All Categories

History

This section provides an overview for safety relays as well as their applications and principles. Also, please take a look at the list of 39 safety relay manufacturers and their company rankings. Here are the top-ranked safety relay companies as of July, 2025: 1.Banner Engineering Corporation, 2.MURRELEKTRONIK INC., 3.Pearse Bertram+ Streamline Contract Manufacturing.

Table of Contents

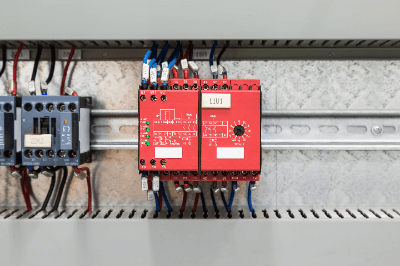

Safety relays are relays used to build safety circuits for machinery and equipment.

Safety Relays have a forced-guide contact structure and are used in the safety-related part of the control system to control the operation of machines only when safety is confirmed. This makes it possible to detect abnormalities and safely shut down equipment accordingly.

The "input section" receives the transmitted signal, determines whether the signal is safe or not, and sends the signal to the "output section. In the module, it plays a central role as the logic section.

Safety Relays are mainly used to monitor safety functions. Examples are emergency stops, safety doors, safety mats, and other safety controls. They are designed to detect abnormalities in devices, sensors, or actuators and control them so that machines and equipment can be brought to a safe stop.

By incorporating modules that utilize Safety Relays, it is possible to ensure the safety of machines and equipment. They protect against hazards by detecting potential danger to operators, abnormalities in machinery and equipment, and potential damage.

Safety Relays differ from ordinary relays in that they have a forced-guide contact structure with two types of contacts, a and b, each separated by a wall that must be insulated from the other. The b-contacts are interlocked according to the ON/OFF of the coil.

The forced guiding contact structure is characterized by a structure that detects abnormal conditions when "if the a contact is welded, all b contacts have a contact gap of 0.5mm or more when the coil is OFF" and "if the b contact is welded, all a contacts have a contact gap of 0.5mm or more when the coil is ON. The structure is characterized by its ability to detect abnormal conditions when "all a-contacts have a contact gap of 0.5mm or more with the coil ON.

Therefore, the a-contact and b-contact are not in the same operating state at the time of contact welding. In the case of a system that controls ON/OFF of a machine, the structure is such that the a-contact is connected to the power control circuit and the b-contact to the monitoring circuit.

By doing so, when the a-contact is welded, the machine will only operate when the coil is in the ON state, and the machine will stop when it is in the OFF state. On the other hand, the b-contact is welded when the coil is in the OFF state, and works as a monitor to detect safety conditions.

An example of a Safety Relay is an emergency stop pushbutton switch. This system has a safety function in which the contactor opens and closes the motor circuit upon actuation of the switch. If the emergency stop pushbutton is pressed while the motor is running, the motor stops immediately.

The emergency stop pushbutton switch uses NC (normally closed) contacts, which remain closed as long as the switch is not pressed. The system sends a safety signal during this time. When the emergency stop pushbutton switch is pressed, the contact opens and no safety signal is output.

The safety relay module detects the input of a safety signal from the emergency stop pushbutton switch and the pressing of the start switch of the control system, and outputs a signal to the contactor to allow motor operation.

If the safety signal from the emergency stop pushbutton switch is not input to the safety relay in this safety function system, the safety relay module stops outputting the signal to the contactor. This stops the motor.

Relay circuit actuation mechanisms include the aforementioned forced guide mechanism and direct circuit actuation mechanism. The direct circuit operating mechanism is a mechanism that pulls the NC contacts of the safety switch apart by the force acting on the actuator when the contacts are welded together.

The forced guiding mechanism prevents the NO (normally open) contact and the NC contact from being turned on at the same time, and by monitoring one contact, it is possible to determine if the other is normal.

However, it is not possible to pull the contacts apart as in the direct circuit operating mechanism.

*Including some distributors, etc.

Sort by Features

Sort by Area

Pepperl+Fuchs, Inc. was founded in Mannheim, Germany in 1945 developing the forerunner of the proximity switch. Pepperl+Fuchs continues to develop proximity sensors as well as other industrial sensors including ultrasonic sensors, rotary encoders, positioning systems, display and signal processing, vibration monitoring, industrial communication, and signal processing as well as related accessories and software. Explosive protection products include safety barriers, surge protection, wireless solutions, HMI systems, power supplies, electrical explosion protection equipment, level measurement, and related software.

Wenglor Sensoric LLC is a supplier and manufacturer of smart sensor and image processing technologies and solutions. Established in 1983, the company is headquartered in Tettnang, Germany. The company's main activities encompass the design, manufacturing, and distribution of sensor solutions for automation and industrial applications such as Sensors, Machine Vision, Connection and Network Technology and Accessories. Wenglor Sensoric specializes in sensors for position, distance, color, and image recognition, catering to industries like automotive, packaging, and logistics. The company offers a range of services including technical support and consultation.

Murrelektronik, established in 1975 and headquartered in Oppenweiler, Germany, is a manufacturer of electrical and electronic installation concepts for machine and system installations. The company's product range includes power supplies, M12 cable, fieldbus I/O, and more. It also offers a wide variety of jacket colors and cable types, including M8 and M12 sensor cables and Mini (7/8”) power cables. Its products simplify industrial image processing with its installation concept. The company is among the TOP 100 for Cube67 Diagnostic Gateway for Cube67 Diagnostic Gateway Students. It serves a wide range of industries, including automotive, food and beverage, and robotics.

Edwards Company Inc., founded in 1872 and currently a subsidiary of Carrier Global Corporation, is an American manufacturer based in Mebane, North Carolina, developing automation signaling solutions. The company’s product range includes electronic audible and visual signals tailored for indoor, outdoor, and hazardous locations. These products include multi-status indicators, outdoor-rated hazardous location bells and horns, and industrial weatherproof beacons. The company also provides a range of alarm devices, appliances, and panels. These products are designed for installation in single and multi-unit residential, industrial and commercial facilities, and hazardous locations.

ifm efector (ifm) is a subsidiary of ifm electronic, founded in Germany in 1969. ifm has developed, manufactured and marketed sensors and controls technology to industries that include assembly and robotics, automotive, material handling, metal forming, mobile equipment, plastics, and food and beverage. Ifm produces sensors, condition monitoring equipment, image processing, safety technology, industrial communication, IO-link, systems for mobile machines, displays, software, connection technology, voltage supplies, as well as other accessories.

ASO Safety Solutions Inc., founded in 1984 as ASO GmbH in Salzkotten, Germany, is a tactile sensor manufacturer based in New Jersey, United States. The company’s product lineup features safety edges for automated doors and gates, catering to general industry applications and safety-sensitive environments. It also provides safety bumpers, mats, and relays to monitor tactile sensors, all marketed under the SENTIR brand. The company also offers signal transmission and drive controls for moving doors and gates, branded as ELMON and DRIVO.

Sick AG, founded in 1946 and headquartered in Waldkirch, Germany, is a manufacturer of sensor and sensor solutions that aid in in production, logistics, and processes automation. The company’s expansive product portfolio includes industrial sensors, encoders, and analyzers. It has over 50 subsidiaries and equity investments as well as several agencies worldwide, and in the 2022 fiscal year, it generated around €2.2 billion. The company established the first subsidiary in France in 1972 and opened another subsidiary in USA in 1975. It changed to a joint stock company in 1996 and the first employee shares were issued in 1999.

Banner Engineering Corporation, established in 1966 and headquartered in Minneapolis, Minnesota, is a manufacturer and supplier of industrial automation products. They offer an extensive range of sensors, including proximity sensors, photoelectric sensors, and limit switches, for detecting object presence, position, and speed. Additionally, Banner provides a different types of switches, such as pushbuttons, toggle switches, and rotary switches, to control electricity flow and offer system feedback. Their wide array of controls includes PLCs, HMIs, and motion controllers, enabling automation of industrial processes.

Pearse Betram+ was founded in 1947 in Bloomfield, Connecticut. Today Pearse Bertram+ is an end-to-end solutions provider for the manufacturing industry. Pearse Bertram+ is ISO 9001:2015 certified and also UL508A (industrial control panels), IPC 620 (wire harness assemblies), and IPC-A-610, J-STD-001, and IPC-7711 certified for soldering. Pearse Bertram+ operates in both contract manufacturing and engineering support. The manufacturing segment includes electrical, pneumatic, robotic, hydraulic, and process systems. Engineering support includes support for operation of robotics, machinery design and usage, industrial automation, value engineering, and auditing.

Euchner-USA, Inc. is based in East Syracuse, New York, USA, and is a manufacturer of industrial safety equipment that was established in 1989 as a subsidiary of Germany’s Euchner GmbH + Co. KG. The company produces magnetically coded and transponder-coded safety switches, emergency stop devices, and safety relays for control systems. It also offers light curtains, handheld pendant stations for controlling machinery or processes, and read heads with external evaluation functionality. The company’s products are commonly used in industrial manufacturing operations, including within the automotive, robotics, and machine tool industries.

Steute Industrial Controls, Inc. is a manufacturer of switchgear and intelligent sensors as well as wireless systems and networks that is headquartered in Bad Oeynhausen, Germany and was established in 1961. The company’s products are divided into three product areas, namely; Meditec, Controltec and Leantec. Its Meditec-certified user interfaces are mainly for medical devices while its Controltec-safe industrial automation products such as controllers, switches and sensors protect, monitor, operate and automate machines and plants. Steute’s Leantec digital shop floor solutions such as the intelligent IIoT Wave.net can be customized and digitally integrated for production anywhere in the world.

Enercorp Instruments, Ltd was born in 1977 and operates out of Brampton, Ontario. Enercorp is a manufacturer of measuring equipment used in markets such as HVAC, industrial monitoring, food processing, waste management, pharmaceutical, lumber, and agriculture. Enercorp produces sensors and components in six categories: temperature, including temperature sensor plates and temperature probes, current such as core current switches and current indicators, Aqua-Boy & curing such as moisture meters and needle electrode heads, pressure such as pressure transducers and pressure transmitters, wind such as ultrasonic anemometers, and binding post, such as lead-through bolts.

elobau Elektrobauelemente GmbH & Co., founded in 1972 with headquarters in Germany, is a manufacturer of contactless sensor technology, operator controls, machine safety, and level measurement. The company's products include multi-axis joysticks, multi-function handles, push buttons, sensor components, and continuous level measurement. elobau’s products are used in both mobile (off-highway) and industrial applications. The company’s products can be found in aircraft, off-road vehicles, agricultural machinery, and industrial machinery. elobau Elektrobauelemente GmbH & Co. has been carbon neutral since 2010.

Hengstler, headquartered in Aldingen, Germany, is a custom manufacturer established in 1846, specializing in industrial components for counting and control applications. They offer a comprehensive range of products, including counters for measuring and counting objects, rotary encoders used for electrical signals, relays for controlling electric circuits, printers for label and document printing, as well as various types of cutters for materials like paper, film, and fabric. Hengstler products are manufactured to order, either in-house or outsourced, in accordance with the Kanban system and FBS system.

WIDE Automation S.r.l., founded in 1985 and headquartered in San Giovanni, Italy, is a manufacturer of industrial safety systems and automation products. Its safety products include bumpers, mats, and edges, serving primarily industrial and agricultural machinery manufacturers. The company also offers automation products like electric cylinders, clutches, and brakes and operates in 12 countries worldwide. It is the first company globally to introduce stereo-vision technology to the industrial safety sector. This technology enables machines to detect humans or objects within the monitoring area and interact with them safely.

DOLD is a manufacturer of safety and interlocking devices, founded in 1928, with headquarters located in Furtwangen, Germany. Their product range includes safety relays, electronic housings, safety switches, as well as solenoid interlocks, and key transfer systems. These devices play a crucial role in ensuring secure operations, controlling access, and protecting workers and equipment during manufacturing processes. DOLD is certified according to DIN EN ISO 9001:2015 for quality management and quality systems.

Dongguan Dadi Electronic Technology Co. Ltd., established in 2003 and headquartered in Dongguan City, Guangdong, is a manufacturer of safety light curtains and infrared sensors. The company offers an extensive range of measurement and automation light curtains, multi-area safety light curtains, and industrial safety mats. It also manufactures a range of proximity, photoelectric, and ultrasonic sensors. These products are used in industrial, commercial, and retail applications where it is necessary to detect, measure, and recognize objects. The company offers OEM part and component production services and also accepts wholesale orders.

Euchner was established in 1953 as a manufacturer of industrial safety products and is based in Germany. The products designed and manufactured by the company are used by industries that want to minimize risks and hazards. One example of their equipment is a Transponder with Coded Key Systems EKS and CKS which is used for controlling machine functions, storing process parameters, maintaining different access rights, and much more and it helps with procedures like automatic logging on and off for safe and controlled access. There are also safety switches, relays, identification systems, emergency stop devices, and similar items.

Siemens began in 1847 and is headquartered in Munich, Germany. Siemens focuses in automation and digitalization technology and operates globally. Siemens’s 5 operating segments are digital industries, smart infrastructure, mobility, Siemens Healthineers, and Siemens Financial Services. Siemens Financial Services provides debt and equity investment as well as financing solutions. Siemens Healthineers is a medical devices company that provides products and consulting. Mobility includes passenger and freight transportation. Smart infrastructure includes full solutions for electrification. Digital industries offer both software and hardware for industries and production efficiency.

Hermann ZANDER GmbH & Co. KG, founded in 1950 and based in Aachen, Germany, is a manufacturer of electrical systems and equipment. The company produces products such as safety sensors, cam controllers, micro switches, coded RFID safety switches, and power supply units and supplies to different industries, including automotive, manufacturing, packaging, shipping, and conveyor systems. With the ISO 9001 quality certification, the company follows all the quality standards to manufacture the products and supply them to customers worldwide.

Wieland, established in 1910 and based in Bamberg, Germany, is a manufacturer and supplier of electrical connection technology. Their product range includes pluggable connections for seamless plug-and-play electrical device connections, insulated connectors that provide electrical insulation in device connections, cable glands for safeguarding cables and ensuring a watertight seal, terminal blocks used for connecting electrical wires, and contact systems facilitating connections between electrical components. Wieland's products find applications in diverse industries, such as building construction, electrical engineering, and automation.

Pilz is headquartered in Ostfildern, Germany. Pilz designs components, systems, and services to assist industrial plant and machinery customers globally. Customers include many industries such as metals, pharmaceutical, food, presses, and robotics. Pilz serves customers through 4 venues: products and industries, services, support, and training. Products and services include everything from sensor technology and small controllers to robotics to software and operation monitoring. Services include machinery and workplace safety and international compliance. Support is offered 24/7. Training is available through courses and qualification programs.

Schneider Electric S.E. is headquartered in Rueil-Malmaison, France, and has been operating since 1836. Schneider Electric provides a number of products and services including electrical car charging, energy management software, surge protection devices, load banks, servers and HMIs, valve and valve actuators, feeder automation, grid automation, and SCADA software products, data center cooling and software, home automation and security, light switches, motion control and robotics, signaling units, solar and energy storage, RFID systems, as well as other hardware, services, and software.

U.S. Tsubaki Power Transmission LLC., founded in 1971 and based in Wheeling, Illinois, is a manufacturer and supplier of motion control and power transmission products and is ISO 9001 certified. Its products include sprockets, conveyor chains, and roller chains used in several industries, including automotive, primary metals, and forest products. It’s a subsidiary of the Tsubakimoto Chain Company, and it has several manufacturing facilities in the United States, including Milwaukee (WI), Sandusky (OH), and Chicopee (MA). The company sells its products through distribution channels but can sell directly to qualified OEMs.

Schmersal GmbH & Co. KG, founded in 1945, by Heinz and Philip Schmersal, is a name in safety technology, is a manufacturer of safety technology solutions, specializing in switchgear and control devices for various industries. With a diverse range of mechanical and electro-sensitive switching devices, they offer an extensive collection of safety switching systems and devices for safeguarding both humans and machinery. The company looks after three key domains: lift technology, automation technology, and safety technology. Their substantial approach position them as a global supplier of safety switching devices, catering to the safety and automation needs of various industries.

Omron Corporation, started in 1933 and headquartered in Kyoto, Japan, is a manufacturer of automation components, equipment, and systems, and it developed the first contactless proximity switch in 1960. It has four domains, including industrial automation, electronic components, healthcare, and social systems, and it provides products and services in around 120 countries and regions. Some of its products include microsensing devices, access control systems, industrial robots, surveillance cameras, and blood pressure monitors. In 1971, it developed the first online cash machine, and in 1972, it established Japan’s first welfare factory.

Phoenix Contact is headquartered in Blomberg, Germany, originally founded in 1923. Phoenix Contact’s Israeli subsidiary was founded in 2006 and located in Quadima Tzoran. Phoenix Contact provides tools and components for e-mobility, power, infrastructure, process industry, production manufacturing, system manufacturing, and others. Phoenix Contact’s product lines include automate including cloud computing, connect including PCB terminal blocks, “mark, assemble, and install” including hand tools, “supply, charge, and protect” including power distributors, and “switch, measure, and monitor” including relays and optocouplers.

COMITRONIC BTI, established in 1981 and based in Canéjan, Nouvelle-Aquitaine, France, is an ISO9001-2015 certified manufacturer and supplier of safety switches and sensors. The company's product range includes safety switches & safety sensors, pressure switches, safety modules, multi-purpose safety systems, and Atex Gamme. These products are used to ensure safety and monitoring in industries like appliances, electrical, and electronics manufacturing. The products are used in safeguarding machine operators and maintenance personnel from potential injuries. The company offers services such as ISO 13849-1 safety of machinery consultation and SYTCOM - assessment of ISO 13849-1 parameters.

Comepi Srl, established in 1963 and based in Robbiate, Lecco, Italy is a manufacturer and distributor of control auxiliaries, limit switches, and foot switches, as well as a vast range of safety switches. The company holds ISO 9001:2008 certification. The company's goods are distributed worldwide. It is specialised in safety devices, proximity sensors, control units, and signalling devices. An effective quality system with UNI EN ISO 9001:2008 certification oversees all procedures of the company.

BERNSTEIN AG is a manufacturer and distributor of electromechanical components that was established in 1947 in Germany. The company manufactures switches and sensors that range from insulated and metal enclosed to foot switches and safety switchgear. They also provide enclosure technology that deals with the implementation of support systems for various applications such as using housing to accommodate electrical, electronic, or pneumatic components and load-bearing systems made of aluminum and stainless steel. They also offer safety solutions related to the operation of lifts and escalators that are placed in malls and airports

Rockwell Automation, Inc. was founded in 1903 and is headquartered in Milwakee, WI. Rockwell Automation provides industrial automation and digital transformation solutions around the world. Rockwell Automation operates through their intelligent devices, software & control, and lifecycle services segments with both hardware and software products and services. The Intelligent Devices segment offers drives, motion, safety, sensing, industrial components, and configured-to-order products. The Software & Control segment provides control and visualization software and hardware, information software, and network and security infrastructure solutions. The Lifecycle Services segment provides consulting, professional services and solutions, and connected and maintenance services through independent distributors.

NHP, established in 1968 and headquartered in Richmond, Victoria, Australia, is a supplier and distributor of electrical and automation products, systems, and solutions. The company operates across Australia and New Zealand, with an array of over 20,000 product lines including industrial electrical products, safety equipment, power distribution drives, motor control drives, and hazardous area equipment. With their supply chain expanding to major sectors like manufacturing, mining, and more, the company’s offerings encompass automation, energy management, industrial control, motor control, and variable speed drives. The company also offers global certificate programs, e-learning courses, virtual coaching, and training workstations.

Altech Corporation, founded in 1984 and headquartered in Flemington, New Jersey, is a supplier and distributor of electronic and control components and is ISO 9001 certified. The company provides a broad line of products, including programmable controllers, monitoring relays, and terminal blocks, used in instrumentation, industrial control, and automation applications. The company’s enclosed disconnect switches are available in different materials like stainless steel, plastic, and aluminum and have a use rating of 16A to 150A/600V AC. The products are all RoHS and REACH compliant and meet diverse national and international standards like IEC, CSA, and UL.

AutomationDirect.com was founded in 1994 to provide solutions for the industrial automation market and has been growing its list of offerings ever since. AutomationDirects’ extensive catalog includes individual components such as cables, various controls, I/O devices, relays, gauges, fittings, and sensors to complete systems. Many parts and devices, especially PLC units are customizable. AutomationDirect.com also provides support via video instructions, online manuals, a learning library, an active community forum to further assist customers.

Ranking as of July 2025

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Banner Engineering Corporation |

8.2%

|

| 2 | Pearse Bertram+ Streamline Contract Manufacturing |

4.9%

|

| 3 | PHOENIX CONTACT |

4.9%

|

| 4 | MURRELEKTRONIK INC. |

4.5%

|

| 5 | SICK AG |

4.5%

|

| 6 | Schneider Electric SE |

3.7%

|

| 7 | Pilz GmbH & Co. KG |

3.7%

|

| 8 | Euchner-USA, Inc. |

3.3%

|

| 9 | Enercorp Instruments Ltd. |

3.3%

|

| 10 | Edwards Signaling |

2.9%

|

Derivation Method

The ranking is calculated based on the click share within the safety relay page as of July 2025. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

Germany

Germany

|

11 | 35.5% |

United States of America

United States of America

|

10 | 32.3% |

Japan

Japan

|

3 | 9.7% |

China

China

|

2 | 6.5% |

France

France

|

2 | 6.5% |

Canada

Canada

|

1 | 3.2% |

Italy

Italy

|

1 | 3.2% |

Australia

Australia

|

1 | 3.2% |

24 products found

24 products

K-MEX Automation Co., Ltd.

200+ people viewing

Last viewed: 20 hours ago

■Smaller and faster - industry's thinnest relay MIRO series Each system contains different types of active interface modules. Relays are used to se...

IDEC Co., Ltd.

640+ people viewing

Last viewed: 16 hours ago

■Features ・Eco & slim safety measures. 2-pole force-guided relay that reduces costs and saves space ・Forced guide type contact structure (EN50205...

IDEC Co., Ltd.

520+ people viewing

■Features ・Safety relay module for IoT ・Equipped with advanced diagnostic and output functions: Predictive maintenance ・Supports connection of v...

IDEC Co., Ltd.

540+ people viewing

Last viewed: 3 hours ago

Features ■Safety system without redundancy Regarding the introduction of safety systems for low-risk machinery: Up until now, it has been difficult...

IDEC Co., Ltd.

330+ people viewing

Last viewed: 22 hours ago

■Explosion-proof performance ・Safety relay barrier: [Ex ia Ga] IIC ・Switch (EB9Z-A): ExiaIICT6 ・Switch (EB9Z-A1): ExiaIIBT6 ■Features ・Achieve...

IDEC Co., Ltd.

310+ people viewing

Last viewed: 14 hours ago

■Explosion-proof performance ・Relay barrier: [Ex ia Ga] IIC ・Switch (EB9Z-A): ExiaIICT6 ・Switch (EB9Z-A1): ExiaIIBT6 ■Features ・Compliant with...

IDEC Co., Ltd.

420+ people viewing

Last viewed: 22 hours ago

■Explosion-proof performance Exd [ia] IIBT6 ■Features ・EB4C type can be installed in Class 1 hazardous locations (Zone 1) and Class 2 hazardous l...

Shinden Technology Co., Ltd.

210+ people viewing

Last viewed: 23 hours ago

Panasonic SF relays and sockets (safety relays) suitable for circuits that require safety standards Features ■Panasonic SF relay slim type ・Force...

Panasonic Industry Co., Ltd.

120+ people viewing

Last viewed: 1 day ago

■Safety relay ・Safety relays that contribute to the construction of safety circuits for devices ・Main applications: Communication equipment, meas...

Panasonic Industry Co., Ltd.

130+ people viewing

Last viewed: 3 hours ago

■Safety relay ・Safety relays that contribute to the construction of safety circuits for devices ・Main applications: Communication equipment, meas...

Panasonic Industry Co., Ltd.

120+ people viewing

■Safety relay ・Safety relays that contribute to the construction of safety circuits for devices ・Main applications: Communication equipment, meas...

Panasonic Industry Co., Ltd.

110+ people viewing

■Safety relay ・Safety relays that contribute to the construction of safety circuits for devices ・Main applications: Communication equipment, meas...

Panasonic Industry Co., Ltd.

110+ people viewing

■Safety relay ・Safety relays that contribute to the construction of safety circuits for devices ・Main applications: Communication equipment, meas...