All Categories

History

This section provides an overview for jig grinding as well as their applications and principles. Also, please take a look at the list of 30 jig grinding manufacturers and their company rankings. Here are the top-ranked jig grinding companies as of July, 2025: 1.US Machine & Tool, Inc., 2.TCS Industries, Inc., 3.Sirois Tool Co., Inc..

Table of Contents

Categories Related to Jig Grinding

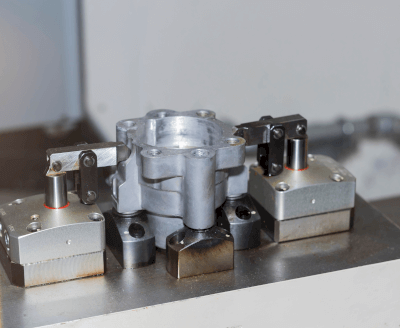

A jig grinding tool is a tool used for cutting, drilling, and other machining operations. It is essential for holding the workpiece firmly during machining or guiding the cutting position.

The purpose of jig grinding is to improve processing quality, achieve uniform processing among different operators, and enhance productivity by increasing efficiency in operations.

Devices like vices, commonly employed in jig grinding, secure workpieces during cutting and drilling. For shaping materials such as sponge or plastic, jig grinding guides the cutter along a tool matching the workpiece shape, ensuring uniform processing and allowing anyone to easily and quickly work on the piece. The increasing automation in machining has led to more widespread use of jig grinding machines, including industrial robots for efficient loading and unloading of workpieces.

Jig grinding encompasses a variety of tools, from high-end and expensive models to simple and affordable jigs like those used for cutting tape. These tools are not only for holding objects but also for precise positioning and quick fixing. Modern robot-based jig grinding systems incorporate various functions to boost productivity. They may use vision cameras for workpiece inspection, input necessary machining operations, and visually inspect parts post-machining. Robots equipped with force sensors, 3D vision cameras, and artificial intelligence can perform repetitive tasks with high accuracy, handling heavy workpieces and tasks that are challenging for humans.

*Including some distributors, etc.

Sort by Features

Sort by Area

US Machine & Tool is a precision CNC machining manufacturer and service supplier that is situated in Murfreesboro, Tennessee, United States. The company offers an extensive array of services, adeptly managing stringent time constraints and exacting tolerances. Its specializations is in designing parts and generating working drawings, performing 3D contour milling utilizing Mastercam and other software, die repairs, and machining parts from drawings. Its capabilities encompass assembly, cutting, laser cutting, stampings, and welding services.

TCS Industries, Inc., established in 1992, is a contract manufacturer and supplier of high-precision CNC machinings, aluminum dip brazing, sheet metal fabrications, electro-mechanical assemblies, cable & wire, and circuit boards for the aerospace, electronics, medical, and communication industries. The Rochester, New York-based business provides auxiliary in-house services such as black zinc plating, powder coating and painting, laser and TIG welding, citric acid passivation, and yellow and clear chromate. The business has ISO 9001, AS9100, and ITAR registration certifications.

Straton Industries was established in 1961, located in Stratford, CT, and is a certified contract manufacturer of molds, tools, dies, and stampings. The portfolio of the company includes Aeroscape Components, Corvetto Turbo, Electronic Components, Mars Rover Curiosity, Robotic Components, and many more. The company also provides services on CNC 5-axis Machining, CNC Jig Grinding, CNC Milling, CNC Long Bed Lathe, Compression Fitting, etc. The company has supplied components for manned and unmanned space missions including the Space Shuttle Program, and the International Space Station. The company is accredited with ISO 9001:2015, FAA Certified Repair Station, AS9100D, and ITAR Registration.

Sirois Tool Co., Inc., established in 1960 by Robert Sirois is a manufacturer of precision tooling, gages, I.D. grinding Quills and parts. The I.D. Grinding Quills product portfolio includes solid carbide quills and spindle parts & accessories, including spindle extensions, wheel screws, wheel-nuts, pulleys, spindle shafts and housings. All the products undergo capabilities, including milling, grinding, WEDM, EDM, CNC, turning, and honing to ensure they meet the customer's standards and requirements. Sirois Tool is AS9100D- certified and registered by the International Traffic in Arms Regulations Compliant.

Precision Glass Products, headquartered in Oreland, Pennsylvania, is a manufacturer of custom precision products founded in 1955. The company produces various precision products from fused quartz, glass, and fused silica. It offers different types of grinding and polishing, such as jig and spherical grinding. It uses OD/ID grinders, surface and jig grinders, and polishing machines, and it serves the electronics and medical industries. The company provides quartz or borosilicate glass cells that contain pure or a mixture of pure gasses according to requirements.

Peerless Precision, Inc., established in 1976, and headquartered in Westfield, Massachusetts, is a custom manufacturer of precision machined parts. The company's custom machining services includes, CNC milling, CNC turning, finishings, assemblies, and fabrication services. Titanium, stainless steel, aluminum, as well as magnesium, carbides, brass, plastics, and exotic materials are used. Many of the components that the company manufactures are used in thermal imaging and fuel and engine systems. The company holds both certifications in AS9100 and ISO 9001:2015 standards.

Nation Grinding, Inc. is an American contract manufacturer specializing in precision grinding and coating since its establishment in Dayton, Ohio in 1954. The company primarily works with hard surfaced wire drawing blocks or capstans in repair, retrofitting and rebuilding operations. They also offer HVOF or plasma metalizing coating as well as precision grinding services using Blanchard, cylindrical, thread, internal diameter (ID) and outer diameter (OD) grinding techniques for working with different materials, or toward unique product applications. Nation Grinding chiefly serves client companies and contractors in the military, defense, marine, mining, and instrumentation sectors.

Machinists, Inc., founded in Seattle, WA, in 1941 is a manufacturer of ISO 9001 certified prototype machining, 5-axis machining, welding, finishing and assembly. The company's product portfolio includes Trim Fixtures, Assembly Fixtures, Holding Fixtures, Work and access stands, and Composite tooling. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and Power Generation. The company provides services such as prototype machining, replacement of broken parts, creation of assembly line spares or new equipment design.

M&M Jig Grinding, Inc. is a manufacturer company for precision grinding of tools, gages, and short run production that is headquartered in Santa Clara, California and was founded in 2002. The company offers grinding, ID & OD grinding, jig grinding, sinker and wire EDM, and surface grinding. The company also caters to all steel types whether ferrous or non-ferrous, aluminum, brass, nickel alloys, and plastics. The industries served by the company range from aerospace, medical, injection molds, special machine tools, and food processing.

Lee's Grinding, Inc. is a manufacturer of close-tolerance and grinding intensive small parts that is headquartered in Strongsville, Ohio and was established in 1958. The company offers a full-service project management that includes machining, electrical discharge machining, plating, thermal spray coating, packaging, assembly, and testing. On the other hand, the company also provides a wide range of service lineup ranging from honing, grinding services such as crush form grinding and external grinding, lapping, and operations. The operations include designing, prototyping, manufacturing, and grinding.

Kent Machine, Inc. is a Pendleton, Indiana-based manufacturer of specialized testing, inspection, and assembly equipment founded in 1988. They produce various gauges and single-station machines, as well as precision-engineered components machined from steel, plastic, and non-ferrous materials for demanding industrial applications. The company is ISO 17025:2017 certified and utilizes automatic presses, robotic welding, CNC machining, and wire EDM on its 3,200 square feet of build floor for clients in the medical, automotive, and aerospace industries. Some of Kent Machine’s client corporations include Zimmer Biomet, Honda, Caterpillar, and GE Aviation.

Ken-Bar Tool & Engineering, Inc. is an American ISO certified tooling and machine manufacturer based in Muncie, Indiana, founded in 1957. The company specializes in creating custom machines for automation in manufacturing industries, additionally producing robotics cells, leak testing equipment, dies, fixtures, and automated gages. They possess machining, fabrication, 3D printing, and CMM measurement capabilities and they offer design, reverse engineering, and equipment upgrading services. The company is affiliated with the Association for Advanced Automation and FANUC ASI as a robotic systems integrator.

INSACO INC. was established in 1947, headquartered in Quakertown, PA, and is a manufacturer and supplier of parts from all technical ceramics, sapphire, glass, and quartz. The portfolio of the company consists of servicing ceramics, sapphire, glass, and quartz items. The company has the ability to use contact and non-contact profilometry to measure surface roughness. The company is capable of handling extremely tight tolerances in ultra-hard materials. Additionally, the business is able to grind and polish spherical radius parts to optical specifications in many hard materials, including inside and outside diameters.

Industrial Tool and Die, Inc., established in 1967, and located in Santa Ana, California, is a manufacturer precision metal stamping and custom tool and die design. Its product range includes custom molds, tools, dies, jigs & fixtures, which serves in industries such as aerospace, automotive, medical, commercial, and electronics. The company is equipped with EDM machines, CNC milling machines, Jig borers/grinders, ID/OD surface grinders, and Lathes. Its products are used for precision manufacturing, shaping materials, and ensuring accurate production processes.

Hammill Medical is a manufacturer of orthopedic implants, implantable medical devices, and spinal implants that is headquartered in Maumee, Ohio, and was established in 1955. The company offers orthopedic and spinal implant systems, surgical instruments, prototype manufacturing, and product development. The manufacturing service of the company includes design manufacturing, and engineering support. Hammill’s capabilities include 5-axis machining, 8-axis Swiss turning, Wire and Ram EDM, CNC milling and turning machining, and laser welding.

Dynamic Precision Tool & Manufacturing., founded in Troy, MI , in 1982 is a manufacturer of precision prototype parts, and special machine components. The company's product portfolio includes custom machine components, CNC Machined Parts and Customized Tooling Solutions for various manufacturing processes, enhancing productivity and reducing downtime. The company serves markets such as automotive, trucking, aerospace, defense, and medical. The company provides services such as Product Selection Guidance, Engineering Support, New Product Design and Development and Custom Manufacturing.

Cox Machine, LLC, established in 2016 and headquartered in Traverse City, United States of America, is a manufacturer of precision machined components and a supplier of machinery services. The company provides services in the form of CNC machining, precision grinding, and secondary processes. It also produces precision machined components for surface grinding, jig grinding, and ID/OD grinding. The products are used for tool and die, oil and gas, aerospace, food processing, and alternative energy and renewable energy industries.

Astro Met, Inc., established in 1961, and located in Cincinnati, Ohio, is a manufacturer of advanced ceramics components to customer specification. Its product line includes alumina, yttria-stabilized zirconia, zirconia toughened alumina and machinable glass ceramics, which caters in industries such as aerospace, medical, defense, industrial, and energy. The company is also capable of ultrasonic machining, form and jig grinding, diamond core drilling, conventional lathe work, and milling/sawing. Its products are used for its high-temperature resistance, electrical insulation, wear resistance, and thermal management properties.

Alpha Carb Enterprises, Inc., established in 1974 and situated in Pittsburgh, Pennsylvania, is a manufacturer specializing in precision carbide progressive stamping dies, carbide and steel die components, and precision metal stampings. The company has a comprehensive product catalog featuring an array of offerings, including die components, stamps, prototype parts, and electrical discharge machining. These precision products find crucial applications across a spectrum of industries, catering to the specific needs of sectors such as automotive, aerospace, medical, electronics, and more.

NASA Machine Tools, Inc., established in 1979 and based in Lincoln Park, New Jersey, is a CNC machine tool manufacturer and service supplier. Some of its unique products are the NASA AGS-3, CNC continuous path Moore jig grinder integrations, developed in 1985 and installed in hundreds of systems globally. The company's PRODUCER line of high-speed, bridge-type CNC machining centers caters to various machining applications, such as graphite electrode machining, industrial engraving, small hole drilling, ceramic machining, and mold making. The company has become a global resource, with an established distribution network that serves small, medium, and large-sized companies.

Mitsui Seiki Kogyo (Mitsui Seiki (U.S.A.), Inc) is a manufacturer of machine tools and compressors since 1928 and is headquartered in Saitama, Japan. The company offers various machine tools such as jig grinders, vertical machining centers, thread grinders, jig borers, and horizontal machining centers in different shapes and sizes which are used for various applications such as mold processing and ball screw grinding. They also produce Z-screw type air compressors and rotary air air compressors used in construction, woodworking metal fabrication, painting & coating applications.

DMG Tool & Die, LLC, founded in 2009, and is headquartered in Bellefontaine, Ohio, is a manufacturer, distributor, and supplier of custom machining and repair services. DMG Tool & Die has a wide range of capabilities, including CNC and manual milling and turning, grinding, and welding, in which catering to industries such as automotive, manufacturing, and general industry. The company ensures their products meet stringent quality standards, in which their tools and dies play a role in various industrial processes.

Stanron Steel Specialties, founded in Ft. Lauderdale, Florida in 1972 is a supplier of precision metal services. The company's product portfolio includes metal fabrication services, including cutting, bending, welding, and assembly, CNC Machining, sheet metal bending, prototyping services and finishing services, including polishing, painting, powder coating, and plating. The company serves markets including Medical and Healthcare, Aerospace and Defense, Consumer Goods, Industrial Manufacturing and Construction and Building. The company has a national distribution network and a customer support center.

Mikromat, established in 1863, and based in Dresden, Germany, is a manufacturer and supplier of precision machinery. The product portfolio of the company includes a diverse range of vertical and horizontal jig bore machines and jig mill machinery. The company also offers precision machinery of JIG 5-side and 5-axis machines with high speed and accuracy. The products are certified with quality tests, specifications, and technological evidence for industrial capability. The products are used in various automated industries involving high quality.

Leech Industries, Inc., founded in Meadville, PA in 1948, is a service provider of tool and die, mold making, stamping, plastic molding, and CNC machining. The company's product portfolio includes Thermoset Molding, Grinding, Thermoplastic Molding, Cylindrical Grinding and Transfer Molding. The company serves industries such as Industrial Machinery and Equipment, Aerospace and Defense, Automotive and Transportation, Construction, and Power Generation. They also provide services including product selection, installation, preventative maintenance, troubleshooting, and repair.

Lansco Manufacturing Services, Inc. was founded in 1986 and is headquartered in Chagrin Falls, Ohio. The company is a manufacturer of equipment ranging from Swiss machined components to complete factory automation. The company’s service offerings include prototyping and R&D services, concurrent engineering, and Kansan stocking programs. Machining capabilities include custom metal fabrication, precision stamping, assemblies, adjustable ergonomic workstations, and more. The company works with many types of plastics and metals including aluminum, high-temperature alloys, carbon steel, and more.

HPL Stampings, Inc., established in 1941 and located in Lake Zurich, Illinois, is a manufacturer specializing in precision metal stampings, sheet metal fabrications, and laser cutting services. Its services include punch press stamping, prototype and short run production, blanking, piercing, and engraving, which serve industries such as aerospace, agricultural, automotive, construction, and packaging. Its services are employed to manufacture precise metal components such as stamped clips for control systems, steel stamped fuse brackets, and circuit board stiffeners, for diverse applications, ensuring efficient production and accurate designs.

Day Tool & Mfg., established in 1962 and headquartered in Central New Jersey, is a manufacturer of precision tooling, stamping dies, custom machines, and precision machined parts. The company manufactures molds and dies, machine parts, process automation, and prototype creation. It has a specialty in CNC milling and turning, wire/conventional EDM, precision grinding, process automation, prototyping, and inspection. The products are used in aerospace, biotech, medical, pharmaceutical, and semiconductor industries. The company has passed SGS North America (AS9100D) and ISO 9001: 2015 certifications.

Ohno Seiko Co. Ltd., founded in 2001, is a Japanese manufacturer and supplier headquartered in Nishio City, Aichi, providing precision metal parts. The company’s product range includes electronic and integrated circuit (IC) parts, such as pallet basses and parts for IC chip carriers. It also offers parts related to lithium batteries and starter devices. The company provides object cutting and welding services as well as grinding processing using cylindrical and surface grinders. It also offers polishing services through lapping processes to achieve surface roughness of specific measurements. These products find applications in various industries, including the automotive and medical sectors.

Ranking as of July 2025

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | US Machine & Tool, Inc. |

15.5%

|

| 2 | TCS Industries, Inc. |

9.5%

|

| 3 | Sirois Tool Co., Inc. |

7.1%

|

| 4 | Lee's Grinding, Inc. |

6.0%

|

| 5 | DMG Tool & Die, LLC |

6.0%

|

| 6 | Precision Glass Products Company |

4.8%

|

| 7 | Straton Industries |

4.8%

|

| 8 | Nation Grinding, Inc. |

4.8%

|

| 9 | Peerless Precision, Inc. |

4.8%

|

| 10 | COX MACHINE, LLC |

3.6%

|

Derivation Method

The ranking is calculated based on the click share within the jig grinding page as of July 2025. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

23 | 95.8% |

Germany

Germany

|

1 | 4.2% |

233 products found

233 products

Ono Seiko

960+ people viewing

Last viewed: 1 hour ago

It is a jig that specializes in shortening and sacrificing the setup time. The processing of the wire cut requires adjusting the sim by biting the...

2 models listed

Tool System Co., Ltd.

590+ people viewing

Last viewed: 1 day ago

■Features Kennametal Corporation is headquartered in Latrobe, Pennsylvania, USA. By offering innovative custom and standard wear solutions, we deli...

6 models listed

Tool System Co., Ltd.

540+ people viewing

Last viewed: 1 day ago

■Features WIDIA is synonymous with thorough quality. For more than 80 years, WIDIA Products has been an industry innovator, designing and manufactu...

4 models listed

Tool System Co., Ltd.

660+ people viewing

Last viewed: 1 day ago

■Features WIDIA is synonymous with thorough quality. For more than 80 years, WIDIA Products has been an industry innovator, designing and manufactu...

6 models listed

Tech Yasuda Co., Ltd.

530+ people viewing

Last viewed: 1 hour ago

Uniform quality, increased speed, and lower costs are constant themes at manufacturing sites. We propose and sell system jigs that use the flex cla...

4 models listed

Ohno Seiki Co., Ltd.

220+ people viewing

Last viewed: 16 hours ago

Turtle chuck G series with improved return accuracy. Practicality has been improved by adding a guide pin mechanism. Return accuracy has been impro...

Relatec Co., Ltd.

220+ people viewing

Last viewed: 7 hours ago

A die collet is a consumable part used in the die bonding process of semiconductor manufacturing to pick up chips with push-up pins, transport them...

Izumi Corporation Co., Ltd.

190+ people viewing

Last viewed: 1 day ago

3 major features. Depend vise that supports powerful and highly accurate workpiece machining ■Versatility Can accommodate any work size Super vers...

Izumi Corporation Co., Ltd.

170+ people viewing

Last viewed: 1 day ago

3 major features. Depend vise that supports powerful and highly accurate workpiece machining ■Versatility Can accommodate any work size Ultra-vers...

Relatec Co., Ltd.

220+ people viewing

Last viewed: 9 hours ago

The resin collet is a collet with different characteristics from other metal collets, which was developed to suppress the impact for picking up chi...

Izumi Corporation Co., Ltd.

250+ people viewing

Last viewed: 25 minutes ago

■Features ・Vise width 30mm, unique point selection ・Positioning of fixed block by mechanism (PAT.P) ・Ideal as a clamping jig for various types o...

Iwai Giken Co., Ltd.

260+ people viewing

Last viewed: 1 day ago

For cutting, use a commercially available cutter. The cutting length is based on the pitch and is a valley center cut. The cut surface is a right a...

Relatec Co., Ltd.

180+ people viewing

Last viewed: 19 hours ago

Transfer pins are parts used in semiconductor manufacturing to spread solder uniformly on the stage and transfer the solder to the target object.

Izumi Corporation Co., Ltd.

160+ people viewing

Last viewed: 1 day ago

Equipped with a point selection mechanism that realizes excellent workability ■Unique clamping method (PAT.) Achieves strong tightening force that...

Relatec Co., Ltd.

160+ people viewing

Last viewed: 1 day ago

A suction nozzle is a component used to suction and pick up IC chips, etc., and transport and bond them onto a lead frame, or in the case of electr...

Aim Co., Ltd.

270+ people viewing

Last viewed: 13 hours ago

Automate welding by letting the robot hold the torch of various welding machines. ■Control box A simple controller that eliminates all unnecessary...

Relatec Co., Ltd.

160+ people viewing

Last viewed: 1 day ago

A stage is a component (table) used to hold a wafer during the process of making chips from a wafer in the semiconductor manufacturing process.

Izumi Corporation Co., Ltd.

170+ people viewing

Last viewed: 1 day ago

■Features and uses ・The finish is made of special steel that is fully quenched and polished to a hardness of HRC55°, allowing for long-term precis...

Aim Co., Ltd.

280+ people viewing

Last viewed: 21 hours ago

Automate welding by letting the robot hold the torch of various welding machines. ■Control box A simple controller that eliminates all unnecessary...

Relatec Co., Ltd.

150+ people viewing

Last viewed: 1 day ago

An intermediate pocket is a part used as a relay when transporting an object from one process to another when sucking and discharging the object wi...

Tech Yasuda Co., Ltd.

440+ people viewing

Last viewed: 1 day ago

Uniform quality, increased speed, and lower costs are constant themes at manufacturing sites. We propose and sell system jigs that use the flex cla...

2 models listed

Izumi Corporation Co., Ltd.

170+ people viewing

■Features and uses ・The finish is made of special steel that is completely quenched and polished to a hardness of HRC55°, allowing for long-term p...

Relatec Co., Ltd.

150+ people viewing

Last viewed: 1 minute ago

The correction claw is a part used to correct tilted chips during the die bonding process during semiconductor manufacturing.

Izumi Corporation Co., Ltd.

160+ people viewing

Last viewed: 1 day ago

■Features and uses ・The finish is made of special steel that is fully quenched and polished to a hardness of HRC55. ・The serration part has a gro...

Honda Technos Co., Ltd.

150+ people viewing

Last viewed: 1 day ago

■We respond to customer requests with our extensive experience in processing materials including iron, stainless steel, aluminum, and cast metals. ...

Relatec Co., Ltd.

180+ people viewing

Last viewed: 1 day ago

The window clamper is a fixture that secures the fingers of the lead frame to the heat block to enable wire bonding between the lead frame and the ...

GTM Co., Ltd. WEIDMANN

210+ people viewing

Last viewed: 1 day ago

We offer a wide variety of defect countermeasures, including board fixation, component lifting prevention, alignment, unsoldered and bridge defects...

Izumi Corporation Co., Ltd.

140+ people viewing

Last viewed: 10 hours ago

■Features and uses ・The finish is made of special steel that is completely quenched and polished to a hardness of HRC55°, allowing for long-term p...

GTM Co., Ltd. WEIDMANN

160+ people viewing

Last viewed: 1 day ago

We can handle everything from thin rigid plates to thick plates with a variety of pallet types. We optimize mounting quality by fixing the board us...

Technoplan Co., Ltd.

160+ people viewing

Last viewed: 1 day ago

■Applications When used in conjunction with a magnetic chuck, it can be used as an auxiliary tool to attract workpieces with shapes that are diffic...