All Categories

History

This section provides an overview for square shims as well as their applications and principles. Also, please take a look at the list of 8 square shim manufacturers and their company rankings. Here are the top-ranked square shim companies as of July, 2025: 1.MSC Industrial Supply Co..

Table of Contents

1985-2014: Worked for Alstom Corporation, ABB Corporation, and Gadelius Corporation, designing Jungstrom air preheaters and mechanical design of diamond soot blowers. (ABB Corporation: https://new.abb.com/jp)

2014-2021: Worked as an engineering and project manager at Alvos Inc.

https://www.linkedin.com/in/yoichi-hiroki-92192394/

A square shim plate is a type of shim plate with a rectangular (square) outside shape.

A shim plate is a component that is inserted between components or between components and equipment or locations to adjust the position, level, and spacing between them. Square shims are mainly classified as base shims and are used to correct and adjust the level and gap misalignment between parts during the assembly of machine components.

This adjustment reduces machine vibration and noise, prevents machine damage, and ensures stable operation.

In addition to square shims, shim plates include shim rings used for bearings and flanges, and shim tapes that can be cut to any length.

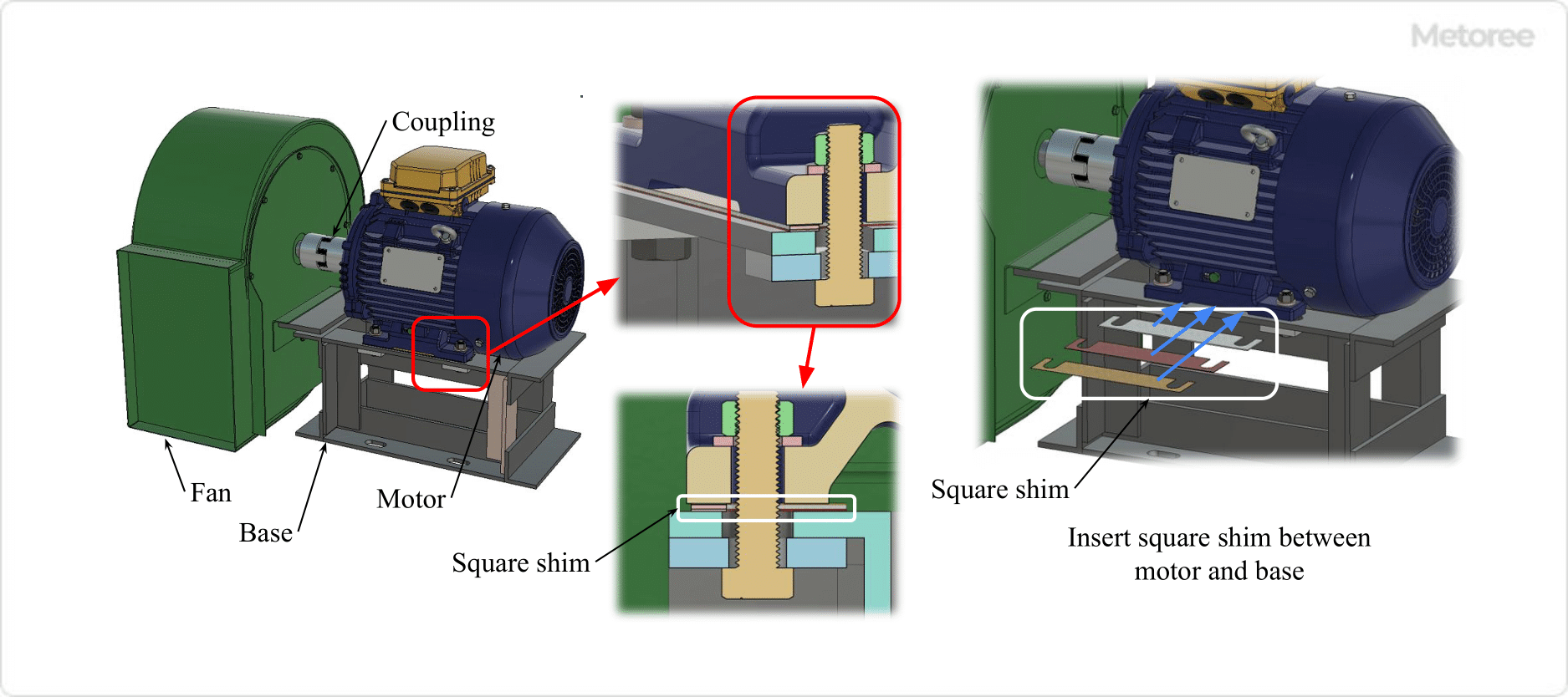

Figure 1. Example of square shim use

Square shims are often used as base shims for fine adjustment of levels between parts. Square shims are available in various thicknesses, for example, t0.05 to t1.0 mm for the same shape, and are adjusted to meet the required accuracy by combining one or more shims.

Square shims, in particular, are prepared in standardized dimensions in terms of size, thickness, and with or without drilling, making it easy to select the dimensions that fit. Therefore, they are used to adjust the level of general-purpose pump motors, pillow blocks, etc., and to adjust the inclination of equipment and facilities that require accurate leveling.

In the above example, a motor is used as a drive for a centrifugal fan. Angular shims (shims for the base) are inserted between the base on which the motor is installed and the motor mounting legs to adjust the tilt and level of the motor. As a result, the center of the motor output shaft - coupling - fan shaft is straight and accurate rotation is possible without vibration.

Spacers are also used to adjust gaps and spacing, but they are primarily used for adjusting the position of parts, not for adjusting the tilt and level. Liners are also used for the same purpose as shims, but with a thickness of t1.0 mm or more.

When high precision is required, simple installation of parts may not be enough to achieve the required accuracy. However, when the number of parts is large, it is not uncommon for the tolerance to accumulate and not be within the required accuracy after the entire assembly is completed.

Therefore, shim plates such as square shims are used for fine adjustment to ensure the required accuracy. The accuracy of the overall assembly is adjusted by inserting square shims between parts to change the tilt of the parts and the level of the parts.

The thickness of the square shim itself also requires accuracy and has a tolerance. It is important to check the thickness accuracy of the square shim to ensure that it meets the required accuracy. For the thickness accuracy, please refer to the dimensional table of each manufacturer.

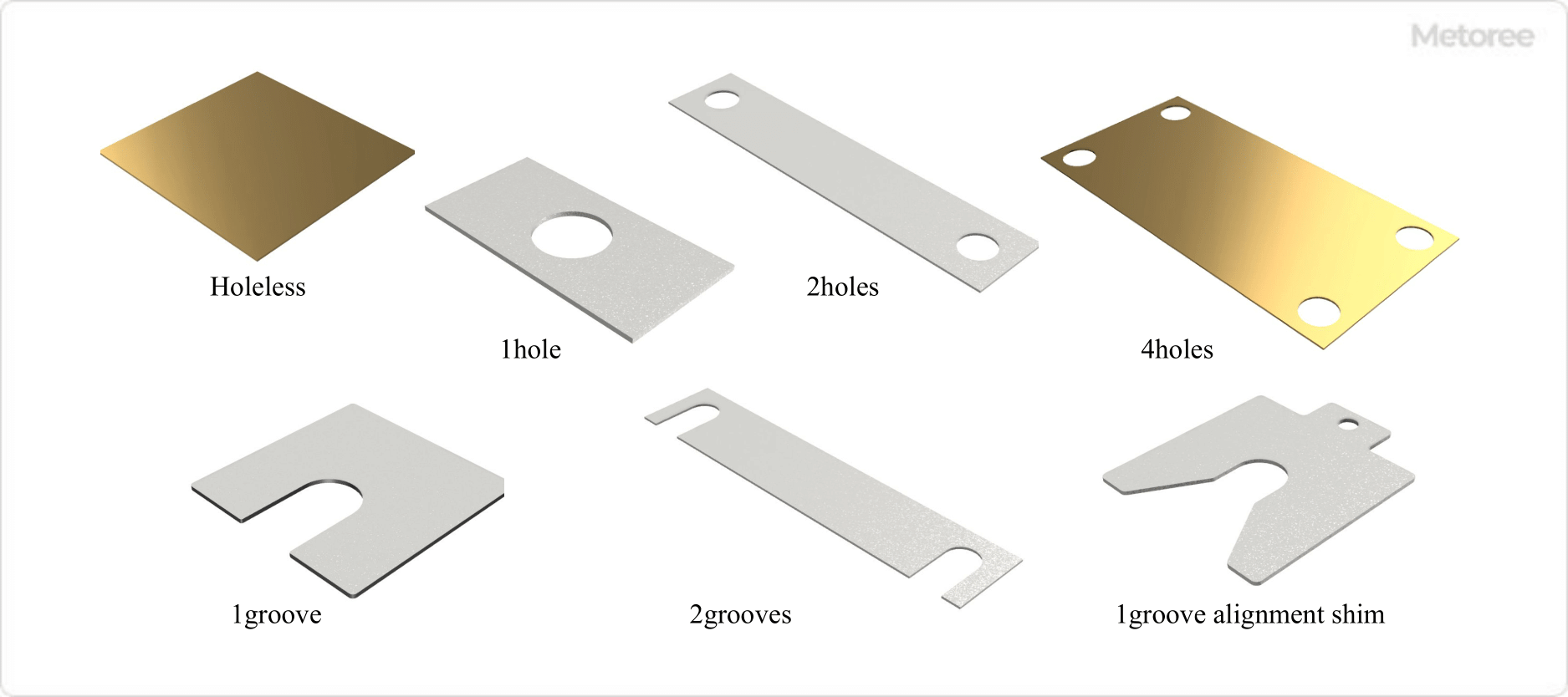

Figure 2. Example of square shim geometry

The main types of corner shim shapes are as follows:

Mounting holes and slots are mainly used for machines and equipment that are mounted and assembled with bolts. Slotted mounting holes allow insertion of bolts without completely removing them.

Alignment shims also have a portion to hook a tool or other object to facilitate insertion and withdrawal operations.

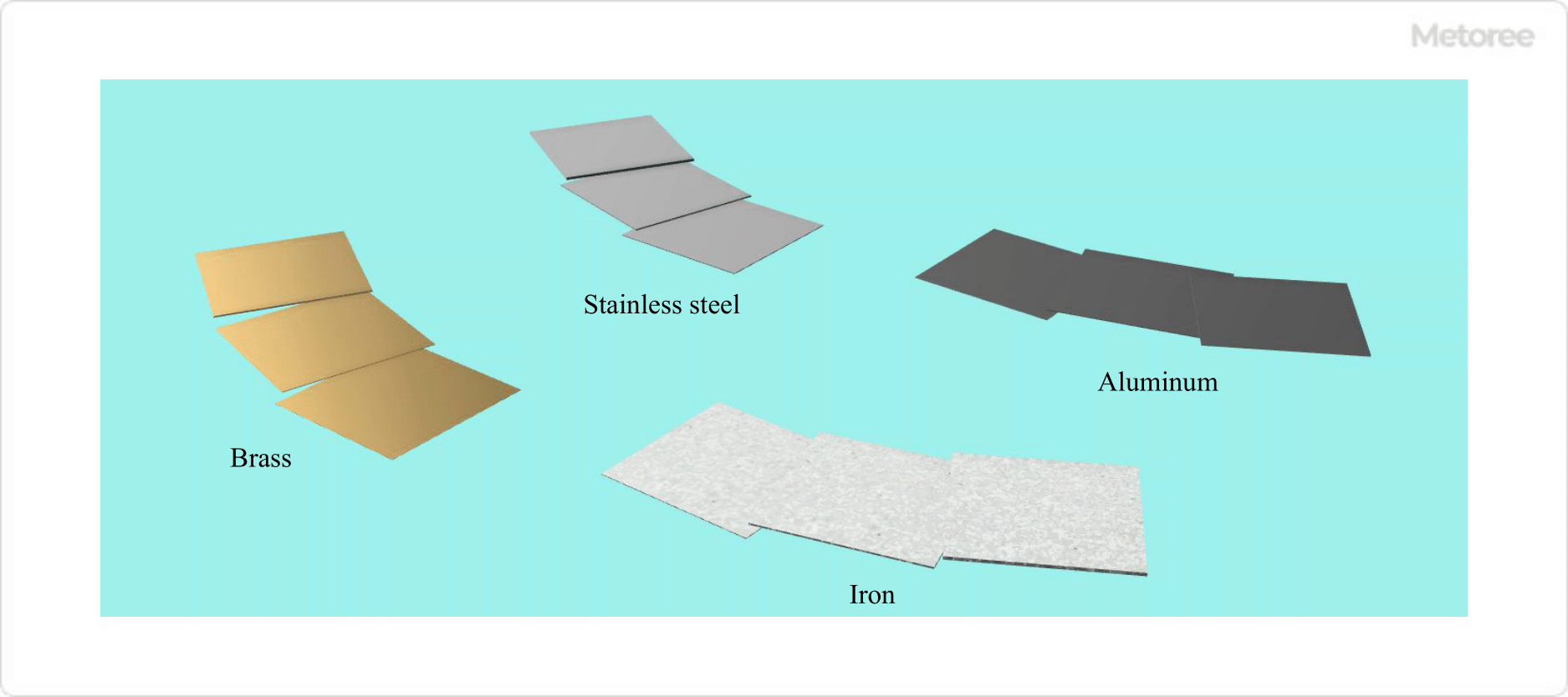

Figure 3. Material example of square shim

The following are the main types of materials used for square shims. For the selection of materials for square shims, stainless steel or aluminum is used if the environment in which they will be used, such as corrosion resistance.

Other types of angular shims include:

*Including some distributors, etc.

Sort by Features

Sort by Area

Trinity Brand Industries, founded in 1989 and located in Burr Ridge, Illinois, is a supplier of tool room specialty products to the industrial market. The company offers a full line of tool room products, which include stainless steel shim, brass shim, aluminum shim stock sheets, titanium coils, and sheets. Its products come with traceability and a Material Test Report (MTR) included with all materials. Pre-cut slotted shims, feeler gage strips, and coils are also available. Its fabrication services include laser cutting, waterjet cutting, wire EDM, and 3D industrial printing.

Quality Bearings & Components (QBC) has been a distributor of bearings and related motion control components since 1950. The company is under the Designatronics division, headquartered in New York, USA. The company supplies various bearings, such as ball, roller, thrust, and spherical plain bearings. These components are critical in reducing friction and facilitating smooth motion in machinery and equipment. The company also has other motion components, including bushings, rod ends and linkages, linear motion products, pillow blocks and flanges, and shafting. The company serves a broad customer across various industries, including manufacturing, automotive, aerospace, agriculture, and industrial machinery.

Iwata Mfg. Co., Ltd., established in 1966 and headquartered in Gifu, Japan, is a manufacturer of commercial machinery components and power transmission equipment. The company offers a wide range of products, including bearing rollers, end plates, leveling systems, nameplates, and seals. It also provides set collars, shims, sensor brackets, and trims. Its product requires less maintenance than oil-injected air compressors because it doesn't require oil changes or filter replacements. It serves a diverse range of industries, including coating applications, refinishing applications, manufacturing, and vacuum pumps.

The Steel Supply Company Inc., established in 1896 and headquartered in New York, United States, is a supplier that provides structural and miscellaneous steel fabricators with a wide range of products. The company's offerings include hooked and straight anchor bolts, threaded rods, masonry anchors, and various hardware and abrasives. These products are utilized by various industries, including construction, manufacturing, and steel fabrication. It specializes in selling standarized and customizable products, which it can provide in high volumes due to its network of warehousing and direct shipment product lines.

MSC Industrial Supply Co. is based in New York, New York, USA, and is a distributor and supplier of metalworking products as well as maintenance, repair and operations (MRO) equipment that was established in 1941 as a subsidiary of MSC Industrial Direct Co., Inc. The company primarily produces holemakers such as reamers and taps, milling equipment such as face mills and indexable inserts, and fixed abrasives such as wheels and belts. It also offers safety equipment such as respirators, reflective signage, and protective eyewear. The company’s products are mainly used in industrial manufacturing operations, with additional applications in construction.

Ranking as of July 2025

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | MSC Industrial Supply Co. |

100.0%

|

Derivation Method

The ranking is calculated based on the click share within the square shim page as of July 2025. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

2 | 40.0% |

Japan

Japan

|

1 | 20.0% |

United Kingdom

United Kingdom

|

1 | 20.0% |

India

India

|

1 | 20.0% |

28 products found

28 products

160+ people viewing

Last viewed: 1 day ago

■Order example SUS plate thickness 0.2 Width A50mm Height H30m Hole position X 10mm Hole depth Y 20mm Hole size D For Φ10

Hayashi Co., Ltd.

320+ people viewing

Last viewed: 10 hours ago

■Summary The shim plates that Hayashi sells under the KiKi brand are well-received for their tolerance accuracy, and have been well-received by peo...

160+ people viewing

Last viewed: 1 day ago

■Order example SUS plate thickness 0.1 Width A30mm Height H50m Hole position X110mm Hole position

170+ people viewing

■Order example SUS plate thickness 0.1 Width A50mm Height H30m Hole position X1 10mm Hole depth Y 8mm Hole pitch P1 25mm Hole pitch P 15mm Hole siz...

190+ people viewing

■Order example SUS plate thickness 0.1 Width A50mm Vertical H30m Groove position X 10mm Groove width 10 Hole depth Y 20mm

160+ people viewing

■Order example SUS plate thickness 0.1 Width A30mm Vertical H50m Groove position X10mm Groove depth Y1 30mm Hole depth Y2 30mm Bitch P 25mm Hole si...

Hayashi Co., Ltd.

260+ people viewing

Last viewed: 15 hours ago

■Summary For fine adjustment of high-precision press dies. Features ■A wide variety of sizes Hayashi's shims for wear plates have a rich lineup. I...

Hayashi Co., Ltd.

220+ people viewing

Last viewed: 1 day ago

■Summary Unwavering tolerances and a complete lineup. Shims for distance plates manufactured based on carefully selected high-precision shim plates...

IWATA MFG.CO.,LTD.

200+ people viewing

■Features ・Can be used to adjust the height of pillow blocks ・You can choose from pillow block product numbers. ・The lineup includes plate thick...

IWATA MFG.CO.,LTD.

170+ people viewing

Last viewed: 11 hours ago

■Features ・Can be used to adjust the height of motor bases, etc. - 0.05mm plates are laminated, allowing highly accurate adjustment by peeling the...

Hayashi Co., Ltd.

250+ people viewing

Last viewed: 15 hours ago

■Summary We will cut the shim plate to your desired width, length, and thickness. ■Characteristics of Sim no Mori “Free Size Sim Regular Type” ・A...

IWATA MFG.CO.,LTD.

170+ people viewing

Last viewed: 14 hours ago

■Features ・Can be used to adjust the height of motor bases, etc. - 0.1mm plates are laminated, allowing highly accurate adjustment by peeling them...

IWATA MFG.CO.,LTD.

250+ people viewing

Last viewed: 10 hours ago

Compatible with your desired size. Manufactured from 1 piece. ■Ordering Please check the specified unit and manufacturing conditions before placin...

IWATA MFG.CO.,LTD.

230+ people viewing

Last viewed: 6 hours ago

Compatible with your desired size. Manufactured from 1 piece. ■Features ・Laminate shim made of 0.05mm plates glued together. - Lightly rub it wit...

IWATA MFG.CO.,LTD.

190+ people viewing

■Features ・Can be used to adjust the height of motor bases, etc. ・The lineup includes plate thicknesses of 0.5mm and 1.0mm. ・Material is iron (b...

IWATA MFG.CO.,LTD.

200+ people viewing

Last viewed: 8 hours ago

Compatible with your desired size. Manufactured from 1 piece. ■Ordering Please check the specified unit and manufacturing conditions before placin...

IWATA MFG.CO.,LTD.

200+ people viewing

Last viewed: 1 hour ago

Compatible with your desired size. Manufactured from 1 piece. Compliant with American aerospace standard AMS-DTL-22499, German aerospace standard ...

IWATA MFG.CO.,LTD.

230+ people viewing

Last viewed: 7 hours ago

Compatible with your desired size. Manufactured from 1 piece. ■Ordering Please check the specified unit and manufacturing conditions before placin...

IWATA MFG.CO.,LTD.

270+ people viewing

Last viewed: 1 hour ago

Compatible with your desired size. Manufactured from 1 piece. ■Ordering Please check the specified unit and manufacturing conditions before placin...

IWATA MFG.CO.,LTD.

200+ people viewing

Last viewed: 1 day ago

Compatible with your desired size. Manufactured from 1 piece. Compliant with American aerospace standard AMS-DTL-22499, German aerospace standard ...

IWATA MFG.CO.,LTD.

220+ people viewing

Last viewed: 15 hours ago

Compatible with your desired size. Manufactured from 1 piece. Compliant with American aerospace standard AMS-DTL-22499, German aerospace standard ...

IWATA MFG.CO.,LTD.

150+ people viewing

■Features ・A set of alignment shims in various board thicknesses and sizes that comes in a case that is convenient to carry on-site. - Comes with ...

IWATA MFG.CO.,LTD.

220+ people viewing

Last viewed: 2 hours ago

■Features ・Can be used to adjust the height of motor bases, etc. ・The lineup includes plate thicknesses of 0.05 to 1.0 mm. ・Materials are iron, ...

IWATA MFG.CO.,LTD.

150+ people viewing

Last viewed: 22 hours ago

A case for storing and transporting alignment shims. It is possible to organize and store items by size and board thickness, supporting accurate wo...

IWATA MFG.CO.,LTD.

190+ people viewing

Last viewed: 12 hours ago

■Features ・Can be used to adjust the height of motor bases, etc. ・The lineup includes plate thicknesses of 0.5mm and 1.0mm. ・Material is iron (b...

IWATA MFG.CO.,LTD.

210+ people viewing

Last viewed: 13 hours ago

Compatible with your desired size. Manufactured from 1 piece. ■Ordering Please check the specified unit and manufacturing conditions before placin...

IWATA MFG.CO.,LTD.

160+ people viewing

Last viewed: 5 hours ago

This is an alignment shim that can be used for level adjustment etc. on site. Comes with a knob for convenient work. You can also easily pull it ou...