established in 1991 and based in Germany, is an ultrasonic testing equipment manufacturer and supplier. The company offers a range of metal, concrete, and composite material testing products, including thickness gauges, flaw detectors, and tomography systems. It also provides professional inspection services for infrastructural concrete and metallic objects, utilizing advanced techniques such as ultrasonic tomography for accurate flaw evaluation. The company offers solutions for various industries, such as construction, manufacturing, and infrastructure maintenance.

Wuxi jiebo electrical technology co.,ltd. was founded in 2009 and is a manufacturer and supplier of high-speed analytical instruments based in Liangxi, Wuxi, China. The company offers various analytical measuring devices such as optical emission spectrometer, inductively coupled plasma, carbon sulfur analyzer, metallographic cutting machine, universal testing machine, and pen type hardness tester. The products have been used in various fields of application such as casting, metallurgy, mechanical, steel, and ore.

PH Tool Reference Standards, established in 1973 and based in Pipersville, Pennsylvania, USA, is a manufacturer and supplier of reference standards and test blocks. The company's product range includes EDM notches, flat-bottom holes, micro-holes, NDT test blocks, and nondestructive testing equipment. These products support different industrial testing applications. They serve the automotive/transportation, education, medical, power generation, aerospace, and government/military industries. In addition to product offerings, the company provides services such as shop test blocks, recalibration services, ultrasonic plotting, and NDT standards for bar & tube inspection systems.

Evident Corporation is a scientific research and development company in Shinjuku, Tokyo that was established in 2008. Formerly known as Olympus Scientific Solutions, the company specializes in developing cutting-edge technology and products for various industries, including aerospace, automotive, electronics, energy, and medical research. Evident Corporation has proliferated and expanded its product offerings and services to meet the needs of its customers. Their product offerings include non-destructive testing (NDT) solutions such as thickness gauges and automated inspection systems, XRF analyzers like handheld XRF analyzers, industrial microscopes, and video scopes and borescopes.

Gao Tek Inc., started in 2001, and headquartered in Manhattan, New York, is a supplier of test and measurement equipment like embedded development tools, electronic measurement instruments, and telecommunication testers. The company is a B2B tech supplier that also stocks drone products, commercial gas detectors, and transceivers and is incorporated in the USA and Canada. It provides a one-year product warranty against defective material or workmanship and offers overnight delivery in the continental USA and Canada. It is a member of the GAO group and has served customers in over 50 countries worldwide.

Elcometer USA, a private company established in 1947, is a design and manufacture company of inspection equipment to the coatings, concrete, and NDT industry, based in the United States. The company specializes in a wide range of products including material and dry film thickness, surface profile and cleanliness, wet film and powder thickness, and pinhole and porosity systems. It also offer adhesion testers, inspection kits, and inspection accessories. Their products are used across multiple industries worldwide. With a global network of representation in over 170 countries, it continues to expand its product range and adapt to changing technologies.

Advanced NDT Limited is a supplier of non-destructive testing equipment founded in 1993 and headquartered in Worcester, United Kingdom. The company’s product offerings include ultrasonic thickness gauges, coating thickness gauges, ultrasonic flaw detectors, and bond testers. It also supplies ultrasonic transducers, UV lights and torches, and forensic lighting, along with portable imaging systems and automated testing systems. The company supplies NDT equipment to various sectors, including power generation, petrochemical plants, automotive, eerospace, and the MOD.

Ranking as of March 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Advanced Test Equipment Corporation (ATEC) |

6.2%

|

| 2 | Hocker Inc. |

3.9%

|

| 3 | S.A.M.A. Italia S.r.l. |

3.9%

|

| 4 | Nishiyama Corporation of America |

3.8%

|

| 5 | PCE Instruments |

3.5%

|

| 6 | Dakota Ultrasonics |

3.4%

|

| 7 | Heation |

3.2%

|

| 8 | ACS-Solutions GmbH |

2.9%

|

| 9 | NDT Systems Inc. |

2.9%

|

| 10 | Nomogroup, Inc. |

2.8%

|

Derivation Method

The ranking is calculated based on the click share within the ultrasonic flaw detector page as of March 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

10 | 28.6% |

China

China

|

9 | 25.7% |

India

India

|

4 | 11.4% |

Japan

Japan

|

3 | 8.6% |

Germany

Germany

|

3 | 8.6% |

United Kingdom

United Kingdom

|

2 | 5.7% |

Italy

Italy

|

1 | 2.9% |

Sweden

Sweden

|

1 | 2.9% |

Switzerland

Switzerland

|

1 | 2.9% |

Israel

Israel

|

1 | 2.9% |

216 products found

216 products

KJTD Co., Ltd.

520+ people viewing

Last viewed: 12 hours ago

The portable ultrasonic flaw detector USFD-20 has a lightweight design, weighing approximately 840g including the battery. We have implemented a 2-...

RYODEN SHONAN ELECTRONICS CORPORATION

900+ people viewing

Last viewed: 2 hours ago

Bolt axial force measurement of bridge structures, etc., long -term axial force management with axial force measurement alone ・ Built -in temperat...

Keisoku Kogyo Co., Ltd.

270+ people viewing

Last viewed: 12 hours ago

■Features ・Small and lightweight multi-channel flaw detector ・Select built-in P/R or external P/R according to the application ・Expandable up to...

Genes Co., Ltd.

390+ people viewing

Last viewed: 12 hours ago

This is a conventional ultrasonic flaw detector that has high-performance flaw detection functions and can be used in a wide range of applications....

Dakota Japan Co., Ltd.

570+ people viewing

Last viewed: 12 hours ago

■Summary ・Flagship model of ultrasonic flaw detector ・Equipped with powerful 400V tone burst ・Supports automatic inspection with external contro...

Genes Co., Ltd.

900+ people viewing

Last viewed: 12 hours ago

Changes in the internal state of the material, such as minute cracks that occur within the material or voids (bubbles) inherent in the base materia...

ULTRASONIC Co., Ltd.

400+ people viewing

Last viewed: 13 hours ago

It is applied to ensure the quality and safety of large diameter steel pipes used for gas pipelines, sewage, construction, etc. We offer three type...

MARKTEC Corporation

550+ people viewing

Last viewed: 13 hours ago

■Features Various choices are available to suit your needs. Selection example ・Portable type with excellent portability/operability: IPX6 compatib...

KJTD Co., Ltd.

380+ people viewing

Last viewed: 11 hours ago

The multi-channel digital ultrasonic flaw detector ULTECT21 is equipped with the functions necessary for automatic flaw detection as standard, and ...

KJTD Co., Ltd.

570+ people viewing

Last viewed: 12 hours ago

X-ray flaw detection and ultrasonic flaw detection are methods for recording images without destroying the inside of the material. We are developin...

Keisoku Kogyo Co., Ltd.

350+ people viewing

Last viewed: 20 minutes ago

■Features ・A new flaw detector that uses USB3.2Gen1 as an interface and achieves high-speed throughput of waveform data. ・Achieved 360MB/s in ben...

Genes Co., Ltd.

470+ people viewing

Last viewed: 13 minutes ago

This is a board type ultrasonic flaw detector. The standard is 4ch and can be expanded up to 32ch.

RYODEN SHONAN ELECTRONICS CORPORATION

760+ people viewing

Last viewed: 12 hours ago

Image processing device that can perform X-Y axis and θ-Z axis analysis ・ The X-Y axis flat scan image processing and θ-Z axial scan can be imaged...

Dakota Japan Co., Ltd.

580+ people viewing

Last viewed: 12 hours ago

■Summary ・Equipped with all the functions necessary for ultrasonic flaw detection ・In addition to AC power and batteries, it also works with AA b...

Ryokosha Co., Ltd.

560+ people viewing

Last viewed: 13 hours ago

Features ■Portable power The OmniScan X3 64 flaw detector has a durable, field-proven housing with a portable design. OmniScan The improved perform...

Oaksonic Co., Ltd.

140+ people viewing

Last viewed: 5 hours ago

■“RD-β” ・Plus/minus shot with wideband frequency characteristics ・Developed a switchable ultrasonic pulser receiver. ・Inspection can be performe...

Shinmei General Co., Ltd.

1130+ people viewing

Last viewed: 4 hours ago

NDI practical test carry-on certified model ■Improved operability - 7-inch, 1,024 x 600 pixel screen, one of the largest in a portable flaw detect...

KJTD Co., Ltd.

660+ people viewing

Last viewed: 7 hours ago

From high-speed scanning systems to online automatic flaw detection, the high-speed, wideband ultrasonic flaw detector HIS3 HF/LF is a stand-alone ...

2 models listed

KJTD Co., Ltd.

750+ people viewing

Last viewed: 8 hours ago

The phased array ultrasonic flaw detection system PA5 was born as the successor to the phased array ultrasonic flaw detection system PA4, which has...

MPS Co., Ltd.

310+ people viewing

Last viewed: 12 hours ago

■Components of automatic equipment Pro-beam supplies nearly 20 automatic electron beam welding lines to Europe and Asia, including automotive parts...

RYODEN SHONAN ELECTRONICS CORPORATION

380+ people viewing

Last viewed: 12 hours ago

・ Automatically controlled the start of the search for a scalpel by an external control signal. ・ Built -in interface function with the control pan...

2 models listed

Dakota Japan Co., Ltd.

740+ people viewing

Last viewed: 5 minutes ago

■Summary ・High performance model of DFX-7 ・Equipped with narrow band filter (2MHz, 5MHz, 10MHz) ・Equipped with all necessary functions in a body...

Eddyfi Technologies Inc.

1100+ people viewing

Last viewed: 12 hours ago

■Powerful signal quality to standard-compliant conventional PAUT and TOFD procedures TOPAZ®64 is a 64CH (or 32CH) fully integrated phased array ult...

Genes Co., Ltd.

550+ people viewing

Last viewed: 12 hours ago

Mechanical scanning and electronic scanning enable high-speed flaw detection. It has the advantage that the focal position and pitch can be set ele...

ULTRASONIC Co., Ltd.

530+ people viewing

Last viewed: 12 hours ago

■Summary ・We provide an ultrasonic flaw detection system for internal defects and surface defects in CC slabs using the EMAT ultrasonic method to ...

KJTD Co., Ltd.

780+ people viewing

Last viewed: 12 hours ago

Introducing a 128-channel parallel drive high-speed phased array flaw detection system. Flash Focus supports ultrasonic flaw detection in special m...

Nihon Matec Co., Ltd.

370+ people viewing

Last viewed: 12 hours ago

The A1220 flaw detector consists of a main body (screen, keyboard) and an antenna array (AA) consisting of 24 (6x4) matrix DPCs. The device's AA el...

Nihon Matec Co., Ltd.

360+ people viewing

Last viewed: 12 hours ago

Temate® PowerBox H is the first handheld battery powered EMAT device capable of delivering MAX 1,200V / 8KW peak power at PRF 100Hz. The instrument...

Nihon Matec Co., Ltd.

700+ people viewing

Last viewed: 12 hours ago

■Leader in next-generation non-destructive testing and composite materials Recognized worldwide for its high-quality, high-resolution ultrasonic no...