All Categories

History

This section provides an overview for nord lock washers as well as their applications and principles. Also, please take a look at the list of 10 nord lock washer manufacturers and their company rankings. Here are the top-ranked nord lock washer companies as of February, 2026: 1.TFC Europe Ltd, 2.U-BOLT-IT, INC., 3.Trinity Equipment Co..

Table of Contents

Categories Related to Nord Lock Washers

Nord-lock washers are two-piece washers with an anti-looseness feature, invented by Nord-lock in 1982.

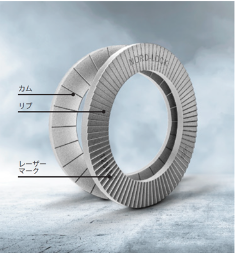

Nord-lock washers come in pairs, with the cam surfaces (see above) facing each other so that the ribs grip the bolt/nut and the mating material. The Nord-lock washers are used to grip the threaded nut and mating material.

Nord-lock washers are effective against screw loosening, but only against rotational loosening. Besides rotational looseness, non-rotational looseness is another type of screw looseness. Non-rotational looseness is caused by plastic deformation of the member sandwiched by the screw.

Nord-lock washers are used in screw fastening where rotational loosening is not allowed. They are therefore used in specific areas in a variety of fields. They are used in buildings, power equipment, railroads, and other transportation systems, as well as various types of equipment.

Examples include cable bands for suspension bridges and steel-frame bridges in the building industry. In the electric power industry, they are used in turbine rotors for wind power generation, reactor pressure vessels for nuclear power plants, converters for tidal power generation, and coupling devices for railroad cars.

The function of a bolt is often compared to that of a spring. The bolt is stretched as it is tightened, and the simultaneous undo force (axial force) grips the object being fastened.

Unlike other anti-looseness products, the Nord-lock washer uses the axial force itself, not friction, to prevent the bolt/nut from returning to its original position. When the bolt or nut is tightened using the Nord-lock washer, the cams engage each other and the two sets of outer ribs grip the bolt/nut and the mating material surface to hold it in place.

This grip mark is left as an impression mark on both the bolt/nut and the mating material and is proof that the anti-looseness effect is working. When a loosening force is applied, the inner cams slide together. The cam angle α is designed to be larger than the thread lead angle β. When the cams move, the washer thickness increases, and pulls the bolt head up.

This wedge-locking technology physically prevents the bolt from loosening even when exposed to severe vibration.

When loosening the bolt/nut, the Nord-lock washer is secured between the bolt/nut and the mating material by the ribs, so only the area between the cams inside the two-piece set slides, and the washer on the mating material side does not move. The axial force increases as the bolt head is pulled up until the cam overcomes one of the mating cams, but once the cam overcomes the mating cam, the wedge lock is released and the bolt can be removed.

The Nord-Lock is designed to allow removal with less than the tightening torque.

Depending on the application, Nord-lock washers are made not only of regular iron (steel, Delta Protect coated) and stainless steel (SUS316L equivalent), but also of super stainless steel, a highly corrosion resistant stainless steel called 254SMO® (SUS312L equivalent), Alloy C276 (Hastelloy C-276 equivalent), Alloy718 Alloy C276 (Hastelloy C-276 equivalent) and Alloy718 (Inconel 718 equivalent).

Nord-lock washers are reusable. The first time they are used, the two pairs of washers are glued together. After the glue is removed for reuse, the washers should be placed on top of each other so that the cam surfaces (large-jagged surfaces) are in contact with each other. The number of times they can be reused depends on the conditions of use and other factors.

The tightening torque for fastening with Nord-lock washers is determined by the required axial force of each user, which is no different from that of general fastening. On top of that, manufacturers have prepared torque guidelines for determining torque and applications for automatic Nord-lock tightening torque calculations.

*Including some distributors, etc.

Sort by Features

Sort by Area

Trinity Equipment Co., founded in 1986 and headquartered in Muskegon, United States of America, is a manufacturer of OEM and replacement parts. The company produces steel wear parts, freight car parts, end-of-car hose assemblies, and load securements for centerbeam railcars. It also delivers lube discs, chains and shim plates, conspicuity tapes, lock washers, and tank car decals. Its end-of-car hose assemblies exceed all AAR specifications and are built to exceed a service life of eight years.

U-BOLT-IT, INC. is a manufacturer and distributor of fasteners and lifting hardware founded in 1988 and based in Houston, Texas. The company offers various standard and custom bolts, nuts, screws, and cables. These include eye and U bolts, hex nuts, cable assemblies, and button socket head screws in a wide range of materials and coatings/finishes. U-Bolt-It products are primarily used by clients in the industrial manufacturing, marine, consumer goods, and off-shore sectors.

Nord-Lock Group, established in 1982 and headquartered in Sandviken, Sweden, is a manufacturer and supplier of wedge-locking technology for bolted joints. The company offers a comprehensive range of products, including Nord-Lock washers to secure bolted joints against loosening in extreme conditions, Boltight washers for high-pressure applications, Expander washers to prevent bolt hole stripping, Torque limiters to prevent over-tightening, and Thread repair inserts for fixing of damaged or worn threads. They cater to diverse industries seeking durable and dependable joint fastening solutions.

J.C Gupta & Sons, established in 1993 and located in Karnataka, India, is a manufacturer and supplier of fasteners, tools, and accessories. The company’s product line includes titanium fasteners, thread inserts, marine fasteners, security fasteners, and expandet screw anchors. It also offers anti-theft tamper-proof screws, thin sheet fasteners like blind rivet nuts and clinch fasteners, and screw designs like ultra-low profile screws and 120-degree CSK screws. Its products serve industries like automotive, construction, and various fabrication units.

Pee Vee Enterprises, established in 1979 and located in Delhi, India, is a wholesaler, manufacturer, and supplier of industrial fasteners. The company’s product line includes helicoil thread repairing products, socket head products, hex bolts, screws, and nuts. It also offers wire thread repair, engineering and application support, on-site consultation services, and customized packing solutions, which can include labeling with part or code numbers, barcoding, and direct dispatch to the end customer, all designed to meet specific customer needs. Its products finds applications in the automobile, mining, cement, paper, and construction industies.

TFC Europe Ltd, founded in the UK in 1981, is a supplier of engineering fastener products. The company offers an extensive selection of bolts and nuts in various sizes, materials, and grades to accommodate different mechanical and construction projects, a diverse range of screws, including machine screws, wood screws, self-tapping screws, and concrete anchors and wall anchors, designed to securely fasten objects to various surfaces. It has ISO 9001:2015 and Aerospace AS9100d & AS9120 certifications.

Berardi Bullonerie, established in 1919 and headquartered in Bologna, Italy, is a distributor of transportation, logistics, supply chain, and storage. The company offers a range of products, including bolts, screws, springs, anchor bolts, and metal. It also offers plastic smallware, unified fasteners, hose clamps, and more. Its product reduces warehouse management costs and minimizes waste. The company has achieved ISO 9001:2015 certification for its quality management systems. It serves various industries such as construction, manufacturing, healthcare, engineering, and more.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | TFC Europe Ltd |

32.7%

|

| 2 | U-BOLT-IT, INC. |

18.2%

|

| 3 | Trinity Equipment Co. |

9.1%

|

| 4 | Swarna Fastners |

7.3%

|

| 5 | Berardi Bullonerie |

7.3%

|

| 6 | J. C. GUPTA & SONS |

5.5%

|

| 7 | Pee Vee Enterprises |

5.5%

|

| 8 | Uma Spring |

5.5%

|

| 9 | Nord-Lock Group |

5.5%

|

| 10 | Tianjin SIMFLEX Company LTD. |

3.6%

|

Derivation Method

The ranking is calculated based on the click share within the nord lock washer page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

India

India

|

4 | 40.0% |

United States of America

United States of America

|

2 | 20.0% |

Sweden

Sweden

|

1 | 10.0% |

China

China

|

1 | 10.0% |

United Kingdom

United Kingdom

|

1 | 10.0% |

Italy

Italy

|

1 | 10.0% |

164 products found

164 products

Otsuki Shoten Co., Ltd.

290+ people viewing

Last viewed: 13 hours ago

■Earthquake-proof and anti-loosening washers that are effective in areas with strong vibrations. This is a vibration-resistant and shock-resistant ...

10 models listed

Yamamoto Neji Kohan Co., Ltd.

470+ people viewing

Last viewed: 14 hours ago

The Wedge Lock Washer is a locking product that uses axial force to tighten bolts and nuts in important locations safely, easily, and reliably. ■F...

Bossard Co., Ltd.

200+ people viewing

Last viewed: 14 hours ago

Generally referred to as a washer, it is inserted between the mating material and the nut when tightening a bolt to prevent it from coming off, cor...

10 models listed

Ti Kato

230+ people viewing

Last viewed: 13 hours ago

It prevents wood thinning, collecting due to load, and loosening due to vibration, preventing the weakness of the joining part, and maintaining the...

5 models listed

Japan Pralad Co., Ltd.

480+ people viewing

Last viewed: 8 hours ago

"Sound Zero washer" that completely prevents bolts around (patented). Bolt size: Compatible with M14 to M72. ■ It is not a washer that uses the fr...

18 models listed

Yunex joint company

170+ people viewing

Last viewed: 14 hours ago

The new high -talk J washer has added a locking function that minimizes the loosening of bolts caused by vibration. As a result, we raised the spec...

11 models listed

Yunex joint company

710+ people viewing

Last viewed: 14 hours ago

High talk washer is the easiest tool for improving safety, speed and accuracy. A system that does not see this kind of patent has eliminated the ne...

Wilco Co., Ltd.

370+ people viewing

Last viewed: 13 hours ago

This washer is manufactured by Sweden's Nord-Lock using a unique technology and has a strong anti-loosening effect. Two uniquely shaped washers are...

Nakajima Koki Co., Ltd.

210+ people viewing

Last viewed: 13 hours ago

Nord-Lock washers, which feature a wedge locking mechanism, use axial force rather than friction to physically prevent bolt connections from loosen...

10 models listed

Nakajima Koki Co., Ltd.

170+ people viewing

Last viewed: 13 hours ago

Nord-Lock X series washers have a wedge locking mechanism that prevents bolts from rotating loosely, and a spring mechanism that compensates for th...

10 models listed

Nakajima Koki Co., Ltd.

160+ people viewing

Last viewed: 50 minutes ago

Nord-Lock SC washers are specifically designed for the construction industry. Each inner diameter is chamfered to optimize the contact surface betw...

8 models listed

Nakajima Koki Co., Ltd.

180+ people viewing

Last viewed: 13 hours ago

Nord-Lock washers, which feature a wedge locking mechanism, use axial force rather than friction to physically prevent bolt connections from loosen...

10 models listed

Nakajima Koki Co., Ltd.

180+ people viewing

Last viewed: 13 hours ago

Nord-Lock washers, which feature a wedge locking mechanism, use axial force rather than friction to physically prevent bolt connections from loosen...

10 models listed

Nakajima Koki Co., Ltd.

150+ people viewing

Last viewed: 13 hours ago

Nord-Lock washers, which feature a wedge locking mechanism, use axial force rather than friction to physically prevent bolt connections from loosen...

10 models listed

Nakajima Koki Co., Ltd.

220+ people viewing

Last viewed: 13 hours ago

Nord-Lock washers, which feature a wedge locking mechanism, use axial force rather than friction to physically prevent bolt connections from loosen...

10 models listed

Accurate Co., Ltd.

510+ people viewing

Last viewed: 14 hours ago

■Summary When the bolt is tightened, the outer radial tooth surface of the HEICO-LOCK® Wedge Lock System is embedded into the underside of the bolt...

Accurate Co., Ltd.

430+ people viewing

Last viewed: 14 hours ago

■Summary HEICO-LOCK® ringlock washers provide high quality and easy bolting for any application. Perfect for repeated use. The RingLock system is d...

Nikki Co., Ltd.

770+ people viewing

Last viewed: 14 hours ago

■What is AW washer (Kiku washer)? Used with AN nuts, they have one tooth on the inside and many teeth on the outside. ■How to use AW washer (Kiku ...

Azumaneji Co., Ltd.

360+ people viewing

Last viewed: 13 hours ago

■Loosening prevention washer (NORD-LOCK®) NORD-LOCK® washers use tension rather than friction to secure bolts. The system consists of a two-piece w...

Nord-Lock Group

300+ people viewing

Last viewed: 13 hours ago

■Summary Nord-Lock washers, which feature a wedge locking mechanism, use axial force rather than friction to physically prevent bolt connections fr...

Nord-Lock Group

370+ people viewing

Last viewed: 6 hours ago

■Summary Nord-Lock washers, which feature a wedge locking mechanism, use axial force rather than friction to physically prevent bolt connections fr...

Nord-Lock Group

260+ people viewing

Last viewed: 13 hours ago

■Summary Nord-Lock washers, which feature a wedge locking mechanism, use axial force rather than friction to physically prevent bolt connections fr...