All Categories

History

This section provides an overview for film inspection machines as well as their applications and principles. Also, please take a look at the list of 11 film inspection machine manufacturers and their company rankings. Here are the top-ranked film inspection machine companies as of February, 2026: 1.Dimatra, 2.TAKANO CO.,LTD., 3.COLLIN Lab & Pilot Solutions GmbH.

Table of Contents

Categories Related to Film Inspection Machines

A film inspection device is a device that inspects for defects that occur during the production of sheets and films.

A film inspection device is a device that inspects for defects that occur during the production of sheets and films.

In our daily lives, films and sheets are used for foodstuffs, home appliances, household goods, and many other applications. On the other hand, most of them are made very thin. However, they are strong enough and do not tear easily.

By adding a film inspection machine to the production line, defects can be inspected during production to ensure that the sheet is up to standard.

A film inspection machine is mainly used to check and inspect sheets for various defects and deficiencies in the manufacturing process. Film inspection machines are installed at various stages of the sheet manufacturing process.

In the film forming process, they inspect the base resin for contamination and fish eyes. In the laminating process, they inspect for inclusions and wrinkles. In the coating process, they inspect the application of chemicals. In the slitter and inspector processes, they perform final shipping inspections. Finding various defects in the manufacturing process is effective in maintaining product quality, preventing defects in subsequent processes, preventing yield loss, and improving productivity.

In recent years, the system has also been used to inspect optical sheets, multilayer sheets, high-performance sheets, coated paper, flooring materials, glass sheets, metal foil sheets, nonwoven fabrics, etc., for defects that are difficult to see with the naked eye.

Although there is no clear definition, the difference between a sheet and a film is often distinguished by their thickness. In this section, all descriptions are for "sheets."

Sheets are manufactured from resins, such as polyethylene using an extruder. In this process, the sheet is stretched from a T-die into a thin slit, cooled by a cooling roll, and wound up by a winder to be completed as a product.

This is called the T-die method. Another method is the inflation method, in which air is used to inflate the sheet into a bag-like shape after cooling to make two overlapping sheets.

In the process of manufacturing these sheets, various defects such as thickness variation, color irregularity, fisheye, foreign matter such as dust and oil adhesion, wrinkles and stripes, scratches, pinholes, stains, and filling defects occur. Film inspection machines detect these defects.

In camera-based inspection, an area camera is used to view the entire area to be inspected, and a line camera is used to inspect the line to be inspected all at once. A line camera is best suited for continuous inspection in a line where sheets are flowing.

Multiple high-resolution line cameras are installed in the sheet width direction, and the sensitivity threshold of each camera is set according to the variation in the sheet geometry. Another method is to use a single scanning camera and inspect by high-speed scanning.

It is also important to select an inspection device according to what is to be inspected, such as a device that inspects thickness using a laser beam and a reflective laser displacement meter.

The purpose of installing film inspection machines is to ensure the detection of defects by mechanizing inspections, to improve product quality by reducing human errors, and to increase productivity.

High-Speed Inspection of Sheet Defects

The system consists of three-line cameras, transmissive and reflective LED line lighting, etc. Two cameras are used to inspect the front and back surfaces of the sheet, and one camera is used to inspect and detect defects at high speed using transmissive and reflective LED line lighting.

Detection of Uneven Coating Defects

When coating a sheet, slight variations in thickness can cause uneven coating defects. Film inspection machines using a multi-wavelength camera can clearly detect uneven coating due to the difference in color components.

Wrinkle Defect Detection

When manufacturing transparent sheets, wrinkle defects may occur due to sheet warpage. Wrinkle defects are difficult to detect with monochrome images because the difference between a flat surface and a defect is small. Wrinkle defects can be detected clearly by acquiring RGB images using a multi-wavelength camera.

Discrimination of Foreign Matter and Air Bubbles

When laminating sheets, it is necessary to distinguish slight air bubbles from foreign matter. In monochrome inspection, shiny foreign matter and bubbles cannot be discriminated because they are the same light defect.

However, inspection with a multi-wavelength camera can detect differences in shading information, making it possible to discriminate between them.

*Including some distributors, etc.

Sort by Features

Sort by Area

Nireco, founded in 1950 and based in Tokyo, Japan, is a manufacturer of control, measurement, and inspection equipment. Its offerings are crucial to the manufacturing processes of various industries, spanning steel, chemicals, food, and printing, enabling businesses to maintain consistent production standards and meet regulatory requirements. These encompass process control systems, automatic marking systems, web control systems, laser devices, and optical equipment. The company has earned ISO9001 certification for all web controllers gained.

Otsuka Electronics, established in 1970, is a manufacturer and supplier based in Osaka, Japan, specializing in optical, medical, and industrial measurement devices. The company's product portfolio spans a broad spectrum of optical, medical, and industrial measurement devices and equipment. Emphasizing advanced technology, Otsuka Electronics provides solutions tailored to various sectors, including medical, pharmaceutical, and electric-related precision devices. With a global network of affiliate companies, Otsuka Electronics supports businesses in the health and medical industry worldwide.

K M Trivedi Engineering Pvt. Ltd., established in 1985 and based in Ahmedabad, Gujarat, India, is a manufacturer, supplier, and distributor of slitting and roller machines. Its product comprises of several machines, including drum sitting, stretch wrapping, and HDPE woven sack rewinder folding machines, serving various industrial applications such as manufacturing, packaging, and material processing. The company's products are generally used for positioning and handling industrial drums, securing pallet loads for transportation, and also for inspecting and rewinding materials.

TAKANO CO.,LTD., established in 1941 and located in Tokyo, Japan, is a developer and manufacturer of inspection and measurement systems. The company offers a range of products that include FDM, films, energy,and semiconductors. These systems are used for inspection, measurement, quality control, and research purposes in industries including electronics, automotive, energy, semiconductor, and medical sectors. TAKANO's solutions are used for ensuring product quality, optimizing manufacturing processes, and supporting research and development efforts in diverse applications.

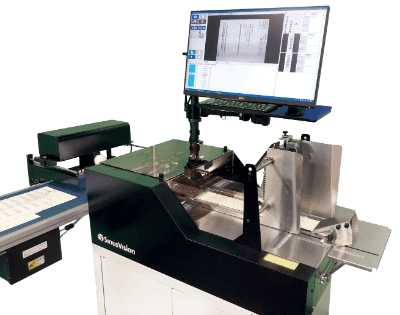

SiriusVision Co. Ltd., established in 1966 and headquartered in Yokohama City, Japan, is a visual inspection and software designer and manufacturer. The company's products include container inspection machines, plate inspection systems, and substrate inspection machines. It also offers seal label inspection machines, conveyor belt automatic inspection machines for single-wafer labels, cards, and sheets, and independent inspection units that include cameras and lighting equipment and can be customized to meet custom requirements. The company's machine vision system software includes the easy-to-use AsmilVision and the more sophisticated FlexVision.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Dimatra |

14.9%

|

| 2 | TAKANO CO.,LTD. |

12.4%

|

| 3 | COLLIN Lab & Pilot Solutions GmbH |

9.9%

|

| 4 | Nireco |

9.9%

|

| 5 | K M Trivedi Engineering Pvt. Ltd |

9.1%

|

| 6 | OTSUKA ELECTRONICS CO.,LTD |

9.1%

|

| 7 | QVision Systems |

7.4%

|

| 8 | Ruian Maoyuan Machine Co.,Ltd |

7.4%

|

| 9 | Sirius Vision |

7.4%

|

| 10 | Webcontrol Machinery Corp |

6.6%

|

Derivation Method

The ranking is calculated based on the click share within the film inspection machine page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

Japan

Japan

|

3 | 30.0% |

India

India

|

2 | 20.0% |

China

China

|

2 | 20.0% |

Mexico

Mexico

|

1 | 10.0% |

Germany

Germany

|

1 | 10.0% |

Taiwan

Taiwan

|

1 | 10.0% |

28 products found

28 products

TAKENAKA SYSTEM CO.,LTD.

890+ people viewing

Last viewed: 1 day ago

overview This is a defect detection device that can be connected to the TLC-7300UCL of the Camera Link output color line scan camera with our high-...

Media Institute Co., Ltd.

710+ people viewing

■Product overview Dr.Schenk provides over 16,000 testing solutions worldwide. Inspection and measurement solutions implemented vary by region and c...

Frontier System

380+ people viewing

Last viewed: 8 hours ago

It is a monochrome surface defective test system equipped with a key emphasis system XG-X2800/XG-X2900. With a stable and high performance and perf...

TAKENAKA SYSTEM CO.,LTD.

820+ people viewing

overview ・ It is a defect detection device for line scan cameras for high -speed and high -resolution. ・ It can be connected to a Camera Link outpu...

Frontier System

290+ people viewing

It is a monochrome surface defect test system with excellent PC -based scalability. A high -precision defect test is realized by combining a line s...

TAKENAKA SYSTEM CO.,LTD.

790+ people viewing

overview This device detects various drawbacks of transparent or non -transparent sheets using a line scan camera online. ・ Each drawback of direct...

Pacific System Co., Ltd.

740+ people viewing

Last viewed: 1 day ago

Detects everything from minute defects to low-contrast unevenness with high precision. We will propose inspection equipment that can meet your need...

C.C.D. Co., Ltd.

640+ people viewing

Last viewed: 1 day ago

■Summary ・Automatic inspection of sheet products using CCD line camera ・Detects defects such as scratches, dirt, and unevenness ・Supports inspec...

Opcell Co., Ltd.

530+ people viewing

This is a third observation device that is neither a microscope nor a CCD camera. This is a device that takes images of large areas at high speed u...

Sensor Technology Co., Ltd.

610+ people viewing

Last viewed: 1 day ago

■Overview This device places a measuring object to detect pinholes between an electrode to which a high voltage is applied and a ground-side electr...

SANKO ELECTRONIC LABORATORY CO.,LTD

710+ people viewing

As an example of a high -voltage discharge pin hole checker, we will introduce film and sheets. The sheet composition container may cause pinholes...

Hexagon AB

200+ people viewing

■Summary HxGN Visual Detection is an automated surface inspection application that can detect defects in a wide range of materials including glass,...

Irie Co., Ltd.

170+ people viewing

Last viewed: 1 day ago

■Features Anyone can easily detect defects that are invisible or difficult to see with the naked eye when inspecting defects inside transparent obj...

CHUO ELECTRIC WORKS L.T.D

600+ people viewing

This is a two-dimensional inspection device that uses a high-resolution camera and a high-precision X-Y stage. Suitable for inspecting surface scra...

Hubrain

750+ people viewing

・ The black spot and dirt of the plain sheet that flows continuously is detected by image inspection. ・ Fish eagle detection of resin sheet is also...

Fukase Shoji Co., Ltd.

700+ people viewing

Last viewed: 14 hours ago

The PDC-F inline pinhole detector is a device that safely and reliably detects pinholes in moving films and sheets. Fault sensors for defect detect...

SANKO ELECTRONIC LABORATORY CO.,LTD

510+ people viewing

■ Features The pinhole automatic continuous detection device is manufactured with an insulation film, lining membrane, taping membrane or other ins...