29 Dial Indicator Manufacturers in 2024

This section provides an overview for dial indicators as well as their applications and principles. Also, please take a look at the list of 29 dial indicator manufacturers and their company rankings. Here are the top-ranked dial indicator companies as of April, 2024: 1.Thermwood Corp., 2.Sunnen Products Company, 3.SAE Manufacturing Specialties Corp.

Table of Contents

What Is a Dial Indicator?

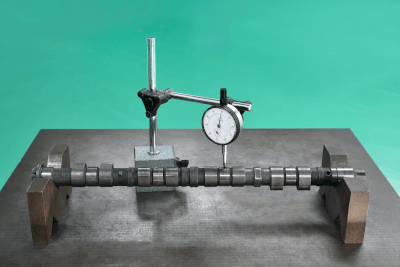

A dial indicator is a measuring instrument used for measuring the length and runout of a workpiece. Similar in shape and function, some products are referred to as dial gauges.

Positioned on a foundation, a dial indicator measures the dimensional variance of a workpiece compared to a standard model, such as a block length gauge. Measurements can be in hundredths or thousandths of a millimeter. Accuracy is contingent on controlled temperature, measurement method, and the condition of the foundation and workpiece; without these controls, significant errors may occur.

Uses for Dial Indicators

Dial indicators are utilized in various applications, including:

- Measuring parts in precision instruments.

- Measuring small-diameter components.

- Assessing the runout of circular parts.

Initially, the base of the dial indicator is set on a stable platform, with gauges or indicators placed on the base's tip.

Next, a dimensional standard is positioned on the base, adjusted to be within the measurable range by touching the tip, and the indicator needle is set to 0 (zero).

After removing the standard, the workpiece is placed between the base and the measuring element. The needle's indication at this point represents the dimensional difference between the standard and the workpiece, allowing for accurate measurement of the workpiece's dimensions.

Principles of Dial Indicators

Dial indicators come in two types: the spindle type, where a rod-shaped measuring element moves vertically to indicate dimensional differences, and the lever type, used in confined spaces where the spindle type cannot fit.

The spindle type, common for simple shapes, features a vertically moving measuring element that can be easily aligned perpendicular to the base.

The lever type, ideal for narrow areas, has a tilting measuring element around its base. It must be installed nearly perpendicular to the direction of dimension change in the workpiece at the measurement point.

In both types, the measuring element’s motion causes the hand to swing like a clock. Dimensional differences from the standard are determined by setting the standard dimension to 0 on the model and reading the needle display while measuring the workpiece. Attention should be paid to the display's resolution and the number of needle rotations, which must be visually confirmed during measurement.

With a defined measurement method and temperature control, even measurements in thousands of a millimeter can be achieved with high accuracy.

List of 29 Dial Indicator Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- United States of America

- Canada

- China

- Japan

-

-

-

Dorsey Metrology International

Jam Proof Dial Indicators

Manufacturer Overview

Dorsey Metrology International, a Poughkeepsie, US-based company established in 1955, is a manufacturer of precision handheld and bench-top dimensional measurement instruments and a supplier of pertinent services. The company provides indicating devices, direct reading gages, large diameter gages, and optical comparators. It also offers calibration, contract manufacturing, engineering, and repair services. The products of the company are used as tools to do measurements. It has passed ISO/IEC 17025:2017 certification, indicating the competence of its laboratories.

-

-

-

-

-

Thermwood Corp.

Dial Indicators

Manufacturer Overview

Thermwood is based in Dale, Indiana, and operates as a multinational diversified CNC machinery manufacturer that markets its products and services globally through offices in 11 countries. The company primarily serves the woodworking, aerospace, plastics, and composites industries but also serves almost every major industry from medicine to entertainment. The company’s products include both hardware and software. Hardware includes 3-axis and 5-axis CNC routers and LSAM machines. Software offerings include Mastercam, Moldplus, and THM Desktop among others.

-

-

-

-

-

Sunnen Products Company

Dial Indicators

Manufacturer Overview

Sunnen Products Company, founded in 1924, is an American manufacturer and supplier headquartered in St. Louis, Missouri, specializing in of high-precision and bore sizing machines, tools, and abrasives. Joe Sunnen, founder of the company, invented the first manual cylinder hone in 1928. Over the years, Sunnen has developed industrial honing machines, tools, and abrasives with bore sizing and finishing systems, lapping machines, deep hole drilling machines and tools, bore gaging and roller burnishing systems. These products find applications in various industries, such as honing solutions in the automotive sector, as well as a line of machines, tools, and abrasives for energy drilling.

-

-

-

-

-

SAE Manufacturing Specialties Corp

Dial Indicators

Manufacturer Overview

Based in Bayville, NY, SAE Manufacturing Specialties Corp. is an ISO-certified supplier and manufacturer of industrial equipment, chemicals, components, ordinance, electronics, and systems for industries ranging from aerospace to high tech to law enforcement. Examples of product offerings include raw materials, chemicals, and lubricants for industrial purposes to finished products such as security helmets for law enforcement, and military ordnances. SAE also provides research and development as well as technical support for other companies in similar industries.

-

-

-

-

-

Pyromation

Dial Indicators

Manufacturer Overview

Pyromation began operations in 1962 and operates out of Fort Wayne, Indiana. Pyromation is a manufacturer of RTD temperature sensors, thermocouples, and thermowells. Pyromation serves the aerospace, aggregate, chemical, energy and power, food and beverage, heat treating, HVAC, incineration, medical, metal processing, mining, oil and gas, pharmaceutical, plastics, rubber, and waste/water industries. Pyromation’s product lines include thermocouples, RTDs, thermowells, transmitters, connection heads, wire, and accessories. Pyromation also offers application assistance, calibration, training, and custom design services.

-

-

-

-

-

Machine Products Corp.

Dial Indicators

Manufacturer Overview

Machine Products Corp. (MPC) is an American designer and manufacturer of fabrication equipment founded in Dayton, Ohio in 1956. The company primarily produces fabrication equipment used in motor manufacturing, such as coil injectors and winders, turn blockers, cleaters, and welders. They also offer various sight flow indicators, windows, and glasses for monitoring the flow of liquid in pipelines and tubing. MPC also offers contract manufacturing, repair, and maintenance services for their clients, which primarily consists of companies in the electric car and green energy industries.

-

-

-

-

-

Lapmaster International, LLC

Dial Indicators

Manufacturer Overview

LAPMASTER WOLTERS’s roots go back as far as 1804 with the founding of Peter Wolters. Lapmaster was founded in Chicago in 1948 as a manufacture of lapping and polishing machines for the mechanical seal market, Lapmaster has grown to a worldwide solution provider for more than 20 industries like precision optics and advanced materials. Lapmaster serves many industries including automotive, semiconductor, electro optics, and medical devices. Lapmaster also sells many consumables including abrasive powders, lapping compounds diamond lubricants, and composite plates. Products include lapping, polishing, bore honing, buffing, grinding, and special purpose machines.

-

-

-

-

-

J.W. Winco, Inc.

Dial Indicators

Manufacturer Overview

J.W. Winco was originally founded as Ganter in 1894 in Germany. Winco specializes in parts manufacturing. Parts offerings the operating parts segment including handles, adjusting, and positioning parts; clamping parts segment featuring tensioning, clamping, switching, and levers; and finally the machine parts segment with indexing, locking, mounting, connecting elements, guides, spindles, rollers, magnets, casters, and wheels. Winco’s complete catalog contains over 75,000 standard parts. Winco is also ISO 9001 certified. Winco offers free CAD downloads and technical documentation for many arts.

-

-

-

-

-

Gem Instrument Co.

Dial Indicators

Manufacturer Overview

Gem Instrument Co., headquartered in Brunswick, Ohio, is a manufacturer of precision measuring instruments. Their product range includes swivel clamps, magnetic bases, as well as dial indicators, and calipers. These instruments play a crucial role in providing accurate measurement, alignment, and positioning solutions to ensure product quality, process efficiency, and regulatory compliance for manufacturing, assembly, and service industries. Gem Instrument Co. also caters to the specific requirements of customized precision products.

-

-

-

-

-

Mitutoyo America Corporation

Dial Indicators

Manufacturer Overview

Mitutoyo America Corporation was founded in Aurora, Illinois in 1963 by Mitutoyo Corporation of Japan as its American sales, marketing, and service subsidiary. The company provides parts service, manufacturing, and turnkey solutions for metrology equipment for aerospace, alternative energy, automotive, semiconductor, and other industries. The company’s product offerings include coordinate measuring machines, sensor systems, test equipment, and vision measuring equipment customized for customer needs. The company’s services include calibration and repair, installation, contract part programming, and training and education for operation as well as calibration.

-

-

-

-

-

Carolina Scales Inc.

Dial Indicators

Company Overview

Carolina Scales is located in West Columbia, South Carolina. Carolina Scales is a distributor of equipment for and service provider for scale calibration and certification. Carolina Scales is ISO/IEC 17025 accredited. Carolina Scales product division includes truck/portable vehicle scales, weight indicators, load cells/weigh modules/junction boxes, floor scales, bench scales, counting scales, check weighers, balances, used scales, crane scales/hanging scales, remote displays/scoreboards, lift truck scales, printers, scanners, medical & health scales, retail scales, belt scales/conveyor scales, railroad, and agricultural scales. Services include scale testing and calibration and equipment rentals.

-

-

-

-

-

-

-

AppMet, Inc.

Dial Indicators

Company Overview

AppMet, Inc was founded in 1993 in North Charleston, South Carolina. AppMet is a calibration and testing company offering dimensional, physical & mechanical, and electronic & electrical calibration services in climate-controlled laboratories as well as on-site calibrations when possible. AppMet is ISO/IEC 17025 as well as Full Service ISO-99001 certified. Electronic calibrations are made with all types of electrical and electronic test equipment from analog multimeters to RF spectrum analyzers. Physical and mechanical calibrations and tests are performed with equipment ranging from analytical balances to vacuum gages. Dimensional calibrations are performed with equipment ranging from 1-2-3 blocks to angle plates to thickness gages.

-

-

-

-

-

Compressed Air Systems, Inc.

Dial Indicators

Distributor Overview

Compressed Air Systems was founded in Tampa, Florida in 1963. Compressed Air Systems supports customers in a wide array of industries including food & beverage, medical applications, industrial, electronics, fleet maintenance, aerospace, pharmaceuticals, plastics processing, CNC machine shops, and woodworking. Compressed Air Systems sells air compressors, railcar gate openers and various related products. Compressed Air Systems also offers services including audit, leak compressed air leak elimination, compressed air rentals, and turnkey packages for industrial equipment systems.

-

-

-

-

-

Teclock

Dial Indicator

Manufacturer Overview

Teclock, founded in 1950 and based in Okaya, Nagano, Japan, is a distinguished manufacturer of precision measuring instruments. Its instruments has a high dimensional accuracy with a smallest scale of 0.0005mm. Its product lineup includes dial indicators, lever testers, thickness gauges, depth gauges, and calipers. The company also offers height gauges, stands, handy durometers, and micrometers. The company also provides a Cloud-based IoT measurement solution, enabling the seamless digitization and analysis of measurement data.

-

-

-

-

-

Shinwa Rules Co., Ltd.

Dial Indicator

Manufacturer Overview

Shinwa Rules Co. was founded in Niigata, Japan, in 1971. Shinwa Rules Co. develops a variety of measuring products including calipers, thermometers, hygrometers, laser optical apparatuses, and sheet heating elements. Above these, Shinwa develops metallic rulers and squares. Additionally, Shinwa operates as an OEM supplier for special calibrations and machine tools, special surface fabrication, and etching on metallic parts.

-

-

-

-

-

NingBo JingYi Tools Factory

Dial Indicators

Manufacturer Overview

NingBo JingYi Tools Factory is a manufacturer in NingBo, China, specializing in the production of magnetic tools with more than two decades of experience. It offers magnetic bases, magnetic chucks, lifting magnets, and other measuring tools available for brand owners, wholesalers, and manufacturers. The company caters to customized OEM orders. The company has served its products to over 120 businesses worldwide. Its quality management system is certified with Iso 9001 and TS 16949.

-

-

-

-

-

Mahr GmbH

Dial indicators

Manufacturer Overview

Mahr GmbH is an ISO 50001-certified manufacturer of metrology and metering products that was established in Göttingen, Germany in 1861. The company’s product lineup includes measuring devices and instruments for quality control applications, and metering systems such as meter mix dispense machines and gear metering pumps for accurate dosing of pastes, gels or liquids. It also offers rotary stroke bearings for creating repeatability in linear or rotary motion. The company’s products are commonly used in the machine building processes, electronics manufacturing, and injection molding.

-

-

-

-

-

Fluidwell bv.

Pressure Indicators

Manufacturer Overview

Fluidwell Bv. is a Dutch ATEX and IECEx-certified manufacturer of process industry electronics that was established in Veghel, Noord-Brabant, in 1993. The company produces level measurement products such as level transmitters, pressure measurement products such as pressure alarms, and panel mounted instruments such as flow calculators. It also offers explosion-proof instruments for process control applications, including flow rate indicators and data loggers. The company’s products are commonly used in the petrochemical, oil and gas, and wastewater treatment industries.

-

-

-

-

-

Tejax Engineering Co.

Dial Indicators

Manufacturer Overview

Tejax Engineering Co. is an American manufacturer of analog and digital position indicators that was established in 1972. Based in Warren, Rhode Island, the company offers various position indicators that assist in managing distances between rollers, gate widths, and valve placement, as well as help regulate and position drive components. These are primarily used in design, engineering, architecture, and construction projects. Tejax Engineering also offers custom dial faces and contract manufacturing options for clients with niche specifications.

-

-

-

-

-

Oil-Rite Corporation

Dial Indicators

Manufacturer Overview

Oil-Rite Corporation was founded in 1933 and is based in Manitowoc, Wisconsin. Oil-Rite is a designer and manufacturer of lubrication equipment used in industries as diverse as automotive, machining, and baking, as well as hydroelectric dams. Oil-Rite’s featured products include constant level lubricators, level gages, feed valves, and oil systems. Additional products include grease and oil dispensers, various valves, and sights. Oil-Rite also offers support including usage, lubrication levels, maintenance, and product selection for specific needs.

-

-

-

-

-

Nath Tools Company

Dial Indicators

Manufacturer Overview

Established in 1992, and based in Haryana, China, Nath Tools Company is a manufacturer and supplier of Milling & Grinding Accessories and Clamping & Holding Elements that are used for machining processes in various industries. The company provides Milling Accessories, Revolving Center, CNC Accessories, Drill Machine Delux model, and, Drill Press Vice Unigrip. They also offer Bench vices, Precision vices, Vernier Caliper, and Drill chucks that have applications in Mining, machinery manufacturing, and, construction industries.

-

-

-

-

-

Dasqua

Dial Indicators

Manufacturer Overview

Dasqua SRL, established in 1980 and headquartered in Nord, Italy, is a designer, manufacturer, and supplier of machinist calibration tools and equipment. The company's products include precision digital precision outside micrometers, stainless steel-made monoblock vernier calipers, and digital zero setter Z-axis scale digital zero setting devices. These products are used for measuring and setting machining equipment. It primarily works with original equipment manufacturers and private label clients, and it also has client service centers and manufacturing facilities in the United States and China.

-

-

-

-

-

John C. Ernst Co. Inc.

Dial Indicators

Company Overview

John C. Ernst Co. is based in Sparta, New Jersey with distribution centers in Australia and Canada. The company is a manufacturer of flow-related products for industrial uses. The company’s product 8 segments include sight flow indicators, flow meters & totalizers, and liquid gauges & valves. The other segments are glass & gaskets, sight windows, switches & flow level, and ejectors and eductors. The company can sell direct to individual customers and to distributors.

-

-

-

-

-

Amtek Tool & Supply

Dial Indicators

Company Overview

Amtek Tool and Supply, Inc. based in Madison Heights, MI. Amtetk is an online super market for tools, supplies, and other hardware for individual, professional, and corporate customers. Product types include milling, threading, and turning devices, tooling systems, saws, broaching and deburring bits, cutting tool blanks and spares, abrasives, power tools, hand tools, safety equipment, measuring devices, lubrication, sanitation supplies, storage, pneumatics, shipping supplies, transmissions, and various other hardware and shipping supplies. Amtek’s online storefront offers precise filters to help find exact products to meet customer needs.

-

-

-

-

-

Abbeon Cal Inc.

Dial Indicators

Company Overview

Abbeon Cal Inc. is a manufacturer, distributor, and supplier of plastic working tools, based in California, USA, since 1995. They offer a wide range of products, including handheld tools for cutting, punching, and bending plastic, as well as machine tools for cutting, drilling, and milling plastic. Accessories like dies, punches, and cutting blades are also available. The company provides plastic working services, including custom tool design, manufacturing, and repair. Some of their featured products include Handheld Thermoplastic Shears, Pneumatic Hot Hole Punch, Automatic Tubing and Cable Cutting Machine, Temperature and Humidity Analog Dials, and Dataloggers.

-

-

-

-

-

Accusize Industrial Tools

Dial Indicators

Distributor Overview

Accusize Industrial Tools was born in Toronto, Canada in 2008. Accusize is a distributor of measuring tools, cutting tools, and machine tools for metalworking companies. A portion of offerings that Accusize offers includes collet blocks, expanding arbors, air tools, power tools, die maker tools, annular cutters, bore gages, boring bars, boring heads, BT40 tooling, CAT40 tooling, calibration, layout, & machine setting tools, calipers & attachments, carbide inserts, end mills, force gauges, and metrology and material testing equipment.

-

-

-

-

-

Precision Calibration Systems, LLC

Dial Indicators

Distributor Overview

Precision Calibration Systems was started in 2009 and is headquartered in Morristown, Tennessee. The company is a full-service ISO 17025 accredited calibration laboratory providing both small firms and Fortune 500 companies in automotive, manufacturing, aerospace, food & drug, and other industries with calibration services for a wide range of measuring instruments. The company offers onsite and in-house calibration services on many types of devices such as medical thermometers, analytical balance scales, pneumatic pressure gauges, optical comparators, and electrical multimeters. The company also offers equipment sales from companies such as Mitutoyo, Starrett, Tohnichi, and Ametek.

-

-

-

-

-

MSI-Viking Gage, LLC

Dial Indicators

Distributor Overview

MSI-Viking Gage, LLC was founded over 50 years ago and is headquartered in Duncan, South Carolina. MSI-Viking provides manufacturing support to the automotive, aerospace, metals, plastics, medical, energy, food & beverage, and machining industries. MSI-Viking product offerings include 3D scanning systems, 3D additive manufacturing, air gages, bore & hole gages, calipers, CMMs, computed tomography, data collection, depth gages, fixture systems, indicators, laboratory equipment, vision systems, and thread gages among others. Services include calibration, metrology, repair, embedded services, training, and metrology pre-op services.

-

-

Dial Indicator Manufacturer Ranking

*Including some distributors, etc.Ranking as of April 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Thermwood Corp. |

18.2%

|

| 2 | Sunnen Products Company |

13.6%

|

| 3 | Tejax Engineering Co. |

9.1%

|

| 4 | SAE Manufacturing Specialties Corp |

9.1%

|

| 5 | Dorsey Metrology International |

4.5%

|

| 6 | Pyromation |

4.5%

|

| 7 | Oil-Rite Corporation |

4.5%

|

| 8 | Teclock |

4.5%

|

| 9 | Mahr GmbH |

2.3%

|

| 10 | Reid Supply |

2.3%

|

Derivation Method

The ranking is calculated based on the click share within the dial indicator page as of April 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

- Fluidwell bv.: 1993 (31 years ago)

- Nath Tools Company: 1992 (32 years ago)

- Shinwa Rules Co., Ltd.: 1971 (53 years ago)

Company with a History

- Oil-Rite Corporation: 1933 (91 years ago)

- Reid Supply: 1948 (76 years ago)

- Lapmaster International, LLC: 1948 (76 years ago)

Dial Indicator Manufacturers in United States

*Including some distributors, etc.

- Dorsey Metrology International

- Thermwood Corp.

- Sunnen Products Company

- SAE Manufacturing Specialties Corp

- Pyromation

- Machine Products Corp.

- Lapmaster International, LLC

- J.W. Winco, Inc.

- Gem Instrument Co.

- Mitutoyo America Corporation

- Carolina Scales Inc.

- Reid Supply

- AppMet, Inc.

- Compressed Air Systems, Inc.

Global Distribution of Dial Indicator Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

14 | 77.8% |

Japan

Japan

|

2 | 11.1% |

China

China

|

1 | 5.6% |

Canada

Canada

|

1 | 5.6% |