All Categories

History

This section provides an overview for energy monitors as well as their applications and principles. Also, please take a look at the list of 13 energy monitor manufacturers and their company rankings. Here are the top-ranked energy monitor companies as of July, 2025: 1.Algodue Elettronica s.r.l., 2.Energy Team, 3.SMARTech Energy.

Table of Contents

Engaged in research on nitride semiconductor growth using the MBE method at Waseda University Graduate School. After graduating from graduate school in 2016, he joined a non-ferrous metal manufacturer.

Engaged in equipment maintenance and engineering work at metal smelting plants. Moved to a chemical manufacturer in 2022. Engaging in similar tasks.

An energy monitor is a product that visualizes energy status by reflecting it on a monitor screen.

It is often used to refer to devices that measure electricity usage, mainly in homes and buildings. They are widely used from industrial to household products. Typical examples of use include checking the usage status of motors and engines of hybrid cars and displaying the power usage status of facilities with power generation systems such as solar power generation systems.

Energy Monitors can be used to monitor infrastructure energy usage, such as electricity and gas. This makes it possible to monitor usage by time of day and by device, which is useful for energy conservation.

It contributes to lower running costs by limiting the use of equipment with high power consumption and introducing energy-saving equipment. Companies may also reduce CO2 emissions to improve their image. It also has advantages such as early detection of abnormal usage.

Energy monitors, like electricity meters, are often designed based on accuracy class 1 electricity measurement technology. Accuracy class is a standard defined by the International Electrotechnical Commission (IEC) and is divided into five levels, from Class 0.1 to Class 3. Class 0.1 is the most accurate, and Class 3 is the least accurate.

For power-related monitors, power consumption is calculated based on current and voltage measurements. Therefore, it consists of a voltage sensor for measuring AC power supply voltage and a current sensor for measuring AC power supply current. These sensors are attached to the equipment's mains power cable for measurement. The voltage sensor measures the supply voltage from the charging unit with an alligator clip or similar, while the current sensor often measures the current through the cable sheath with a clamp or similar.

The measured current and voltage are calculated by an internal microcomputer board or other control unit. Models with communication functions will also have a communication module.

The above calculated values are used to calculate power consumption, which is displayed on a monitor in real time or stored in a data log. In large factories, the ON/OFF status of various connected machines may be displayed, and real-time power details may be displayed numerically.

Various types of Energy Monitors are available for different applications. The following are examples of types of Energy Monitors:

Stand-alone Energy Monitors are energy monitors that can be used by themselves. These monitors have built-in voltage and current sensors to measure power consumption. However, a separate power supply for driving the Energy Monitor is often required.

These Energy Monitors are installed as meters provided by the power company, just like regular electricity meters. It is compatible with the smart grid and real-time communication, and can provide real-time notification of electricity usage. This type may be used when a solar system or internal combustion private power generation equipment is present.

When installed in a solar system, it is used to measure power generation and power consumption. It is also used to monitor electric power consumption of lighting equipment, air conditioners, etc.

Energy Monitors can be mounted directly on a switchboard or control panel. These monitors are typically used for industrial or commercial energy management. Because the products are linked to control equipment, they are often sold by instrumentation manufacturers.

These Energy Monitors are designed as small portable devices. They are used to measure energy use locally or for short periods of time. Products with built-in batteries, etc., are also available, in which case measurements can be made without the need for a power supply. They can also be used to measure the power consumption of household appliances and office equipment.

*Including some distributors, etc.

Sort by Features

Sort by Area

EpiSensor was founded in 2007 and is a developer, manufacturer, and supplier of wireless sensors and infrastructure headquartered in Munster, Ireland. It offers the EpiSensor Gateway (ZGW), designed to build a wide range of IoT solutions, including energy monitoring and management, demand response, asset tracking, and industrial automation. It also provides wireless sensors, including the Demand Response Controller, Wireless Electricity Monitor, Analogue Signal Sensor, and Modbus Interface. The company adheres to CE, RoHS, WEEE, and FCC standards. It serves commercial and industrial sectors in over 20 countries to improve energy performance, lower energy costs, and reduce environmental impact.

Pressac Communications Limited., founded in Bilborough, Nottingham, in 1950 is a manufacturer of smart-building IoT and connectivity technology. The company's product portfolio includes Energy monitoring sensors, Environmental monitoring sensors, Occupancy monitoring sensors, IAQ sensors, and Room Conditions Sensors. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and Power Generation. The company has 5,000 sqm manufacturing facility that is ISO quality and environmental management assured.

Xiamen ZTC Technology Co., Ltd (Zentar), established in 1993, is a manufacturer of current transformers, based in Xiamen, China. With over 30 years of expertise, they have over 250 dedicated workers produce more than 2000 customized products for electrical safety and electric measuring needs of their customers. The company has an ISO 9001, ISO 14001, and IATF16949 certified factory. Their processes are not only UL ETL CE CCC certified but also in compliance with RoHS REACH. They manufacture advanced current transformers for EV charging modules, GFCI, RCD, and wireless energy monitors, contributing to safer electrical practices.

SHENZHEN SAILWIDER ELECTRONICS CO. LTD. is a developer and manufacturer of energy monitoring and control systems founded in 2004 in Guangdong, China. The company specializes in wireless energy-saving monitoring, IHD monitoring integration for smart meters, and solar inverters. Its product line includes unidirectional and bi-directional electricity energy-saving monitors, sensor terminals, wireless switch sockets, and centralized power-saving management systems. The company adheres to ISO 9001:2005, ISO/TS 16949:2009, ISO 14001:2009, and ISO 13485:2010 quality management systems. It serves the electronics sector to minimize energy consumption and reduce environmental pollution.

Omron Corporation, started in 1933 and headquartered in Kyoto, Japan, is a manufacturer of automation components, equipment, and systems, and it developed the first contactless proximity switch in 1960. It has four domains, including industrial automation, electronic components, healthcare, and social systems, and it provides products and services in around 120 countries and regions. Some of its products include microsensing devices, access control systems, industrial robots, surveillance cameras, and blood pressure monitors. In 1971, it developed the first online cash machine, and in 1972, it established Japan’s first welfare factory.

SMARTech Energy was founded in 2014 and is a developer and manufacturer specializing in energy management and reduction for commercial businesses and organizations based in Wiltshire, UK. The company offers the Energy Efficiency-as-a-Service program, designed to overcome financial and logistical barriers to reducing energy consumption, costs, and carbon. It also provides the Eniscope energy monitor and the management software for commercial vehicles called SMARTdrive. The company delivers and installs over 33 energy-efficient technologies, like solar panels, energy monitoring systems, heating solutions, power optimization, and LED lights. It caters to various industries, including food manufacturing, farming, and education.

Energy Team, established in 1996, is an Italian developer, manufacturer, and supplier of energy monitoring, management systems and renewable energy solutions headquartered in Milan, Italy. The company provides a range of services, including energy audits, energy efficiency design and implementation, and energy monitoring systems. It also offers power plant controllers, energy management software, and various renewable energy solutions. The company is certified with ISO 9001, ISO 50001, ISO 14001, and CEI 11352, and it is affiliated with Renantis, a global developer of onshore wind farms, solar PV plants, floating offshore wind farms, and energy storage facilities.

Scitec Instruments Ltd is an ISO 9001:2015-certified manufacturer and distributor of photonic products that was established in Taunton, Somerset, United Kingdom, in 1983. The company’s products include lock-in amplifiers for measuring sensitive signals with noise rejection, optical choppers for modulating beams of light at user-specified frequencies, and energy meters for analyzing laser power output. The company also provides custom design and development services for its clients in research and educational institutions and the industrial sector.

Phoenix Contact is headquartered in Blomberg, Germany, originally founded in 1923. Phoenix Contact’s Israeli subsidiary was founded in 2006 and located in Quadima Tzoran. Phoenix Contact provides tools and components for e-mobility, power, infrastructure, process industry, production manufacturing, system manufacturing, and others. Phoenix Contact’s product lines include automate including cloud computing, connect including PCB terminal blocks, “mark, assemble, and install” including hand tools, “supply, charge, and protect” including power distributors, and “switch, measure, and monitor” including relays and optocouplers.

Aris Engineers, founded in 2016, is a manufacturer, supplier, and distributor of control panels, temperature scanners, and digital temperature indicators located in Gujarat, India. The company's product line consists of electromagnetic water flow meters, temperature controllers, pressure gauges, digital pyrometers, and wireless data loggers. It also offers automatic meter reading systems and energy monitoring software. The company's products and solutions are utilized in power generation, manufacturing, pharmaceutical, oil and gas, and chemical industries. It deals with brands such as Aster, WEST, and Ness and exports to Bangladesh, Nepal, Turkey, Oman, and Thailand.

Rockwell Automation, Inc. was founded in 1903 and is headquartered in Milwakee, WI. Rockwell Automation provides industrial automation and digital transformation solutions around the world. Rockwell Automation operates through their intelligent devices, software & control, and lifecycle services segments with both hardware and software products and services. The Intelligent Devices segment offers drives, motion, safety, sensing, industrial components, and configured-to-order products. The Software & Control segment provides control and visualization software and hardware, information software, and network and security infrastructure solutions. The Lifecycle Services segment provides consulting, professional services and solutions, and connected and maintenance services through independent distributors.

With over 35 years of experience, Algodue Elettronica has specialized in the design and manufacture of instruments for the measurement of energy, the monitor of electrical usage, and the analysis of energy power quality for low voltage systems. Starting with the in-house development of our products, we provide technical knowledge and consulting service to research and realize custom-made solutions according to special requirements. Every instrument from Algodue product range allows an efficient and performative measurement of power consumption, and establish the actions needed to reduce energy costs. Each instrument covers multiple requirements coming from the main sectors like industry, manufacturing, commercial, residential, and the ever-increasing renewable energies. Algodue supports all customers with a dedicated team of specialized technicians and engineers for pre-sale consultancy service for device adaptation and design of specific projects, and after-sale activities to follow every request of support and service. We invest 10% of our yearly profit on research and innovation,to guarantee customers with always up-to-date solutions in line with the latest market trends.

Ranking as of July 2025

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Energy Team |

12.7%

|

| 2 | Algodue Elettronica s.r.l. |

12.7%

|

| 3 | SMARTech Energy |

12.3%

|

| 4 | SHENZHEN SAILWIDER ELECTRONICS CO., LTD. |

10.0%

|

| 5 | Xiamen ZTC Technology Co., Ltd |

9.1%

|

| 6 | Rockwell Automation |

7.3%

|

| 7 | Omron |

6.8%

|

| 8 | PHOENIX CONTACT |

6.4%

|

| 9 | EpiSensor |

5.9%

|

| 10 | Aris Engineers |

5.5%

|

Derivation Method

The ranking is calculated based on the click share within the energy monitor page as of July 2025. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United Kingdom

United Kingdom

|

2 | 25.0% |

China

China

|

2 | 25.0% |

Ireland

Ireland

|

1 | 12.5% |

Japan

Japan

|

1 | 12.5% |

Germany

Germany

|

1 | 12.5% |

Italy

Italy

|

1 | 12.5% |

35 products found

35 products

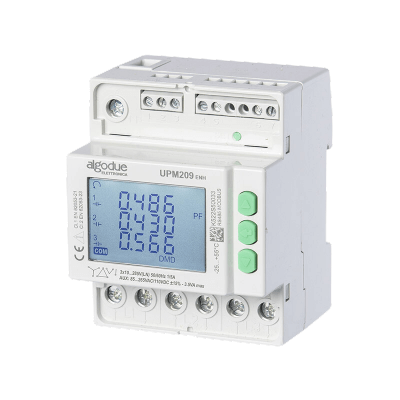

Algodue Elettronica s.r.l.

500+ people viewing

UPM209 is an innovative power meter for measuring and recording electrical parameters. It is suitable for analysis and management of consumption, e...

2 models listed

Custom Co., Ltd.

540+ people viewing

Last viewed: 7 hours ago

Started power saving by knowing the amount of electricity used. "Eco Keeper®" that can measure electricity power by simply connecting an outlet and...

Algodue Elettronica s.r.l.

680+ people viewing

Last viewed: 16 hours ago

UPM309 is an innovative network analyzer that measures and records electric parameters. It is suitable for analysis and management of consumption, ...

2 models listed

SIRC

270+ people viewing

Last viewed: 9 hours ago

■Summary ・Send measurement data via LTE communication ・Can be connected to up to 20 sensors ・SIRC cloud dedicated gateway ■SIRC cloud dedicated...

Cybercraft Co., Ltd.

390+ people viewing

■ Overview ・ Cybercraft's power consumption monitor “Watt-Monitor” will help you solve your concerns about power. ・ It is a device that intensive...

Shinei Electronic Measuring Instruments Co., Ltd.

280+ people viewing

Last viewed: 14 hours ago

■SUN-A4,A3,A2,A1 LED display type power generation monitor Can be connected to any solar cell manufacturer, analog & RS-485 connection ■With data ...

Cybercraft Co., Ltd.

430+ people viewing

Last viewed: 6 hours ago

■ Overview ・ Cybercraft's power consumption monitor “Watt-Monitor” will help you solve your concerns about power. ・ It is a device that intensive...

Algodue Elettronica s.r.l.

710+ people viewing

Last viewed: 1 day ago

UPM209 is an innovative power meter for measuring and recording electrical parameters. It has a good quality-price ratio and is particularly suitab...

2 models listed

Algodue Elettronica s.r.l.

700+ people viewing

Last viewed: 17 hours ago

UPM309 is an innovative network analyzer for measuring and recording electrical parameters. It has a good quality-price ratio and is particularly s...

2 models listed

Cybercraft Co., Ltd.

280+ people viewing

Last viewed: 11 hours ago

■Details Added a function to monitor the AC current waveform to monitor and improve the power factor. Displays 2 channels of voltage and current wa...

Irie Co., Ltd.

200+ people viewing

Last viewed: 8 hours ago

■PLUS 2 Power & Energy Meter (Display) The Plus 2 is a handheld, lightweight touchscreen meter designed by Laserpoint to measure the optical power/...

Codec Co., Ltd.

270+ people viewing

Last viewed: 8 hours ago

Energy Saving Monitor" is a system that encourages power saving by measuring the power consumption in general households, etc., and displaying the ...

TAIYO Co., Ltd.

260+ people viewing

Last viewed: 5 hours ago

It is a master unit programmed with IQANdesign and can be used in combination with various expansion modules. A joystick or sensor is connected to ...

Sky Electronics Co., Ltd.

280+ people viewing

Last viewed: 23 hours ago

This bicycle generator for energy training My Challenge has the following features. With eight 60W bulbs (100W bulbs available) as the load, the n...

CAREL Japan Co., Ltd.

130+ people viewing

Last viewed: 1 day ago

It is a measuring device that senses the main electronic parameters and the consumption of the connected load. ■By recording consumption and provi...

CAREL Japan Co., Ltd.

140+ people viewing

Last viewed: 20 hours ago

It is a measuring device that senses the main electronic parameters and the consumption of the connected load. ■By recording consumption and provi...

CAREL Japan Co., Ltd.

160+ people viewing

Last viewed: 9 hours ago

CAREL products for energy control and monitoring encompass a wide range of products designed to significantly reduce energy waste and reduce end-us...

CAREL Japan Co., Ltd.

150+ people viewing

This product series is a lighting and non-food equipment control and monitoring solution that significantly reduces energy waste, resulting in cost...

CAREL Japan Co., Ltd.

180+ people viewing

Last viewed: 6 hours ago

The rTM system establishes a new product code because the improvements introduced regarding the ZigBee wireless communication protocol are not comp...

CAREL Japan Co., Ltd.

180+ people viewing

Last viewed: 1 day ago

The rTM system establishes a new product code because the improvements introduced regarding the ZigBee wireless communication protocol are not comp...

Nippon Weidmuller Co., Ltd.

260+ people viewing

Last viewed: 30 minutes ago

■Automation through innovative engineering Weidmüller's u-create software prepares you for a wide range of applications, including the implementati...

Nippon Weidmuller Co., Ltd.

240+ people viewing

Last viewed: 1 day ago

■Introducing Weidmüller's comprehensive expertise into your energy management system Energy management is the recording of all relevant energy cons...

Shinei Electronic Measuring Instruments Co., Ltd.

220+ people viewing

Last viewed: 12 minutes ago

◼︎Waterproof solar power monitoring device - Can be connected to any solar cell manufacturer, analog & RS-485 connection ・With data logger functio...