7 Heat Flux Sensor Manufacturers in 2024

This section provides an overview for heat flux sensors as well as their applications and principles. Also, please take a look at the list of 7 heat flux sensor manufacturers and their company rankings. Here are the top-ranked heat flux sensor companies as of July, 2024: 1.KYOTO ELECTRONICS MANUFACTURING CO., LTD., 2.Reading Thermal, 3.Captec.

Table of Contents

Graduated with a master's degree in mechacanical engineering from the Department of Mechanical Engineering, University of Tokyo.

As a student, he was engaged in research on thermophysical properties and materials, such as thermal interface materials and heat insulating materials.

After that, he mainly engaged in the development of coating equipment and CAE work at a chemical manufacturing company. Currently, he is engaged in research and development related to CFD, molecular dynamics, chemical equilibrium, and gas-liquid equilibrium at a food manufacturing company.

What Is a Heat Flow Sensor?

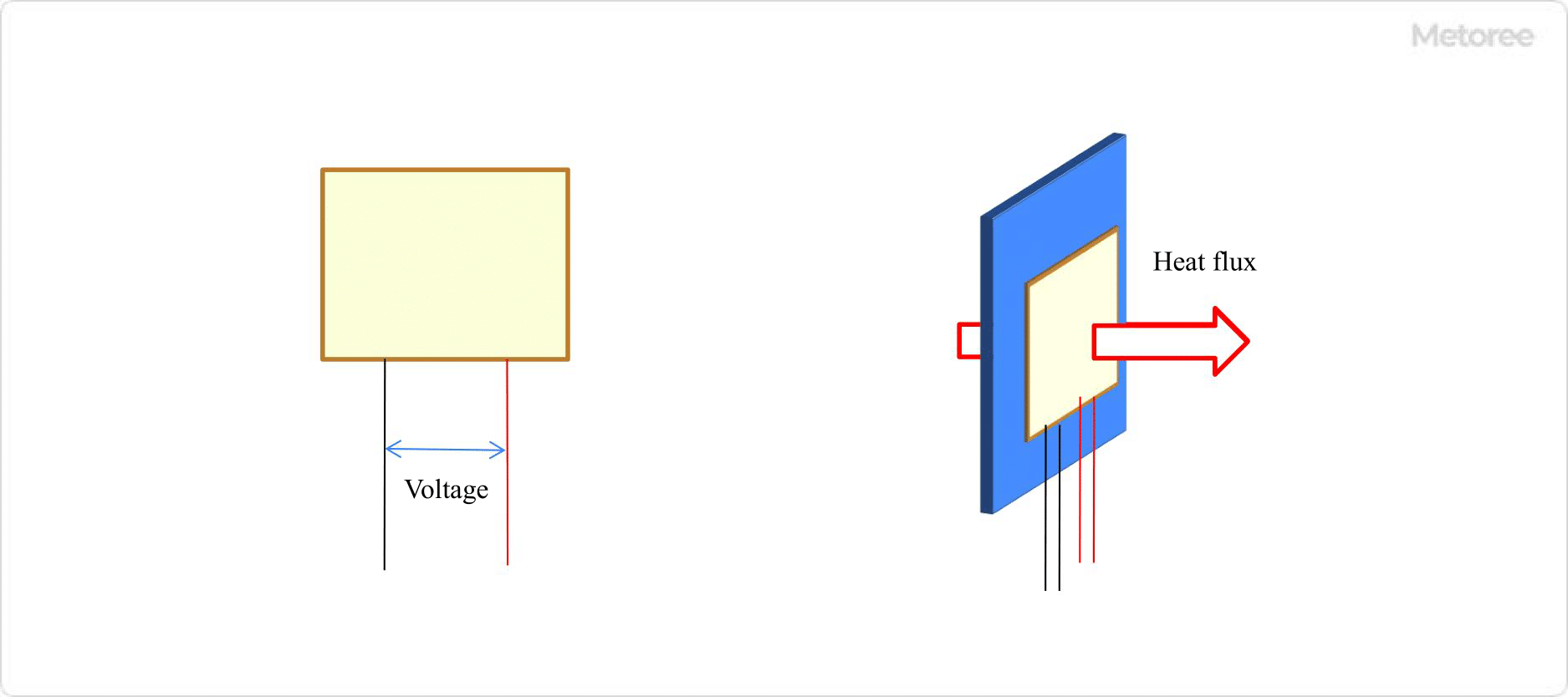

Figure 1. What is a heat flow sensor?

A heat flux sensor is a device used to measure the amount of heat transfer, also known as heat flow. Heat generally moves from an area of higher temperature to a lower temperature. By measuring this heat flow, the amount of heat transfer can be quantified, and subsequent temperature changes can be estimated.

These sensors convert the heat passing through them into an electrical signal. They are available in flexible designs for curved surfaces and waterproof versions, suitable for various applications.

Applications of Heat Flux Sensors

Heat flux sensors are commonly used in evaluating the thermal insulation performance of housing equipment. With advances in miniaturization and flexibility, their usage has expanded beyond housing applications to include areas such as electronic components and automotive engineering, where they help monitor heat dissipation and loss.

For example, these sensors can be installed inside electronic components to measure the heat they generate. In automobiles, they are used for evaluating heat loss in engine compartments, seat heaters, and air conditioners. Additionally, heat flux sensors are instrumental in measuring the amount of heat flow in and out of materials during phase changes. One innovative application involves enclosing the material to be measured in a bag-shaped heat flux sensor. This setup allows for the measurement of heat flow in and out of the object and can be coupled with a cooling agent to monitor cooling capacity and duration.

Principle of Heat Flow Sensor

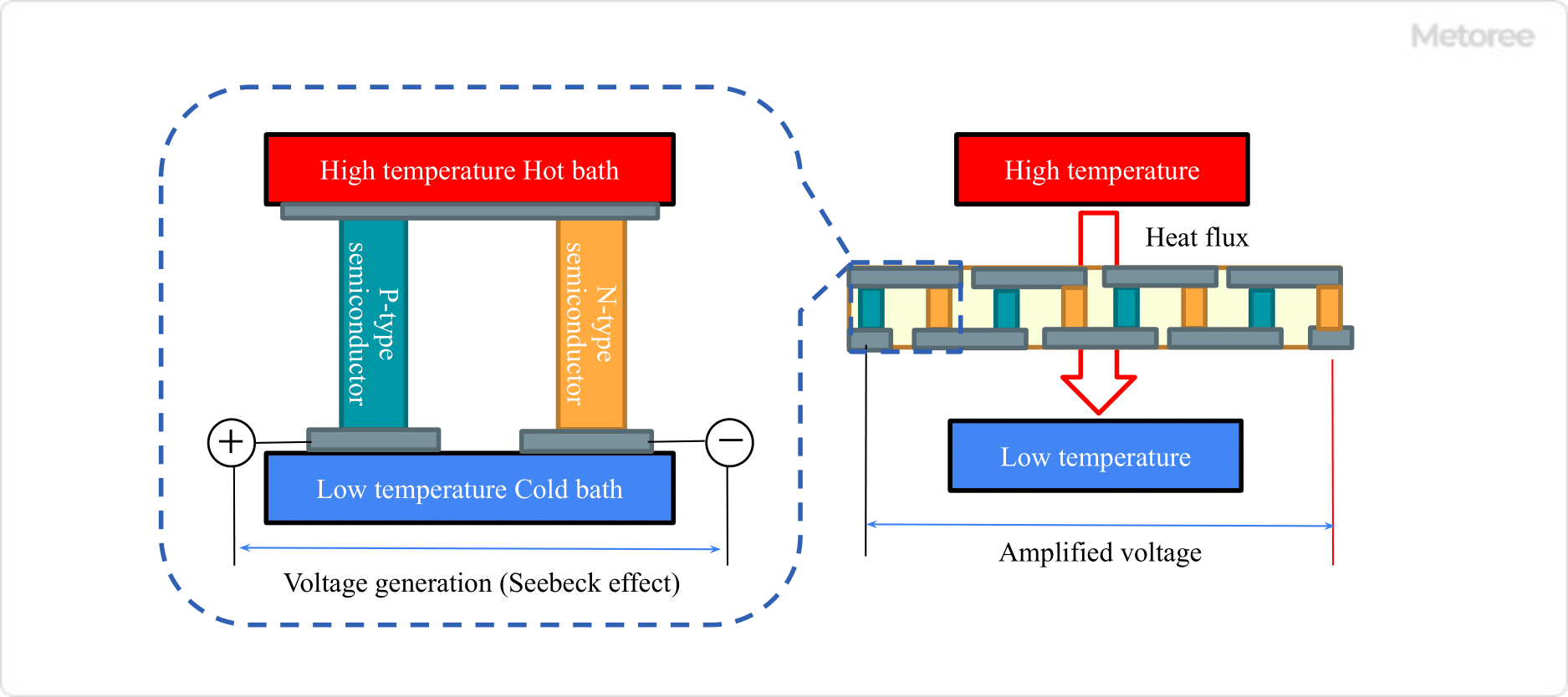

Figure 2. Principle of heat flow sensor

Heat flux sensors operate based on Fourier's law and the Seebeck effect. Fourier's law indicates that heat flow per unit area and time is proportional to the temperature gradient. The Seebeck effect generates a voltage when a temperature difference is applied across a substance.

The internal structure of these sensors typically includes N-type and P-type semiconductors, which exhibit the Seebeck effect, and thermocouple materials like copper and chromel-alumel connected in series. This configuration amplifies the small voltage generated by each component, enabling effective detection of heat flow.

Other Information on Heat Flow Sensors

How to Use Heat Flow Sensors

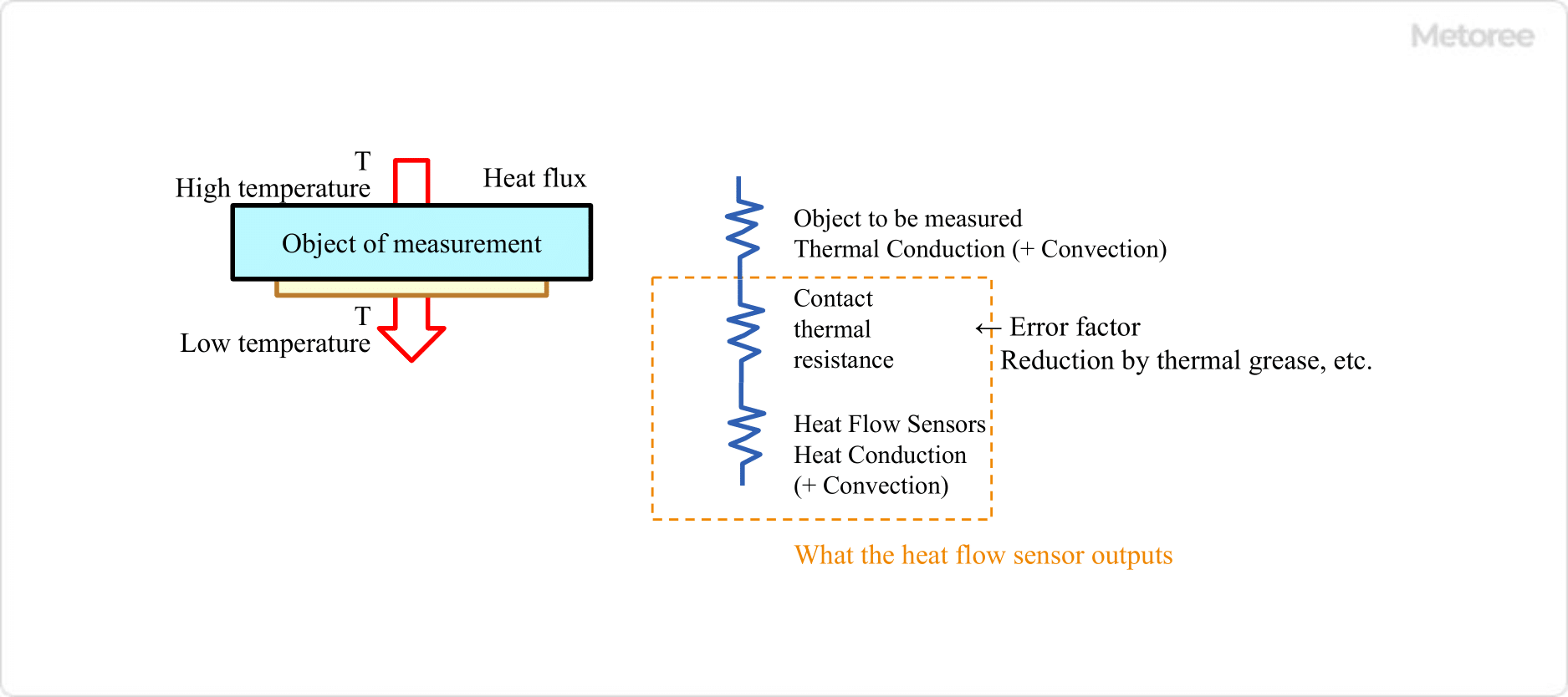

Figure 3. How to use a heat flow sensor

Proper selection and installation of heat flux sensors are crucial. It's important to adhere to the specified temperature range limits to avoid issues like adhesive surface peeling. Sensors should be securely attached to the measurement object, using high-conductivity adhesives or silicon grease to minimize errors due to contact thermal resistance.

Before installation, it's necessary to ensure that no air or foreign matter is trapped under the sensor and to check the direction of heat flow and the polarity of the sensor's output by applying a temperature difference.

List of 7 Heat Flux Sensor Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- United States of America

- China

- France

- Japan

- Netherlands

-

-

-

Reading Thermal

Heat Flux Sensors

Manufacturer Overview

Reading Thermal is a developer and supplier of temperature measurement as well as data logging systems established in 1986 as a division of Reading Bakery Systems. Based in Sinking Spring, Pennsylvania, the company offers various digital humidity sensors for measuring relative humidity in different baking chambers, as well as their SCORPION 2 branded profiling system, which is an all-in-one measurement solution for analyzing key baking parameters like temperature, heat flux, air velocity, and humidity. Reading Thermal serves clients throughout the baked goods, confectionery and snack foods sectors, including Nabisco, Mondelez International, and Frito-Lay.

-

-

-

-

-

AMI Instrument

HEAT FLUX SENSOR

Manufacturer Overview

AMI Instrument , established in 1998 in Shanghai, China, is a manufacturer of advanced heat flux sensors and optimal meters for various applications. The product lineup includes various types of heat flux sensors, radiometers, and meters,each designed to accurately measure heat transfer in different environments and conditions. These sensors play a crucial role in industries such as aerospace, automotive, construction, and material research by providing valuable insights into thermal performance and efficiency. The products offer benefits like optimal sensitivity, robust construction, and precise data collection, enabling engineers, researchers, and manufacturers to optimize designs, enhance energy efficiency, and improve product performance.

-

-

-

-

Manufacturer Overview

EKO Instruments, founded in 1927 in Tokyo, Japan, is a manufacturer of advanced scientific instruments and solutions. The company specializes in producing unique instruments for measuring solar radiation, measuring photovoltaic performance, and environmental parameters. The products include solar radiation sensors, pyranometers, photovoltaic analyzers, and meteorological instruments. These products provide accurate data collection, enabling professionals in industries such as renewable energy, meteorology, agriculture, and environmental research to make informed decisions and optimize their processes. EKO Instruments' precision, adaptability, and technological advancement in the field of solar measurement and environmental monitoring result in the global transition towards sustainable and efficient energy solutions.

-

-

-

-

-

Captec

Heat Flux Sensor

Manufacturer Overview

Captec, in Lille, France, founded in 1995, is a designer and manufacturer of heat flux sensors, radiant flux sensors, thermal transducers, thermal conductivity meters, ultra-thin heaters, nickel-plated probes to monitor surface temperatures, and heat flux gage for high heat flux. All products can be made to specifications and make heat flux measurement easier in various research and industrial fields, such as civil and building engineering, solar energy, thermal resistance measurement, thermal conductivity, and radiative heat transfer.

-

-

-

-

-

KYOTO ELECTRONICS MANUFACTURING CO., LTD.

Heat Flow Sensors

Manufacturer Overview

Kyoto Electronics Manufacturing Co., Ltd. (KEM), established in 1961 in Japan, is a manufacturer and supplier of scientific instruments, medical instruments, and medical substance generators. The company's product line has grown to include an extensive line of analytical instruments and thermal measuring equipment that includes automatic potentiometric titrators, Karl Fischer moisture titrators, density and specific gravity meters, and thermal measuring instruments to measure the thermal conductivity and heat flow of various substances and materials. The company's equipment and instruments are used across the chemical, electricity, paint, food and beverage, and petrochemical industries, among many others.

-

-

-

-

-

Hukseflux

Heat flux sensors

Manufacturer Overview

Hukseflux, is a manufacturer of heat flux measurement sensors that employ thermopiles, located in Delft, The Netherlands and founded in 1993. The products include heat flux measuring systems, soil temperature sensors, and heat flux sensors such as high-temperature foils, water-cooled cone calorimeters, heat flux plates, ultra-sensitive, and self-calibrating heat flux sensors applied in data loggers and amplifiers. The company provides application support, pyranometer calibration, special engineering services, software, and downloadable manuals.

-

-

-

-

-

Vatell Corporation

Heat Flux Microsensors

Manufacturer Overview

Vatell Corporation, founded in 1985 by Lawrence Langley, is a Christiansburg, Virginia-based manufacturer and supplier of heat flux measurement instruments such as heat flux microsensors, Thermogages and heat flux sensors. The Thermogage is a Vatell’s patented product segment comprising Water-Cooled Heat Flux Sensors, Conduction-Cooled Heat Flux Sensors, and Water-Cooled Radiometers. The company also offers dual channel HFM amplifiers and single channel Amp-6 to Amp-15 amplifiers designed to work with their sensors. Their products are used in aerospace, vehicle instrumentation, explosion characterization, rocketry and process control applications.

-

-

Heat Flux Sensor Manufacturer Ranking

*Including some distributors, etc.Ranking as of July 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | KYOTO ELECTRONICS MANUFACTURING CO., LTD. |

34.5%

|

| 2 | Reading Thermal |

20.3%

|

| 3 | Captec |

12.8%

|

| 4 | Vatell Corporation |

10.8%

|

| 5 | AMI Instrument |

8.8%

|

| 6 | EKO |

8.1%

|

| 7 | Hukseflux |

4.7%

|

Derivation Method

The ranking is calculated based on the click share within the heat flux sensor page as of July 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

- KYOTO ELECTRONICS MANUFACTURING CO., LTD.: 350

Newly Established Company

- Reading Thermal: 1999 (25 years ago)

- Hukseflux: 1993 (31 years ago)

- Vatell Corporation: 1985 (39 years ago)

Company with a History

- EKO: 1927 (97 years ago)

- KYOTO ELECTRONICS MANUFACTURING CO., LTD.: 1961 (63 years ago)

- Vatell Corporation: 1985 (39 years ago)

Heat Flux Sensor Manufacturers in United States

*Including some distributors, etc.

Global Distribution of Heat Flux Sensor Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

Japan

Japan

|

2 | 33.3% |

United States of America

United States of America

|

1 | 16.7% |

China

China

|

1 | 16.7% |

France

France

|

1 | 16.7% |

Netherlands

Netherlands

|

1 | 16.7% |