All Categories

History

This section provides an overview for circuit board heat sinks as well as their applications and principles. Also, please take a look at the list of 13 circuit board heat sink manufacturers and their company rankings. Here are the top-ranked circuit board heat sink companies as of February, 2026: 1.Himalay Engineering Co., 2.Heatell, 3.Zaward Corporation.

Table of Contents

Categories Related to Circuit Board Heat Sinks

A circuit board heat sink is a cooling device attached to the circuit boards of electronic equipment and computers.

They are used to stabilize circuit operation by dissipating heat generated by electronic and electrical components mounted on printed circuit boards. Semiconductor components in various circuits tend to generate large amounts of heat when large drive power is required.

With the evolution of semiconductor processes, large-scale integrated circuits have been realized in extremely small sizes. In devices that realize such complex and advanced functions and performance, the amount of heat generated is also often large.

To reduce the amount of heat generated, various efforts are being made on the semiconductor device side to reduce power consumption. However, in most cases, heat sinks are required to maintain stable operation when used in various environments.

Circuit board heat sinks are cooling devices that are primarily used on electronic equipment and computer circuit boards. The following are some of their main uses:

The CPU is an important component responsible for computing and controlling the computer. A high-performance CPU performs many calculations and generates a lot of heat as a result. Overheating may cause performance degradation or damage.

Circuit board heat sinks are attached to the CPU to absorb the heat generated by the CPU. Heat exchange with the surrounding air is facilitated through the fins of the heat sink. This allows the CPU to maintain proper operating temperature and maximize performance.

The GPU is responsible for graphics-related tasks such as processing 3D graphics and decoding video. The GPU also often generates a lot of heat during graphics-intensive situations such as high-resolution games and video editing. Circuit board heat sinks are attached to the GPU to provide proper cooling and maintain high performance.

Power electronics are electronic components that control or convert power. Inverters and motor drivers are examples.

These components handle high power and generate a large amount of heat. Circuit board heat sinks are attached to these components to provide efficient cooling. As a result, damage due to overheating can be prevented.

The cooling principle of circuit board heat sinks is to effectively remove the heat generated on electronic device boards by using the processes of thermal conduction and thermal radiation.

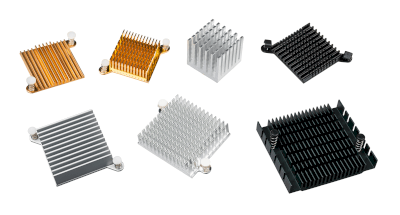

Circuit board heat sinks use aluminum, iron, and copper as their materials because of their good thermal conductivity. In addition, to increase the heat dissipation capacity of heat sinks, they are often designed to increase their surface area.

One example of such a device is to increase the surface area of a heat sink by placing many thin plates side by side on the surface of the heat sink with space between them. Products with many rod-like structures bonded to the surface are another way to increase surface area. In addition, when heat is to be dissipated efficiently, forced air cooling may be used to lower the ambient temperature.

There are various ways to secure a heat sink to a PCB, including double-sided tape, pins, and clips. In some cases, double-sided thermally conductive tape is used to secure the heat sink.

In this method, double-sided adhesive tape with high thermal conductivity is placed between the heat sink and the heating element. This method is often used for small and lightweight heat sinks. Another method is to fix the heat sink and board with push pins.

The heat sink is held in place by spring tension. Another method is to secure the heat sink to the board with stepped screws, which makes it easy to replace the heatsink.

The Z-shaped clip method uses two anchors on the board and a Z-shaped wire clip to secure the heatsink in place. It is characterized by ease of attachment and removal.

Circuit board heat sinks can be classified into two types depending on the cooling method: natural air cooling and forced air cooling.

Natural air cooling is a method that relies solely on heat dissipation from the heat sink. It is more advantageous in an open space with no enclosure.

Forced air cooling is a cooling method that uses a fan. Forced-air cooling is more efficient when there is an enclosure. This system controls the air velocity inside the chassis by the size of the duct opening to dissipate heat.

In forced air cooling, too large a flow path reduces air velocity, and too small a flow path reduces airflow. To maintain proper air velocity and air volume, the minimum cross-sectional area of the flow path must be equal to or greater than the minimum cross-sectional area of the fan.

*Including some distributors, etc.

Sort by Features

Sort by Area

Millennium Circuits Ltd, founded in 2005, based in Pennsylvania, United States, is a manufacturer and supplier of PCBs. Their product portfolio includes printed aluminum and ceramic PCBs circuit boards, and SMT stencils. The company also offers a range of PCB solutions with the cutting-edge technology of high-frequency laminate, microwave circuits, good quality control, technical support, and ISO certifications. The products have multiple applications in medical instrumentation, test, and measurement, LED lighting, automotive, consumer electronics, marine, and industrial equipment, as well as electronic and manufacturing industries.

Epec is an American manufacturer of high-reliability electronic components established in 1952 in New Bedford, Massachusetts. The company produces various electronic manufacturing components used in a wide range of industries, including battery packs, printer circuit boards (PCBs), cable assemblies, and fan motors. They also offer custom engineering, supply chain management, and after-sale support services to their customers. Epec operates internationally via a network of facilities and offices in the United States, China, and United Kingdom. The company has served notable clients such as Medtronic, Schneider Electric, and Samsung.

Nishimura Advanced Ceramics Co., Ltd., founded in Japan, is a manufacturer of ceramics including kneading materials, forming, firing, and other processing to finish products. The company's product portfolio includes ceramic circuit boards, ceramic for machine parts and pump parts, optical products, temperature sensor parts, and lighting apparatuses. It also offers various firing techniques, including reduction, oxidation, and alternative firing methods, to achieve unique glazes and finishes. It also collaborates with clients to produce custom ceramic products tailored to their specific design and functional requirements.

A.L.M.T. Corp., founded in Japan in 1939, is a manufacturer of heat spreaders, tungsten/molybdenum powder and machined products. The company's product portfolio includes diamond cutting tools, CBN cutting, grinding tools, metallic materials that are used for electrodes in various electronics and heat-resistant parts for high temperature furnaces and drawing dies. The company serves industries such as oil and gas, aerospace and defense, automotive and transportation, construction, and power generation. The company also provides services including national distribution, product selection, installation, preventative maintenance, troubleshooting, repair and customer service.

Nippon Electric Glass Co., Ltd. (NEG) is a glass technology products manufacturer originally founded in 1949 and headquartered in Otsu, Shiga. The company specializes in glass for tech and computing applications, particularly for flat-panel displays (FPDs). Their product portfolio includes substrates for FPDs and liquid crystal displays (LCDs), organic light-emitting diodes (OLEDs) and touch panels for smart devices. Other products include high modulus glass fiber, heat-resistant glass and chemically strengthened glass. NEG primarily serves clients in the digital display, automotive, and information technology markets.

Resonac Corporation is a Japanese chemical manufacturer and supplier, catering to various industries was established in June 1939. Resonac Corporation has developed expertise in electronics, mobility, high-performance materials, olefins and derivatives, basic chemicals, graphite, device solutions, and life sciences. Serving a diverse range of industries, their product portfolio includes inorganics, aluminum, electronics, chemicals, and inorganic materials. With its headquarters in Tokyo, Japan, the company provides innovative solutions and products tailored to diverse customer needs. Resonac Corporation is recognized for its advanced technologies in the industry.

RayMing Technology, founded in 2005 and based in China, is a manufacturer of PCBs and related components. Its offered services include Printed Circuit Board Assembly, PCB Fabrication, and Component Sourcing services from PCB Production to PCB Prototypes. The company has served more than 6,000 Contract Assemblers and more than 10,000 Electronic Engineers. Its manufacturing assets that help make High-End PCB products include PCB Testing Laboratory, PCB Fabrication Equipments, Electronics Laboratory and PCB Assembly Equipments.

Himalay Engineering Co., founded in India in 1998, is a manufacturer of Extruded and Cast Aluminum Heat Sinks, Gravity Dies, stack assembly, and Aluminum Plates and Bus Bars. The company's product range includes a wide variety of aluminum heat sinks, designed for efficient heat dissipation in electronic and industrial applications, gravity die casting capabilities enable the production of precision-crafted aluminum components, and aluminum plates are produced to exacting standards, suitable for various applications in engineering and manufacturing.

PW Circuits Ltd, founded in the UK in 1968, is a manufacturer of printed circuit boards. The company's product range includes single-layer, double-layer, and multi-layer rigid PCBs, flexible PCBs, also known as flex circuits, and rigid-flex PCBs, ideal for applications that demand a combination of rigid and flexible board designs. Its products find application in development of smartphones and laptops, and automotive electronics, including infotainment systems, safety features, and electric vehicle technologies.

Zaward Corporation, founded in Taiwan in 1996, is a manufacturer of cooling systems. The company's product range includes DC/AC fans, DC blowers, diversified processes of heat sinks, heat pipes, vapor chambers, CPU and GPU coolers to peripheral components such as fan guards, and thermal pads. The company is a solution provider for various fields, such as automotive, consumer electronics, industrial computer, LED lighting, and telecom. It also provides OEM and ODM services from concept to design through manufacturing and after-market services for worldwide electrical companies.

db Electronic, founded in Germany, is a manufacturer of printed circuit boards. The company's product range includes single-layer, double-layer, and multi-layer rigid PCBs tailored to various applications, including consumer electronics, automotive, industrial, and medical devices. It also provides expert consultation, design support, and customized solutions to help clients choose the right PCBs for their specific projects. The company serves industries such as automotive, consumer electronics, medical devices, and aerospace technology.

Based in Ibaraki Prefecture north of Tokyo, Takagi Manufacturing Company is a specialized metal manufacturer specializing in copper components, especially for computing and technology industries. Takagi Manufacturing Company is a pioneer in thermal products, focusing on original product designs of various types including plating, Seebeck units, and heater coolers with a recent emphasis in water-cooled heatsinks for the electronics industry.

Heatell, founded in Zenjiang, China, is a supplier of thermal solutions. The company's product range includes a wide variety of thermal management solutions, including heat sinks, fans, cooling systems, and thermal interface materials, designed to address heat-related challenges in various applications. It also offers customized thermal solutions tailored to the unique requirements and expert guidance on material selection, design optimization, and thermal analysis to ensure optimal heat management and reliability.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Himalay Engineering Co. |

17.9%

|

| 2 | Heatell |

11.9%

|

| 3 | Zaward Corporation |

10.4%

|

| 4 | Nishimura Advanced Ceramics Co., Ltd. |

9.0%

|

| 5 | db Electronic |

7.5%

|

| 6 | RayMing Technology |

7.5%

|

| 7 | Millennium Circuits Limited |

7.5%

|

| 8 | PW Circuits Ltd |

6.0%

|

| 9 | Epec |

6.0%

|

| 10 | A.L.M.T. Corp. |

6.0%

|

Derivation Method

The ranking is calculated based on the click share within the circuit board heat sink page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

Japan

Japan

|

5 | 45.5% |

United States of America

United States of America

|

2 | 18.2% |

China

China

|

2 | 18.2% |

India

India

|

1 | 9.1% |

United Kingdom

United Kingdom

|

1 | 9.1% |

179 products found

179 products

Mizutani Electric Industry Co., Ltd.

600+ people viewing

■Small semiconductor heatsink As a heatsink for molded transistors, it is made of processed colored aluminum and is lightweight and inexpensive. Fu...

TAKAGI MFG.CO.,LTD.

760+ people viewing

Last viewed: 1 day ago

Copper water-cooled heat sink with outstanding cooling effect. It can also be used to heat hot water. We have standard products ranging from 20mm s...

Marix Co., Ltd.

190+ people viewing

Last viewed: 2 hours ago

It is possible to fix the semiconductor to the printed circuit board together with the heat sink. For fixing, we offer round pin soldering, termina...

5 models listed

Mizutani Electric Industry Co., Ltd.

410+ people viewing

Last viewed: 4 hours ago

■Small semiconductor heatsink As a heatsink for molded transistors, it is made of processed colored aluminum and is lightweight and inexpensive. Fu...

TAKAGI MFG.CO.,LTD.

740+ people viewing

Last viewed: 10 hours ago

Made of copper with excellent performance and durability, it is lightweight with a thickness of 3 to 20 mm. You can choose from various types such ...

Mizutani Electric Industry Co., Ltd.

420+ people viewing

■Small semiconductor heatsink As a heatsink for molded transistors, it is made of processed colored aluminum and is lightweight and inexpensive. Fu...

TAKAGI MFG.CO.,LTD.

710+ people viewing

Last viewed: 1 day ago

A conventional water-cooled heat sink with copper or SUS pipe sandwiched between aluminum plates. Although its performance is inferior to laminated...

Widework Co., Ltd.

1160+ people viewing

■ Overview ・ It is a CPU cooler compatible with Intel Socket LGA1700. ・ The aluminum heat sink is attached to the CPU contact surface of the alum...

Mizutani Electric Industry Co., Ltd.

460+ people viewing

■Small semiconductor heatsink As a heatsink for molded transistors, it is made of processed colored aluminum and is lightweight and inexpensive. Fu...

TAKAGI MFG.CO.,LTD.

550+ people viewing

Last viewed: 17 hours ago

A thin water cooling plate (heat sink) that meets the demand for weight reduction. Although it is 3mm to 5mm thin, it is made of oxygen-free copper...

Mizutani Electric Industry Co., Ltd.

350+ people viewing

Last viewed: 1 day ago

■Small semiconductor heatsink As a heatsink for molded transistors, it is made of processed colored aluminum and is lightweight and inexpensive. Fu...

TAKAGI MFG.CO.,LTD.

540+ people viewing

Last viewed: 5 hours ago

Although it has inferior cooling capacity and durability compared to copper, it is lightweight, so it can be used for cooling heat-generating mater...

Widework Co., Ltd.

470+ people viewing

Last viewed: 21 hours ago

■ Overview ・ Passive heat sink for Intel Socket LGA3647. ・ It is mainly used for rack mount servers and small industrial equipment. Since this pr...

4 models listed

Asuka electronic service Co., Ltd.

260+ people viewing

■ Characteristics It is a heat sink developed for LSI. * There are other models.

10 models listed

Mizutani Electric Industry Co., Ltd.

340+ people viewing

Last viewed: 16 hours ago

■Small semiconductor heatsink As a heatsink for molded transistors, it is made of processed colored aluminum and is lightweight and inexpensive. Fu...

TAKAGI MFG.CO.,LTD.

770+ people viewing

Last viewed: 1 day ago

Made of copper with excellent performance and durability, it is lightweight with a thickness of 5 to 10 mm. There are 8 standard products available...

TAKAGI MFG.CO.,LTD.

640+ people viewing

Although it has inferior cooling performance and durability compared to copper, it has excellent liquid resistance and can be used with special ref...

Mizutani Electric Industry Co., Ltd.

330+ people viewing

■Small semiconductor heatsink As a heatsink for molded transistors, it is made of processed colored aluminum and is lightweight and inexpensive. Fu...

TAKAGI MFG.CO.,LTD.

620+ people viewing

Last viewed: 1 day ago

Using the P-B bonding method, which combines plating and brazing, we are now able to provide products that are much cheaper and more reliable than ...

Mizutani Electric Industry Co., Ltd.

410+ people viewing

■Small semiconductor heatsink As a heatsink for molded transistors, it is made of processed colored aluminum and is lightweight and inexpensive. Fu...

Widework Co., Ltd.

290+ people viewing

■ Overview ・ Passive heat sink for Intel Socket LGA1150/1151/1155/1156/1200. ・ It is mainly used for rack mount servers and small industrial equi...

4 models listed

Widework Co., Ltd.

440+ people viewing

Last viewed: 2 hours ago

■ Overview ・ Passive heat sink for Intel Socket PGA989/988/G1/G2. ・ Mainly used for rack mount servers for 1U and small industrial equipment. ・ ...

2 models listed

TAKAGI MFG.CO.,LTD.

610+ people viewing

Last viewed: 12 hours ago

In addition to regular air cooling fins, we also have air cooling fins equipped with the highest performance fans and heat pipe types that can cool...

Mizutani Electric Industry Co., Ltd.

320+ people viewing

■Small semiconductor heatsink As a heatsink for molded transistors, it is made of processed colored aluminum and is lightweight and inexpensive. Fu...

Mizutani Electric Industry Co., Ltd.

320+ people viewing

■Small semiconductor heatsink As a heatsink for molded transistors, it is made of processed colored aluminum and is lightweight and inexpensive. Fu...

Thermal Component Co., Ltd.

230+ people viewing

Last viewed: 1 day ago

Forged aluminum. A heat sink that has been modified from the FT series so that it can be fixed by drilling a φ2.8 hole on the PCB.

Mizutani Electric Industry Co., Ltd.

300+ people viewing

Last viewed: 11 minutes ago

■ Heat sink with pin Solderable Heat Sinks for Mold Power TR The BPU series of heatsinks with pins is a long-running model with a history of 40 yea...

Mizutani Electric Industry Co., Ltd.

270+ people viewing

Last viewed: 2 hours ago

■Heat sink with board terminal Heat Sinks for PC Board The SAS series, SBS series, I series, and RAS series heatsinks with plate terminals can be s...

Thermal Component Co., Ltd.

250+ people viewing

Last viewed: 21 hours ago

Forged aluminum. A heat sink that has been modified from the FT series so that it can be fixed by drilling a φ2.8 hole on the PCB.

Mizutani Electric Industry Co., Ltd.

360+ people viewing

Last viewed: 15 hours ago

■ Heat sink with pin Solderable Heat Sinks for Mold Power TR The BPU series of heatsinks with pins is a long-running model with a history of 40 yea...