All Categories

History

This section provides an overview for pillow blocks as well as their applications and principles. Also, please take a look at the list of 29 pillow block manufacturers and their company rankings. Here are the top-ranked pillow block companies as of July, 2025: 1.Triangle Manufacturing Company, 2.Stock Drive Products/Sterling Instrument - SDP/SI, 3.TIMKEN.

Table of Contents

1985-2014: Worked for Alstom Corporation, ABB Corporation, and Gadelius Corporation, designing Jungstrom air preheaters and mechanical design of diamond soot blowers. (ABB Corporation: https://new.abb.com/jp)

2014-2021: Worked as an engineering and project manager at Alvos Inc.

https://www.linkedin.com/in/yoichi-hiroki-92192394/

A pillow block is a bearing assembly that includes a housing with a mounting seat and bolt holes for mounting on a support surface parallel to the bearing center axis, along with a radial bearing.

The choice between spherical ball bearings and spherical roller bearings depends on the shaft diameter, with the bearing housing and bearings being interchangeable across different manufacturers.

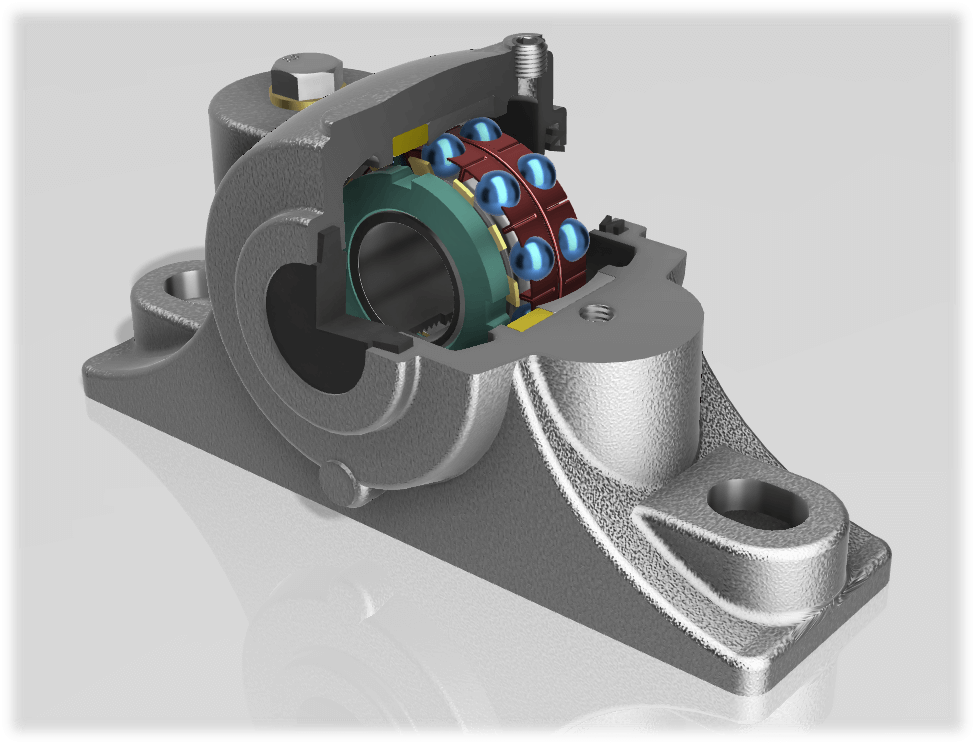

Figure 1. Example of Plummer Block Application (Turbofan Bearing)

Pillow blocks support rotating shafts with bearings in situations where the machine or equipment cannot directly accommodate the bearings, typically installed at both ends of a shaft.

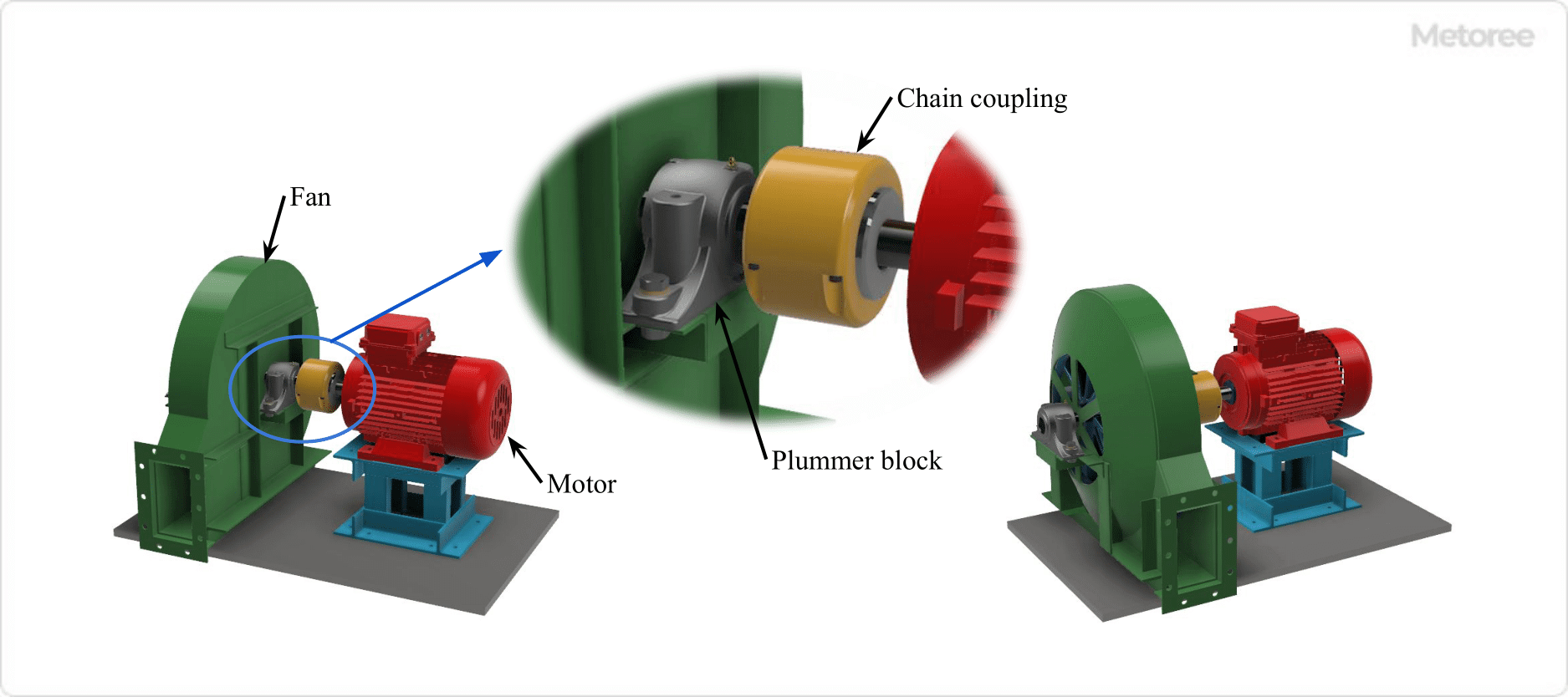

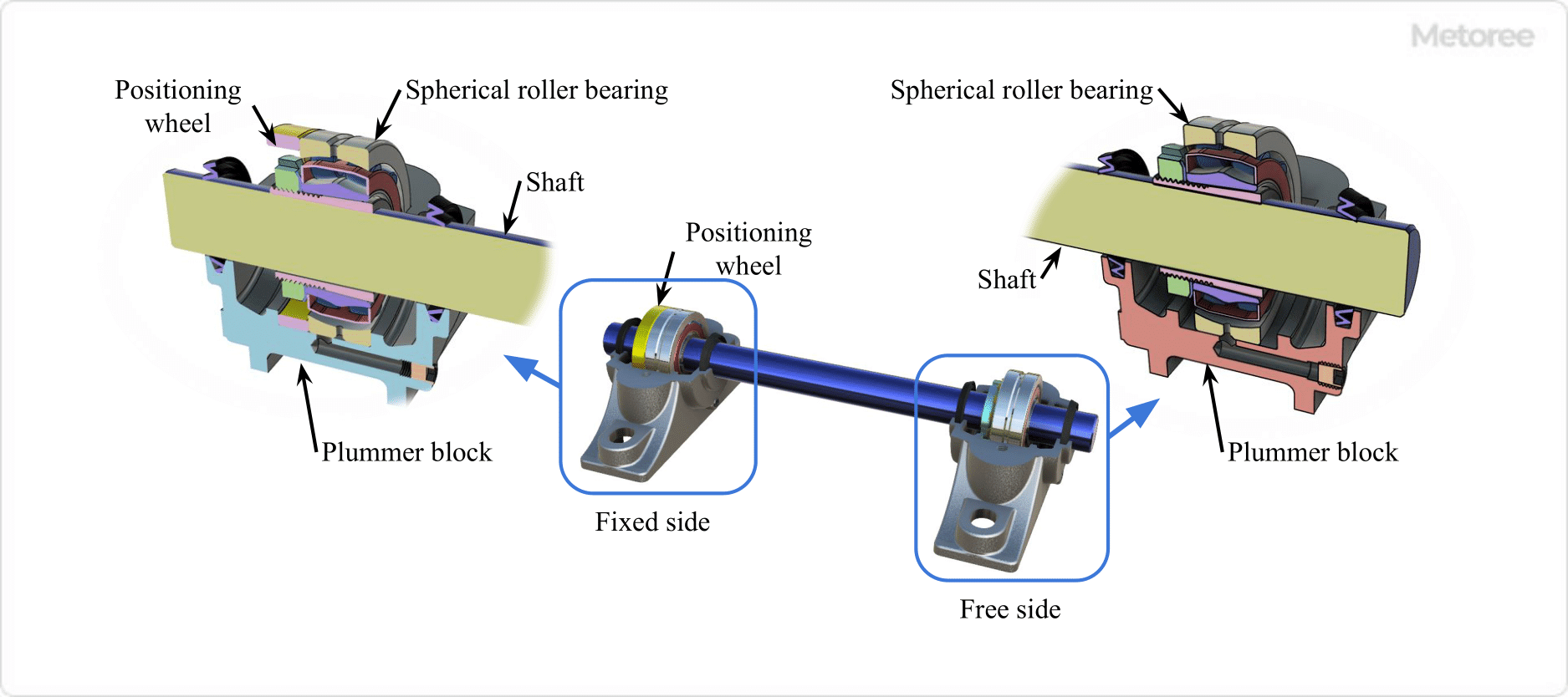

Figure 2. Fixed Side and Free Side

Pillow blocks, accommodating both radial and a certain amount of thrust loads, should differentiate between the fixed side and the free side for optimal performance, as illustrated in Figure 2.

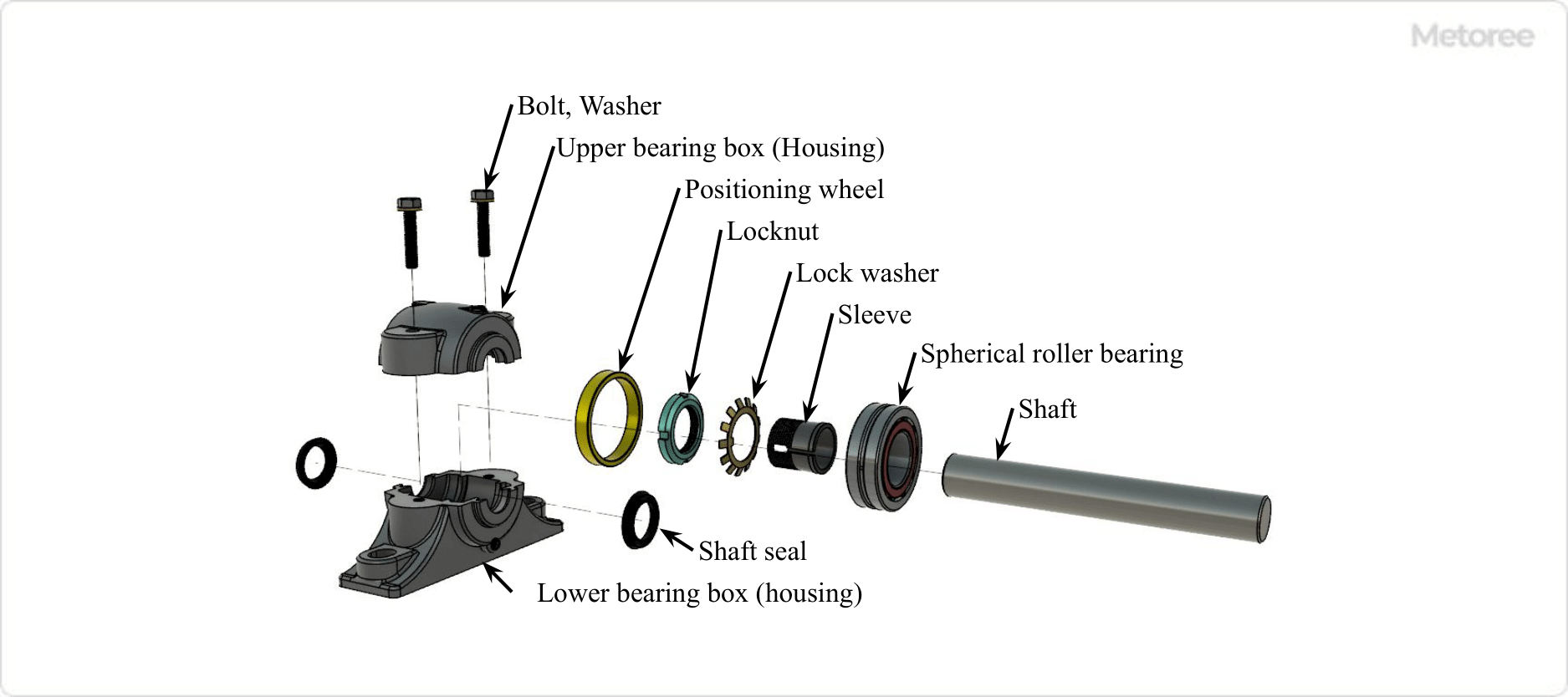

Figure 3. Structure of a Plummer Block (Segmented Type)

The structure of a pillow block includes a bearing housing, bearings, and a shaft seal, which can be of the split or integral type, each suited for different applications.

The split type, allowing for easy bearing replacement and maintenance, contrasts with the integral type, known for its rigidity and suitability for large shaft diameters.

Shaft seals, crucial for preventing lubricant leakage, vary between contact and non-contact types, each offering different benefits.

Pillow blocks adhere to standards such as ISO 113, ensuring reliability and quality.

Materials used for pillow block housings include grey cast iron, spheroidal graphite cast iron, carbon steel castings, and carbon steel forgings, chosen for their durability and performance.

Another bearing assembly with a similar shape and usage to the pillow block is the pillow block. Both are used by assembling a bearing housing and a bearing, but there are some differences.

While the plummer block allows the replacement of individual bearings, the pillow block does not allow replacement of individual bearings and requires replacement of the entire assembly.

Other differences in application are as follows.

| Pillow Blocks | Plummer Blocks | |

| Loads that can be supported | Large loads | Relatively small load |

| Applicable shaft diameter | Large diameter | Small bore diameter |

| Rotation supported | High-speed rotation | Low-speed rotation |

*Including some distributors, etc.

Sort by Features

Sort by Area

SDP/SI was founded in 1950 and is situated in New Hyde Park, New York. SDPP/SI is a manufacturer of precision gears and high-quality mechanical components used in the aerospace, industrial manufacturing, medical technology, and robotics fields. The company manufactures parts in a variety of materials including alloy steel, stainless steel, bronze, brass, nylon, and titanium. The company also provides coating services such as heat treating, zinc plating, and painting. Additional custom options are available including manufacturing to customer drawings and specifications.

Rexnord, is a Regal Rexnord Brand, founded in 1948, and is a manufacturer of industrial lead products for the toughest applications. The products include bearings, conveying solutions, couplings, gears, industrial chains, and PT drive components. Smart solutions include smart condition monitoring systems, smart tags, and digital productivity platforms for use in aerospace, mining, beverage & food, energy, and marine markets. The Milwauke, Wi company offers services such as coupling re-certification, gap walk, gearbox repair & upgrade, custom gears & drives, and installation & rebuild services.

Lucas Industrial was founded in 1988 in Cedar Hill and is a manufacturer and supplier of power transmission products used in the construction, material handling, and industrial automation industries. It specializes in making stock collars like threaded and clamp-type. The company also supplies power transmission products like ball bearings, lumber conveying chains, roller chains, rigid couplings, and leaf chains. Clients can request finishing services for the following split collars: nickel, chrome, and yellow zinc.

KMS Bearings, Inc. is a manufacturer of plastic and AISI 316 stainless raceway, radial ball bearings. The company is located at Anaheim, California and established in 1979. Their product portfolio includes plastic radial ball bearings out of Engineering Polymers, Thin section ball bearings, 4-Points contact ball bearings, insert bearings, Skate wheel ball bearing, conveyor ball bearing and 316 stainless radial ball bearings. The company provide bearing solutions through the use of Design, Innovation and Material selections that suit the application.

The Timken Company (Timken) was founded in 1899 and is headquartered in North Canton, Ohio. Timken designs, manufactures, and manages engineered bearings and industrial motion products worldwide. Timken operates in two segments, Mobile Industries and Process Industries. The Mobile Industries segment’s portfolio includes bearings, seals, and lubrication devices and systems. The Process Industries segment provides industrial bearings and assemblies; industrial motion components, such as gears and gearboxes; and linear motion products, couplings, seals, lubricants, chains, belts, and related products and services to OEMs and end users in various industries.

Triangle Manufacturing Company, established in 1922, based in Oshkosh, Wisconsin, manufactures stamped and fabricated motion components and assemblies to meet the needs of equipment manufacturers. The company’s product portfolio includes bearings, linkages, rod ends, Lazy Susan turntable bearings, and motor mounts. Their team of engineers help design the products from quoting to prototyping and manufacturing to on-time delivery. The company’s services provided will assist customers in creating ideal solutions to improve products and increase efficiency.

American Pulley Co., headquartered in Pelham, Alabama, serves as a manufacturer of conveyor pulleys, shafting, bushings, bearings, and power transmission components. The company produces a range of products including CEMA class pulleys, mine duty pulleys, and special pulleys, both lagged and unlagged. It maintains substantial inventory in its Alabama and Phoenix, Arizona warehouses and benefits from the support of an extensive network of authorized industrial distributors across North and South America.

Dial Manufacturing, Inc. based in Phoenix, Arizona, USA and was founded in 1965 is a manufacturer and supplier of portable evaporative coolers, mini-split air conditioners, and replacement parts and accessories for evaporative coolers. The company’s main products include pumps, motors, pads, covers, maintenance and accessories for evaporative coolers. These products are used for cooling and heating indoor and outdoor environments. The company is advanced in evaporative cooling products and offers a range of products and services to meet the needs of various markets. It also has an in-house engineering department that provides quality control and product design.

Quality Bearings & Components (QBC) has been a distributor of bearings and related motion control components since 1950. The company is under the Designatronics division, headquartered in New York, USA. The company supplies various bearings, such as ball, roller, thrust, and spherical plain bearings. These components are critical in reducing friction and facilitating smooth motion in machinery and equipment. The company also has other motion components, including bushings, rod ends and linkages, linear motion products, pillow blocks and flanges, and shafting. The company serves a broad customer across various industries, including manufacturing, automotive, aerospace, agriculture, and industrial machinery.

LDK Bearings, established in 1986 in Fujian, China, is a manufacturer specializing in producing a diverse range of advanced-quality bearings. The company manufactures deep groove ball bearings, angular contact ball bearings, tapered roller bearings, and cylindrical roller bearings. The bearings are equipped with precision, optimal durability, and robust performance, assisting in improved machinery efficiency and stability. These bearings find applications in various industries, including automotive, industrial machinery, agriculture, and construction. It is IATF 16949 certified and offers testing capabilities for Fatigue life, Tensile strength, Noise & Vibration and Salt spray testing.

Zhejiang Waxing Electromechanical Co., Ltd., established in 2000 as Linqing Shengli Factory, is based in Zhejiang, China, as a manufacturer and supplier of various types of bearing. The company offers various types of bearing including Deep Groove Ball Bearings, Cylindrical Roller Bearings, Tapered Roller Bearings, Angular Contact Bearings, Thrust Ball Bearings, among others. These products are utilized in many industries such as automobile industry, agriculture industry, textile industry, and plastic industry as important internal components of various machineries. The company also offers custom requests to fulfill customers with special quality requirements and specifications.

NACHI-FUJIKOSHI CORP. is a Japanese manufacturer of industrial machinery and tools, such as bearings, hydraulic equipment, robots, and cutting tools. They also provide services such as machine maintenance and repair. The company's products are used in automotive, aerospace, construction, and electronics. One of NACHI-FUJIKOSHI's renowned products is their robotic arm, the "MZR series," which is designed for precision assembly and inspection tasks in industries. They received several awards for their technological advancements and contributions to the industry, including the 2021 Japan Society of Mechanical Engineers Medal for new hydraulic equipment technology and the 2020 Nikkan Kogyo Shimbun Grand Technology Award.

JTEKT was born from the merger of bearing maker Koyo Seiko and machine tool maker Toyoda Machine Works. JTEKT focuses on environmental sustainability to create automotive-specific components as well as industry-agnostic components including sensors, gears, displays, storage devices, and hydraulic units. JTEKT also creates and designs machine tools and equipment necessary for machine production. JTEKT is also developing "internet of everything" (IoE) solutions for modern industry.

NSK Ltd., based in Japan, is a manufacturer of precision bearings and motion control solutions which started its journey in 1916. The company has established itself as a major supplier for multiple industries, including automotive, industrial machinery, and aerospace. Their extensive product portfolio encompasses ball bearings, roller bearings, and linear motion components. Their Motion & Control products and technologies support the motion that brings comfort and convenience in cars, planes, wind turbines, satellites, and almost anything with moving parts.

Vibac Group has been a manufacturer of tapes and films since 1968 and is headquartered in Ticineto, Italy. The company provides a range of products, including BOPP films, labels, carton sealing tapes, masking, and specialty tapes. The films come in different portfolios such as coated and uncoated, metalized, transparent, matt polypropylene, and white, with variations in thickness, support, and coating of adhesive. These products are used in flexible packaging across various industries for applications like repairing, fixing, and masking. They are widely used in the food and beverage industry and other sectors that require labeling on products.

Marvel Engineering Works has been a manufacturer of iron products since 1975 and is based in Gujrat, India. The company designs cast iron foot valves that prevent backflow of water and has applications in fire fighting and irrigation systems; the pillow block bearing is used in conveyor systems, fans, and blowers, whereas the Plummer block contains a bearing and a seal to provide support and lubrication. The Steering bearings are also manufactured and facilitate vehicles' steering, serving the automotive, mining, cement, agriculture, and similar industries.

PBC Linear, a Pacific Bearing Company founded in 1983 with headquarters in the USA, is a manufacturer of linear motion products. The company's product line includes bearings, shafting, rail assemblies, and cam roller sliders. PBC Linear also offers lead screw and ball screw assemblies, small to large actuators, and Cartesian systems. The company provides custom engineering, manufacturing, and assembly services, along with automation tools for the packaging, distribution, medical device, robotics, and transportation industries.

A.S. International, founded in 2008 and based in Mumbai, Maharashtra, India, is a manufacturer and distributor of bearings and chains. The company's product portfolio includes ball bearings, roller bearings, specialty bearings roller chains, and conveyor chains. These products are used in various industrial applications for efficient power transmission, material handling, and radial load handling. The company serves diverse industries such as manufacturing, automotive and transportation, agriculture, as well as mining and construction.

Jinan Shenglei Bearing Co., Ltd (ZYSL) is a manufacturer and distributor of various bearings. The company was established in 1999 and is based in Jinan City, China. ZYSL specializes in the manufacturing of various ball bearings and roller bearings including Angular Contact Ball Bearings, Ceramic Bearings, Cylindrical Roller Bearings as well as Insert Bearings and Non-Standard Bearings. The company also offers modified standard products for special applications and is an OEM service provider.

Nishi Enterprise, established in 1978 and based in Ahmedabad, Gujarat, India, is a manufacturer and supplier of high-end mechanical power transmission products. The company's product range includes conveyors, head pulleys, tail pulleys, idler rollers, ball mill parts, and simplex duplex sprockets. These products facilitate the efficiency of power transmission systems. They serve industries such as power plants, steel plants, sinter plants, fertilizers, and cement plants. It also provides services like versatile manufacturing techniques, delivering customized solutions, using quality raw materials, and ensuring prompt deliveries.

Collective Trade Links Pvt. Ltd. has been a manufacturer and supplier of bearings since 1980 and is based in Ahmedabad, India. The company designs and supplies stainless steel, super precision, CAM clutches, and unidirectional and deep groove bearings along with couplings, ball screws, and various components that have applications in electric motors, machine tools, engines, and conveyor systems, overall serving the semiconductor, agriculture, automotive, renewable energy and industries that deal in machinery and motors.

THB Bearings Co.Ltd, a company established in 2009, based in Shanghai, China, is a manufacturer and supplier of various types of bearings and related products. The company provides various products such as wire wound resistors, metal glaze film resistors, oxide film resistors, water cooled resistors, and ribbon wound resistors. These products are designed to be durable, energy efficient, and engineered to save money. A specialized solutions provider of bearing technology and it is an industrial technical services company that offers customers a simple and convenient source for bearing components, technical services and solutions.

BDH International is a manufacturer and supplier of ball bearings and is based in Ahmedabad, India. The company provides deep groove ball bearings primarily used in vehicles and pillow block bearings, which are used in various types of machinery for support and reduction in friction. Motor bearings have applications in industrial and household motors, whereas tractor and pump bearings are designed for particular purposes, serving the agricultural, construction, ceramic, automobile, and transmission system industries.

Ranking as of July 2025

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Triangle Manufacturing Company |

9.5%

|

| 2 | TIMKEN |

7.9%

|

| 3 | Stock Drive Products/Sterling Instrument - SDP/SI |

7.4%

|

| 4 | Rexnord |

6.3%

|

| 5 | American Pulley Co. |

6.3%

|

| 6 | Lucas Industrial |

6.3%

|

| 7 | KMS Bearings, Inc. |

6.3%

|

| 8 | JTEKT Corporation |

4.8%

|

| 9 | BDH Bearings |

4.2%

|

| 10 | ZYSL Co., Ltd |

3.7%

|

Derivation Method

The ranking is calculated based on the click share within the pillow block page as of July 2025. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

10 | 35.7% |

China

China

|

8 | 28.6% |

India

India

|

6 | 21.4% |

Japan

Japan

|

3 | 10.7% |

Spain

Spain

|

1 | 3.6% |

248 products found

248 products

Robotena Co., Ltd.

400+ people viewing

Last viewed: 1 day ago

Compatible with 6mm thickness

3 models listed

Kashima Chemical Metals Co., Ltd.

360+ people viewing

A wide range of compatibility with a wide range of installation conditions such as dry, salt, moisture, and chemical environments, and excellent we...

Tescom Co., Ltd.

500+ people viewing

Last viewed: 1 day ago

Deltec's fully enclosed stainless steel bearing units provide stainless steel bearing units used in the most demanding environments in the food and...

Yamaden

3220+ people viewing

Last viewed: 6 hours ago

It supports a wide range of industries, including bearings, home appliances, automobiles, railways, wind power, aircraft and rockets, which are ind...

82 models listed

Takahashi Metal Co., Ltd.

370+ people viewing

Last viewed: 1 hour ago

■We manufacture and sell amphibious vehicles that meet the legal standards of each country, not only in Japan but also around the world. Amphibious...

Ozak Seiko Co., Ltd.

1220+ people viewing

Last viewed: 38 minutes ago

■ Overview ・ It is a series that incorporates straight maintenance free bearings in a box -shaped aluminum case. ・ Since we only provide a straig...

10 models listed

Ozak Seiko Co., Ltd.

1260+ people viewing

Last viewed: 11 hours ago

■ Overview ・ It is a series that incorporates straight maintenance free bearings in a box -shaped aluminum case. ・ Since we only provide a straig...

10 models listed

Ozak Seiko Co., Ltd.

1070+ people viewing

Last viewed: 3 hours ago

■ Overview ・ It is a series that incorporates straight maintenance free bearings in a box -shaped aluminum case. ・ Since we only provide a straig...

10 models listed

Ozak Seiko Co., Ltd.

1240+ people viewing

Last viewed: 1 hour ago

It is an automatic or high -rigidity series that incorporates a linear bearing into a casting case. Ultra series compatible ■ Abundant types OZAK...

10 models listed

Ozak Seiko Co., Ltd.

1040+ people viewing

Last viewed: 10 hours ago

It is a type that incorporates a linear bearing into an aluminum box type housing. In some model number, a retrofit felt seal that enhances dustpro...

10 models listed

Ozak Seiko Co., Ltd.

960+ people viewing

Last viewed: 5 hours ago

■ Overview ・ It is a series that incorporates straight maintenance free bearings in a box -shaped aluminum case. ・ Since we only provide a straig...

10 models listed

Ozak Seiko Co., Ltd.

920+ people viewing

Last viewed: 3 hours ago

It is a type that incorporates a linear bearing into an aluminum box type housing. In some model number, a retrofit felt seal that enhances dustpro...

10 models listed

Ozak Seiko Co., Ltd.

820+ people viewing

Last viewed: 3 hours ago

■ Overview ・ It is a series that incorporates straight maintenance free bearings in a box -shaped aluminum case. ・ Since we only provide a straig...

10 models listed

Ozak Seiko Co., Ltd.

870+ people viewing

Last viewed: 19 hours ago

It is a type that incorporates a linear bearing into an aluminum box type housing. In some model number, a retrofit felt seal that enhances dustpro...

10 models listed

Ozak Seiko Co., Ltd.

1000+ people viewing

Last viewed: 36 minutes ago

A unit that combines linear bearing linear shaft in two axes. It is also possible to purchase the adjusted finished product or the parts alone. Si...

10 models listed

Ozak Seiko Co., Ltd.

1060+ people viewing

Last viewed: 6 hours ago

A unit that combines linear bearing linear shaft in two axes. It is also possible to purchase the adjusted finished product or the parts alone. Do...

10 models listed

Ozak Seiko Co., Ltd.

1050+ people viewing

Last viewed: 33 minutes ago

There are rounds, corners, T (small format) type flange, flange boss position type using in -in, OZAK's unique oil hole type. Flange shape: square...

10 models listed

Ozak Seiko Co., Ltd.

1080+ people viewing

Last viewed: 6 hours ago

Ozac original product group ■ Characteristics ・ Our unique special parts. ・ There are rotating bearings with flange, low -priced products, compa...

8 models listed

Ozak Seiko Co., Ltd.

1080+ people viewing

Last viewed: 56 minutes ago

There are rounds, horns, T (small format) type flange, flange boss position type using in -in, flange center position type, and OZAK's unique oil h...

10 models listed

Ozak Seiko Co., Ltd.

1390+ people viewing

Last viewed: 10 minutes ago

It is a type that incorporates a linear bearing into an aluminum box type housing. In some model number, a retrofit felt seal that enhances dustpro...

10 models listed

TOAMEC Co., Ltd.

250+ people viewing

Last viewed: 2 hours ago

SUNGIL not only supplies support units using precision grade (P5) bearings, but also medium preload (C8) and light preload (P0-C7) products. Bearin...

TOAMEC Co., Ltd.

220+ people viewing

Last viewed: 17 hours ago

■In addition to the pillow type and flange type, special specifications are also available. ・Stainless steel series (stainless steel bearing + sta...

Matsumoto Machine Industry Co., Ltd.

210+ people viewing

Last viewed: 17 hours ago

Small bearing for laser processing machine

Yoshino Co., Ltd.

180+ people viewing

Last viewed: 1 day ago

Yoshino Co., Ltd.

150+ people viewing

Last viewed: 15 hours ago