All Categories

History

This section provides an overview for flanged shaft couplings as well as their applications and principles. Also, please take a look at the list of 22 flanged shaft coupling manufacturers and their company rankings. Here are the top-ranked flanged shaft coupling companies as of July, 2025: 1.TIMKEN, 2.Stoffel Polygon Systems, Inc., 3.AISCO INDUSTRIAL COUPLINGS.

Table of Contents

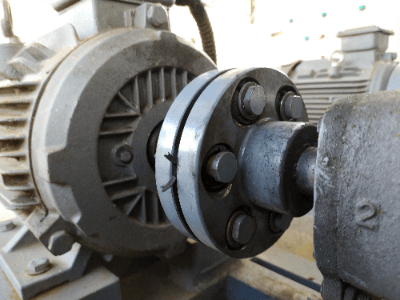

Flanged shaft couplings are mechanical devices designed to connect two rotating shafts for power transmission. They are made for permanent coupling needs, where shafts remain connected, and applications requiring disconnection capabilities similar to clutches.

These couplings are particularly valued for their ability to align the drive and driven shafts precisely, accommodating slight displacements, deflections, and ensuring high rigidity and accuracy in power transmission and shaft alignment.

Flanged shaft couplings perform essential roles in various applications:

By fulfilling these roles, flanged shaft couplings enhance the operation of machinery with rotating parts, reducing vibration effects and ensuring stable performance.

Shaft couplings are classified into various types:

Flanged shaft couplings connect driving and driven shafts in a straight line using flanges and coupling bolts. This setup allows for minor misalignments, transmitting motor rotation or movement from other equipment with high fidelity.

Deflection shaft couplings, including gear and roller chain types, offer specific benefits:

Elastic shaft couplings, like metal spring types, provide backlash-free operation and longevity without internal friction damping.

Comprising two flanges connected by bolts, flanged shaft couplings use elastic rubber bushes to fasten the flanges together, allowing for angular misalignment tolerance. The design ensures torque transmission through bushing compression while accommodating shaft flexibility.

Materials for flanged shaft couplings must comply with industry standards to ensure durability and proper function. Components include flanges, joint bolts, nuts, washers, spring washers, and bushes, each selected for quality and performance.

Regular maintenance, including bushing inspection and replacement, is crucial for prolonging the lifespan of flanged shaft couplings. Attention to bushing material is important, as some materials degrade faster when exposed to certain chemicals or oils.

*Including some distributors, etc.

Sort by Features

Sort by Area

The Timken Company (Timken) was founded in 1899 and is headquartered in North Canton, Ohio. Timken designs, manufactures, and manages engineered bearings and industrial motion products worldwide. Timken operates in two segments, Mobile Industries and Process Industries. The Mobile Industries segment’s portfolio includes bearings, seals, and lubrication devices and systems. The Process Industries segment provides industrial bearings and assemblies; industrial motion components, such as gears and gearboxes; and linear motion products, couplings, seals, lubricants, chains, belts, and related products and services to OEMs and end users in various industries.

Stoffel Polygon Systems, Inc., established in Duluth, Georgia in 1981 is a manufacturer of polygon connections. The company's product range includes CNC Machined Parts, 3D Printed Prototypes, Injection Molded Parts and sheet metal components fabricated to precise specifications. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and Power Generation. The company also provides services including Surface Grinding, Polygon Grinding, Cylindrical Grinding, technical support and customer service.

SDP/SI was founded in 1950 and is situated in New Hyde Park, New York. SDPP/SI is a manufacturer of precision gears and high-quality mechanical components used in the aerospace, industrial manufacturing, medical technology, and robotics fields. The company manufactures parts in a variety of materials including alloy steel, stainless steel, bronze, brass, nylon, and titanium. The company also provides coating services such as heat treating, zinc plating, and painting. Additional custom options are available including manufacturing to customer drawings and specifications.

Royerford Foundry & Machine Co., Inc., established in 1890 and based in Phoenixville, Pennsylvania, is a manufacturer specializing in precision power transmission products and machine tools. Its comprehensive product portfolio encompasses various vital components catering to diverse applications, which includes a range of bearings, such as pillow blocks and flange bearings, essential for industrial machinery and automotive engines. The company also produces couplings, from flexible to rigid, facilitating seamless power transmission between shafts. Further offerings include safety set collars for shaft security and arbor presses pivotal in machining operations across industries like aerospace and automotive.

Lovejoy was founded in the 1920s and is headquartered in Downers Grove, Illinois as a subsidiary of Timken. The company is an ISO 9001 certified manufacturer of couplings, universal joints, hydraulics, and vibration demeaning products serving customers located around the world in the energy, fluid power, food & beverage, and paper & steel industries. The company carries many types of couplings including grid, flexible, disc, and gear type and is the inventor of jaw type couplings.

System Components, Inc. established in 1967, System Components, Inc. is a manufacturer specializing in gear couplings such as flange-type gear couplings, sleeve-type gear couplings, and disc couplings. The company is based in Michigan, USA, but has several representatives throughout the country. Aside from gear couplings, the company also manufactures torque limiters in different designs, such as DIN universal joints, SAE universal joints, and sprockets. System Components, Inc. also offers custom machining on top of custom engineered couplings.

AISCO Industrial Couplings is a manufacturer of universal joints for industrial, off-highway, and transportation applications, established in 2013 and is located in Oconto Falls, Wisconsin, the United States. The company manufactures gear couplings, disc couplings, and elastomeric couplings. Custom designed universal joints and shaft connections are also available. It has been serving a broad spectrum of industries for years, from oil to paper to steel to marine to glass and general industries. It represents the finest driveshaft component manufacturers in the world and can offer help or assistance in designing the right driveshaft for customer application.

Norwood Screw Machine Parts (NSMP) is an American contract manufacturer specializing in custom and Swiss screw machine parts that was established in 1958. Located in Mineola, New York, the company is equipped to handle short and long run prototype to large-scale production operations, offering capabilities such as standard and Swiss screw machining, as well as CNC milling and turning. These are geared to the production of various precision parts including bushings, fasteners, fittings, couplings, and flanges. NSMP chiefly serves clients in the military, transportation, telecommunication, and marine sectors.

NBK America LLC, founded in 2015 and based in King of Prussia, Pennsylvania, is an American manufacturer and a subsidiary of Japan's Nabeya Bi-tech Kaisha, specializing in mechanical components. Their product range includes couplings, like miniature shaft couplings for precision machine tools and semiconductor manufacturing equipment, special screws, such as vacuum application screws and other machine components. NBK offers finite automaton (FA) solutions, including wireless positioning units for production lines and setup operations. NBK provides machine component servicing, such as vibration resistance treatment and laser engraving. Services for couplings and special screws include coupling stainless steel screw alteration and screw length adjustment.

Stafford Manufacturing Corp., founded in 1975 and located in Wilmington, Massachusetts, is a manufacturer and distributor of shaft collars, rigid shaft couplings, and specialty mechanical components. It offers precision machining and fabrication of small to medium-sized components of various designs. It also provides high-tolerance components, including simple parts, mated assemblies, and full enclosures. The company's service portfolio includes CNC milling, 3D prototyping, and laser engraving for prototyping and production.

The Rowland Company was founded in 1732 in Philadelphia, Pennsylvania when Benjamin Franklin was just 25 years old. Today the Rowland Company specializes in the distribution, fabrication, and assembly of industrial power transmission products, including application engineering, and modification of products to customer needs. Industries served include commercial laundry, amusement parks, marine, metalworking, power generation, pulp & paper, transit, water treatment and wastewater treatment Rowland Company’s product categories include air starters, brakes, clutches, crane controls & electrification, flexible couplings, friction and wear materials, gearboxes, industrial lighting & signals, mobile crane brake parts, universal joints, and driveshafts.

B & S Aircraft Alloys was founded in 1979 and headquartered in Syosset, New York. The company is a distributor of precision parts and titanium, nickel, aluminum, stainless, and commercial alloys to customers in the aerospace as well as medical, scientific, petrochemical, and industrial industries across the United States. The company meets with certifications for military and other specifications and supplies customers such as Boeing, NASA, Honeywell, and General Motors. The company provides parts and service for several aircraft including commercial 737s and military F-15s.

Miki Pulley Co., Ltd., founded in 1939, is a manufacturer and provider of solutions for power transmission and control problems, headquartered in Kawasaki City, Japan. They manufacture various products essential for all industries, including couplings for high-precision power transmission, electromagnetic clutches and brakes for power transmission when energized, and speed changers and reducers for controlling the speed of machinery. They also offer inverters, linear shaft drives, rotation speed indicators, torque limiters, and ROSTA rubber springs.

RINGFEDER Power Trans-Mission GmbH, established in 1922 in Germany, is a manufacturer in niche markets for drive and damping technology. The company offers users worldwide outstanding locking devices, damping solutions, and coupling systems for functionality and durability requirements in various industries. It is appreciated for its customer-specific, application-oriented solutions, which ensure optimum facility operation for its customers. It is a global major player in niche markets for drive and damping technology. Under its strong brand RINGFEDER, it develops, manufactures, and supplies superior shaft-hub connections, damping components, couplings, brake systems, and etc.

JBJ Techniques Limited, founded in 1974 and based in Redhill, Surrey, is a manufacturer of industrial machinery. It offers mechanical and fluid power products, including couplings/bell housings, gearboxes/ clutches, printed wiring boards, pumps/ motors, seals, level indicators and more. The company offers ISO-9001-certified and BS ISO-45001:2018 certified goods and services from specification to technical support, as well as, manufacture to after-sales support to its customers in the UK and across the globe.

RINGSPANN GmbH, founded in 1944 with headquarters in Germany and operations worldwide, is a manufacturer and supplier of transmission components and precision clamping fixtures. The company's wide-ranging product line includes integrated freewheels, brake systems, drive shaft connections, clamping fixtures, and torque limiters. RINGSPANN's products are used in mining for conveyor belts, energy plants for wind turbines, electric bike OEM manufacturing, and food and packaging machines used by the food processing and production industries. The company's products are available from the RINGSPANN website and to commercial and enterprise clients through regional facilities.

Huco Engineering Industries Ltd., founded in BL – England, in 1965 is a manufacturer of Couplings, Air motors, Shaft Collars, and Universal Joints. The company's product portfolio includes Planetary Gearboxes, Dynatork Service Kits, Geared Motors, Aluminium Motors and Acetal Motors. Their products ae used in markets including food processing, energy, textiles, medical, packaging, metals, machine tools, and material handling on applications such as stepper & servo drives, dynamometers, scanners, pumps, fans & blowers, mixers, conveyors and compressors.

ABB E-mobility provides electric vehicle charging solutions for customers around the globe. ABB E-mobility offers DC fast chargers as well as AC chargers with focus on reliability and uptime. Since 2010, ABB E-mobility has sold over 50,000 DC fast chargers and over 1 million total AC chargers. ABB E-mobility offers home single and multi-charge units, retail, workplace, and hospitality charge units, electric vehicle fleet sales, as well as public transportation. Additionally, numerous digital solutions and software services are available.

Clutch Engineering Co. was established in 1960 and is headquartered in Canton, Connecticut. The company is a distributor and specialty fabricator of industrial power transmission components, providing specialized engineering solutions to their specific needs. Customers typically come from industries such as mining, power generation, water treatment, shipbuilding, and transit. The company works with manufacturers such as Easton, Wichita Clutch, SEW-Eurodrive, and Lesson. Products typically used in customers’ products include couplings, electrification units, friction & wear materials, and air starters.

SERVICE COMPANY was founded in the 1930s in Pittsburgh, Pennsylvania. Today BEARING is a manufacturer and national distributor of bearings and power transmission parts and components. BEARING offers services such as field service inspections, damage analysis, surveys, reverse engineering, repair, part identification, and selection. BEARING parts include seals, gaskets, accessories, couplings, electric motors, gearboxes & gearing, chains, sprockets, belts, sheaves, material handling equipment, linear motion equipment, lubrication, and, naturally, many varieties of bearings.

Lenze Selection, established in 1970, is a supplier company that offers drive components for machines and installations, located in Poland. The company’s products include electrically/electromagnetically switchable couplings and brakes, belt drives, linear motion, universal joints and cardan shafts, and hydraulic components. It has a history of providing drive components for mechanical and plant engineering. Its drive components are used whenever a force or movement has to be transferred between two parts of a machine. It offers assistance with the dimensioning of mechanical drive trains and selecting the optimal products.

Ranking as of July 2025

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | TIMKEN |

13.3%

|

| 2 | Stoffel Polygon Systems, Inc. |

11.1%

|

| 3 | AISCO INDUSTRIAL COUPLINGS |

8.9%

|

| 4 | Lovejoy, Inc. |

8.9%

|

| 5 | Royersford Foundry & Machine Co., Inc. |

6.7%

|

| 6 | System Components, Inc. |

6.7%

|

| 7 | Lenze Selection |

4.4%

|

| 8 | Norwood |

4.4%

|

| 9 | ABB E-mobility |

4.4%

|

| 10 | Stafford Manufacturing Corp. |

4.4%

|

Derivation Method

The ranking is calculated based on the click share within the flanged shaft coupling page as of July 2025. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

12 | 66.7% |

Japan

Japan

|

2 | 11.1% |

Germany

Germany

|

2 | 11.1% |

United Kingdom

United Kingdom

|

2 | 11.1% |

121 products found

121 products

Seiichi Kiko Co., Ltd.

1410+ people viewing

Last viewed: 1 hour ago

■Characteristics of safety coupling Combines features of coupling and torque limiter, power transmission and overload 1.Wide torque range Various ...

9 models listed

Seiichi Kiko Co., Ltd.

1080+ people viewing

Last viewed: 18 hours ago

■STL-F series: Safety coupling for overload protection (flange type) ・Torque limiter side standard type (set screw) ・Torque limiter side A.P. LOC...

9 models listed

Sanki Co., Ltd.

300+ people viewing

Last viewed: 4 hours ago

Features of SPC coupling ■Lubricant-free/maintenance-free Since there are no sliding or rolling parts, no lubricating oil is required. Therefore, t...

Kyushu Hasek Co., Ltd.

300+ people viewing

Last viewed: 1 day ago

■Features BS couplings are elastic couplings that use barrel springs (barrel-shaped coil springs) as elements. As for its characteristics, it has e...

Asa Electronics Industry Co., Ltd.

210+ people viewing

Last viewed: 18 hours ago

Disc coupling ■Summary ・Zero backlash ・Smooth rotation transmission ・A wide variety of variations to suit every purpose A disc type coupling is...

Kyushu Hasek Co., Ltd.

340+ people viewing

Last viewed: 13 hours ago

■Features No backlash, high torque, high rotation, high durability and long life. Furthermore, it is a safe mechanism even in the event of an overl...

Kyushu Hasek Co., Ltd.

340+ people viewing

Last viewed: 9 hours ago

■Features No backlash, high torque, high rotation, high durability and long life. Furthermore, it is a safe mechanism even in the event of an overl...

Kyushu Hasek Co., Ltd.

280+ people viewing

Last viewed: 1 day ago

■Features BS couplings are elastic couplings that use barrel springs (barrel-shaped coil springs) as elements. As for its characteristics, it has e...