All Categories

History

This section provides an overview for ultrasonic thickness gauges as well as their applications and principles. Also, please take a look at the list of 20 ultrasonic thickness gauge manufacturers and their company rankings. Here are the top-ranked ultrasonic thickness gauge companies as of February, 2026: 1.L.S. Starrett Company, 2.Dakota Ultrasonics, 3.REED Instruments.

Table of Contents

Categories Related to Ultrasonic Thickness Gauges

Engaged in research on nitride semiconductor growth using the MBE method at Waseda University Graduate School. After graduating from graduate school in 2016, he joined a non-ferrous metal manufacturer.

Engaged in equipment maintenance and engineering work at metal smelting plants. Moved to a chemical manufacturer in 2022. Engaging in similar tasks.

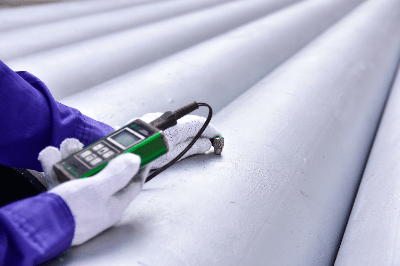

An ultrasonic thickness gauge is a device that employs ultrasonic waves to measure the thickness of an object.

It determines the thickness by measuring the time ultrasonic waves take to traverse the object. This non-destructive method is ideal for product and material quality control. The gauges are highly accurate, capable of detecting minute thickness variations and measuring the thickness of thin materials efficiently.

The operation typically involves pressing the device against the object's surface and activating the measurement button. Many models boast digital displays and automated measurement functions. Their portability makes them suitable for on-site usage, and their compact design allows for measurements at various locations.

Ultrasonic thickness gauges find applications in various scenarios where thickness measurement is essential.

In the manufacturing sector, these gauges are crucial for measuring the thickness of materials such as steel plates and aluminum plates. They are instrumental in ensuring precision in products like automotive body panels and aircraft frames.

In the construction field, these gauges are employed to measure the thickness of concrete in structures and floors, aiding in strength assessment and uniformity checks. They are also invaluable for detecting corrosion in metals, especially in areas like underground piping or building interiors, as they measure thickness reduction non-destructively.

Ultrasonic thickness gauges operate on the principle of measuring an object's thickness using the travel time of ultrasonic waves. The gauge comprises an ultrasonic generator, usually made of piezoelectric or magnetic elements, transforming electrical energy into ultrasonic waves.

These waves are emitted towards the object, where they are reflected and scattered by the internal structure and interfaces. The reflected waves are then captured by a receiver, transformed back into electrical signals, and their travel time is measured.

The calculation unit computes this travel time. With pre-set ultrasonic wave velocity data for the specific material, it calculates the object's thickness. Accurate velocity data is crucial, as ultrasonic wave speed varies with the material's composition and density.

Different types of ultrasonic thickness gauges are designed for specific applications:

This gauge utilizes a single transmitter/receiver element, making it suitable for simple thickness measurements in thinner materials.

With separate transmitter and receiver elements, this gauge offers enhanced signal accuracy and sensitivity, applicable to various uses.

This type has both transmitter and receiver elements in the same sensor head, ensuring more accurate measurements, particularly under high-temperature conditions and on uneven surfaces.

This gauge features multiple transmitting and receiving elements, allowing for thickness measurements on complex surfaces and shapes.

Consider the following aspects when choosing an ultrasonic thickness gauge:

Reflect on the material type and surface condition of the object. Specific materials and shapes might necessitate specialized gauges.

Evaluate the range of thickness to be measured and the precision needed. Gauges vary in their capacity to measure ultra-thin or thick materials.

Usability is crucial. Consider features like user-friendly interfaces, simple navigation, and data recording functions.

*Including some distributors, etc.

Sort by Features

Sort by Area

Phase II, founded in 1982 and headquartered in Upper Saddle River, New Jersey, is a manufacturer of material testing tools. The goods include durometers, force gauges, vibration meters, hardness & surface roughness testers, and ultrasonic thickness gauges. The machine tool accessories include change tool holders, rotary table tailstocks, lathe tool post sets, collet indexers, and dex spacers. The firm provides Gage calibration and certification services and is AMTMA, ASNT, and ASTM International member.

L.S. Starrett Company is a manufacturer of precision tools and instruments established in 1880 and based in Massachusetts, United States. It specializes in manufacturing precision measuring tools like micrometres, callipers, bevel vernier protractors, dial indicators, and granite surface plates. The company is in compliance with the RoHS standards and has acquired several certifications, including ISO 9001:2015, ISO/IEC 17025:2017, and ANSI/NCSL Z540.1-1994. Its manufactured products are utilized for metalworking, automotive, aviation, marine, and farm industries across America.

Dakota Ultrasonics is an American manufacturer of industrial ultrasonic testing equipment, based in Scotts Valley, California. The company's product line includes corrosion gauges for measuring the effects of corrosion on structures, precision gauges for measuring material thickness, racing gauges to measure parts of race cars, and specialty gauges for measuring the thickness of materials that are difficult to penetrate with sound, all of which can be controlled using software and wireless applications. The company also offers flaw detectors, bolt tension monitors, and related accessories Dakota Ultrasonics' products find usage across diverse sectors, including petrochemical, aerospace, power generation, and automotive.

Phase II Plus, incorporated in 1982 and based in Upper Saddle River, New Jersey, is a manufacturer of material testing instrument as well as machine tool accessories and precision measuring tools. The company offers a comprehensive line of hardness testers, including rockwell hardness testers, portable hardness testers, Brinell hardness testers, and Vickers hardness testers. The company also offers ultrasonic thickness gauges for testing both ferrous and non-ferrous substrates, durometers, as well as force gauges comprising of analog handheld force gauges, ranging up to 100lb/50kg capacity.

DeFelsko Corporation is a manufacturer of coating thickness gauges and inspection instruments, located in Ogdensburg, NY, USA, and was established in 1965. The company offers a range of products, including, environmental gauges, soluble salt testers, ultrasonic wall thickness gauges, and analog & digital material hardness testers, used in various industries, including metals, fiberglass, and plastic.They continue to develop new products and technologies to meet the needs of customers. They also actively participate in several key organizations (SSPC, NACE, ASTM, ISO) to improve and promote the science of coating inspection.

REED Instruments was established in 2004 and is headquartered in Wilmington, North Carolina, United States. The company is a manufacturer of portable precision test and measurement instruments. Its product range goes over 200 instruments and includes moisture meters, temperature meters, humidity meters, and more. REED Instruments has been developing cutting-edge test and measurement technologies, and its products are used by a wide range of customers, including industrial, commercial, and educational institutions. Along with the outstanding quality products, the company sell its products mainly through an authorized distribution network in North America.

SONOTEC GmbH, established in 1991, is a German manufacturer based in Halle (Saale), Saxony-Anhalt, specializing in ultrasonic measurement technology solutions. The company offers non-invasive flow meters and air bubble detectors for fluid monitoring in medical technologies, bioprocessing, and the semiconductor industry. It also supplies ultrasonic testing devices used for condition monitoring, inspections, predictive maintenance, tightness testing, and ultrasonic leak detection. Additionally, the company engages in non-destructive testing (NDT) using ultrasound, primarily for flaw detection, thickness measurements, and weld seam testing, commonly applied in industries like aerospace, aviation, power plants, as well as other sectors including pipelines, railways, and sheet metal inspections.

Link Instruments, established in 1998, is a manufacturer and supplier of Ultrasonic Instruments based in Hampshire, UK. The company specializes in designing and producing Level indicators, Gas Detectors, Gas Leak Detectors, and Thickness Gauges and offers custom electronic development and small-scale production services. With a global reach, Link Instruments serves industries including Fire Safety, Marine, Oil, Gas, and more. The company offers comprehensive in-house services, including repair, re-calibration, and spare parts.

Sensotec, founded in 1985, is a manufacturer and application service supplier of sensors and transmitters specializing in pressure, level, and force measurements in Cornella de Llobregat, Barcelona. Sensotec offers pressure, level, and force transmitters. Its products cater to various industries and OEM manufacturers, providing sensors, transducers, and transmitters with output signals compatible with diverse measurement equipment. The company owns four brands: Lexitron, Leveltec, Nivomat, and Sensotec. The company serves customers from Africa, Asia, America, Europe, and Oceania.

JFE Advantech Co.,Ltd. was established in 1973 and is a manufacturer of water instruments and measuring devices based in Nishinomiya, Hyogo, Japan. The company produces various products such as submerged level detectors, ultrasonic pulse coherent flowmeters, optical dissolved oxygen meters, electromagnetic flow velocity meters, and comprehensive water quality meters. The products have been used in various applications including sewage treatment plants, agricultural water systems, factory drainage, hydroelectric power plant, and deep wells management. The company have been certified with ISO 9001 for the water instruments and measuring products in 1995.

NDT-KITS (Honesdom International HK Limited), established in 1973, is a Hong Kong-based manufacturer of non-destructive testing (NDT) instruments that are used to evaluate materials’ non-conformity with specifications as well as surface and internal defects without causing any damages. The instruments developed include the company’s first digital ultrasonic flaw detector, which garnered recognition from the Chinese Academy of Science (CAS) and a patent from the State Intellectual Property Office (SIPO). Other instruments developed are time-of-flight diffraction (TOFD) and phased array ultrasonic testing (PAUT) flaw detectors. NDT-KITS has achieved ISO 9001:2000 certification and adheres to the CE mark and EU EN-12668 standards.

Extech Instruments Corp., founded in 1971 in the USA and acquired by Teledyne FLIR in 2007, is a manufacturer of consumer test and measurement tools. Today, the brand’s extensive catalog of handheld test equipment and accessories includes multi-functional handheld meters, including meters with integration with mobile devices via the use of iOS and Android apps and Bluetooth connectivity. Extech brand products are distributed across more than 100 countries worldwide and available for purchase online.

ACS-Solutions GmbH, established in 1991 and based in Germany, is an ultrasonic testing equipment manufacturer and supplier. The company offers a range of metal, concrete, and composite material testing products, including thickness gauges, flaw detectors, and tomography systems. It also provides professional inspection services for infrastructural concrete and metallic objects, utilizing advanced techniques such as ultrasonic tomography for accurate flaw evaluation. The company offers solutions for various industries, such as construction, manufacturing, and infrastructure maintenance.

Beijing Dragon Electronics Company (DGC), founded in 1993 and headquartered in Beijing, China, is a manufacturer of portable measuring equipment. The company produces handheld devices such as ultrasonic thickness gauges, flaw detectors, and hardness testers. Its products are used in manufacturing, aerospace, and automotive industries for material inspection and defect detection. For example, construction companies use the company's ultrasonic flaw detectors to assess structural integrity. The company has distributors across China and also exports 60% of its products globally.

Cygnus Instruments Ltd, established in 1987, and based in Florida, USA, is a manufacturer and supplier of ultrasonic measurement equipment. Their product portfolio includes ultrasonic thickness gauges, hatch cover leak detectors, and flooded member detection systems. The products are used in various applications which include aeronautical, electrical, forensic, mechanical, civil, and medicine systems. The company offers robust ultrasonic thickness gauges with high quality and premium expertise. They also provide digital multiple echo technology for accurate measurements.

Matcon B.V., founded in 1978, is a manufacturer and supplier based in Middenbeemster, the Netherlands, specializing in emergency safety equipment. The company's lineup promotes worker safety in case of accidental exposure to hazardous materials. These products include emergency and safety showers, eyebaths, and protective clothing that provides a physical barrier against chemicals, gases, and other hazards. The company serves customers across diverse industries, including chemical, oil and gas, and pharmaceutical. It also caters to other workplaces where safety regulations mandate such equipment.

Headquartered in London, Coltraco Ultrasonics is a global company specialising in research, design, development, manufacture, integration and sustainment of high-tech systems, products and services. Our organisation is comprised of Manufacturing, Scientific, Research and Technological Development & Solutions: Our Company: COLTRACO ULTRASONICS Our Laboratory, co-located with the Centre for Advanced Instrumentation, part of the Department of Physics, Durham University Our Research Organisations, the Durham Institute of Research, Development & Invention (DIRDI) Our Centre for Underwater Acoustic Analysis (CUAA) Coltraco Ultrasonics offers non-invasive fluid monitoring for various containers, airtightness and watertightness testing, flow rate calculations, and NDT instruments for material thickness measurement, mainly for corrosion monitoring, all while delivering genuine value to their customers globally through their scientific and institutional values and the quality of their services.

Evident Corporation is a scientific research and development company in Shinjuku, Tokyo that was established in 2008. Formerly known as Olympus Scientific Solutions, the company specializes in developing cutting-edge technology and products for various industries, including aerospace, automotive, electronics, energy, and medical research. Evident Corporation has proliferated and expanded its product offerings and services to meet the needs of its customers. Their product offerings include non-destructive testing (NDT) solutions such as thickness gauges and automated inspection systems, XRF analyzers like handheld XRF analyzers, industrial microscopes, and video scopes and borescopes.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | L.S. Starrett Company |

11.1%

|

| 2 | Dakota Ultrasonics |

10.3%

|

| 3 | REED Instruments |

8.8%

|

| 4 | Phase II |

6.3%

|

| 5 | Coltraco Ultrasonics |

6.1%

|

| 6 | DeFelsko Corporation |

5.4%

|

| 7 | SONOTEC GmbH |

5.0%

|

| 8 | Evident |

4.8%

|

| 9 | Link Instruments Ltd. |

4.6%

|

| 10 | Phase II Plus |

4.2%

|

Derivation Method

The ranking is calculated based on the click share within the ultrasonic thickness gauge page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

6 | 37.5% |

United Kingdom

United Kingdom

|

3 | 18.8% |

Germany

Germany

|

2 | 12.5% |

Japan

Japan

|

2 | 12.5% |

China

China

|

2 | 12.5% |

Spain

Spain

|

1 | 6.3% |

82 products found

82 products

Nihonkai Keisoku Tokki Co., Ltd.

490+ people viewing

Last viewed: 1 hour ago

Features ◼︎High-precision measurement of thicknesses of tens of microns using 125MHz high-frequency ultrasound Ultrasonic thickness gauges can meas...

2 models listed

A and Day Co., Ltd.

720+ people viewing

Last viewed: 1 hour ago

For thickness measurement of a wide range of materials such as metal, glass, plastic, ceramic, and epoxy. ・One unit covers a wide measurement ran...

2 models listed

ANT Ltd.

430+ people viewing

Last viewed: 1 hour ago

■Features - Compact and dual power supply method (battery/AC) ・Real-time data output per pulse up to PRF 5KHz (analog, digital parallel) ・Can b...

Time Technology Japan Co., Ltd.

310+ people viewing

Last viewed: 1 hour ago

The film thickness meter DT-156 is a dual type, so it can measure the film thickness of various coatings on magnetic metals (iron, steel, ferritic ...

Dakota Japan Co., Ltd.

660+ people viewing

Last viewed: 1 hour ago

■Summary ・Dakota's most powerful ultrasonic thickness gauge ・Glass/carbon fiber reinforced plastic (GFRP/CFRP) ・Rubber, high-density polyethylen...

Dakota Japan Co., Ltd.

860+ people viewing

Last viewed: 1 hour ago

■Summary ・Thickness gauge for measuring cast iron and cast aluminum ・Special design enables accurate thickness measurement ・Measurement range: 1...

Shinmei General Co., Ltd.

610+ people viewing

Last viewed: 1 hour ago

■High performance, portable, ultrasonic thickness gauge with A scope DMS Go's lightweight and compact design allows it to be operated even in harsh...

Dakota Japan Co., Ltd.

650+ people viewing

Last viewed: 1 hour ago

■Summary ・Flagship model for thin materials and precision inspection ・Highest precision ultrasonic thickness gauge ■Features PVX is a flagship m...

Shinmei General Co., Ltd.

960+ people viewing

Last viewed: 1 hour ago

The DM5E series is a small and lightweight ultrasonic thickness gauge. It has a robust design that further improves stability and reproducibility a...

Ryokosha Co., Ltd.

320+ people viewing

Last viewed: 1 hour ago

■Summary High performance, easy operation, robust design, and reliability. This handheld thickness gage is compatible with most ultrasonic wall thi...

Dakota Japan Co., Ltd.

780+ people viewing

Last viewed: 1 hour ago

■Summary ・Flagship model for thin materials and precision inspection ・Highest precision ultrasonic thickness gauge ・Measurement range: I-E-E mod...

Custom Co., Ltd.

1100+ people viewing

Last viewed: 1 hour ago

■ Various materials from metal to non -metals can be measured. ・ The thickness is calculated by measuring the time (propagation time) (propagation...

Dakota Japan Co., Ltd.

650+ people viewing

Last viewed: 1 hour ago

■Summary ・Flagship model for thin materials and precision inspection ・Highest precision ultrasonic thickness gauge ■Features PVX is a flagship m...

Dakota Japan Co., Ltd.

700+ people viewing

Last viewed: 1 hour ago

■Summary ・A scope & independent 2 gates ・All-round model that can be used for multiple purposes ・Measurement range: Pulse/echo: 0.63mm to 1,000m...

Dakota Japan Co., Ltd.

810+ people viewing

Last viewed: 1 hour ago

■Summary ・Suitable for all types of measuring objects with 5-level sensitivity adjustment function ・Mid-range thickness gauge with various functi...

Dakota Japan Co., Ltd.

820+ people viewing

Last viewed: 1 hour ago

■Summary ・Flagship model equipped with all functions ・Highly accurate and powerful ultrasonic thickness gauge ・IP65 (dustproof/splashproof), 2 y...

Dakota Japan Co., Ltd.

1690+ people viewing

Last viewed: 1 hour ago

■Summary ・Overwhelmingly high accuracy and measurement range achieved through newly designed signal processing technology ・Ultrasonic thickness g...

Dakota Japan Co., Ltd.

630+ people viewing

Last viewed: 1 hour ago

■Summary - Collaborates with Mitutoyo calipers to save labor on thickness input ・Ideal for controlling graphite nodularity in cast iron ・Measurem...

Dakota Japan Co., Ltd.

1110+ people viewing

Last viewed: 1 hour ago

■Summary ・Handy type sound velocity meter ・Ideal for controlling graphite nodularity in cast iron ・Measurement range: 305 to 18,542m/sec ・Funct...

Custom Co., Ltd.

480+ people viewing

Last viewed: 1 hour ago

STG-01U dedicated contact mediation Ultrasound thickness meter For replenishment when the attached caprant is used up to STG-01U.

Dakota Japan Co., Ltd.

780+ people viewing

Last viewed: 1 hour ago

■Summary ・Flagship model equipped with all functions ・Highly accurate and powerful ultrasonic thickness gauge ・IP65 (dustproof/splashproof), 2 y...

Custom Co., Ltd.

490+ people viewing

Last viewed: 1 hour ago

STG-01U replacement exploration child Ultrasound thickness meter It is for replacement when the exploder attached to the STG-01U is damaged or lost.

SANKO ELECTRONIC LABORATORY CO.,LTD

860+ people viewing

Last viewed: 1 hour ago

The glue and gap state of the detection layer in the shell wall of the science fiction double shell tank are easily detected from the outer shell p...

SANKO ELECTRONIC LABORATORY CO.,LTD

830+ people viewing

Last viewed: 1 hour ago

■ Features ・ Thickness measurement of iron, copper, cast iron, aluminum and other metals, hard plastic, glass, porcelain, etc. ・ There are variou...

Dakota Japan Co., Ltd.

670+ people viewing

Last viewed: 1 hour ago

■Summary ・Next generation precision ultrasonic thickness gauge ・Achieves stable measurement in 0.001mm increments ・Measurement range: Echo echo:...

FTS Co., Ltd.

540+ people viewing

Last viewed: 1 hour ago

FT-4000 is a portable ultrasonic thickness gauge for glass fiber and FRP. A/B scan model with Echo-Echo functionality, automatic probe recognition,...

FTS Co., Ltd.

840+ people viewing

Last viewed: 1 hour ago

UPG-07 is a portable ultrasonic thickness gage designed for non-destructive testing. Measurement objects include steel coils, fiberglass boards, ti...

Dakota Japan Co., Ltd.

1620+ people viewing

Last viewed: 1 hour ago

■Summary ・Flagship model equipped with all functions ・Highly accurate and powerful ultrasonic thickness gauge ・Measurement range: Pulse echo: 0....