All Categories

History

This section provides an overview for screwless terminal blocks as well as their applications and principles. Also, please take a look at the list of 5 screwless terminal block manufacturers and their company rankings. Here are the top-ranked screwless terminal block companies as of February, 2026: 1.CUI Devices, 2.Wieland Electric Inc., 3.SATO PARTS CO.,LTD..

Table of Contents

Categories Related to Screwless Terminal Blocks

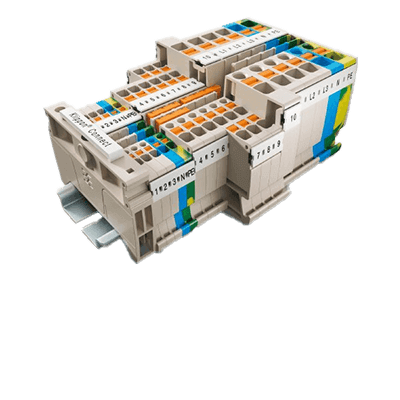

Screwless terminal blocks are a method of securing wiring without the use of screws.

This design significantly reduces the time and effort required for wiring work and at the same time improves the quality of signal transmission. It also greatly improves long-term reliability because it reduces the risk of contact failures due to loose screws.

Especially for hardware engineers and purchasing managers, it is worth seriously considering the use of screwless terminal blocks as an option for new projects and upgrades, as they can be expected to increase production efficiency, enhance maintainability, and even reduce overall costs.

In light of the above, screwless terminal blocks are gaining attention in many industries as a connection solution for modern electronic technology due to their superior characteristics and advantages.

Screwless terminal blocks are increasingly being used in a variety of industries and applications as a screwless signal and power connection technology. Here we examine their main applications in detail.

Distribution boards and switchboards are central devices for power distribution and control. Screwless terminal blocks are extremely useful in these installations because they require solid connections and long-term reliability. They improve safety and maintainability by reducing the risk of loose screws and poor contact.

In semiconductor manufacturing processes, which require precision and advanced technology, reliable electrical connections are essential. Screwless terminal blocks are ideal for quick and reliable wiring while maintaining signal accuracy and quality.

Machine tools often operate in harsh environments with vibration and heat, requiring highly reliable connection technology. Screwless terminal blocks can maintain stable connections even under such conditions.

Screwless terminal blocks are increasingly being used to connect storage batteries. This technology is suitable for applications involving high currents and rapid charging and discharging, which require secure connections and high durability.

Photovoltaic and solar power generation equipment is sensitive to environmental influences and requires long-term reliability and ease of maintenance. Screwless terminal blocks are the ideal choice to meet these requirements.

The springs set into screwless terminal blocks are often made of stainless steel, and the conductive parts are electrolytic copper or tin plated, making them as durable as or more durable than screw-type terminal blocks over long periods of use. The clamping force of screwless terminal blocks is based on spring force, so they do not require periodic retightening as screw-type terminal blocks do.

The spring force set inside the terminal block secures the wire, and the larger the diameter of the wire, the stronger the clamping force. Therefore, even when using cables of different diameters on the same terminal block, the wire is not easily loosened and can be secured without damaging the wire.

To secure a wire that has been stripped of its sheath, use a flat-blade screwdriver or a dedicated knob to reduce the force exerted by the spring to hold the wire in place, and insert the wire all the way to the back of the connection port. When removing an electric wire, use a flat-blade screwdriver or a dedicated knob to weaken the spring-loaded restraining force and pull the wire out of the connection port.

Screwless terminal blocks are widely used in many industries for their convenience and reliability. Various types of screwless terminal blocks are designed and manufactured to suit different uses and applications.

Screwless terminal blocks for panel mounting are designed for direct mounting on the external panel of equipment and facilities. This allows for easy access and maintenance.

Primary applications include large equipment, facilities, and electrical wiring termination connection points.

Screwless terminal blocks for board mounting are designed for direct mounting on electronic boards. This allows them to be used in applications requiring compact design and high integration.

Primary applications include wiring terminations in electronic devices and PCBs, connections between modules, and signal transfer points.

Screwless terminal blocks for relaying are used to easily connect and relay two or more electrical circuits. They are characterized by multifunctionality and modular design. In many cases, they are compatible with existing wiring systems.

Primary applications include connecting and branching between cables and extending or modifying electrical circuits.

*Including some distributors, etc.

Sort by Features

Sort by Area

CUI Devices, established in 1989 and headquartered in Lake Oswego, Oregon, is an electronic components manufacturer that is ISO 9001 certified. It stocks motion, sensor, and relay solutions and works with several distribution partners, including Mouser Electronics, Digi-Key Electronics, and Electro Sonic. The company gives back to the community by supporting organizations like Tualatin School House Pantry, Girls Who Code, and Friends of Trees, which aim to uplift society by providing basic needs, STEM education, and environmental stewardship. It has contract manufacturing facilities in other countries, including China, Vietnam, and Japan.

SATO PARTS CO., LTD. is a Japanese-based company founded on March 1, 1948, and headquartered in Sotokanda, Chiyoda-ku, Tokyo, and has established itself as a supplier and manufacturer of terminal blocks and electrical components. The company offers a wide range of products, including screwless terminal blocks, screw-type terminal blocks, fuse holders, and indicator lights. These products are utilized in industries such as automotive, electronics, and machinery manufacturing. The company also offers customer services such as customer consultation and email accommodation.

KLS Electronic, founded in 2002 with headquarters and factories in China, is a manufacturer of electronic components that has expanded to have more than 10 subsidiary companies. The company's extensive product line includes resistors, inductors, wiring accessories, automotive connectors, and heat sinks, which are supplied to the industrial automation, instrumentation, power, transport, shipbuilding, and new energy sectors, among others, across 30 regions worldwide. KLS Electronic also holds ISO 9001 management system certificates.

Wieland Electric is headquartered in Hamberg Germany and was founded in 1910. Weiland Electric is a manufacturer of electrical connection and industrial automation products used in conveying, logistics, horticulture, lighting, machine building & safety, and energy industries. Wieland Electric’s product categories include active industrial products, passive industrial products, modular wiring systems, power distribution for electric vehicles, integrated lighting & building solutions, and indoor interconnect products such as metal fabrication, 3D printing for prototyping, electrical design, and box build fabrication.

Dinkle Group was established in 1983 and is headquartered in Taipei, Taiwan. Dinkle is a multi-national, ISO 9001-certified manufacturer and distributor of electronics and equipment for industrial sectors such as factory automation, transportation, new energy, telematics, and equipment manufacturing. Dinkle has 4 product lines: terminal blocks, electronics & interface, electronic housings, and tools. Terminal blocks include PCB terminal blocks, barrier terminal blocks, and NEMA terminal blocks. Electronics & interface include interface modules, surge protection devices, and industrial relays. Electronic housings include enclosures for bus systems, DMEB component housing, and PCB carriers. Tools include drivers, marking systems, ferrules, and others.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | CUI Devices |

27.3%

|

| 2 | Wieland Electric Inc. |

22.7%

|

| 3 | SATO PARTS CO.,LTD. |

22.7%

|

| 4 | Dinkle International Co. Ltd |

18.2%

|

| 5 | KLS Electronic |

9.1%

|

Derivation Method

The ranking is calculated based on the click share within the screwless terminal block page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

1 | 20.0% |

Japan

Japan

|

1 | 20.0% |

China

China

|

1 | 20.0% |

Canada

Canada

|

1 | 20.0% |

Taiwan

Taiwan

|

1 | 20.0% |

128 products found

128 products

Nippon Weidmuller Co., Ltd.

400+ people viewing

■Original Klippon® Connect from 1948 Conduction of power, signals, and data is a traditional requirement in electrical engineering and control cabi...

Nippon Weidmuller Co., Ltd.

420+ people viewing

■Original Klippon® Connect from 1948 Conduction of power, signals, and data is a traditional requirement in electrical engineering and control cabi...

IDEC Co., Ltd.

890+ people viewing

Last viewed: 54 minutes ago

■Easy & stack ・You can easily assemble the required number of poles at your own hands without using any special tools. ・We can respond flexibly t...

IDEC Co., Ltd.

600+ people viewing

Last viewed: 1 day ago

■Features ・No estimate required ・No need to select accessories ・No assembly work required ・No need to cut DIN rail ・Reduction of parts managem...

IDEC Co., Ltd.

650+ people viewing

Last viewed: 3 hours ago

■Features ・No tools or ferrules are required when wiring. Wiring is as simple as inserting a stripped thin stranded wire (KIV wire) into the conne...

IDEC Co., Ltd.

560+ people viewing

■Features ・Man-hour saving: Approximately 55% reduction in wiring labor (*) ・Easy connection with no tools required, easy crossover wiring ・Exce...

Shinden Technology Co., Ltd.

430+ people viewing

Push type Screwless (5.0mmPitch) Features ■Equipped with a screwless type European style terminal block ・Since it is firmly fixed with spring pre...

Toho Technology Co., Ltd.

430+ people viewing

Last viewed: 2 hours ago

■Product overview ・Push-in method for single wires and wires with ferrules, where the work is completed just by plugging them in. ・By arranging t...

Nippon Weidmuller Co., Ltd.

300+ people viewing

Last viewed: 1 day ago

■Original Klippon® Connect from 1948 Conduction of power, signals, and data is a traditional requirement in electrical engineering and control cabi...

Nippon Weidmuller Co., Ltd.

280+ people viewing

Last viewed: 9 hours ago

■Original Klippon® Connect from 1948 Conduction of power, signals, and data is a traditional requirement in electrical engineering and control cabi...

Nippon Weidmuller Co., Ltd.

230+ people viewing

■Earth terminal block and PE terminal block Protection of humans and machines The earth terminal block is a protective feedthrough terminal with PE...

Nippon Weidmuller Co., Ltd.

290+ people viewing

■Terminal block with cutting function for measuring inside the control panel The testing and measurement of electrical switchgear and disconnection...

Nippon Weidmuller Co., Ltd.

250+ people viewing

■Easy operation Advanced protection In energy monitoring, incorrect wiring can damage current and voltage transformers. Thanks to a number of conne...

Mibu Electric Manufacturing Co., Ltd.

390+ people viewing

Last viewed: 22 hours ago

A terminal block that allows direct push-in connection of cables. Three features ■Significant reduction in work man-hours (simple wiring work) ・D...