All Categories

History

This section provides an overview for enabling switches as well as their applications and principles. Also, please take a look at the list of 7 enabling switch manufacturers and their company rankings. Here are the top-ranked enabling switch companies as of March, 2026: 1.Osaka Automatic Electric Co., Ltd., 2.EUCHNER GmbH + Co. KG, 3.Rockwell Automation.

Table of Contents

Categories Related to Enabling Switches

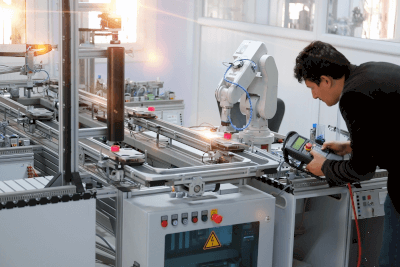

Enabling switches, also known as enabling grip switches, 3-position enabling switches, or simply enable switches, are safety devices integrated into teaching pendants for industrial robots and other machinery.

These switches allow operations only when the operator demonstrates clear intent by holding the switch in the ON position, ensuring that industrial robots are manually operated under controlled and intentional circumstances. This feature is crucial for preventing accidental robot operations and ensuring worker safety.

Enabling switches are critical safety components mounted on teaching pendants, which are used to manually operate equipment like industrial robots. While safety measures usually prevent worker access to operational areas of production equipment, there are instances where operators need to bypass these measures, such as during startup or troubleshooting. Enabling switches ensures that machinery operates only when the operator intentionally engages the switch, thereby protecting them from unintended and potentially hazardous actions.

Unlike standard two-position "ON/OFF" switches, enabling switches operate on a three-position "OFF/ON/OFF" system, which is button-operated. The first position is a neutral state where no contact is made, and the machinery remains inactive regardless of any attempted operations. A light press transitions the switch to the second position, enabling operation as commands are executed. Releasing the button reverts it to the neutral state, allowing for immediate cessation of activity. A stronger press from the second position shifts it to the third, where the machinery stops upon receiving a stop command.

The design of enabling switches considers human reflexes in dangerous situations—whether releasing or gripping the object more tightly. This ensures immediate machine stoppage in both scenarios, thus protecting the operator during unexpected robot movements. The dual-stop mechanism accommodates the unpredictable nature of human reflexes, safeguarding the operator by halting operations whether the switch is released or pressed firmly.

When selecting enabling switches and systems, prioritize those with high safety standards suitable for hazardous areas. Opt for switches with dual contacts and systems designed with controllers capable of shutting down machinery and maintaining safety even if one contact fails. Such systems are engineered to detect faults only when the two contact signals are in agreement, enhancing operational safety.

*Including some distributors, etc.

Sort by Features

Sort by Area

IDEC Corporation was founded in 1945 and is headquartered in Japan as the manufacturer of automation and control products. The company provides solutions that meet the evolving needs of customers. With a focus on areas such as IoT implementation, automation advancements, and manufacturing site safety, IDEC offers a diverse range of products such as electromechanical control products such as relays, timers, and switches. The company also manufactures automation products, such as Micro Programmable logic controllers, power supplies, and touch-screen displays. Their goal is to help businesses adapt to changing technologies, improve operational efficiency, and prioritize safety in industrial environments.

Panasonic Industry Europe is the European branch of Panasonic, a global manufacturer of electronics and houseware, originally founded in 1918. Panasonic Industry Europe manufactures in 4 categories: components, devices, energy & building, and automation devices & solutions. Components include relays, capacitors, resistors, sensors, switches, connectors, couplers. Devices include wireless connectivity, e-bike systems, motors, compressors, thermal solutions, GPS antennas, as well as electronic materials. Energy & building includes batteries, fuel cells, solar sells, power tools, and home IoT. Automation devices & solutions include sensors for factory automation, industrial motors, laser welding, and more.

Euchner was established in 1953 as a manufacturer of industrial safety products and is based in Germany. The products designed and manufactured by the company are used by industries that want to minimize risks and hazards. One example of their equipment is a Transponder with Coded Key Systems EKS and CKS which is used for controlling machine functions, storing process parameters, maintaining different access rights, and much more and it helps with procedures like automatic logging on and off for safe and controlled access. There are also safety switches, relays, identification systems, emergency stop devices, and similar items.

Omron Corporation, started in 1933 and headquartered in Kyoto, Japan, is a manufacturer of automation components, equipment, and systems, and it developed the first contactless proximity switch in 1960. It has four domains, including industrial automation, electronic components, healthcare, and social systems, and it provides products and services in around 120 countries and regions. Some of its products include microsensing devices, access control systems, industrial robots, surveillance cameras, and blood pressure monitors. In 1971, it developed the first online cash machine, and in 1972, it established Japan’s first welfare factory.

Rockwell Automation, Inc. was founded in 1903 and is headquartered in Milwakee, WI. Rockwell Automation provides industrial automation and digital transformation solutions around the world. Rockwell Automation operates through their intelligent devices, software & control, and lifecycle services segments with both hardware and software products and services. The Intelligent Devices segment offers drives, motion, safety, sensing, industrial components, and configured-to-order products. The Software & Control segment provides control and visualization software and hardware, information software, and network and security infrastructure solutions. The Lifecycle Services segment provides consulting, professional services and solutions, and connected and maintenance services through independent distributors.

OMRON Industrial Automation is the UK branch of OMRON, originally founded in Japan in 1933. OMRON Industrial Automation serves food and beverage industry, panel board design, automotive manufacturing industries among others. OMRON Industrial Automation products categories include automation systems such as industrial PCs and human machine interfaces (HMI), safety such as safety switches and safety logic control systems, switching components such as solid state relays, motion & drives such as motion controllers, sensing such as photoelectric sensors, software, robotics, quality control & inspection systems, as well as control components including power supplies and digital panel indicators.

Ranking as of March 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Osaka Automatic Electric Co., Ltd. |

31.4%

|

| 2 | EUCHNER GmbH + Co. KG |

20.0%

|

| 3 | Rockwell Automation |

17.1%

|

| 4 | Panasonic Industry Europe GmbH |

11.4%

|

| 5 | OMRON Industrial Automation |

8.6%

|

| 6 | IDEC Corporation |

5.7%

|

| 7 | Omron |

5.7%

|

Derivation Method

The ranking is calculated based on the click share within the enabling switch page as of March 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

Japan

Japan

|

2 | 50.0% |

Germany

Germany

|

2 | 50.0% |

21 products found

21 products

IDEC Co., Ltd.

570+ people viewing

Last viewed: 12 hours ago

■Features - 3-position operation, OFF⇒ON⇒OFF, to avoid danger based on ergonomics. - Built-in snap action switch from position 1 to position 2 prov...

Tokyo Measuring Instruments Co., Ltd.

1000+ people viewing

Last viewed: 12 hours ago

■Features - Made of resin, the box is small and lightweight, so you won't get tired even when working for long hours. ・Free design: The layout of ...

Matsushima Measure Tech Co., Ltd.

1170+ people viewing

Last viewed: 12 hours ago

Pull -stop is an emergency stop switch around conveyors and transport machines. In addition to the basic functions of sister products, the followin...

2 models listed

IDEC Co., Ltd.

730+ people viewing

Last viewed: 12 hours ago

■Features - 3-position operation, OFF⇒ON⇒OFF, to avoid danger based on ergonomics. - Built-in snap action switch from position 1 to position 2 prov...

IDEC Co., Ltd.

530+ people viewing

Last viewed: 12 hours ago

■Features - 3-position operation, OFF⇒ON⇒OFF, to avoid danger based on ergonomics. ・The structure does not turn ON between pushing OFF (position 3...

IDEC Co., Ltd.

750+ people viewing

Last viewed: 12 hours ago

■Features - 3-position operation, OFF⇒ON⇒OFF, to avoid danger based on ergonomics. ・The built-in snap-action switch from position 1 to position 2 ...

IDEC Co., Ltd.

680+ people viewing

Last viewed: 3 hours ago

■Features - Lineup of models equipped with control units suitable for various uses. - Compact design that fits your hand, ergonomic grip shape, sma...

Asano Orimono Joint Stock Company

180+ people viewing

Last viewed: 12 hours ago

■Features A string that can be used for hanging picture frames, etc. Special orders are also available upon request. *If you are a vendor and woul...

4 models listed