27 Clean Room Rag Manufacturers in 2024

This section provides an overview for clean room rags as well as their applications and principles. Also, please take a look at the list of 27 clean room rag manufacturers and their company rankings. Here are the top-ranked clean room rag companies as of July, 2024: 1.High-Tech Conversions, Inc., 2.MicroCare, 3.Contec, Inc..

Table of Contents

What Is a Clean Room Rag?

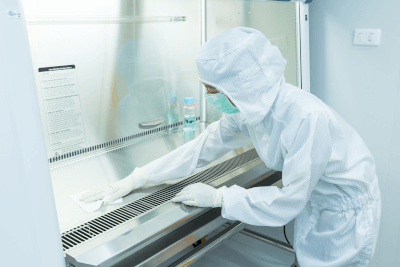

Clean room rags are specialized cleaning materials designed for use in controlled environments, such as clean rooms. These rags are made from special fibers that minimize dust generation, unlike typical rayon rags. They are essential in maintaining the stringent cleanliness standards required in clean rooms by protecting against particle contamination and promoting orderly maintenance.

Additionally, clean room rags are often chemically resistant, highly absorbent, and contain minimal impurities, making them suitable for demanding environments like manufacturing processes.

Applications of Clean Room Rags

Clean room rags are versatile and have various applications:

1. Surface Cleaning

Used for cleaning workbenches and equipment surfaces in clean rooms to remove microscopic particles and dust.

2. Equipment Maintenance

Employed in regular maintenance of clean room equipment and devices to ensure operational accuracy and reliability.

3. Product Assembly

Integral in assembling high-precision products, these rags help in maintaining cleanliness during the assembly process.

4. Cleaning Work

Used for cleaning parts and tools in clean rooms, these rags are effective in removing dirt and drying surfaces after washing.

Principle of Clean Room Rags

Clean room rags are designed to minimize particle generation and contamination. They are typically made from synthetic fibers like polyester, nylon, and polypropylene, chosen for their fine fibers and static resistance. Special fiber processing methods and surface treatments are used to reduce particle shedding and static electricity generation.

How to Select Clean Room Rags

Consider the following when choosing clean room rags:

1. Material

Choose materials that are low in particle generation and static electricity. Consider polypropylene for its lightweight and high absorbency.

2. Cleanroom Class

Select rags compatible with the cleanliness level of your clean room. The class of the clean room dictates the permissible level of particle emissions.

3. Size

Ensure the size of the rag matches the work area and task requirements for efficient and effective cleaning.

List of 27 Clean Room Rag Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- United States of America

- China

- Germany

- India

- Ireland

- Japan

-

-

-

Texwipe

Vertex Dry Cleanroom Wipers

Manufacturer Overview

Texwipe, established in 1964 and based in Kernersville, North Carolina, is a manufacturer of contamination control supplies and critical cleaning products. The company offers a wide range of wipers, swabs, mops, cleaning solutions, and stationery items for use in cleanroom settings. The company creates consumables for the semiconductor, life science, and electrical sectors. The firm has sales offices across North America, Europe, and Asia to service its international clients. It has an ISO 9001:2015 certificate of approval for a quality management system. Modern testing and quality control procedures are used to support all of the products.

-

-

-

-

-

MicroCare

Clean Room Wipes, Premium Grade, Large

Manufacturer Overview

MicroCare is a manufacturer of cleaning, coating, and lubricating fluids, established in 1983 and headquartered in Connecticut, USA. The company’s product line consists of aerosol dusters, degresears, lubricants and coatings, flux removers, and freeze sprays. It also offers high-purity fluids, PCB cleaning tools, and workspace cleaners, along with custom formulations. The company is ISO 9001:2015 certified, FDA registered, and has sub-brands like MicroCare Medical, Sticklers, and Stereze. It serves the electronics, medical, fiber optics, and metal finishing industries in more than 40 countries worldwide.

-

-

-

-

-

Berkshire Corporation

CLEAN ROOM RAGS

Manufacturer Overview

Berkshire Corporation, established in 1960 and based in the US, is a manufacturer of products for critical surfaces and controlled environments worldwide. The company is registered to the ISO9001: 2015 Standard. The company offers everything from eyeglass tissues and wiping materials to face masks, mop systems, swabs, documentation systems, and disinfectants. Beyond the semiconductor industry, the products are used by the biotech, medical device, and pharmaceutical sectors. For its sterilization validation process, the company adheres to ANSI/AAMI/ISO 11137 American National Standards. The company uses statistical process control, or SPC, to determine if a process is functioning within acceptable bounds.

-

-

-

-

-

High-Tech Conversions, Inc.

NOVA SCRUB textured cleanroom wipes

Company Overview

High-Tech Conversions, Inc. is a manufacturer and supplier of cleanroom supplies and cleaning products for various high-tech industries and it is based in Enfield, Connecticut, USA and was established in 1995. The products include cleanroom wipes, gloves, garments, sticky mats, tacky rollers, and stencil wiping rolls. The companies’ products are designed to perform under the challenging industrial applications and are used in controlled environments, PCB assembly lines, laboratories, and manufacturing facilities across the world.

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Cleanroom Connection

CLEANROOM WIPES

Distributor Overview

Cleanroom Connection, established more than a quarter century, is headquartered in Spring Branch, Texas, USA, and is a distributor and supplier of cleanroom supplies and equipment. The company offers a diverse range of critical cleanroom supplies, including apparel, gloves, wipes, disinfectants, and specialized equipment for industries requiring stringent cleanliness standards. It provides personalized account management, expert advice, product samples, backorder prevention, and competitive pricing for superior customer satisfaction. It caters to industries like pharmaceuticals, electronics, and healthcare.

-

-

-

-

-

GUARDNER Corporation

LTK wiper

Manufacturer Overview

Guardner Co. Ltd., founded in 1986 and based in DaimonCho, Kazo, Saitama Prefecture, is a manufacturer of clean and sanitary environment wear. The company specializes in advanced cleanroom apparel and accessories for semiconductors, healthcare, and cosmetics. Its products, such as the AQUA SUNNY series and ADCLEAN shoes, feature technologies for contamination control and user comfort. Its product line also includes photo-deodorant fabrics, air-permeable garments, and low-dust wipers, enhancing cleanroom environments. These products support stringent contamination control and find application across electronics, pharmaceuticals, and nanotechnology sectors. The company also provides operational support with IC tags and comprehensive after-sales services.

-

-

-

-

-

Dastex

cleanroom wipes

Manufacturer Overview

Dastex is a manufacturer of clothing and equipment for cleanrooms and controlled environments that was established in 1979 and is based in Muggensturm, Germany. The company specializes in designing and producing cleanroom garments and accessories. The company's product range includes coveralls, hoods, and gloves, serving industries such as pharmaceuticals, medical devices, and electronics. Dastex offers services like garment customization and cleanroom consultation. Its clothing and equipment help in maintaining a controlled and sterile environment.

-

-

-

-

-

Chemtronics

Coventry Poly-Wipes

Manufacturer Overview

Chemtronics has been a manufacturer of precision cleaning solutions since 1958, in Georgia. The company provides Cleaner Degreasers for precision cleaning, Aerosol Duster for cleaning sensitive electronics, Conformal Coating for maximum PCB Protection, Medical high purity solvents, and Fiber Optic cleaning products amongst other products that are engineered to meet cleaning, coating, and maintenance solutions for the electronics, telecommunications, and critical environments markets. They serve the Aviation, Medical and Biotech, Life Sciences, Electrical Contact Cleaning and Controlled Environment and Cleanroom industries.

-

-

-

-

-

SHIMIZU CORPORATION

Contec Cleanroom Wipes

Manufacturer Overview

SHIMIZU CORPORATION, a company founded in 1804 and headquartered in Chuo-ku, Tokyo, Japan, is a construction and engineering company. The company provides a wide range of construction services, including building construction, civil engineering, and environmental solutions. They also engage in delivering projects that adhere to stringent safety standards. Their services cater to various sectors such as commercial, residential, healthcare, and infrastructure. The company also offers customer services, including consultation, project planning, and post-construction support to meet clients’ requirements.

-

-

-

-

-

Suzhou Jujie Electron Co., Ltd

Cleanroom Wipes

Manufacturer Overview

Suzhou Jujie Electron Co.,Ltd., established in 2009, is a manufacturer of cleanroom consumables headquartered in China. The company’s product line includes cleanroom wipers, sticky mats, and other related products. These products are used by industries worldwide that require controlled environments, such as electronics, semiconductors, pharmaceuticals, and healthcare. It is also sales agent of Kimberly Clark products. It also exports its products to Europe, South America, Africa, the Middle East, Russia, Southeast Asia and other countries, with sales agents in Korea, Vietnam and India.

-

-

-

-

-

ACL Staticide, Inc.

ACL Staticide Low Lint Wipes

Manufacturer Overview

ACL Staticide, Inc., founded in 1960 with headquarters in the USA, is a manufacturer of static control products and PCB cleaning and repair chemicals. The company's products include anti-static liquid concentrates, anti-static ESD packaging, anti-static workbench tools, and anti-static wearables such as gloves. ACL Staticide, Inc.'s products are used across a diverse range of industries, including the automotive, electronics, medical device, and telecommunications markets. The company's quality control management system is ISO 9001:2015 certified.

-

-

-

-

-

Contec, Inc.

Wipes

Manufacturer Overview

Contec Cleanroom, established in 1988 and based in Spartanburg, South Carolina, is a manufacturer of contamination control products. The company's product portfolio includes swipes, swabs, disinfectants, wipes and mopping systems. These products are used in life sciences, aseptic services, microelectronics and semiconductors, and industrial cleanrooms. Additionally, the company also enacts renewable energy and has 2888 solar panels that supply power to its facilities. In 2022, EcoVadis, a company that advocates for corporate sustainable goals, gave Contec Cleanroom a Bronze Sustainability rating.

-

-

-

-

-

Kimberly-Clark Corporation

COMMERCIAL WIPING

Manufacturer Overview

Kimberly-Clark Corporation, established in 1872, is headquartered in Dallas, Texas, is a manufacturer of brands that are an indispensable part of life for people in more than 175 countries. The company's portfolio of brands including Huggies, Kleenex, Scott, Softex, Viva and WypAll, hold No. 1 or No. 2 share positions in approximately 80 countries. Fueled by ingenuity, creativity, and an understanding of people's essential needs, it create products that help individuals experience more of what's important to them. Its sustainable practices support a healthy planet and build stronger communities to ensure its business thrives for decades to come.

-

-

-

-

-

Morrison Berkshire, Inc.

CLEANROOM WIPES

Manufacturer Overview

Morrison Berkshire, Inc., established in 1983 in New Adams, Massachusetts, USA, is a manufacturer of precision machining and fabrication products. The company offers a diverse range of products, including fabrications, precision turned components, and machined parts. These products provide optimal precision and stability, making them useful in various industries such as aerospace, pulp manufacturing, automotive, and industrial manufacturing that seek advanced machining and fabricating solutions. The company also specializes in making needle looms, ultrasonic bonding machines, button breakers, and PMC finishing machine components while operating in compliance with ASME and AWS codes of standard.

-

-

-

-

-

Naturelle Ltd

Microsafe Polyester Wipes

Company Overview

Naturelle Ltd, founded in 1987 and based in Omagh, Co. Tyrone, Ireland, is an ISO 13485/cGMP certified manufacturer and supplier of disposable contamination control products. The company's product range includes individual sachets for various cleansing, liquid/gel blending, aseptic processing, personal protective equipment, and cleanroom consumables. These products are utilized for tasks such as skin and eye cleansing, disinfecting medical devices, wound care, and more. The company serves the medical, pharmaceutical, industrial, and retail markets. Its services comprise private label manufacturing, contract manufacturing, distribution to global markets, and launching innovative products.

-

-

-

-

-

Mars Supply

Rags & Wipes

Company Overview

Mars Supply, established in 1924 and headquartered in New Brighton, Minnesota, USA, is a manufacturer of industrial supplies and tools. Tools, abrasives, safety gear, and MRO (Maintenance, Repair, and Operations) supplies are among the few of the many product types the company offers. It provides premium items that improve workplace security, boost productivity, and shorten customer downtime. In order to provide the necessary equipment and supplies that keep businesses operating efficiently, these offerings cater to an array of industries, spanning manufacturing, construction, mining, and transportation.

-

-

-

-

-

VWR International, LLC.

Cleanroom Wipes

Company Overview

VWR International, LLC., established in 1852 and based in Pennsylvania, United States of America, is a manufacturer of laboratory products. The company produces products such as abrasion testers, Chromatography detectors, earmuffs, and face shields and supplies to different industries such as industrial, education, government, biotechnology, and pharmaceutical. The ISO standards for environment, quality, health, and safety make sure that all its products are tested for quality and are environment safe. The company has manufacturing, distribution, and customer service resources to supply the products to 4000 suppliers worldwide.

-

-

-

-

-

Jiangxi Clean Room Science And Technology Co. Ltd

Freshly Scented Eco-Friendly Cleaner Wipes Clean Room Wipes

-

-

-

-

-

Suzhou ORDER Cleanroom Materials Co., Ltd.

High quality optical-grade lint-free fiber optic cleaning wipers

-

-

-

-

-

-

-

Dallas Wiping

TJ Wipes

-

-

-

-

-

Gardner Business Media, Inc.

Wiping It Clean

Company Overview

Gardner Buisness Media, Inc. was established in the year 1928 in Ohio, United States and it is a publisher for manufacturing companies in North America. The company products and services are magazines, digital media, E-mail, events, lead generation and research. The company also writes manufacturing and marketer blogs, industry and media reports, economic intelligence and automotive articles. It also provides with Manufacturing Marketer Newsletter. The company also organises digital, in-person and calendar events.

-

-

Clean Room Rag Manufacturer Ranking

*Including some distributors, etc.Ranking as of July 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | High-Tech Conversions, Inc. |

28.6%

|

| 2 | MicroCare |

14.3%

|

| 3 | Contec, Inc. |

14.3%

|

| 4 | Berkshire Corporation |

14.3%

|

| 5 | Texwipe |

14.3%

|

| 6 | GUARDNER Corporation |

14.3%

|

Derivation Method

The ranking is calculated based on the click share within the clean room rag page as of July 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

- SHIMIZU CORPORATION: 19,869

Newly Established Company

- Jiangxi Clean Room Science And Technology Co. Ltd: 2008 (16 years ago)

- Suzhou Jujie Electron Co., Ltd: 2005 (19 years ago)

- Midwest Production Supply: 2001 (23 years ago)

Company with a History

- Kimberly-Clark Corporation: 1872 (152 years ago)

- Mars Supply: 1924 (100 years ago)

- Dastex: 1979 (45 years ago)

Clean Room Rag Manufacturers in United States

*Including some distributors, etc.

- Texwipe

- MicroCare

- Berkshire Corporation

- High-Tech Conversions, Inc.

- LabClean

- Carter Health Disposables, LLC

- Specialty Optical Systems, Inc.

- Teknipure

- Midwest Production Supply

- Cleanroom Connection

Global Distribution of Clean Room Rag Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

10 | 52.6% |

China

China

|

4 | 21.1% |

Japan

Japan

|

2 | 10.5% |

Germany

Germany

|

1 | 5.3% |

India

India

|

1 | 5.3% |

Ireland

Ireland

|

1 | 5.3% |