All Categories

History

This section provides an overview for multitubular heat exchangers as well as their applications and principles. Also, please take a look at the list of 18 multitubular heat exchanger manufacturers and their company rankings. Here are the top-ranked multitubular heat exchanger companies as of February, 2026: 1.Resistencias Tope, SA, 2.SACOME, 3.URMOJATOR.

Table of Contents

Categories Related to Multitubular Heat Exchangers

A multitubular heat exchanger is a type of heat exchanger.

A multitubular heat exchanger is a type of heat exchanger.

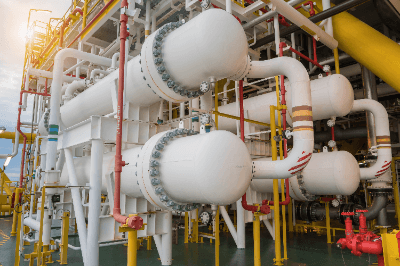

A shell-and-tube heat exchanger consists of a thick cylindrical body (shell) and a number of thin tubes to increase the installation area, and heat is exchanged between the fluid flowing on the body side and the fluid on the tube side.

Since the hot and cold fluids must not mix directly but only transfer heat, it is important that both fluids flow through a fixed wall separated by a metal or other material to ensure efficient heat transfer.

In actual use, there are various factors such as the temperature and pressure to be used, the nature of the fluid, and the location of installation, and there are a wide variety of applications. Typical examples of heat exchangers classified by structure are multitubular heat exchangers and plate heat exchangers.

Multitubular heat exchangers can be used for all purposes, from low pressure to high pressure, low or high temperature, super-heating, cooling, evaporation, etc. Therefore, they are not only used in air conditioning and sanitary facilities, but have also been used in various industrial fields, such as chemical plants and oil refining facilities, for many years.

Multitubular heat exchangers can be used in a wide range of applications from low pressure to high pressure and can accommodate high viscosity fluids because their structure allows for a small pressure drop. The simplicity of the structure allows many models to be disassembled, making maintenance relatively easy. Waste heat can also be used on the refrigerant side, leading to energy savings.

A heat exchanger with liquid or gas phase on one side is called a single-phase heat exchanger. Two-phase heat exchangers include those that heat a liquid to boiling gas (steam) (boilers) and those that cool steam to a condensing liquid (condensers), with the phase change usually occurring on the shell side.

Boilers in steam engines are usually large, cylindrical shell-and-tube heat exchangers. In large power plants with steam turbines, shell-and-tube surface condensers are used to condense the exhaust steam from the turbine into condensate, which is then turned back into steam in the steam generator.

Among multitubular heat exchangers, they can be broadly classified into three types according to their structure.

The fixed tube-plate type has a simple structure with tubes fixed to tube plates at both ends of the body. To dissipate thermal stress, expansion joints are sometimes provided in the body.

The U-tube has a U-shaped bend in the pipe, with the end face of the U-tube fixed to the pipe plate on one side of the body. The tube can be freely expanded and contracted.

The floating head has a fixed tube plate on one side and a floating tube plate on the other side, allowing free movement. The floating head can be disassembled and can be used even in harsh operating environments, but it has the disadvantage of a more complicated structure and a larger number of parts than other types of heat exchangers.

The plate heat exchanger has a structure in which high-temperature and low-temperature fluids flow alternately between heat-transfer plates, which are made up of a series of complex press-formed thin plates. Compared to the multi-tube type, the plate heat exchanger has higher heat exchange efficiency and is lighter and more compact than the multi-tube type with equivalent performance, but it cannot be disassembled and is difficult to maintain.

The shape of the heat-transfer plates creates a turbulent effect of fluid flow and prevents dirt from adhering to the plate surfaces, but this structure can cause clogging in the flow path.

Tubes for multitubular heat exchangers are generally made of metals such as aluminum, copper alloys, stainless steel, carbon steel, and nonferrous copper alloys. Since incorrect selection of tubing material may result in leakage from the shell-and-tube sides, cross-contamination of liquids, and pressure loss, it is important to select tubing carefully by taking the following points into consideration when choosing the right tubing.

*Including some distributors, etc.

Sort by Features

Sort by Area

Evoqua Water Technologies began in 2013 and is headquartered in Pittsburgh, Pennsylvania. The company is a manufacturer and service provider of water and wastewater treatment systems, serving commercial, industrial, and municipal water treatment customers both in the United States and globally. The company’s two operating segments are Integrated Solutions and Services, and Applied Product Technologies. The former provides water service contracts providing water cleaning services including odor and corrosion control services. The latter sells advanced filtration products including self-cleaning filters, disinfection solutions, and non-chemical disinfection products.

Advanced Pressure Technology, founded in Jeffersonville, IN in 2000 is a manufacturer and supplier of custom heat exchange systems and process systems. The company's product portfolio includes Aseptic Processing Systems, Extended Shelf Life - UHT Systems, Multitube and Coil Heat Exchangers, Supplemental Equipment, and Sanitary Process Systems. The company's products are used in markets such as automotive and transportation, food and beverage, industrial automation, healthcare and medical devices, and consumer goods.

Resistencias Tope, SA, founded in 1953 and headquartered in St. Andreu de la Barca, Barcelona, is a manufacturer and designer of customized electric heating elements. The company provides an array of products, such as immersion heaters for water, immersion heaters for corrosive fluids, and railway points heating systems. These products serve various applications, including heating corrosive liquids in hazardous areas, in the plastic processing industry, and within the petroleum sector. Additionally, the company offers services for installing flanged immersion heaters in tanks and pipelines.

GEA Group Aktiengesellschaft, founded in 1881 with headquarters in Germany, is an integrated manufacturer of process technology, machinery, and production plants. The company offers various products, including complete turnkey solutions for beverage plants, as well as beverage packaging services. The company has more than 18,000 employees working across five divisions and has facilities in over 60 countries, serving the food and beverage, chemical, marine, pharmaceutical, and energy markets, among others. GEA Group Aktiengesellschaft's service division works with clients to improve their production plant productivity, especially in the food and beverage industry.

USUI CO., LTD. established in 1941, and headquartered in Shizuoka Prefecture, Japan, is a manufacturer and supplier of processed tubes. The company's product range includes automobile brake tubes, fuel tubes, power steering tubes, high-pressure fuel tubes for gasoline direct injection engines, and plastic cooling fans. These products play crucial roles in vehicles, ensuring safety and enhancing performance. They serve industries such as the automotive, energy, and machinery sectors. Besides its core manufacturing operations, the company offers services in research and development, technical support, product customization, and global distribution.

Kamui Co., LTD., established in 1960 and headquartered in Tokyo, Japan, is a manufacturer that manufactures and sells heat exchangers. The company offers a range of products that are designed to keep hydraulic fluid, compressors, and gas turbine generators. It also provides a wide range of maintenance and support after product delivery. Its products can be used with any equipment in any environment and have short lead times. The company has received an award from the Inspector of Chiba Prefectural Labor Standards. It serves various industries such as Industrial equipment, Construction equipment, Chemical devices, and more.

Fluitec, established in 1993, is a Neftenbach, Switzerland-based manufacturer of mixing, flow chemistry and static mixing products. The company’s product portfolio comprises static mixing products such as laminar static mixers, turbulent static mixers, and static mixers as well as flow chemistry products such as reaction systems, reaction calorimetry, mixer/heat exchanger, and contiplants and its peripherals such as sensors and actuators. Its products offer solutions in various industries including pharmaceutical, biotechnology, cosmetics, and food.

Bronswerk Heat Transfer BV, founded in 1940 and headquartered in Nijkerk, Gelderland, the Netherlands, is a developer and specialist manufacturer of industrial heat exchange solutions. The company offers three main heat exchange solutions: air-cooled coolers, shell and tube heat exchangers, and complete heat transfer systems. Each of the solutions the company provides is custom-manufactured and specific to customer requirements, applying the company's experience and know-how. It also provides custom revamping and updating for existing heat exchange systems. The company's services include equipment and systems inspections, project management, and ongoing maintenance programs after installation.

Sulzer Ltd. is a fluid engineering and chemical processing solutions manufacturer originally founded in 1775. The company has been headquartered in Winterthur, Switzerland since 1834, maintaining a network of 180 manufacturing facilities and service centers around the world. The company has an expansive product portfolio including distillation and absorption columns, agitators, reactors, crystallizers, and polymerization systems. These supply clients in the metals, plastics, chemicals, power, and pharmaceutical industries. Sulzer Ltd. also offers a range of services, such as testing and diagnostics, prototyping, retrofitting, and upgrades, including technical training with long-term support for their customers.

HRS Heat Exchangers is a manufacturer of heat transfer products located in Watford, Hertfordshire, and was founded in 1981. The company's product line includes plate heat exchangers, aseptic fillers, hydraulic piston pumps, multitubular heat exchangers and CIP packages. It serves a wide range of industries, including the pharmaceutical, food and beverage, Industrial, and environmental Industries. The company provides food processing, environmental, and product and process trial systems. Its systems are designed to maximize energy efficiency and reduce waste.

SPX Flow, established in 1912, is a manufacturer of industrial machinery to solve processing challenges based in Charlotte, North Carolina. The company manufactures various machinery such as mixers, pumps, valves, homogenizers, and heat exchangers. The machinery is used in nutrition, health, mining, construction, and chemical industries. The company provides services such as designing, engineering, and installing turnkey process units or full-scale plants. The SPX Flow brands include Anhydro, Bran+Luebbe, Gerstenberg Schrӧder, Pneumatic Products and Seital Separation.

EagleBurgmann, a company founded in 1884 and headquartered in Wolfratshausen, Germany, is a manufacturer and supplier specializing in industrial sealing technology. The company's range of sealing technology includes mechanical seals, carbon floating ring seals, and seal supply systems. These products find applications in various industries, including the petrochemical industry, renewable energy generation, and shipbuilding. The company also offers services, including technical support, product training, and customized solutions to meet the specific requirements and applications of individual customers. The company has sales offices and service centers in various countries, including the United States, India, and China.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | GEA Group Aktiengesellschaft |

10.2%

|

| 2 | Resistencias Tope, SA |

9.3%

|

| 3 | SACOME |

8.5%

|

| 4 | URMOJATOR |

7.6%

|

| 5 | Bronswerk Heat Transfer |

6.8%

|

| 6 | Flowlink BV |

5.9%

|

| 7 | Sulzer Ltd |

5.9%

|

| 8 | USUI CO., LTD. |

5.9%

|

| 9 | XLG Heattransfer |

5.1%

|

| 10 | Advanced Process Solutions |

5.1%

|

Derivation Method

The ranking is calculated based on the click share within the multitubular heat exchanger page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

Spain

Spain

|

5 | 29.4% |

United States of America

United States of America

|

3 | 17.6% |

Germany

Germany

|

2 | 11.8% |

Japan

Japan

|

2 | 11.8% |

Switzerland

Switzerland

|

2 | 11.8% |

Netherlands

Netherlands

|

2 | 11.8% |

United Kingdom

United Kingdom

|

1 | 5.9% |

215 products found

215 products

Matsuzawa Works Co., Ltd.

420+ people viewing

Last viewed: 12 hours ago

You can design the optimal cooling equipment according to your purpose and use.

4 models listed

Matsuzawa Works Co., Ltd.

290+ people viewing

Last viewed: 12 hours ago

You can design the optimal cooling equipment according to your purpose and use.

4 models listed

Yoshiro Kiko Co., Ltd.

500+ people viewing

Last viewed: 12 hours ago

Due to the high-precision helical structure heat exchange tube position accuracy, baffle, the fluid flow through the heat exchanger can create a tu...

SGL Carbon Technique Japan Co., Ltd.

240+ people viewing

Last viewed: 12 hours ago

■Summary We use Tokabait, a structural material for chemical equipment that is made by impregnating graphite material with excellent corrosion resi...

10 models listed

Yoshiro Kiko Co., Ltd.

430+ people viewing

Last viewed: 12 hours ago

■Silicon carbide tube Silicon carbide (SIC) Silicon carbide tubes, which are the core components of heat exchangers, are manufactured from high-pur...

SGL Carbon Technique Japan Co., Ltd.

160+ people viewing

Last viewed: 12 hours ago

■Summary We use Tokabait, a structural material for chemical equipment that is made by impregnating graphite material with excellent corrosion resi...

10 models listed

TIG Co., Ltd.

610+ people viewing

Last viewed: 12 hours ago

The turbulent flow effect of corrugated pipes increases the heat exchange rate, making it suitable for a wide range of uses, even in large-scale fa...

SGL Carbon Technique Japan Co., Ltd.

170+ people viewing

Last viewed: 12 hours ago

■Summary We use Tokabait, a structural material for chemical equipment that is made by impregnating graphite material with excellent corrosion resi...

10 models listed

SGL Carbon Technique Japan Co., Ltd.

220+ people viewing

Last viewed: 12 hours ago

■Summary We use Tokabait, a structural material for chemical equipment that is made by impregnating graphite material with excellent corrosion resi...

10 models listed

Meiwa Co., Ltd.

340+ people viewing

Last viewed: 7 hours ago

As one of the few manufacturers of pressure vessels (receivers, accumulators, etc.) and double pipe condensers in Japan, we offer general-purpose p...

6 models listed

TIG Co., Ltd.

550+ people viewing

Last viewed: 12 hours ago

High-performance double tubes have successfully reduced costs, are significantly smaller, the entrance and exit directions can be freely adjusted, ...

SGL Carbon Technique Japan Co., Ltd.

180+ people viewing

Last viewed: 12 hours ago

■Summary We use Tokabait, a structural material for chemical equipment that is made by impregnating graphite material with excellent corrosion resi...

10 models listed

Frontier technology Co., Ltd.

670+ people viewing

Last viewed: 12 hours ago

■ Characteristics ・ Can be produced from small size to large size. ・ Because there are few seals, the risk of fluid leakage is small. ・ Because ...

Meiwa Co., Ltd.

340+ people viewing

Last viewed: 2 hours ago

As one of the few manufacturers of pressure vessels (receivers, accumulators, etc.) and double pipe condensers in Japan, we offer general-purpose p...

6 models listed

TIG Co., Ltd.

530+ people viewing

Last viewed: 12 hours ago

High performance that can be bent and installed by hand, significantly smaller size, entrance/exit direction can be freely adjusted, and flexible t...

SGL Carbon Technique Japan Co., Ltd.

240+ people viewing

Last viewed: 12 hours ago

■Summary We use Tokabait, a structural material for chemical equipment that is made by impregnating graphite material with excellent corrosion resi...

10 models listed

Meiwa Co., Ltd.

400+ people viewing

Last viewed: 12 hours ago

As one of the few manufacturers of pressure vessels (receivers, accumulators, etc.) and double pipe condensers in Japan, we offer general-purpose p...

4 models listed

Morimatsu Industries Co., Ltd.

830+ people viewing

Last viewed: 12 hours ago

We design and manufacture heat exchangers of all shapes and materials, including U-tube and floating head types. ■Material The standard product is...

SGL Carbon Technique Japan Co., Ltd.

170+ people viewing

Last viewed: 12 hours ago

■Summary We use Tokabait, a structural material for chemical equipment that is made by impregnating graphite material with excellent corrosion resi...

10 models listed

SGL Carbon Technique Japan Co., Ltd.

170+ people viewing

Last viewed: 10 hours ago

■Summary We use Tokabait, a structural material for chemical equipment that is made by impregnating graphite material with excellent corrosion resi...

10 models listed

SGL Carbon Technique Japan Co., Ltd.

220+ people viewing

Last viewed: 12 hours ago

■Summary We use Tokabait, a structural material for chemical equipment that is made by impregnating graphite material with excellent corrosion resi...

10 models listed

Masaie Co., Ltd.

380+ people viewing

Last viewed: 12 hours ago

■ Features Refradation Research Desperate Heat heat exchangers are used to cool the exhausted superheated gas from the compressor. It is possible t...

4 models listed

MDI Co., Ltd.

640+ people viewing

Last viewed: 1 hour ago

It offers overwhelming benefits precisely because it is in the thoroughly low-temperature latent heat region of combustion exhaust gas, where corro...

MDI Co., Ltd.

340+ people viewing

Last viewed: 12 hours ago

■Features ・All made of titanium, all made of SUS316, and other special materials such as Hastelloy and Inconel can also be manufactured. ・To area...

MDI Co., Ltd.

470+ people viewing

Last viewed: 12 hours ago

By changing from the conventional straight tube shell and tube to this corrugated shell and tube, heat transfer efficiency is greatly improved due ...

MDI Co., Ltd.

600+ people viewing

Last viewed: 12 hours ago

By making the corrugated tube into a coiled shape, it can be installed at sites where installation space is limited. Also, since it uses a corrugat...

Taisei Kogyo Co.,Ltd.

360+ people viewing

Last viewed: 12 hours ago

This type of heat exchanger/oil cooler has cooling pipes (tubes) running inside the body (shell) through which high-temperature fluid flows, and th...

Taisei Kogyo Co.,Ltd.

370+ people viewing

Last viewed: 12 hours ago

This type of heat exchanger/oil cooler has cooling pipes (tubes) running inside the body (shell) through which high-temperature fluid flows, and th...

Taisei Kogyo Co.,Ltd.

470+ people viewing

Last viewed: 12 hours ago

This type of heat exchanger/oil cooler has cooling pipes (tubes) running inside the body (shell) through which high-temperature fluid flows, and th...

Taisei Kogyo Co.,Ltd.

520+ people viewing

Last viewed: 12 hours ago

This type of heat exchanger/oil cooler has cooling pipes (tubes) running inside the body (shell) through which high-temperature fluid flows, and th...