All Categories

History

This section provides an overview for cleanrooms as well as their applications and principles. Also, please take a look at the list of 12 cleanroom manufacturers and their company rankings. Here are the top-ranked cleanroom companies as of February, 2026: 1.Allied Cleanrooms, 2.aes Clean Technology, 3.Clean Air Products.

Table of Contents

Categories Related to Cleanrooms

A cleanroom is a room in which the cleanliness of the air is controlled.

A cleanroom is a room in which the cleanliness of the air is controlled.

A cleanroom is a space in which airborne particles and microorganisms are controlled to a cleanliness level below a certain level. Materials, chemicals, and water supplied to the room are also maintained at the required cleanliness level, and environmental conditions such as temperature, humidity, and pressure are controlled as needed.

The cleanliness of the air can be checked by counting the size and number of particles in the air using particle sensors. Cleanrooms are used in the manufacture of products where dust and particulates are a major problem. Cleanrooms are called by various names, such as dust-proof rooms, sterilization rooms, and bio-clean rooms, depending on the intended use.

Cleanrooms are used in the manufacture of industrial products such as semiconductors, liquid crystals, and electronic components. This is because even the smallest dust particles can have a significant impact on product quality.

Especially in the front-end process of semiconductors, cleanrooms with the highest level of cleanliness, Class 1 to 10 in the US Federal Standard, and Class 3 to 4 in the ISO standard, are used. Factories that manufacture precision equipment, such as electronic components and optical machinery, and factories that handle chemicals and food products, require ISO Class 5 to 7 cleanrooms.

Cleanrooms are also widely used in other industries, such as printing, paint, lenses, and films.

Cleanrooms maintain cleanliness by preventing particulates of human origin from entering the room and by capturing them with high-performance filters. In order to maintain the cleanliness of a cleanroom, it is first necessary to reduce the amount of dust, germs, sweat, hair, and other debris emitted by humans.

Depending on the required level of cleanliness, workers change into special white dustproof clothing and shoes, put on gloves, and wear caps to keep hair out. In addition, safety glasses and masks may be used. When entering the cleanroom, the workers are given an air shower to wash the dust from their bodies.

The air taken in through the intake ports in the cleanroom is circulated and purified of particulates and other contaminants by high-performance filters called HEPA filters installed in the air outlets. The cleanliness of the cleanroom can be monitored by a particle sensor.

Cleanrooms are also airtight, and are designed to prevent unnecessary particulates from entering from the outside by adjusting the air pressure in the room.

Cleanrooms can be broadly classified into two types: those used for precision equipment manufacturing, or those used for food production and medical or life science research. Cleanrooms used in medical and life science research institutions are specifically referred to as bio-cleanrooms or sterile rooms.

In industrial applications, dust in the air is expected to be eliminated, but in bioclean rooms, in addition to this, it is necessary to prevent contamination by microorganisms such as bacteria and viruses.

Cleanrooms are further classified according to the number of particles per unit volume of air. In Japan, three types of standards are used for classifying clean rooms: the U.S. Federal Air Ductility Standard (FED), the ISO standard.

U.S. Federal Clean Air Standard FED209E

The U.S. Federal Standard for Air Quality, FED209E, was discontinued in 2001 and replaced by the ISO standard 14644-1, but the industry still uses the widely used FED in many cases.

FED

The FED is classified into six categories, from Class 1 to Class 100,000, with the class number representing the number of particulates per unit volume. In other words, the smaller the class number equates to a higher level of cleanliness.

ISO Standards

ISO standards are further subdivided into nine (ISO) classes, from Class 1 to Class 9, in addition to the six classes corresponding to the FED standards.

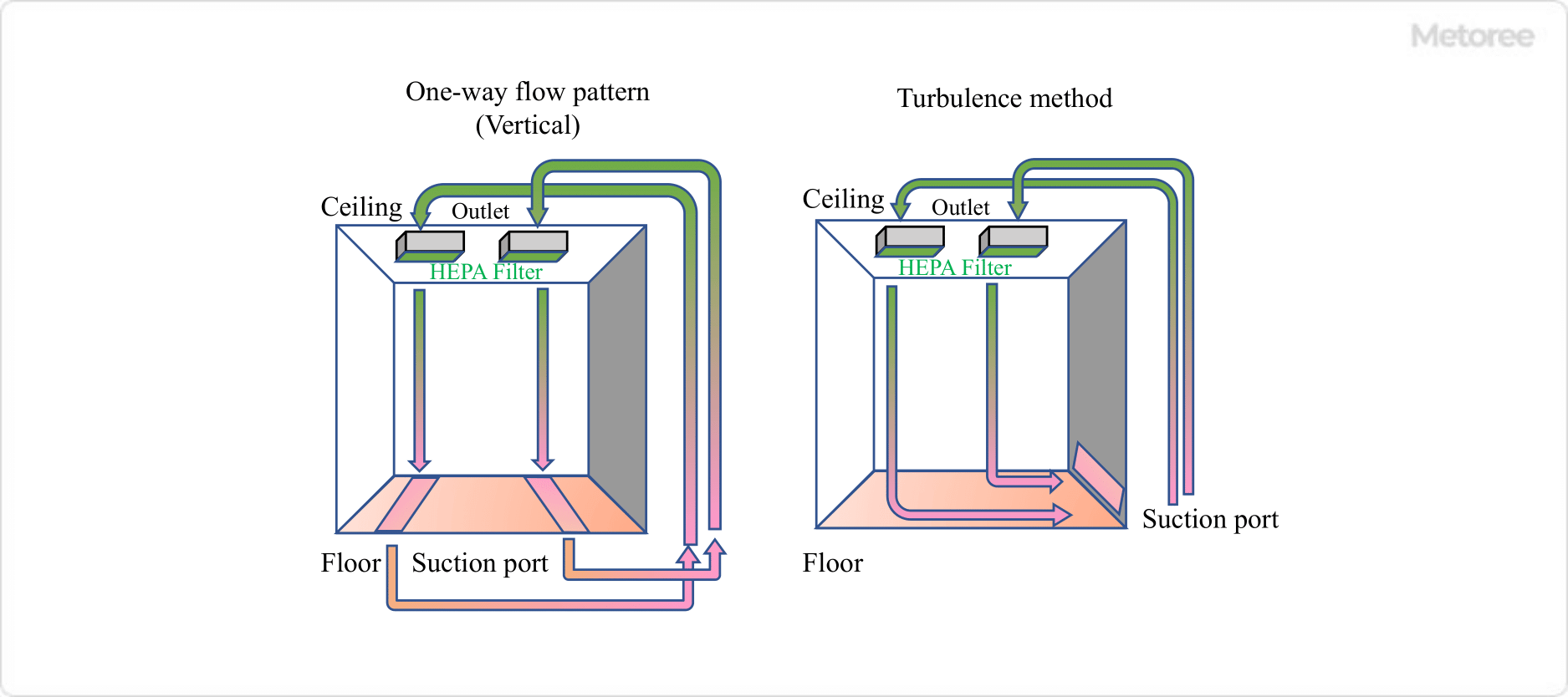

Figure 1. Clean room system

Cleanrooms can be classified into two types according to the way in which air is circulated, i.e., the way in which airflow is created: the unidirectional flow method and the turbulent flow method.

Unidirectional Flow Method

In the one-directional flow method, the air outlets and inlets are installed facing each other to create a uniform air flow. If a ceiling vent and floor inlet are installed, a uniform airflow can be created vertically. If a vent is installed on one wall and an inlet on the opposite wall, a uniform airflow can be created horizontally.

The unidirectional flow method can maintain a high level of cleanliness because the airflow is constantly circulating.

Turbulent Flow Method

The turbulent airflow method is a method in which the air outlets are installed on the ceiling and the intake ports are installed on the wall. Because there are areas where airflow stagnates, the cleanliness is inferior to that of the unidirectional flow method, but the advantage is that it can be introduced and operated at a relatively low cost.

*Including some distributors, etc.

Sort by Features

Sort by Area

Clean Air Products, founded in 1969, is headquartered in Minneapolis, Minnesota, USA, and is a manufacturer of cleanroom solutions. The company's products include laminar flow hoods, modular cleanrooms, FFUs, pass-through chambers, air showers, softwall and hardwall cleanrooms, and workstations. It has received awards such as the prestigious Cleanroom Excellence Award in 2005 and holds certifications like ISO 9001 for quality management. Its products cater to a diverse clientele in critical industries like pharmaceuticals, electronics, aerospace, and healthcare.

AES Clean Technology was established in 1986 as a manufacturer of designer cGMP modular cleanroom solutions with headquarters in Montgomeryville, PA. The components include Modular walls, ceilings, and LED lighting systems used in the semiconductor, pharmaceutical, biotechnology, microelectronics, and life science industries. The company offers installation, project management, and in-house services for cleanroom products. It acquired Unified Building Systems to provide onsite labor to consumers in North and South America and Europe in 2013.

Allied Cleanrooms has been a manufacturer and supplier of turnkey cleanroom solutions since 1989, with manufacturing facilities in Texas, California, and Tennessee. The company manufactures soft wall, modular, and hard wall cleanrooms, specializing in class 10 to class 100,000 cleanrooms. The equipment is used in test chambers, storage rooms, laboratories, controlled rooms, and laser rooms in the pharmaceutical, biosafety, research, microbiology, and medical industries. The cleanrooms are environmentally friendly, reusable, reconfigurable, and meet the regulatory compliance line USP 797.

CLEAN AIR TECHNOLOGY, INC.,established in 1982 and headquartered in Canton Town, Michigan, USA, is a manufacturer of advanced cleanroom, air purification, and filtration products. The product range includes air purifiers, filtration systems, and HVAC upgrades that offer improved indoor air quality, reducing pollutants, allergens, and contaminants. These products find application across industries such as healthcare, commercial, residential, and industrial sectors. By providing superior air purification systems, the company plays a crucial role in various industries, helping to improve the health, productivity, and well-being of building occupants.

Atmos-Tech Industries is a designer and manufacturer of controlled environment and cleanroom products based in New Jersey, United States. Atmos-Tech specializes in the design and manufacture of contamination control equipment such as the AC Absolute Console Series Laminar Flow Bench which provides and maintains the necessary environment required in the electronics and pharmaceutical industries. Other products include Air and Misting showers, Cleanroom Filtration and HEPA Filters, and Through Wall Pass-Thru Systems for maintaining air pressure and minimizing particle migration.

Technical Air Products, founded in 1992 in Belmont, Michigan, USA, is a manufacturer of cleanroom products for various industries. The company manufactures a range of product varieties including modular cleanrooms, rigidwall cleanrooms, softwall cleanrooms, and pass-through chambers. These products offer controlled environments that ensure the optimum levels of cleanliness, particle control, and contamination prevention. The products find applications in industries such as pharmaceuticals, biotechnology, electronics, and healthcare, where stringent environmental control is necessary for research, manufacturing, and production processes. It delivers state-of-the-art cleanroom solutions tailored to the unique needs of its diverse clientele.

Clean Rooms International, Inc. established in 1982 in Grand Rapids, Michigan, USA, is a manufacturer of modular cleanroom products. The company produces a comprehensive range of product varieties, including modular hardwall cleanrooms, softwall cleanrooms, and ISO Class 5-8 cleanrooms. These solutions provide controlled environments that prevent contamination, ensuring paramount quality standards for sensitive processes. The products cater to industries like pharmaceuticals, electronics, aerospace, and healthcare, where maintaining a clean and controlled environment is critical. The company's customization, quality, and technological advancement help in energy efficiency, sustainability, safeguarding product integrity and personnel safety.

Abtech, Inc., established in 1992, is a manufacturer of modular cleanroom buildings, mezzanines, and related equipment based in California, USA. The company specializes in producing environmentally controlled modular cleanrooms, offering both prefabricated and custom turnkey solutions. Its product range includes hardwall cleanrooms, and softwall cleanrooms, featuring advanced temperature and humidity control capabilities. Alongside cleanroom structures, the company manufactures an array of related equipment, including laminar flow benches, air showers, and various cleanroom accessories.

NORTEK AIR SOLUTIONS, established in 1977 and headquartered in St. Louis, Missouri, is a premier provider of advanced air management solutions. Specializing in HVAC systems, the company offers a comprehensive product range including air handlers, fans, and ventilation systems, vital for ensuring optimal indoor air quality and climate control in diverse applications. Its solutions are integral to various industries, from commercial buildings and healthcare facilities to data centers and industrial settings. NORTEK AIR SOLUTIONS' promise to modern technology and sustainability underscores their role as a spearhead in creating efficient and comfortable environments globally.

Subzero Engineering, founded in 2005 and headquartered in Salt Lake City, Utah, is a manufacturer of data center containment solutions and is part of Senneca Holdings. The company makes modular cleanroom enclosures, vinyl curtains, and containments for data centers and cleanrooms. It tests simplex vinyl materials for conditions like fire retardancy, outgassing, and sound reduction and makes the results available. It can also offer turn-key solutions to customers in a bundled service from implementation to long-term maintenance. The company serves several industries like electronics manufacturing, food preparation, and pharmaceutical compounding and also offers services such as consultation, optimization, and installation.

MECART Cleanrooms, established in 1974 in Quebec, Canada, is a manufacturer of advanced modular cleanroom and noise control products. The company manufactures a diverse range of product varieties, including modular cleanrooms, softwall cleanrooms, and hardwall cleanrooms. These solutions offer robust control over environmental factors such as temperature, humidity, and particle levels, ensuring optimal conditions for sensitive processes. The products find applications in industries such as pharmaceuticals, biotechnology, electronics, and research, where stringent cleanliness and controlled environments are vital. With advanced expertise, the cleanrooms deliver customized solutions designed to meet specific requirements, maintaining optimal levels of quality and compliance.

Modular Cleanrooms Inc., founded in 1994 and based in Denver, Colorado, is a supplier of Modular and Portable cleanrooms. The company has been a supplier of cleanroom and cleanroom components to the pharmaceutical, medical device, aerospace, mold injection, optics and military industries. It offers various designs of cleanrooms such as softwall, hardwall, bio-clean and micro-clean cleanrooms that can be custom designed for specific industry needs. The company also offers a full line of consumable products to complete the cleanroom such as disposable garments, gloves, shoe covers, wipers and mops.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Allied Cleanrooms |

15.8%

|

| 2 | aes Clean Technology |

11.6%

|

| 3 | Clean Air Products |

11.2%

|

| 4 | Atmos-Tech Industries |

9.1%

|

| 5 | CLEAN AIR TECHNOLOGY,INC. |

8.4%

|

| 6 | Clean Rooms International, Incorporated |

7.7%

|

| 7 | NORTEK AIR SOLUTIONS |

7.3%

|

| 8 | Abtech Incorporated |

6.3%

|

| 9 | Technical Air Products |

6.2%

|

| 10 | Modular Cleanrooms Inc. |

6.0%

|

Derivation Method

The ranking is calculated based on the click share within the cleanroom page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

9 | 100.0% |

73 products found

73 products

Magnetic Research Institute Co., Ltd.

300+ people viewing

Last viewed: 1 day ago

■Features The 12-inch mini portable cleanroom hood creates a compact positive pressure environment for applications that require a clean workspace....

Sun Wise Co., Ltd.

810+ people viewing

Last viewed: 7 hours ago

Anyway, it is a light ultra -light steel door. It is half the weight compared to a general lightweight steel door, and it is a utility door for gen...

Toyoshima Electric Co., Ltd.

440+ people viewing

Last viewed: 3 hours ago

■Line-type clean room system enables easy construction, short delivery times, and low prices. A clean room is a room in which air cleanliness is ma...

Tanimura Co., Ltd.

420+ people viewing

Last viewed: 16 hours ago

■Features ・This product uses clean fabric HM-CLC. ・This fabric is also used for clean room wear. ・Uses carbon thread with excellent conductivity...

Yoshida Kogyo Co., Ltd.

380+ people viewing

Last viewed: 1 day ago

■Surprising ventilation speed. Create a clean space in about 1 minute Can be used in high temperature (80℃) to low temperature (-20℃) environments....

NCC Co., Ltd.

580+ people viewing

Last viewed: 8 hours ago

Overview ■Reduce the amount of fiber waste that gets into the work to "zero" as much as possible.For hand-held work such as assembly, inspection, a...

Kakino Seisakusho Co., Ltd.

420+ people viewing

Last viewed: 1 day ago

A system house that enables the production of sterile products through the sixth industrial processing of agricultural products. ■Features ・Suita...

Idea Manufacturing

320+ people viewing

Features ■Initial installation and running costs are overwhelmingly low Generally, constructing a clean room costs a lot of money. Also, to maintai...

10 models listed

Magnetic Research Institute Co., Ltd.

300+ people viewing

Last viewed: 1 day ago

■Features The 18-inch wide mini portable cleanroom hood creates a compact positive pressure environment for applications that require a clean works...

Tanimura Co., Ltd.

380+ people viewing

Last viewed: 16 hours ago

■Features ・This fabric is also used for clean room wear. ・Uses carbon thread with excellent conductivity, so it does not get charged. ・Approxima...

Magnetic Research Institute Co., Ltd.

330+ people viewing

Last viewed: 6 hours ago

■Features The 24-inch wide portable clean room hood creates a compact positive pressure environment for applications that require a clean workspace...

Yoshida Kogyo Co., Ltd.

390+ people viewing

Last viewed: 1 day ago

Can be switched between negative pressure and positive pressure depending on the situation ■TYPE-A Preventing mass infections and secondary damage...

Magnetic Research Institute Co., Ltd.

280+ people viewing

Last viewed: 1 day ago

■Features The 40-inch wide portable clean room hood creates a compact positive pressure environment for applications that require a clean workspace...

Tanimura Co., Ltd.

390+ people viewing

Last viewed: 16 hours ago

■Features - Heat-resistant fabric that uses long fibers to suppress dust generation. - Conductive carbon thread is sewn into it so it will not be c...

Tanimura Co., Ltd.

470+ people viewing

Last viewed: 16 hours ago

■Features - Dust-free fabric used for clean room wear. ・Uses carbon thread with excellent conductivity, so it does not get charged. ・Approximatel...

NCC Co., Ltd.

370+ people viewing

Overview ■Easily create a clean environment with an “air barrier” that keeps out foreign substances and is ideal for inspection and packaging proce...

NCC Co., Ltd.

350+ people viewing

Last viewed: 9 hours ago

Overview ■Creating a “no-enclosure” clean environment that changes conventional wisdom ``I don't need such large-scale equipment to create the clea...