All Categories

History

This section provides an overview for non-destructive testing (ndt) systems as well as their applications and principles. Also, please take a look at the list of 33 non-destructive testing (ndt) system manufacturers and their company rankings. Here are the top-ranked non-destructive testing (ndt) system companies as of February, 2026: 1.Coltraco Ultrasonics, 2.MFE Inspection Solutions, 3.Inspection Technologies Inc.

Table of Contents

Categories Related to Non-Destructive Testing (NDT) Systems

Non-destructive testing (NDT) systems inspect an object's interior or surface without destroying or damaging it.

The purpose of the inspection is to check for scratches, defects, cracks, voids (bubbles), etc., inside or on the surface of the inspected object. This inspection allows us to examine manufactured products without destroying them and to provide reliability and assurance.

Many types of non-destructive testing (NDT) systems are based on various principles. These systems can be used for multiple purposes. A certification test for NDT systems determines whether a person is proficient in using NDT systems and meets the inspection techniques for each of the six inspection categories as specified.

The equipment is used to determine the presence or absence of melts and weld defects inside welds, cracks, voids, and other imperfections and defects inside materials, as well as scratches and cracks on the surface of materials that cannot be identified visually.

Non-destructive testing does not always require equipment (visual inspection, penetrant testing, etc.), but there are many situations where equipment is needed. For example, non-destructive inspection is used for aging steel frames inside concrete buildings, bridges, tunnels, and elevated bridges; in-process inspection of steel, copper, and aluminum pipes; aircraft fuselage inspection; and inspection of containers and pipes inside nuclear power plants. X-ray imaging, CT scans, and magnetic resonance imaging used for inspecting the human body are also forms of non-destructive testing (NDT) systems.

Non-destructive testing involves a variety of methods based on several principles. This section describes the inspection methods and principles that require NDT systems.

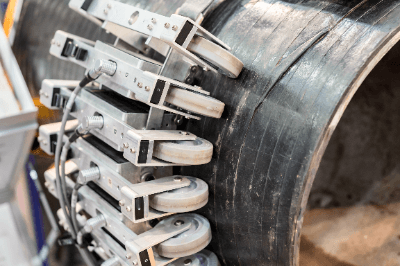

Figure 1. Principle of ultrasonic testing systems

Ultrasonic testing equipment emits high-voltage ultrasonic waves from an ultrasonic probe. It receives echoes when vibrations propagate or are transmitted through the surface or interior of an object and are reflected by internal defects or surface flaws, thereby identifying the location and size of internal defects or surface flaws.

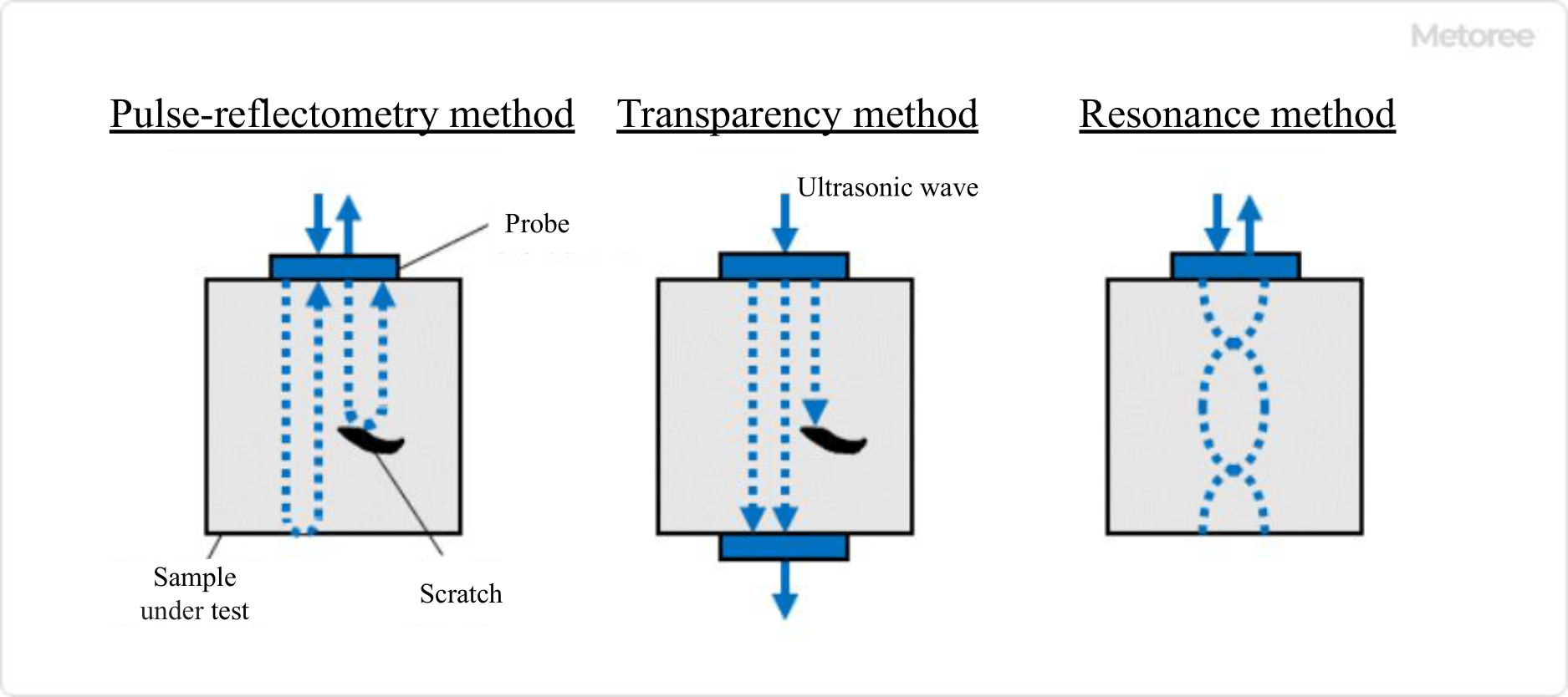

Figure 2. Types of ultrasonic testing systems

There are three types of ultrasonic inspection methods: the pulse reflection method, the transmission method, and the resonance method.

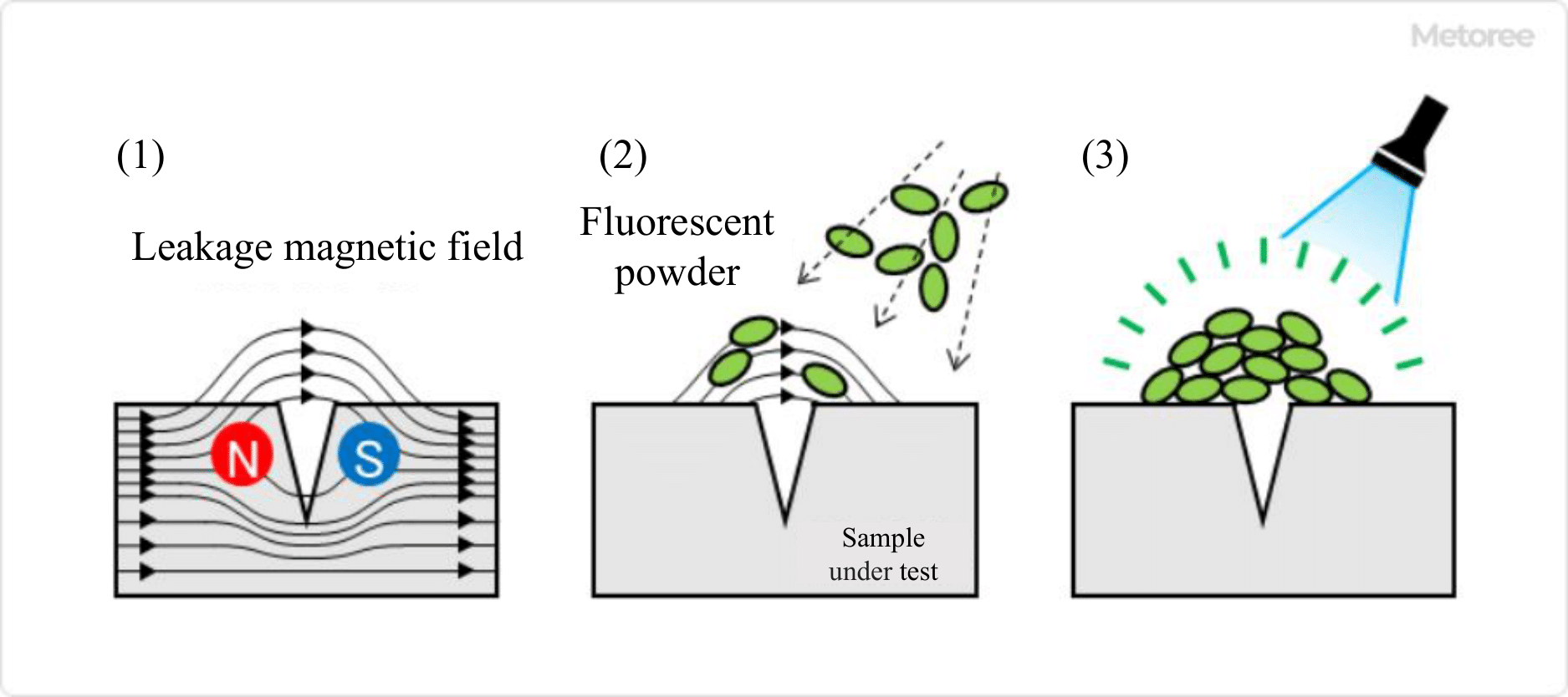

Figure 3. Principle of magnetic particle inspection systems

Magnetic particle inspection equipment is a method that utilizes the magnetic flux disorder generated in the surface flaw area.

When a strong magnetic field is applied to a magnetic object to be inspected, a disturbance of the magnetic flux is generated in the area where the surface flaw is located. When colored iron powder or fluorescent magnetic powder is sprinkled on the inspected object, the iron powder or fluorescent magnetic powder aligns with the shape of the magnetic flux leakage at the surface defects, making them visible as a pattern or a set of lights.

Typically, this method is mainly used for visual inspection without equipment, but automatic magnetic particle inspection equipment equipped with an image recognition device is also used.

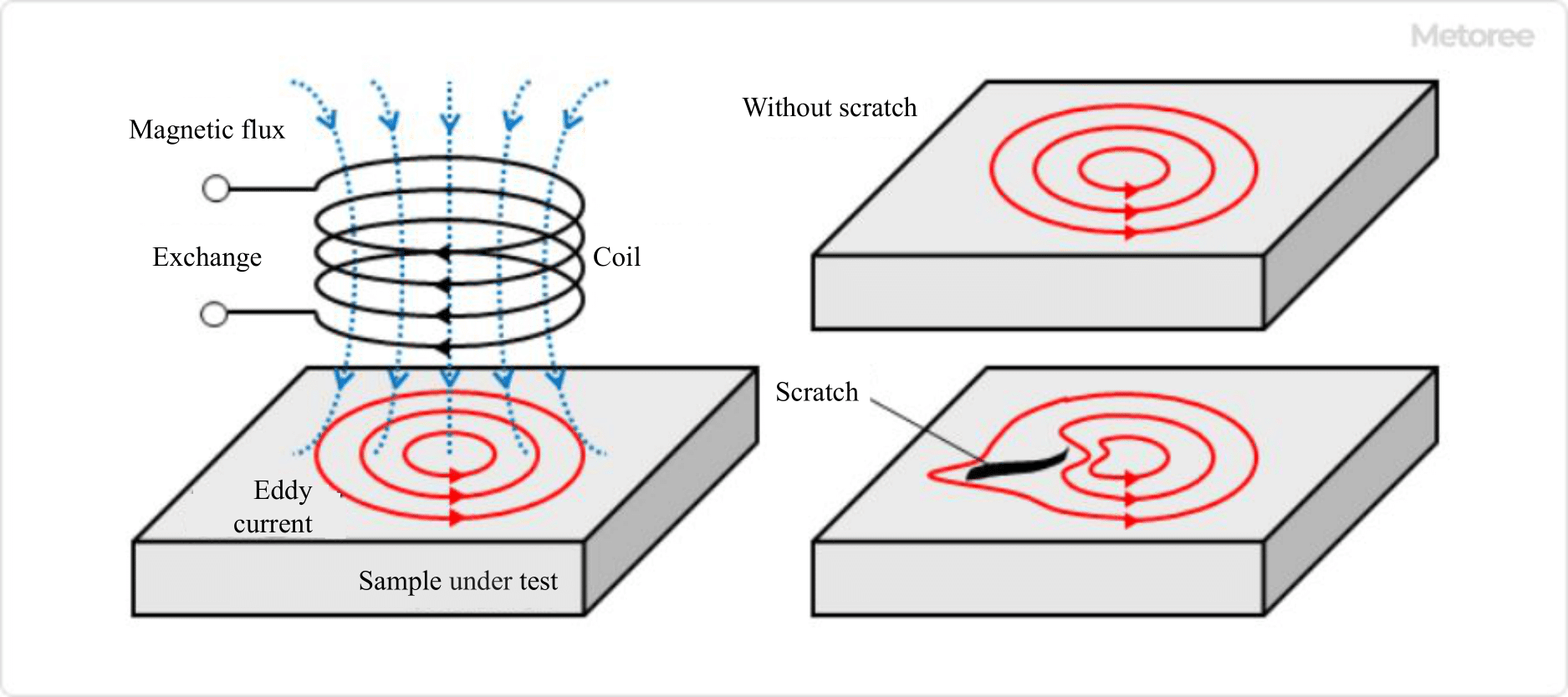

Figure 4. Principle of eddy current testing systems

In the eddy current flaw detector, a probe with an embedded coil of copper wire is brought into proximity to the surface of the object to be inspected by passing an alternating current through it, and the presence of flaws is determined by measuring the turbulence of the overcurrent generated on the object's surface.

Since the accuracy and sensitivity of flaw detection require a coil shape that matches the object to be inspected, this type of equipment is often used when inspecting many objects of the same shape.

Figure 5. Principle of radiation transmission testing systems

X-rays penetrate the object to be inspected using high-energy X-rays, which have the highest penetrating performance among all types of radiation. A detector receives the transmitted radiation, and the signal is used for drawing or image recognition to detect defects inside the inspected object.

In the past, defects were determined visually by sensitizing a film with radiation, as in the X-ray inspection of the human body. Still, more and more equipment automatically identifies defects by image recognition.

Non-destructive testing (NDT) systems are very useful, but it is essential to understand that each measurement principle has disadvantages.

Ultrasonic Testing

Spherical flaws and cavities are difficult to detect because echoes are reflected in all directions. It is also not suitable for inspecting complex shapes or coarse-grained materials. This is because minute echoes generated randomly at each tissue's boundaries spread randomly and are superimposed as noise on the echoes to be detected.

Magnetic Powder Inspection

Not applicable for the inspection of non-magnetic materials.

Eddy Current Inspection

It is difficult to inspect nonconductive materials and detect internal defects. It is also not suitable for objects with complex shapes.

Radiation Penetration Test

Special equipment is required to inspect thick objects because of the extremely high-energy radiation required. It is also not good at detecting surface defects and closely adhered cracks. Above all, radiation safety control requires careful attention.

The market size of non-destructive testing in Japan is estimated to be 200~300 billion yen when adding the inspection service market to equipment sales.

Increasingly, manufacturers are not only conducting inspections in-house but are also outsourcing to inspection companies. As cities and industries become more sophisticated, safety, security, and quality control are becoming more important, and non-destructive testing is playing an increasingly important role. From the perspective of safety and consideration for the natural environment, the market for non-destructive testing is expected to grow further.

Construction Industry

In the construction and civil engineering industries, the market for non-destructive testing and diagnosis of concrete structures will continue to grow. This is due to the growing importance of extending the service life of concrete structures and the need to perform preventive maintenance before deterioration becomes pronounced.

Other Industries

Non-destructive testing is also expected to expand in the energy and heavy industry sectors, promising markets for future growth.

*Including some distributors, etc.

Sort by Features

Sort by Area

SpotSee, founded in 1976 and headquartered in Dallas, Texas, is a manufacturer of condition-indicating and monitoring solutions. The company offers a range of products, including ShockWatch, ShockLog, and WarmMark, which are designed to monitor and record shock, temperature, and other environmental conditions. These products are used in industries such as life sciences, transportation, aerospace, and manufacturing to protect sensitive products during transport and storage. Its solutions provides connected, mechanical, and chemical solutions that enable its customers and partners in 62 countries to detect changes in the condition of everything from vaccines to spaceships.

FUJIFILM Holdings America Corporation, founded in 1934 and located in Valhalla, New York, is a manufacturer of imaging and information solutions. The company is the regional headquarters for the Americas and is comprised of more than 20 affiliate companies spanning across a broad spectrum of industries, including medical and life sciences, electronics, chemicals, graphic arts, and information systems. Its industrial segments include data storage, electronic materials, chemicals, industrial testing products, and graphic arts products and services.

Humboldt Mfg. Co., founded in 1909 with headquarters in the USA, is a manufacturer and supplier of testing equipment used for evaluating construction and civil engineering materials. The company's products include hand-held thermometers, augers used for soil sampling, a CBR field test set designed for making relative strength determinations in the field, dynamic cone penetrometers for determining the in-situ CBR values of pavement base, as well as soil probe rods. Humboldt Mfg. Co.'s equipment is sold worldwide and used for testing soil, concrete, cement, asphalt, and aggregate materials in construction projects that include roads, bridges, tunnels, dams, and airports.

Gilson Company, Inc. is an American manufacturer and supplier of construction material testing equipment based in Lewis Center, Ohio. The company was established in 1939 with a primary focus on manufacturing the testing screen, a laboratory-scale screening machine, to cater to the mining and highway construction industries' requirements. Over time, Gilson has expanded its product portfolio and now offers a wide range of equipment, including ovens and furnaces, scales and balances, general laboratory testing equipment, as well as material testing equipment for aggregates, asphalt, concrete, and soils.

McGean-Rohco Inc. is a manufacturer of specialty chemicals, founded in 1929 and headquartered in Cleveland, Ohio, USA. The company's diverse product range includes aircraft cleaners, engine overhaul products, paint strippers, and maritime solutions. The company is also providing lavatory maintenance items like deodorants, cleaners, fresheners, and portable toilet deodorants. McGean-Rohco's Ohio and Michigan facilities hold certifications to SOCMA's ChemStewards EHS&S management system, while its U.K. facility holds ISO 14001 certification for the environmental management system.

Rad Source Technologies, established in 1997, is a manufacturer of radiation technology solutions. It's headquartered in Georgia, Unites States and it specializes in the development and manufacturing of advanced X-ray irradiators and non-nuclear irradiation systems. Its products catalog includes the RS 2000 Small Animal Irradiator, the blood irradiator, the Biological Irradiator, the 420 Cannabis Decontamination Systems, among others. Its cutting-edge products find applications in various industries, including medical research, pharmaceuticals, and food safety.

Magnetic Analysis Corp., founded in 1928 and located in Elmsford, New York, is an American manufacturer providing instruments, solutions, and systems for nondestructive testing (NDT). The company offers eddy current testing (ECT) and multichannel ultrasonic testing (UT) instruments, designed for bars, tubes, and pipes, as well as eddy current and ultrasonic rotaries for testing round bars and tubular products. It also provides ultrasonic velocity measurement equipment, used for testing automotive parts, along with rail wheel testers. The company further offers flux leakage testing instruments for defect detection in hot rolled black steel bars and flaw identification in heavy wall magnetic tubing.

James Instruments Inc., established in 1985 and based in Chicago, USA, is a manufacturer and supplier of non-destructive testing equipment for concrete and construction materials. The company provides instruments for measuring strength (compressive and tensile), locating rebar, and assessing moisture content. Its products are used in testing requirements for professionals and organizations such as the New York DOT, the University of Texas, and the Hong Kong Housing Authority. The company offers rental services, allowing customers to try equipment before purchase. It provides global rental, calibration, and repair services for its products.

Dayton T. Brown, Inc., established in 1950, provides testing services, on-demand engineering, logistical services, and technical publications to the aviation, governmental, aerospace, and commercial industries. The testing services include remote test witnessing, structural testing, optical testing, survival equipment testing, and environmental testing. The engineering services include reverse engineering, structural & stress analysis, inspection services, research & development, and design engineering. The company in Bohemia, NY, is ISO 9001 and AS9100 registered, compliant with DCMA accounting demand, and approved & secured by DoD.

ISOFLEX Radioactive LLC, established in 1996, is a supplier of the nondestructive testing (NDT) industry. Based in Louisiana, United States, its products catalog includes Radioactive Sources, Radiographic Testing (RT), Ultrasonic Testing (UT), Liquid Penetrant Testing (PT), Magnetic Particle Testing (MT), among others. It offers consulting services such Radioactive Materials License QA Program Development, Training Programs, Sealed Source and Device (SS&D) Applications, Radiation Safety Programs (RSPs), and others. The company is certified in ISO 9001:2015 for Sales, Design, Manufacture and others.

NOMO Group, Inc., founded in 2009, and based in South America, is a distributor of nondestructive testing, heat treatments, welding equipment, and consumables. The company offerings include instruments like the sentinel model 880 delta, finder testing equipment, and Labino line products. Nondestructive testing inspects materials for defects without altering their original structure, ensuring their safety in everyday use. These products and services cater to industries ranging from aerospace, petrochemical, manufacturing, and automotive to consumer products. The company supports its customers' growth by providing timely supply and strong vendor relationships.

Inspection Technologies Inc. is a supplier of non-destructive testing (NDT) equipment and systems. Formed in 1985, this California-based company offers systems, equipment, and stock supplies for multiple NDT methods including liquid penetrant, eddy current, and ultrasonic testing. Along with its range of products, the company provides training and consultation for various NDT applications, calibration to ISO 17025 and ANSI/NCSL Z540-1 standards, and repair services. Inspection Technologies Inc. serves clients in the oil and gas, aerospace, and power generation industries.

Building on decades of experience and an unfailing passion for technology, Comet Yxlon is a globally leading company for industrial X-ray and CT system solutions with integrated services for industrial environments – from R&D labs to production settings. Comet Yxlon supplies tailored service solutions for a wide range of production environments through offline applications, at-line scenarios, or in-line implementation, and their diverse field of quality assurance and quality control. With inspection systems that help manufacturers and developers control product quality, their specialized systems are used in the most diverse areas such as aerospace, automotive, electronics, science & research, and many more.

MARKTEC Corporation, founded in 1955 as Tokushu Toryo Co. Ltd., and based in Tokyo, Japan, is a manufacturer and seller of fluorescent paint and metal testing materials. The company offers a wide range of products for Penetrant Testing such as Dye Penetrant Flaw Detection Material, Magnetic Particle Testing, Eddy Current Testing, Ultraviolet Light Testers, and many more. The company’s products serve various industries such as automobile, construction, steel, and heavy industries among others. It holds the ISO 9001:2015 and ISO 14001: 2015 certifications.

RX Solutions, established in 2006 and headquartered in Chavanod, France, is an engineering company and a designer and manufacturer of X-ray imaging systems. The company's main products include microfocus tomographs for inspection of small parts, micro and nanofocus tomographs for inspection of medium-sized parts, and microfocus and nanofocus laboratory tomography systems for inspection of large parts. These products are used for precise and non-destructive examination of the internal and external structures of components. The company's support services include training, support, and ongoing maintenance.

SECU-CHECK GmbH, based in Germany, is a manufacturer of UV-LED Lamps and systems for non-destructive testing (NDT), security-relevant and demanding applications. It specializes in the industrial usage of UV-Radiation in different industrial branches. Its products catalog includes Full Range of Fluorescent Dyes, Tracers and Markers for Leak Detection, Yellow LED Lamps for Wafer Inspection, Yellow LED Lamps for Wafer Inspection, Electrostatic Spraying Systems (FPI). It provides tailored process consulting services for all variants of NDT.

Baker Hughes Co. (BHC) is an American service provider and manufacturer of industrial oilfield equipment that was established in 1987 following the merger of Baker International and Hughes Tool Company. Based in Houston, Texas, the company produces several categories of oilfield products including drilling equipment, pipe and subsea production systems, generators, and storage systems. It also offers process control components and actuators such as pumps, valves and regulators. BHC provides various services for oilfield and liquefied natural gas (LNG) operations, including regasification, well construction, transportation, and storage.

JMD Inc, founded in 2015, is a manufacturer of non-destructive testing products and accesories. Based in Texas, United States. Its products catalog includes objects for Magnetic Particle Inspection and Radiography Testing like LED UV Lamp, LED UV Bulb, LED Film Viewer, Centrifugal Tube, Digital Densitometer, among others. Its products offer solutions for measuring UVA irradiation and visible illumination, fluorescent inspection, measuring the transmitted density of X Ray film, and others. It has accesories such Cassettes/X-ray Film Holders, Lead Identification Markers, and Radiation Warning Signs.

PACSESS Group is a German-based manufacturer of cutting-edge digital imaging solutions that was established in 1996. The company serves industries such as healthcare, automotive manufacturing, aerospace, telecommunications, and energy. Its range of products includes digital radiography, RX film digitization, RT1 software, automatic defect recognition, and the Enterprise platform. These products find application in enabling efficient inspection and imaging processes by optimizing operations, enhancing efficiency, and ensuring precision across healthcare diagnostics, quality control in manufacturing, and non-destructive testing in aerospace and automotive sectors.

ALPS Inspection was founded in 1974, and is headquartered in Harrison, Ohio. We offer non-destructive, pressure decay leak testing equipment for empty industrial containers. The company's main product portfolio includes leak detection devices, sensors, and monitoring systems used in various industries such as automotive, HVAC, and industrial equipment. ALPS's products play a crucial role in preventing leaks and ensuring the efficient functioning of fluid systems. Their quality solutions enhance the safety and reliability of critical applications. The company continues to provide cutting-edge leak detection technology to industries worldwide, enhancing operational efficiency and reducing risks.

Millholland Conrad, Inc. was established in 1960 in Westfield, Indiana as a full-service industrial sales agency. Today, Millholland Conrad is a distributor for manufacturers in the automotive, appliance, medical, packaging, and construction industries across the heartland of the United States. Milholland has 3 general product lines including extrusion & recycling, blow molding, and injection molding. Extrusion & recycling includes recycling lines, modular systems, palletizing systems, and inspection systems for sheet, film, and pellets. Blow molding includes blow molding machines and auxiliary equipment, leak detection systems, and automated takeout for containers. Injection molding includes all-electric machines, robots & sprue pickers, and more.

Headquartered in London, Coltraco Ultrasonics is a global company specialising in research, design, development, manufacture, integration and sustainment of high-tech systems, products and services. Our organisation is comprised of Manufacturing, Scientific, Research and Technological Development & Solutions: Our Company: COLTRACO ULTRASONICS Our Laboratory, co-located with the Centre for Advanced Instrumentation, part of the Department of Physics, Durham University Our Research Organisations, the Durham Institute of Research, Development & Invention (DIRDI) Our Centre for Underwater Acoustic Analysis (CUAA) Coltraco Ultrasonics offers non-invasive fluid monitoring for various containers, airtightness and watertightness testing, flow rate calculations, and NDT instruments for material thickness measurement, mainly for corrosion monitoring, all while delivering genuine value to their customers globally through their scientific and institutional values and the quality of their services.

Carestream Non-Destructive Testing, founded in 2007 and headquartered in Rochester, New York, is a manufacturer and supplier specializing in digital imaging systems. The company’s product portfolio includes HPX-DR 2530 PH non-glass detectors, HPX-PRO portable digital system, and INDUSTREX photochemicals. These products are used in various industries, including power generation, aerospace, and the oil and gas industry. The company possesses ISO 14001 Environmental Management System (EMS) certification, with locations in various countries including Canada, Germany, and Australia.

DANTEC DYNAMICS A/S, founded in the United States in 2000, is a supplier of test equipment and components. The company offers a diverse array of test equipment, including measuring instruments, test meters, analyzers, and more, designed for accurate data collection and analysis and a wide selection of components, such as sensors, transducers, connectors, and cables, tailored to meet the unique needs of various applications. It also provides engineering services for product development and custom test solutions.

Eddies Engineering and Solutions Pvt Ltd., is an engineering and solutions supplier for the sky, earth and sea across various industries. Based in Lahore, Pakistan, it specializes in Ultrasonic, Electromagnetism, Remote Visual Inspections, Material analysis and Condition Monitoring. Its products catalog includes Ultrasonic Flaw/Phased Array Flaw Detector, Remote Visual Inspection, Scanners, NDT Consumable, Industrial Radiographic Equipment, among others. It serves many sectors like Fertilizers,TIC, Steel Manufacturing, EPC Contractors, Oil & Gas, among others.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Coltraco Ultrasonics |

5.1%

|

| 2 | Inspection Technologies Inc |

5.1%

|

| 3 | MFE Inspection Solutions |

4.8%

|

| 4 | ISOFLEX Radioactive LLC |

4.1%

|

| 5 | Magnetic Analysis Corp. |

4.1%

|

| 6 | James Instruments Inc. |

4.0%

|

| 7 | FUJIFILM Holdings America Corporation |

4.0%

|

| 8 | Rad Source Technologies |

3.8%

|

| 9 | DCM Tech, Inc. |

3.8%

|

| 10 | Dayton T. Brown, Inc. |

3.8%

|

Derivation Method

The ranking is calculated based on the click share within the non-destructive testing (ndt) system page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

16 | 61.5% |

Japan

Japan

|

3 | 11.5% |

Germany

Germany

|

2 | 7.7% |

France

France

|

1 | 3.8% |

Austria

Austria

|

1 | 3.8% |

United Kingdom

United Kingdom

|

1 | 3.8% |

Denmark

Denmark

|

1 | 3.8% |

| Pakistan | 1 | 3.8% |

568 products found

568 products

Measurement Technology Service Co., Ltd.

930+ people viewing

Last viewed: 4 hours ago

The ADSPIRE01, equipped with cutting-edge digital signal processing technology jointly developed by KGS and the University of Tokyo, is now availab...

Eddyfi Technologies Inc.

1070+ people viewing

Last viewed: 1 hour ago

■Powerful signal quality to standard-compliant conventional PAUT and TOFD procedures TOPAZ®64 is a 64CH (or 32CH) fully integrated phased array ult...

Japan Probe Co, Ltd

910+ people viewing

Last viewed: 16 hours ago

■Features ・High speed, automation compatible model ・Pulse (variable pulse width) / burst / chirp wave ・Power 10W ・Minimum crosstalk ・Voltage 1...

Eddyfi Technologies Inc.

580+ people viewing

Last viewed: 4 hours ago

■Compact and lightweight advanced phased array PantherTM combines the speed and performance of phased array ultrasound technology in a compact hous...

RYODEN SHONAN ELECTRONICS CORPORATION

1480+ people viewing

Last viewed: 5 hours ago

・ Equipped with JSNDI function ・ Equipped with high brightness LED LCD ・ Intuitive operation with direct key ■ Corresponds to a wide range of need...

Japan Probe Co, Ltd

710+ people viewing

Last viewed: 16 hours ago

■Features ・Basic specifications model ・Pulse (variable pulse width) / burst / chirp wave ・Voltage 10-600V variable ・Frequency 30kHz to 10MHz ・...

Eddyfi Technologies Inc.

540+ people viewing

Last viewed: 9 hours ago

Emerald is a compact, compact design that delivers exceptional performance for the most challenging inspection challenges and environmental conditi...

Japan Probe Co, Ltd

580+ people viewing

Last viewed: 16 hours ago

■Features ・High frequency compatible model ・Frequency 1MHz to 25MHz ・Rectangular pulse wave (variable pulse width) / Spike pulse wave ・Voltage ...

Roman Japan

740+ people viewing

Last viewed: 9 hours ago

Released in 2017. Full model change based on the predecessor PL500. Super high expandability to control a simple hardware configuration, low noise,...

YXLON International

1370+ people viewing

Last viewed: 13 hours ago

■ Powerful X -ray / CT inspection device ・ Automatic calculation of voice by VOIDINSPECT ・ High -sensitivity type 16 -bit (65,000 gradations) Out...

2 models listed

KJTD Co., Ltd.

730+ people viewing

Last viewed: 9 hours ago

The phased array ultrasonic flaw detection system PA5 was born as the successor to the phased array ultrasonic flaw detection system PA4, which has...

Spectory

2680+ people viewing

Last viewed: 6 hours ago

■ Desktop type / X -ray diffraction device (XRD) AERIS (XRD), a desktop type X -ray diffraction device (XRD), has achieved data quality and data ac...

Tokyo Optoelectronic Industry Co., Ltd.

1150+ people viewing

Last viewed: 16 hours ago

■Features ・Instantly measure outer diameter and gap without contact using laser light ・Equipped with simultaneous display of two types of measure...

8 models listed

ANSeeN Co., Ltd.

590+ people viewing

Last viewed: 10 hours ago

Features ■High sensitivity The 1mm thick cadmium telluride (CdTe) semiconductor detector images X-rays much more efficiently than traditional X-ray...

ULTRASONIC Co., Ltd.

540+ people viewing

Last viewed: 9 hours ago

■Summary ・We provide an ultrasonic flaw detection system for steel sheet quality inspection using the EMAT ultrasonic method to suit customer requ...

Eddyfi Technologies Inc.

530+ people viewing

Last viewed: 9 hours ago

■Can be carried anywhere Mantis™ is a rugged, lightweight flaw detection instrument that provides UT, PAUT, TOFD, and TFM through the Capture softw...

Nihon Matec Co., Ltd.

670+ people viewing

Last viewed: 3 hours ago

■Leader in next-generation non-destructive testing and composite materials Recognized worldwide for its high-quality, high-resolution ultrasonic no...

Japan Probe Co, Ltd

640+ people viewing

Last viewed: 16 hours ago

■Features ・High frequency compatible model ・Frequency 1MHz to 25MHz ・Voltage 10-300V variable ・Rectangular pulse wave (variable pulse width) / ...

YXLON International

1140+ people viewing

Last viewed: 13 hours ago

Micro CT system for R & D, defective analysis, or CT measurement. It is designed for inspection of very small parts and objects in the electronics ...

Nihon Matec Co., Ltd.

440+ people viewing

Last viewed: 7 hours ago

The latest tomography device employing multi-SAFT and digital focus array (DFA). Conventional single type probes can also be used, so it can also b...

Tokyo Optoelectronic Industry Co., Ltd.

360+ people viewing

Last viewed: 9 hours ago

■Summary ・For measuring the outer diameter of end mills and drills ・High precision measurement with reproducibility within ±2μm ・Supports even n...

2 models listed

F.I. Tech Co., Ltd.

480+ people viewing

Last viewed: 9 hours ago

ULTRASONIC Co., Ltd.

510+ people viewing

Last viewed: 9 hours ago

■Summary ・We provide an ultrasonic flaw detection system for internal defects and surface defects in CC slabs using the EMAT ultrasonic method to ...

Eddyfi Technologies Inc.

490+ people viewing

Last viewed: 9 hours ago

Designed to drive the Scorpion2 tank shell crawler, Swift UT software enables unique UT gate processing (such as floating gates and tracking gates)...

Japan Probe Co, Ltd

570+ people viewing

Last viewed: 16 hours ago

■Features ・High voltage model ・Pulse (variable pulse width) / burst / chirp wave ・Voltage 30 to 1,800V variable ・Frequency 20kHz to 1MHz

YXLON International

570+ people viewing

Last viewed: 13 hours ago

The optional double pipe setup combines the unprecedented CT data quality and the highest versatility in the examination of small and medium -sized...

2 models listed

Nihon Matec Co., Ltd.

420+ people viewing

Last viewed: 7 hours ago

A circle is a circle, a vertical is accurately displayed vertically, and adjacent defects are also displayed separately. Few setting items, easy se...

Advanced Technology Research Institute Ltd.

580+ people viewing

Last viewed: 10 hours ago

A state-of-the-art machine that uses original technology "Laser light diffraction/Light speed automatic difference method" ■Summary This device is...

Tokyo Optoelectronic Industry Co., Ltd.

350+ people viewing

Last viewed: 9 hours ago

If you memorize the measurement items (outer diameter, runout, roundness, straightness, crown shape, etc.), measurement points, and type of created...

4 models listed

F.I. Tech Co., Ltd.

480+ people viewing

Last viewed: 9 hours ago