11 Jig Parts Manufacturers in 2024

This section provides an overview for jig parts as well as their applications and principles. Also, please take a look at the list of 11 jig parts manufacturers and their company rankings. Here are the top-ranked jig parts companies as of April, 2024: 1.Foothills Machining, Inc., 2.Penta Precision Engineering, 3.STAL Ltd..

Table of Contents

What Is a Jig Part?

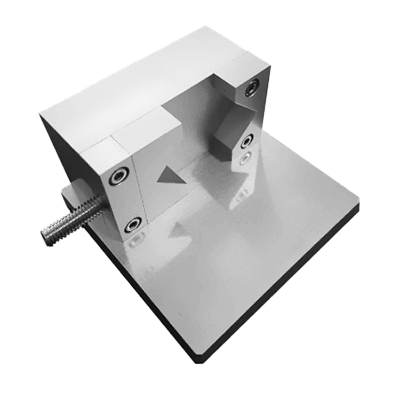

A jig is a positioning device used in machine tools to consistently produce products of high quality in large quantities.

Jigs are also employed to securely hold products in place. When a product is set and fixed within a jig, it remains in the same position, ensuring stability during processes like drilling. The jig is equipped with several components to position the product accurately.

These components include positioning pins, reference seat blocks, clampers, and rough guides.

Applications of Jig Parts

Below are examples of how jig parts are utilized:

- Machining Jigs

Jigs are employed on machine tools such as machining centers, lathes, and milling machines to eliminate the need for operators to make positioning adjustments for each product. - Assembly Jigs

In the assembly process, industrial robots are used to install components like bolts.

Unlike human workers, products must be consistently positioned; otherwise, assembly defects may occur when using industrial robots.

In the inspection process utilizing image processing, the product is assessed by comparing it to registered image data.

Features of Jig Parts

Key features of jig parts are explained for each type of jig component:

- Positioning Pin

These pins are inserted into the material hole, serving as the processing reference for the product.

Typically, a pair of pins is used, one with a round tip and the other with a diamond tip.

The round pin determines the product's position, while the diamond pin determines the phase.

The reason for having one pin as diamond-shaped is to ensure proper product placement, as it would be challenging with two round pins. - Reference Seat Block

This component is attached to the jig to ensure the parallelism of the product.

It is designed to receive the position known as the reference seat of the product.

Normally, three points are used for receiving the product, as using four or more points could miss the reference seat.

To prevent incorrect product placement, some reference seats have air holes to monitor pressure inside the reference seat. - Clamper

The clamping mechanism holds the product firmly in place, preventing movement under load during processing.

Various power sources, such as springs, air, and hydraulic pressure, are used to secure the product. The selection is based on the clamping force required to withstand the processing load.

List of 11 Jig Parts Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- United States of America

- China

- Germany

- Japan

- United Kingdom

- Vietnam

-

-

-

Mahuta Tool Corp.

Jig Parts

Manufacturer Overview

Mahuta Tool Corp., founded in 1988, is a manufacturer and service provider of CNC machining based in Wisconsin, USA. The company offers various services, including CNC machining, manufacturing assemblies, fixtures, and tooling. Additionally, the company designs and builds progressive metal stampings and pierce and blanking dies, with details such as incorporating sensors for die protection and quick die changes to reduce setup time. The company is 9001:2015 certified for quality management systems and also Mil-Spec compliant, indicating its ability to meet military specifications and standards.

-

-

-

-

-

-

-

Rother Machine, Inc.

Jig Parts

Distributor Overview

Rother Machine, Inc. is a supplier of industrial control services, established in 1971 and based in Hastings, United States of America. The company provides machine design, assembly, fabrication, welding, and electrical services to its customers. It also offers wire electric discharge machining, manual and CNC turning, CNC milling, and CNC machining services. It can tailor its machine to fit the customer’s product, packaging materials, and compliance regulations, such as automotive emblem packaging equipment. It serves electrical and gas, technology, automotive, paper, and plastic industries.

-

-

-

-

-

Spreitzer GmbH & Co. KG

ALUMESS Fixturing systems

Manufacturer Overview

Spreitzer GmbH & Co. KG, founded in 1983 and located in Baden-Württemberg, Germany, is a designer and manufacturer of clamping technology and measuring technology. The company’s diverse range of products includes mechanical centric vises, hydraulic centric vises, concentricity gages centerless, electric drives, and gages with tailstocks. These products are essential in precision machining, manufacturing, and quality control processes, offering accurate clamping, measurement, and control solutions. The company’s products are used to enhance the efficiency and precision of industrial applications, including milling, drilling, grinding, and quality assurance in manufacturing and machining operations.

-

-

-

-

-

Futaba

Parts for guide positioning

Manufacturer Overview

Futaba, founded in Japan, in 1985 is a manufacturer of vacuum tubes, electronic equipment, and radio control equipment. The company's product portfolio includes OLED Displays, Touch Sensors, Electronic Modules, Radio Control Equipments for Industrial Use, and Radio Control Equipments for Hobby Use. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and Power Generation. The company provides services such as Product Selection Guidance, Engineering Support, and Custom Manufacturing.

-

-

-

-

-

Graphel Carbon Products

Jig Parts

Manufacturer Overview

Graphel Carbon Products is a manufacturer and supplier of carbon and graphite products based in Ohio, USA, founded in 1965. The company offers a wide range of carbon and graphite solutions used in various industrial applications due to its unique properties, such as high thermal conductivity, electrical conductivity, and resistance to extreme temperatures. Carbon and graphite materials are used to manufacture electrodes and tooling for various processes, including applications in EDM (Electrical Discharge Machining), die sinking, and other precision machining operations. The company serves a range of industries, including aerospace, automotive, semiconductor, energy, and medical.

-

-

-

-

-

-

-

-

-

-

-

Penta Precision Engineering

Jig Parts

Company Overview

Penta Precision Engineering is a reputable precision engineering company based in Portsmouth, United Kingdom. Established in 1998, the company has a long-standing history of excellence. Penta Precision Engineering, an ISO 9001:2015 accredited company, specializes in providing a wide range of precision engineering services, including CNC machining, milling, turning, and assembly. These services cater to various industries, such as aerospace, automotive, and medical technology. The company offers comprehensive solutions, including CNC Milling, CNC Turning, Honing, Lapping, Screen printing and Plating.

-

-

-

-

Jig Parts Manufacturer Ranking

*Including some distributors, etc.Ranking as of April 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Foothills Machining, Inc. |

15.0%

|

| 2 | Penta Precision Engineering |

15.0%

|

| 3 | STAL Ltd. |

10.0%

|

| 4 | Rother Machine, Inc. |

10.0%

|

| 5 | Mahuta Tool Corp. |

10.0%

|

| 6 | Graphel Carbon Products |

10.0%

|

| 7 | Spreitzer GmbH & Co. KG |

10.0%

|

| 8 | Formaplex Technologies Ltd |

5.0%

|

| 9 | Proto MFG Co.,Limited. |

5.0%

|

| 10 | Intech Mechanical |

5.0%

|

Derivation Method

The ranking is calculated based on the click share within the jig parts page as of April 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

- Futaba: 4,006

Newly Established Company

- Proto MFG Co.,Limited.: 2014 (10 years ago)

- Formaplex Technologies Ltd: 2007 (17 years ago)

- STAL Ltd.: 2001 (23 years ago)

Company with a History

- Futaba: 1948 (76 years ago)

- Graphel Carbon Products: 1965 (59 years ago)

- Penta Precision Engineering: 1998 (26 years ago)

Jig Parts Manufacturers in United States

*Including some distributors, etc.

Global Distribution of Jig Parts Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

3 | 30.0% |

United Kingdom

United Kingdom

|

3 | 30.0% |

Germany

Germany

|

1 | 10.0% |

Japan

Japan

|

1 | 10.0% |

China

China

|

1 | 10.0% |

Vietnam

Vietnam

|

1 | 10.0% |

List of Jig Parts Products

63 products are listed.

Musashino Denshi, INC.

The sample is kept from both sides with a stopper.

It is possible to break the sample along the injury line. It is a broken jig used by the precision manual scriver. ■ Features ・ It is possible to...

Innovalia Metrology

Quick and cost -efficient module jig

10+ people viewing

■ Overview Innovalia Metrology's jig solution allows users' unique measurement mechanisms quickly and more efficiently. Module jigs are designed fo...

Musashino Denshi, INC.

Tilt to the part you want to polish and set the center of gravity

■ Characteristics ・ If there is an inclination on the processing surface using another sample holder, it is a holder to correct the slope. ・ Norm...

Musashino Denshi, INC.

Adjustable amount of polishing with a minimum of 10 μm scale adjustment holder

■ Characteristics ・ The amount of polishing is set and the required amount of polishing is possible. ・ The amount of polishing can be adjusted at...

Musashino Denshi, INC.

Holder that can be polished at right angle

■ Characteristics ・ It is possible to set a plate -shaped sample in three parts and polish at a right angle. ・ Since the upper and lower surface ...

Innovalia Metrology

Ideal for customization of jigs, module jigs Inno-fix kit M

■ Overview Innovalia Metrology's jig solution allows users' unique measurement mechanisms quickly and more efficiently. Module jigs are designed fo...

Musashino Denshi, INC.

At the same time, multiple samples are polished and embedded.

■ Characteristics ・ At the same time, multiple resin -filled samples and cylindrical samples can be polished, and work efficiency can be improved....

Musashino Denshi, INC.

Holder in parallel to the paste plate in parallel

■ Characteristics ・ When polishing in parallel to the paste plate, it is suitable to use a holder that supports guiding. ・ It is best to use a fl...

Musashino Denshi, INC.

A simple 2 -axis goniometer sample holder can be polished by modifying the two axis

It is possible to polish by modifying the direction of the two axis. The angle polishing work can be performed easily. ■ Characteristics By using ...

Musashino Denshi, INC.

Autumn chuck type holder can be automatically polished with set polishing amount

■ Features ・ A holder that can automatically polish the set polished amount. ・ The setting accuracy of the polishing amount can be adjusted with ...

Izumiya Machinery Co., Ltd.

The best system hand and jigs for factories

Last viewed: 22 hours ago

We will design and create hands and jigs corresponding to various works and specifications, and propose optimal systems to customer factories. * T...

System Giken Co., Ltd.

3.8φ and 5.6φCAN for each lineup semiconductor laser device hold sample

We will start selling detachable fixes that are optimal for high -frequency characteristics evaluation for 10GHz CAN LD/PD for high requests. The 1...

Innovalia Metrology

Create a jig that matches the measurement target product Modular jig inNO-FIX kit e

■ Overview Innovalia Metrology's jig solution allows users' unique measurement mechanisms quickly and more efficiently. Module jigs are designed fo...

Musashino Denshi, INC.

Ideal for pre -treatment for samples Model 160

It is possible to accurately manage the polishing thickness of the sample by the scale. Ultra -precision dating grinder is a polishing jig mounted ...

Maekawa Test Machine Manufacturing

Anti -fold / bending test hell BE series

10+ people viewing

Anti -folded / bending test jigs BE series for various metal materials By installing this jig in a universal test machine or in the compressed spa...

Musashino Denshi, INC.

Diamond Wire Saw CS-203

■ Features ・ In addition to the standard jigs attached to the Diamond Wire Saw CS-203, a wide variety of jigs, such as ion milling samples and vic...

Musashino Denshi, INC.

Automatic polishing work is possible TEM holder

■ Characteristics ・ The amount of polishing is set and the required amount of polishing is possible. ・ It can also be used to polish a sample bur...

Musashino Denshi, INC.

Screw -containing diamond stopper holder

■ Characteristics ・ Three diamond stopers are screw -contained, and the amount of polishing can be adjusted. ・ The stopper screw can be adjusted ...

Musashino Denshi, INC.

Automatic polishing of the set polished amount can be polished high -precision holder

■ Characteristics ・ A holder that can automatically polish the set polished amount. ・ The setting accuracy of the polishing amount can be adjuste...

Musashino Denshi, INC.

Fixed 1 embedded sample holder while adjusting the amount of polishing

■ Characteristics ・ It is possible to fix the resin wrapping sample and cylindrical samples while adjusting the polishing amount with the height a...

Ecort Precision Co., Ltd.

jig

The jigs for holding work in dip coating are determined according to their conditions, such as applying methods and processing amounts, regardless ...

Musashino Denshi, INC.

Can be processed by controlling the amount of polishing

It is a polishing holder that can be used with MM-200 for hand-polishing equipment. You can set the amount of polishing. ■ Characteristics ・ Used...

Innovalia Metrology

Reusable module jig inno-fix kit C

■ Overview Innovalia Metrology's jig solution allows users' unique measurement mechanisms quickly and more efficiently. Module jigs are designed fo...

Musashino Denshi, INC.

Multipurpose holder that can polish both ends

■ Characteristics ・ The sample can be adhered in the size of 40mm x 30mm with a jig for pasting and polishing. ・ A diagonal polishing jig (inclin...

System Giken Co., Ltd.

Semiconductor laser temperature -tailed jig series

Custom designs will be made according to the requested device for temperature control, the purpose of measurement, method, necessary parameters, etc.