21 Box Making Machine Manufacturers in 2024

This section provides an overview for box making machines as well as their applications and principles. Also, please take a look at the list of 21 box making machine manufacturers and their company rankings. Here are the top-ranked box making machine companies as of April, 2024: 1.T-Roc Equipment, LLC, 2.Zhejiang Feida Machinery Co.,Ltd, 3.autoboxup.com.

Table of Contents

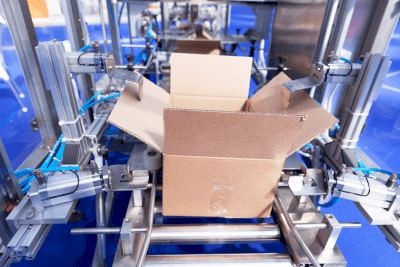

What Is a Box Making Machine?

A box-making machine is a machine that assembles folded corrugated boxes into a three-dimensional structure and applies tape or hot melt to the bottom of the box, thereby reducing the need for manual labor.

A box-making machine is a machine that assembles folded corrugated boxes into a three-dimensional structure and applies tape or hot melt to the bottom of the box, thereby reducing the need for manual labor.

On the other hand, the machine that applies tape to the top surface of a box after its contents have been filled is called a box sealing machine. Some products combine the functions of both.

By incorporating fully automatic box-making machines, which are currently the mainstream, into the production line, the only work required of line workers in the box-making process is the supply of corrugated board sheets, thus achieving significant labor savings.

Applications of Box Making Machines

Box-making machines are used to assemble corrugated boxes in factories and warehouses in a wide range of industries, including manufacturing, agriculture, forestry, fisheries, and mail-order sales.

The most standard type is for assembling and taping A-type corrugated boxes (so-called "tangerine boxes"). However, there are also products that use hot-melt adhesives for gluing, as well as those for assembling one-touch boxes and trays.

Semi-automatic box-making machines perform only the folding of corrugated boxes and tape application by hand, while fully automatic box-making machines perform both box folding and tape application automatically.

Principle of Box Making Machines

In the most common type of box-making machine, which performs the assembly and bottoming of corrugated boxes, corrugated sheets loaded in the magazine section are taken into the machine one by one, the bottom flap is folded, taped, and then discharged from the machine. Electricity and air pressure are used together for power.

Different equipment is needed to assemble different types of corrugated boards. However, the size can be adjusted by operating handles and other controls for the same type of corrugated board.

Various sensors, alarms, and forecasting devices are installed to prevent such problems from occurring or to deal with them when they do occur.

On the other hand, semi-automatic box-making machines exclude the tape application mechanism found in fully automatic box-making machines, so manual work is required for box-making. However, compared to fully automatic box-making machines, semi-automatic box-making machines are sometimes used for cost-effectiveness, since they are smaller, have a simpler structure, are less expensive to install, and can be operated either by electricity or pneumatic pressure.

List of 21 Box Making Machine Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- United States of America

- China

- Germany

- India

- Italy

- Poland

- Taiwan

-

-

-

T-Roc Equipment, LLC

AUTOMATED BOX MACHINES

Manufacturer Overview

T-Roc Equipment, LLC, founded in 1985 and headquartered in Kansas City, Kansas, USA, is a manufacturer of conveyor systems and box automation equipment. It is partnered with the company DeHoff Tool & Die Manufacturing. The company specializes in designing and fabricating custom material handling solutions for industries including automotive, food and beverage, and logistics. Its main products encompass automated box gluers, heavy-duty machines, and automatic feeders. These solutions find applications in production lines, warehousing, and distribution centers.

-

-

-

-

-

Miller Weldmaster Corporation

Box Making Machines

Manufacturer Overview

Miller Weldmaster Corporation, established in 1974 and headquartered in Navarre, Ohio, United States, is a manufacturer of heat-sealing and welding equipment. Some of the products offered include hot air welders, hot wedge welders, impulse welders, radio frequency welders, and automated welding machines. These products are used for welding and sealing various materials, including plastics, industrial fabrics, and geomembranes. The company also has a support center located in Europe specifically in Nieuw-Vennep, The Netherlands.

-

-

-

-

-

Neway Packaging Corporation

Box Making Machine

Distributor Overview

Neway Packaging was started in 1977 in Torrance, California and has branched out into 7 other states across the United States. The company serves agriculture, bakery, construction, lumber, and other industries with packaging products, services, and equipment. The company’s products include a full range of single use products such as boxes and safety supplies to cushioning products and janitorial supplies. Equipment includes sales of sealing machines, stretch wrapping machines, and other equipment. Services include custom box & packaging solutions, product packaging & graphic design, preventative maintenance, and equipment installation.

-

-

-

-

-

SCM Group

Packaging

Manufacturer Overview

SCM Group was established in 1952 and is headquartered in Rimini, Emilia-Romagna, Italy, as a manufacturer of industrial equipment for the non-ferrous metals, plastics, and wood processing sectors. Their products comprise band saws, radial saws, universal combination machines, throughfeed moulders, thicknessing planers, sliding table saws, and semi-automatic boring machines, among others. These tools are utilized in woodworking shops, construction, manufacturing, carpentry, art, and DIY projects for tasks such as cutting, shaping, and joining wood materials accurately and efficiently. The products are extensively employed in the furniture, automotive, construction, plastic processing, shipbuilding, and aerospace industries.

-

-

-

-

-

Friends Engineering

Carton Box Making Machine

Manufacturer Overview

Friends Engineering, established in 1965 and headquartered in Amritsar, India, is a manufacturer and exporter specializing in printing, packaging, and binding machinery. The company's product range includes an array of machinery, such as the die punching machine, hot foil leaf stamping machine, thermal lamination machine, sheet lamination machine, paper cutting machine, and more. These products serve various industries, finding application in the packaging of electronic products, glassware, hosiery and ready-made garments, pharmaceuticals, automobile components, and beyond.

-

-

-

-

-

Zemat Technology Group

BOXMAT BOXMAKERS

Manufacturer Overview

Zemat Technology Group is a manufacturer of a wide range of industrial machines, founded in 1957 and headquartered in Lodz, Poland. The company’s product line covers welding and sealing machines, Boxmat Boxmakers, and Randix digital cutting machines. It also offers roller die cutters, thermoformers, presses, and solid-state HF generators. The company holds ISO, CE, and EMF certifications and has operations across America and Europe. It caters to various industries, including automotive, conveyor belts, medical, packaging, and aeronautics.

-

-

-

-

-

QINGDAO AOPACK ON DEMAND PACKAGING Co., Ltd.

Most Cost-effective Carton Box Making Machine

Manufacturer Overview

Qingdao Aopack On Demand Packaging Co. Ltd. is a manufacturer of automatic box-making machines founded in 2014 and headquartered in Shandong, China. The company offers a wide range of automatic box-making machines, such as the Carton Box Machine BM2508-Plus and BM2508-SE, the Boxmaker Machine BM3000, and the Fanfold Cardboard Box Making Machine FF2800. It also provides custom box-making machines suitable for box factories, fulfillment centers, and furniture factories. The company’s machines are installed in over 50 countries worldwide, including Japan, America, the UK, and India. It caters to diverse sectors, such as e-commerce, food and beverage, pharmaceuticals, and more.

-

-

-

-

-

INNOVATOR MACHINERY CO., LTD.

Box Making Machine

Manufacturer Overview

Innovator Machinery Co. Ltd. is an international veneering machine manufacturer established in 2003 and headquartered in Taichung City, Taiwan. The company specializes in the design and production of various kinds of veneering machinery, including guillotines, splicers, and other veneer processing equipment. Its product line consists of crossfeed veneer splicers, double knife veneer guillotine, edge reinforcing devices, veneer fanning machines, and various accessories. The company holds ISO 9001:2008 and CE certifications and has a global distribution network spanning Europe and Asia. It caters to the decorative board, door, and furniture industries, as well as veneer and plywood processing plants

-

-

-

-

-

Shinko Machine Co., Ltd.

Box-making machines

Manufacturer Overview

Shinko Machine Co. Ltd., established in 1961 and headquartered in Osaka Prefecture, Japan, is a manufacturer of carton box-making and printing machines. The company produces the Shinko Super Alpha, Shinko High Printer, and hard die cutter. It excels in custom-made solutions, offering flexibility in handling materials from E to G corrugated board. It is known for its high-mix, low-volume production capacity. The company's expertise extends to multi-color printing, efficient, energy-saving technology, and maintenance support.

-

-

-

-

-

Rengo Co., Ltd.

Box/tray making machines

Manufacturer Overview

Rengo Co., Ltd., a company founded in 1909 and headquartered in Osaka, Japan, is a manufacturer and supplier of packaging materials and solutions. The company offers a wide range of packaging products, including corrugated boxes, folding cartons, flexible packaging, and paperboard. Their solutions cater to various industries such as food and beverage, pharmaceuticals, consumer goods, and e-commerce. The company also offers customer services such as product customization, design support, and logistics management.

-

-

-

-

-

MITSUBISHI HEAVY INDUSTRIES, LTD.

BOX MAKING MACHINE

Manufacturer Overview

Mitsubishi Heavy Industries Ltd., established in 1884 and headquartered in Tokyo, Japan, is a manufacturer of products, machinery, and operations. The company offers a wide range of products and machinery, including thermal power plants, nuclear power generation, rocket engines, home air-conditioners, and cargo ships. It also offers renewable energy power plants, marine vessels, centrifugal chillers, passenger ships, and space station rocket launchers. Its product features allergen clear operation, which works to deactivate any odor-causing bacteria, including mold and viruses. It has achieved Automotive SPICE Ver. 3 certification in 2018. It serves industries such as energy, marine, chemical, infrastructure, and more.

-

-

-

-

-

KOLBUS America

BOXER BX200

Manufacturer Overview

Kolbus America is a manufacturer of new equipment solutions for the paperboard packaging sector, founded in 1775 and headquartered in Huntersville, North Carolina. The company specializes in digital and flexographic printing, converting equipment for corrugated boards, and automated production solutions for rigid boxes. Its product line consists of the AutoBox AB300, Kolbus RD 115S, Kolbus DA 370, Box Line Wrapper BLW 200, and AutoBox BX Motion. The company is a subsidiary of Kolbus GmbH & Co. KG, a German manufacturer of bookbinding, printing, and finishing equipment. It caters to commercial printers and packaging sectors.

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

dataTec AG

Fully Integrated Packaging Machines

Distributor Overview

DataTec AG, established in 1985 and headquartered in Reutlingen, Germany, operates as a distributor specializing in measurement and testing technology for electrical and electronic variables. The company offers a diverse range of products, including power supplies, oscilloscopes, measuring devices, test systems, testing devices, thermal imaging cameras, and more. These products include brands such as Tektronix, Teledyne FLIR, Rohde & Schwarz, GW Instek, Gossen Metrawatt, and others. It serves a broad spectrum of sectors, including medical, automobile, security, electronics, and other industries.

-

-

Box Making Machine Manufacturer Ranking

*Including some distributors, etc.Ranking as of April 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | T-Roc Equipment, LLC |

25.0%

|

| 2 | Zhejiang Feida Machinery Co.,Ltd |

12.5%

|

| 3 | autoboxup.com |

12.5%

|

| 4 | Master Automation Co., Ltd |

12.5%

|

| 5 | Miller Weldmaster Corporation |

12.5%

|

| 6 | SCM Group |

12.5%

|

| 7 | Rengo Co., Ltd. |

12.5%

|

Derivation Method

The ranking is calculated based on the click share within the box making machine page as of April 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

- MITSUBISHI HEAVY INDUSTRIES, LTD.: 77,283

- Rengo Co., Ltd.: 22,548

Newly Established Company

- Dongguan Pinchuang Automation Equipment Co.,Ltd.: 2015 (9 years ago)

- QINGDAO AOPACK ON DEMAND PACKAGING Co., Ltd.: 2014 (10 years ago)

- Zhejiang Feida Machinery Co.,Ltd: 2010 (14 years ago)

Company with a History

- MITSUBISHI HEAVY INDUSTRIES, LTD.: 1884 (140 years ago)

- Friends Engineering: 1965 (59 years ago)

- Neway Packaging Corporation: 1977 (47 years ago)

Box Making Machine Manufacturers in United States

*Including some distributors, etc.

Global Distribution of Box Making Machine Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

China

China

|

8 | 47.1% |

United States of America

United States of America

|

3 | 17.6% |

India

India

|

2 | 11.8% |

Italy

Italy

|

1 | 5.9% |

Poland

Poland

|

1 | 5.9% |

Taiwan

Taiwan

|

1 | 5.9% |

Germany

Germany

|

1 | 5.9% |

List of Box Making Machine Products

26 products are listed.

Sekisui Material Solutions

Fully automatic boxing machine Quick Casser

10+ people viewing

Last viewed: 4 hours ago

Stable high -speed bonft is possible even in large cases and elongated cases feature ・ Stable bonus with a simple mechanism. ・ Various alarms and...

Sekisui Material Solutions

Completely automatic e -machine / exclusive option tape auto changer

Last viewed: 4 hours ago

feature ・ The tape is automatically supplied to the bonus machine without interruption. ・ Selectable 2 types (AC-505/AC-503) ・ Press the tapes with...

Corporation

Case Former F176

30+ people viewing

Last viewed: 7 hours ago

The pin pickup method has been realized at low cost. The left and right safety cover is standard equipment and the safety performance has been impr...

Corporation

Case Former F175

10+ people viewing

Last viewed: 8 hours ago

The pin pickup method has been realized at low cost. The left and right safety cover is standard equipment and the safety performance has been impr...

Sekisui Material Solutions

Heavy case with pusher Easy minija CK-100-SE

10+ people viewing

Last viewed: 4 hours ago

A semi -automatic boxing machine that can easily handle "assembly", "box stuffing", and "transport". feature ・ Operation switches can be installe...

Corporation

Case Former F177

40+ people viewing

Last viewed: 7 hours ago

The pin pickup method has been realized at low cost. The left and right safety cover is standard equipment and the safety performance has been impr...

Sekisui Material Solutions

Fully automatic high -speed boxing machine Quick Casser

Last viewed: 4 hours ago

Stable high -speed bonft is possible even in large cases and elongated cases feature ・ Stable bonus with a simple mechanism. ・ Eight -minute spee...

Sekisui Material Solutions

The definitive workmate of the easy -to -handle box machine that is compact and easy to handle 13

Last viewed: 4 hours ago

A semi -automatic boxing machine that is ideal for assembling the case and saving the bottom paste work. Ideal for a bonus site that is not enough ...

Sekisui Material Solutions

Semi-automatic boxing mini-kaser CK-100-N that can easily handle "assembly", "box stuffing" and "transport"

Last viewed: 4 hours ago

Ideal for medium and lightweight packaging. feature ・ Economy type that does not require air. ・ With casters that can be easily moved. ・ Since thi...

Sekisui Material Solutions

"Booking" and "Sealing" 2 functions that can easily handle two functions with one unit 34

10+ people viewing

Last viewed: 4 hours ago

A compact design that allows a flexible line set with casters. feature ・ Easy to change left and right operations. ・ Ideal for making and storing...

Sekisui Material Solutions

High -performance semi -semi -automatic self -automatic boxing machine workmate 12 in small cases

Last viewed: 4 hours ago

We squeezed the box size and saved space. feature ・ With a case adsorption holding mechanism, the bottom is automatically inserted even if you re...

Corporation

Case Former F800A

Last viewed: 7 hours ago

The first eight -shaped cardboard case has been realized for the first time by tape pasting. ◆ Type A 8 square cardboard merit Cardboard collapse ...

Sekisui Material Solutions

Dedicated cardboard case for apples / no dedicated boxes, sealing machine workmate 43apn

Last viewed: 4 hours ago

A semi -automatic e -seal machine that can easily handle two functions and "seal" with one function. feature A random -type semi -automatic e -aut...

Sekisui Material Solutions

Fully automatic boxing machine workmate series

Last viewed: 4 hours ago

Enhanced lineup according to processing capacity and cardboard size feature ・ Realize safe and comfortable operability by standardization of touc...

Lampack Co., Ltd.

Adjustable tray molding packing solution FORM'IT! ™ Tray

Last viewed: 7 hours ago

■ Adjustable tray molding A new technology developed through continuous research and development for many years, and is easily and cost -efficient ...

Lampack Co., Ltd.

Semi -A -type carton molded packing solution FORM'IT! ™ case

10+ people viewing

Last viewed: 5 hours ago

■ Semi -A carton molding Carton molding is easier than ever. With many years of research and development, we have developed a group of semi -automa...