All Categories

History

This section provides an overview for corrugated sheets as well as their applications and principles. Also, please take a look at the list of 37 corrugated sheet manufacturers and their company rankings. Here are the top-ranked corrugated sheet companies as of July, 2025: 1.Metal Sales Manufacturing Corporation, 2.Niagara Sheets LLC, 3.Corrugated Metals, Inc..

Table of Contents

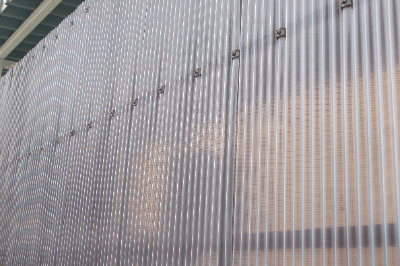

Corrugated sheets are materials shaped like waves and are known for their strength, light weight, and resistance to breakage. Their design facilitates water runoff during rain, making them ideal for roofing and wall materials in temporary buildings or sheds. Compared to other building materials, corrugated sheets offer a cost-effective solution.

Corrugated sheets serve multiple purposes due to their light weight and durability. Made from materials like polycarbonate resin or metal such as galvanized steel, they're utilized based on their unique advantages.

Used for roofing and walls in residential terraces, parking lots, and sheds, these sheets provide high transparency and are chosen for lightweight constructions to avoid overloading supporting structures.

Galvanized steel sheets are strong, durable, and corrosion-resistant, making them suitable for factory roofing due to their thermal barrier properties and opacity.

The wavy shape of corrugated sheets enhances their strength and facilitates efficient drainage. Available in various designs, these sheets support mass-produced housing and offer an economical building material solution.

Corrugated sheets are stronger and lighter than flat sheets and offer superior drainage. They're available in designs like trapezoidal and square shapes, catering to different building needs.

The durability of corrugated sheets varies by material. PVC sheets have a short lifespan but are easily workable, while materials like polycarbonate and galvalume steel offer longer durability with specific application advantages.

Choosing the right tools is crucial for cutting corrugated sheets, with options ranging from special scissors for PVC to saws for metal sheets. Proper marking and careful cutting are essential to prevent overcutting.

Installation involves fastening the sheets with screws, nails, or hook bolts, ensuring proper overlap for water runoff. Correct fastening techniques are crucial for secure and effective installation.

*Including some distributors, etc.

Sort by Features

Sort by Area

Corrugated Metals, Inc., founded in Belvidere, Illinois, in 1887 is a manufacturer of custom roll formed metal products, providing metal corrugating and complementary services. The company's product portfolio includes extra wide corrugated roofing and siding, Sinewave products, Custom roll forming, Interior Liner Panels, and Architectural Wall Panels. The company serves markets including Medical and Healthcare, Aerospace and Defense, Consumer Goods, Industrial Manufacturing and Construction and Building. They also offer custom packaging, warehousing, and distribution services.

Metal Sales Manufacturing was established in 1963 in Antioch, TN, and is a manufacturer of wall, metal roofing, and building systems made of steel, weathering steel, and aluminum substrate materials. Its product catalog includes corrugated roofs, wall panels, double walls, and classic ribs. It also offers these product series: exposed fastened, contempra, deep rib, T-armor, and TLC. The company has done projects for Alaska Rock Gym, Asu Walter Cronkite School of Journalism, Bluegrass Harley Davidson, Calvary Chapel, and Cameron Parish La School Board.

Western States Decking, Inc., established in 1996 and based in Arizona, United States, is a distributor of Verco metal decking products. The company produces products such as metal roofing exposed fasteners, metal roofing standing seam, metal siding exposed fasteners, and metal siding concealed fasteners and supplies for the construction industry. Apart from this, the company also has painted products that look like old weather galvanized steel, old rusted roofs, and painted copper. The company also manufactures metal roof panels and wall panel profiles.

Shanghai Metal Corporation, established in 1980 as a state-owned Shanghai Metal Materials Company headquartered in Shanghai, China, is a manufacturer and supplier specializing in metal materials and products. The company's metal offerings include aluminum, copper, stainless steel, galvanized steel, and steel products. It also provides metal machines for forming, cutting, bending, and processing. Additionally, the company offers various containers, gas cylinders, fire extinguishers, mechanical products, and electrical systems. These products find applications in various industries, such as automobile, construction and decoration, electrical and transformer components, machinery, and packaging. Other applications include oil, gas, and water pipelines, as well as boilers and tanks.

TuoLian Metal based in China, is a manufacturer of stainless-steel sheets, stainless steel tubes, stainless steel flat bars, steel coils, and steel rods. The products produced by the company are used in various applications such as marine, defence, aerospace, pump manufacturing, and energy & industry. Using the stainless-steel material, the company designs and constructs elevators. The high-grade stainless-steel materials are available in different thicknesses, sizes, and surface finishes and are used for elevator doors, walls, ceilings, control panels, and handrail systems.

COSASTEEL was founded in 2016 and is headquartered in Shandong Province, China, as a manufacturer of steel coils. This company holds the highest position as the principal producer of pre-painted steel on a global scale, exhibiting a sincere devotion to the field of metal construction. The company possesses a state-of-the-art production line for coated steel coil, ensuring a consistent supply of products to its customers. To achieve flawless manufacturing of products, the company has implemented a comprehensive procedure for managing product quality and successfully implemented process control for color-coated items.

Colibrys, a joint company established in 2001 and headquartered in Yverdon-les-Bains, Switzerland, is a manufacturer, designer, and supplier of micro-electro-mechanical system sensors and electronic machines. The company offers a wide range of products including mechanical power transmissions, power generation systems, and seismic sensors. These products are used in industries such as aerospace, defense, energy, and transportation. Their products are utilized for various applications including measuring acceleration, inclination, and seismic activity, enabling data collection for various critical applications. The company also offers services such as aerial refueling and air delivery systems.

Petersen Aluminum Corporation, established in 1965 and headquartered in Illinois, US, is a manufacturer that specializes in architectural metal products. The company offers a wide range of products, including metal wall panel systems, metal roof panels, soffit panel systems, and more. It also offers perforated metal panels, coil and flat sheets, and column covers. Its soffit panel systems provide a finished look to the underside of eaves and canopies. It serves various industries, including commercial and residential design.

China Lucky Steel Co., Ltd, established in 2000 and based in Qingdao, China, is a manufacturer and distributor of steel products. The company's product range includes steel coil, carbon steel strip, stainless steel coil, stainless steel welded pipe, and aluminum coil. These products are primarily used in the construction, automotive, infrastructure, and industrial sectors. The company primarily serves industries involved in building, manufacturing, and transportation. The company also offers services such as custom product solutions, one-stop service for orders, and production as per international standards.

Goldeco Steel, established in 2008 and based in Foshan, China, is a manufacturer and supplier of stainless steel sheets. The company's product range includes embossed stainless steel sheets, etched stainless steel sheets, bead blast stainless steel sheets, vibrated stainless steel sheets, and circle polished stainless steel sheets. These products are used for various aesthetic and functional purposes in the mining and other related sectors. They primarily serve industries such as construction, interior design, automotive, and consumer goods. The company's services include chemical testing, secure delivery, custom sizing, and customer support.

Pruszyński, established in 2004 and based in Sokołów, Komorów, Poland, is a manufacturer and supplier of roofing and elevation materials. The company's product range includes custom-made steel tiles, elevation panels, trapezoidal sheets, sandwich panels, and NIAGARA gutters. These products are used in building roofs, elevations, and various construction applications. It serves industries such as construction, architecture, and building material supply. The company also offers services like sheet metal processing, cutting, perforation, and custom product manufacturing.

Shandong Future Metal Manufacturing Co., Ltd, established in 2021 and located in Shandong, China, is a manufacturer and supplier of metal products, including carbon steel, stainless steel, galvanized materials, and aluminum. The company’s product line includes seamless steel pipes, stainless steel pipes, welded pipes, hot-dip galvanized pipes, and steel coils. Its products find markets in more than 50 countries and regions, including North America, South America, Europe, Africa, the Middle East, and Southeast Asia. Its products serve industries such as power plant desulfurization, petrochemical equipment, coal chemical, fluorine chemical, and fine chemical industries.

Gostar Corporation Limited, established in 1998 and based in Shanghai, China, is a manufacturer and supplier of industrial materials. The company's product range includes coil, sheet, fitting, valve, and wire. These products are used in applications such as power plants, construction, and infrastructure development. It primarily serves industries like power generation, construction, petroleum, and the chemical sector. The company also offers services in exporting complex non-standard items, providing custom-made materials, and producing a variety of other products using different materials and dimensions.

Palram Industries Ltd, established in 1963 and based in Ramat Yohanan, Israel, is a manufacturer and supplier of semi-finished extruded thermoplastic sheets and panel systems. The company's product range includes corrugated polycarbonate sheets, condensation control corrugated polycarbonate sheets, corrugated PVC sheets, PVC liner sheets, and architectural roofing panel systems. These products are used in glazing, architectural projects, and construction. It mainly serves the DIY, construction, advertising, and agriculture sectors. The company's services include roofing & siding, skylights, interior cladding & liners, and facades & curtain walls.

Brett Martin Ltd. was established in 1958 and is headquartered in Newtownabbey, County Antrim, England, as a manufacturer and supplier of plastic products. The product portfolio of the company consists of Drain Pipe and Fittings, Sewer, Marlon Clickfix, Marlon ST Solar Control, and Marlon ST Opaque, among others. The products provide flexible solutions for various industries, including drainage systems, roofing, cladding, and architectural projects, meeting diverse needs and ensuring efficient wastewater management, weather protection, and aesthetics in buildings. The company serves the construction, architectural, roofing, drainage, and wastewater management industries.

Cladco Profiles, established in 1972 and based in Okehampton, England, is an ISO 9001, ISO 14001, and ISO 45001 certified manufacturer and supplier of roofing sheets and composite outdoor products. The company's product range includes steel roofing sheets, PVC Plastisol coated finishes, polyester paint-coated finishes, Prelaq mica-coated cladding panels, and metal roofing accessories. These products are utilized in building construction, architectural design, residential projects, commercial development, and agricultural facilities. The company also offers services in manufacturing, product development, customer consultation, and sales support.

Hebei Sinostar Trading Co., Ltd., established in 2005 and headquartered in Hebei, China, is a supplier of various building materials, tools, hardware, and home furniture. The company offers a wide range of products, including roofing sheets, metal pipe, wire, fences, gates, and more. It also provides fitting and valves, iron art, scaffolding, and home furniture. Its roofing tiles can help maintain a comfortable indoor temperature and potentially reduce energy costs. The company has received ISO 9001 and ISO 45001 certification. It serves industries such as construction, roofing, furniture, and more.

Madar Building Materials, founded in Saudia Arabia in 1969, is an ISO certified supplier of building materials. The company's product portfolio includes a wide range of lumber and timber products, including dimensional lumber, plywood, and engineered wood, essential for framing, structural support, and finishing, siding materials such as vinyl, wood, and fiber cement siding, and a variety of fasteners, tools, and hardware to assist in construction, renovation, and repair projects.

Industrial Metal Supply Company is based in California with locations across California, Arizona, and Northern Mexico. The company is a distributor of metals and accessories for dealing with metal. The company also provides numerous finishing services. The company works with many types of standard metals such as steel, aluminum, and copper as well as many specialty metals including hobby metals. The company offers metals in bar, tube, pipe, sheet, and plate forms. Services include cutting to size, laser cutting water jet, and custom extrusions among others.

Ariel Plastics Ltd, founded in the UK, is a supplier of roofing sheets, roof lights, and roofing accessories. The company's product portfolio includes roofing sheets in various materials, including metal, corrugated, and composite panels, designed for durability and weather-resistance, skylights, roof windows, and accessories to enhance interior illumination while maintaining energy efficiency and insulation solutions to ensure the roofing systems meet energy efficiency standards. The company has nationwide logistic and customer support operations in the UK.

Safari Metal Trading LLC, founded in UAE in 1994, is a supplier of stainless steel. The company's product portfolio includes an extensive selection of stainless steel sheets and plates in various grades and finishes that are used for manufacturing, construction, and architectural projects, stainless steel pipes, and tubes, suitable for applications in plumbing and stainless steel fittings, including couplings, elbows, tees, and more. It exports to more than 20 countries such as Muscat, Qatar, Bahrain, and Saudi Arabia.

Ranking as of July 2025

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Metal Sales Manufacturing Corporation |

9.7%

|

| 2 | Niagara Sheets LLC |

9.1%

|

| 3 | Corrugated Metals, Inc. |

9.1%

|

| 4 | Florida Corrugated Metals |

8.1%

|

| 5 | Tri State Matal Roofing Supply |

4.9%

|

| 6 | Western States Metal Roofing |

4.5%

|

| 7 | COSASTEEL |

4.2%

|

| 8 | Shanghai Metal Corporation |

4.2%

|

| 9 | Petersen Aluminum Corporation |

3.2%

|

| 10 | Sumitomo Bakelite Co., Ltd. |

3.2%

|

Derivation Method

The ranking is calculated based on the click share within the corrugated sheet page as of July 2025. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

China

China

|

7 | 29.2% |

United States of America

United States of America

|

5 | 20.8% |

India

India

|

4 | 16.7% |

United Kingdom

United Kingdom

|

3 | 12.5% |

Japan

Japan

|

1 | 4.2% |

Poland

Poland

|

1 | 4.2% |

United Arab Emirates

United Arab Emirates

|

1 | 4.2% |

Germany

Germany

|

1 | 4.2% |

| Saudi Arabia | 1 | 4.2% |

47 products found

47 products

Daiwa Slate Co., Ltd.

380+ people viewing

Last viewed: 2 hours ago

■Construction without removing the existing large wave slate roof Since this construction method allows construction on the existing large wave sla...

Daiwa Slate Co., Ltd.

300+ people viewing

Last viewed: 4 hours ago

This accessory is compatible with Yamato Cover Roof 650. The wind resistance and load strength of curved buildings are several times higher than th...

Yoshikawa Shoko Co., Ltd.

310+ people viewing

Last viewed: 2 hours ago

*We accept orders starting from 1 piece. ■What is embossing? Ground glass condition. I can't see you face to face. It is used for roofs and blindf...

Yoshikawa Shoko Co., Ltd.

200+ people viewing

Last viewed: 15 hours ago

*4, 5, and 12 shaku, this product is made to order. It will be shipped in a package of 10 pieces of each size. (Please note that roses are not all...

Daiwa Slate Co., Ltd.

370+ people viewing

Last viewed: 14 hours ago

■Construction without removing the existing super large wave slate roof Existing Super Large Wave Slate (Roof Wide) Since this construction method ...

Yoshikawa Shoko Co., Ltd.

280+ people viewing

Last viewed: 13 hours ago

Cross line corrugated board has a pattern. Contains no fiber. The pattern is beautiful and looks great. *Shipped in units of 10 pieces. Roses are ...

Daiwa Slate Co., Ltd.

260+ people viewing

Last viewed: 20 hours ago

This is a folded plate that can be made economical and labor-saving in construction work by lowering the mountain height and widening the working w...

Daiwa Slate Co., Ltd.

340+ people viewing

Last viewed: 1 day ago

With a working width of 750 mm, it has excellent workability and is economical. The straight lines give a sharp impression, making it ideal for lar...

Daiwa Slate Co., Ltd.

270+ people viewing

Last viewed: 1 day ago

Our special technology allows us to create products with high processing precision that prevent the board from warping, using Galva Onami's back in...

Daiwa Slate Co., Ltd.

320+ people viewing

Last viewed: 13 hours ago

Our special technology allows us to apply insulation material to the back side of Galva corrugated plates, resulting in highly accurate products th...

Yoshikawa Shoko Co., Ltd.

290+ people viewing

Last viewed: 16 hours ago

*We will ship from 1 piece. Heat ray cut polycarbonate corrugated sheet is a corrugated building material made from polycarbonate resin, and is a ...

Daiwa Slate Co., Ltd.

260+ people viewing

Last viewed: 1 day ago

Using our patented technology, we can create a product with high processing accuracy that prevents warping of the iron plate with insulation materi...

Yoshikawa Shoko Co., Ltd.

180+ people viewing

Last viewed: 6 hours ago

*Shipped in units of 10 pieces. Roses are not allowed. Heat ray cut polycarbonate corrugated sheet is a corrugated building material made from pol...

Daiwa Slate Co., Ltd.

210+ people viewing

Last viewed: 1 day ago

Yamato Roof 150 is the most popular steel plate roofing material made of stacked folded plates. It is used in medium to large-sized buildings (fact...

Chiyoda Steel Industries Co., Ltd.

300+ people viewing

Last viewed: 1 day ago

■NM-8697 This product uses a non-combustible material (NM-8697) that has been collectively certified by the Minister of Land, Infrastructure, Trans...

Daiwa Slate Co., Ltd.

240+ people viewing

Last viewed: 19 hours ago

Smart Wall YS is a steel plate wall material using the small wave slate exterior wall repair method and new construction method. ■Features ・The e...

Daiwa Slate Co., Ltd.

280+ people viewing

Last viewed: 1 day ago

Available in a variety of colors (*1), it vividly colors the roofs and exterior walls of stores and factories. Using a water-based acrylic silicone...

Daiwa Slate Co., Ltd.

260+ people viewing

Last viewed: 1 day ago

This is an SDS label based on the PRTR Act.

Daiwa Slate Co., Ltd.

290+ people viewing

Last viewed: 9 hours ago

It can be used in fireproof structures as a legally noncombustible material, and can be used in the roof walls of steel-framed buildings to make th...

Daiwa Slate Co., Ltd.

360+ people viewing

Last viewed: 3 hours ago

It can be used in fireproof structures as a legally noncombustible material. It is mainly used as an exterior wall material and is widely used for ...

Daiwa Slate Co., Ltd.

290+ people viewing

Last viewed: 1 day ago

This product is manufactured using our unique technology and is ideal for areas with frequent typhoons, heavy snowfall, and buildings with strong v...

Daiwa Slate Co., Ltd.

220+ people viewing

Last viewed: 11 hours ago

This is an energy-saving building material with rigid polyurethane foam bonded to the back side of slate. Excellent heat insulation and non-hygrosc...

Daiwa Slate Co., Ltd.

230+ people viewing

Last viewed: 28 minutes ago

Urethane slate is an energy-saving building material that combines hard polyurethane foam with the back side of corrugated slate, creating an indoo...

Daiwa Slate Co., Ltd.

310+ people viewing

Last viewed: 1 day ago

■First in the industry. Wide size with working width of 750 mm Since it has a wide working width of 750 mm, it is possible to reduce the number of ...

Watanabe Koken Co., Ltd.

160+ people viewing

Last viewed: 12 hours ago

◼︎Main features ・Conventional wave type ・For slate roof replacement ・Possible ・Can also be pasted on the back ◼︎Main uses Roof and wall materi...

Sumitomo Bakelite Co., Ltd.

250+ people viewing

Last viewed: 2 hours ago

■Product introduction Polykanami au is a corrugated plate for livestock manure houses with improved ammonia resistance. Features ■Ammonia resistan...

Watanabe Koken Co., Ltd.

150+ people viewing

Last viewed: 1 day ago

◼︎Main features Widely used as a traditional exterior material ◼︎Main uses Roofs and exteriors of factories, warehouses, poultry houses, agricultu...