All Categories

History

This section provides an overview for driveshafts as well as their applications and principles. Also, please take a look at the list of 16 driveshaft manufacturers and their company rankings. Here are the top-ranked driveshaft companies as of February, 2026: 1.Quigley Motor Company, Inc., 2.Mark Williams Enterprises Inc., 3.Johnson Power, Ltd..

Table of Contents

Categories Related to Driveshafts

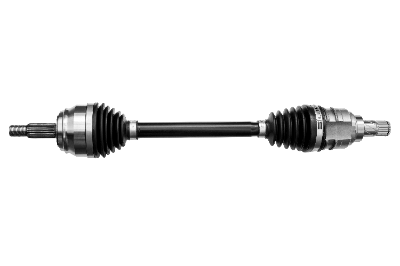

A driveshaft is a rotating shaft used to transmit the power of a prime mover to rotating equipment.

A driveshaft is a rotating shaft used to transmit the power of a prime mover to rotating equipment.

Driveshafts are generally known as automobile driveshafts, but they are also widely used for power transmission in ships, industrial machinery, construction machinery, railcars, and other vehicles.

Driveshafts do not have to be arranged in a straight line from the power section to the transmission section, but can still transmit power by using constant velocity joints.

Driveshafts are especially needed in automobiles to drive wheels that are subject to large vibration displacement.

Driveshafts are also most commonly used in automobiles. Driveshafts in automobiles are components that transfer the power of the engine to the wheels.

In front-wheel drive vehicles, power is transmitted from the engine to the wheels via the Driveshaft. In the case of rear-wheel-drive vehicles, power from the engine is transmitted via the propeller shaft to a differential gear in the rear, which drives the wheels using the Driveshaft.

For applications other than automobiles, the propeller shaft is connected to motors for blowers, pumps, compressors, cranes, reduction gears, etc., and to drive shafts for rolling mill rolls and tension reels in steel manufacturing machinery. They are also used as drive shafts for rolls in chemical machinery, hydraulic pump drive shafts in construction machinery, and hydraulic pump drive shafts in truck mixers.

Further applications include work equipment drive shafts for agricultural tractors and drive shafts for machine tools, printing machinery, and paper manufacturing machinery.

Driveshafts in automobiles and other equipment usually do not form a straight line from the engine power unit to the wheel power transmission unit. Therefore, constant-velocity joints are installed at both ends of the shaft to smoothly transmit power at a constant velocity even if the shaft is angled.

There are two types of constant velocity joints: fixed type and sliding type.

This type cannot slide in the direction of the drive shaft. The constant velocity joint has parts called the outer race and inner race, and several steel balls are placed inside the outer race and outside the inner race. The steel balls allow the constant velocity joint to be angled.

This type can slide in the direction of the drive shaft. There are two types: One type has grooves on the outer race and inner race that are parallel to the axial direction and can slide in the axial direction. The other type has a three-axis component attached to one of the rotating shafts, each end of which has a roller. When rotated at an operating angle, the rollers roll in grooves inside the housing to enable axial sliding.

The life of a Driveshaft is generally the time it takes for the constant velocity joint to wear out to the point of noise or breakage. For automobiles, the standard is 200,000 km in terms of mileage.

A symptom of a failing Driveshaft approaching the end of its service life is the production of abnormal noise.

The most common type of vehicles in which abnormal noise can be easily recognized are front-wheel drive (FF) vehicles. When the angle of the constant velocity joint is large due to steering, a rattling noise may occur when accelerating. The cause of the noise is excessive clearance due to wear of the inner race, outer race, and steel balls, which are the key parts of the constant velocity joint.

The main causes of wear are deterioration of lubrication performance due to deterioration or decrease in the amount of grease sealed in the constant velocity joint for lubrication, and accelerated wear due to foreign matter such as sand entering the joint.

Grease deterioration can be caused by aging due to long-term use, early deterioration due to heat generation in the joint caused by continuous high load, and deterioration due to moisture contamination. Most of the causes of low grease level and foreign matter contamination at joints are deterioration or damage to the bellows-like parts called boots that protect the joints.

Boots protecting joints are mainly manufactured from rubber or flexible resin. The boots are cylindrical bellows-shaped, installed to cover the entire joint and secured with metal bands tightened at both ends.

The main functions of the boot are to retain lubricating grease in the joint and to prevent foreign matter from entering the joint. When inspecting the Driveshaft externally, it is important to check if the boot is torn or if grease is leaking from the fixed part. Reduced lubrication and foreign matter in the joints accelerate wear.

Replacing the boot used to require removal of the Driveshaft from the vehicle body, but now there are split-type boots that can be replaced without removing the boot from the vehicle body.

After the old boot is removed, the new boot, which is split in two, is installed so that it is sandwiched between the joints, and the mating joints are welded together with adhesive and heat to achieve a strength similar to that of conventional products.

When replacing the boot, the grease inside is also replaced with a new one, thus restoring lubrication performance.

*Including some distributors, etc.

Sort by Features

Sort by Area

Mark Williams Enterprises Inc. is an American manufacturer based in Louisville, Colorado, specializing in automotive and industrial driveline components. The company's extensive product offerings include axles, brakes, chassis components, and modular rear ends. Moreover, the company provides components tailored for specific applications, such as classic or drag racing purposes, off-road driving, as well as the National Association for Stock Car Auto Racing (NASCAR). The company provides industrial services such as broaching, induction hardening, and torsional testing. Its expertise also extends to the manufacturing of custom parts, specifically addressing components like shafts and spines that might be challenging to source through conventional means.

Precision Shaft Technologies, founded in 2002 and located in Clearwater, Florida, is a manufacturer of driveshafts. The company offers a diverse range of products, including drag shafts, circle track shafts, and custom driveshafts. These driveshafts are used for enhanced performance, durability, and customization in racing and specialized automotive applications. The company’s products are designed for specific applications, including drag racing, circle track racing, and custom vehicle setups. Precision Shaft Technologies caters primarily to the automotive performance, racing, and customization sectors.

The Driveshaft Shop, founded in 1995 and located in Salisbury, North Carolina, is a manufacturer of drivetrain solutions for street and racing use. Its broad range of products includes CV axles, driveshafts, conversions, and custom applications. These products have specific uses, such as upgrading street and racing vehicles, handling engine swaps, and catering to unique vehicle builds. The company's offerings are used to improve performance, durability, and customization in the automotive industry. The Driveshaft Shop caters to sectors such as automotive performance, racing, customization, and restoration.

Johnson Power Ltd. is a manufacturer and supplier of industrial universal joint drive shafts, composite drive shafts, gear couples, repairs and custom components. The company was founded in 1866 and established at Mba USA. The company specializes in shafts, gear, pumps used in steel and paper mills, water treatment plants, and other industrial power hauling machines. The Markets Johnson Power Ltd serve includes steel and paper mills, pump, and other industrial applications.

Quigley Motor Co., Inc. (QMC) is an American manufacturer specializing in four-wheel drive (4x4) conversion solutions that was established in 1974. Based in Manchester, Pennsylvania, the company primarily produces 4x4 conversions for full-sized vans and cut-aways, as well as specialty upfits and driveshafts. They offer customized 4x4 systems to optimize for different specifications, such as stability, clearance, or traction. QMC products and services are used by client companies and businesses in the construction, tourism, emergency services, and recreational vehicles markets.

Orlandi Gear Co. (OGC) is an American ISO 9001 certified manufacturer of mechanical power transmission components that was established in 1944 in Fraser, Michigan. The company's products include splined and keyed shaft models, spur and bevel gears, and various couplings as well as connectors for joining components together. These are used in hydraulic pumps, construction equipment, power take-off systems, and mining operations. OGC also offers various customization and finishing services including hobbing, broaching, honing, and coating for protective or decorative purposes.

Sunnen Products Company, founded in 1924, is an American manufacturer and supplier headquartered in St. Louis, Missouri, specializing in of high-precision and bore sizing machines, tools, and abrasives. Joe Sunnen, founder of the company, invented the first manual cylinder hone in 1928. Over the years, Sunnen has developed industrial honing machines, tools, and abrasives with bore sizing and finishing systems, lapping machines, deep hole drilling machines and tools, bore gaging and roller burnishing systems. These products find applications in various industries, such as honing solutions in the automotive sector, as well as a line of machines, tools, and abrasives for energy drilling.

USA Standard Gear, founded in 2006 and headquartered in Everett, Washington State, is a supplier of differential and traction, driveshafts, transfer cases, and manual transmission. The company offers a diverse range of products, including bearing kits, front driveshafts, dropout housings, front OE replacements, and spider gears. The company’s products find specific applications in automotive repair, off-road upgrades, customization, and drivetrain overhauls. These products are used to ensure smooth operation, performance enhancement, and customization options for differentials, driveshafts, and transmissions in vehicles.

Modern DriveLine, founded in 1998 and located in Caldwell, Idaho, is a supplier and distributor of flywheels and driveshafts. The company’s diverse range of products includes bellhousings, MDL flywheels, MDL clutches, Tremec crossmembers, and supporting parts. These products are utilized for automotive conversions, performance upgrades, custom builds, and proper mounting. The company’s offerings cater to automotive performance enhancement, customization, and conversions. Modern DriveLine's products are used to improve drivetrain compatibility, enhance vehicle performance, and provide customization options within the automotive industry.

American Powertrain, founded in 2003 and located in Cookeville, Tennessee, is a distributor of drivetrain technology. Its broad range of product lines includes Pfitzner sequential, hydraulic clutch systems, clutches, fluids, and electric power steering. The company’s product line is used for different purposes, such as automotive performance enhancement, racing applications, custom builds, clutch optimization, and power steering enhancement. These products cater to vehicle enthusiasts, racers, and customization needs and are used to improve performance and control in the automotive industry.

The Rowland Company was founded in 1732 in Philadelphia, Pennsylvania when Benjamin Franklin was just 25 years old. Today the Rowland Company specializes in the distribution, fabrication, and assembly of industrial power transmission products, including application engineering, and modification of products to customer needs. Industries served include commercial laundry, amusement parks, marine, metalworking, power generation, pulp & paper, transit, water treatment and wastewater treatment Rowland Company’s product categories include air starters, brakes, clutches, crane controls & electrification, flexible couplings, friction and wear materials, gearboxes, industrial lighting & signals, mobile crane brake parts, universal joints, and driveshafts.

Comer Industries S.p.A., established in 1970 and headquartered in Reggiolo, Italy, is an industrial and agricultural mechatronic components and solutions manufacturer. The company's agricultural products include planetary drives, gear boxes, and hydrostatic traction drives. Its industrial products include tractor attachments, electric motors, and single-drum compactors. These products are used in road construction vehicles, mining machines, and construction equipment. The company also owns a number of brands, including Walterscheid, Walterscheid Services, and Mechanics Drive Shafts.

Drive Shafts Incorporated, founded in 1977 and located in Tulsa, Oklahoma, is a designer and custom manufacturer of driveshafts. Its broad range of product lines includes the series transmission yoke, series U-joint, series chromoly transmission yoke, series quick disconnect yoke, and center supporting bearing. The company’s specific product applications include easy maintenance and driveshaft stability. These products are used in connecting and transmitting power within drivetrain systems, enhancing vehicle performance, flexibility, and durability. Drive Shafts Incorporated caters to automotive repair, performance enhancement, customization, and specialized vehicles.

Stromag, founded in 1932 and based in Unna, NRW, Germany, is a manufacturer and supplier of power transmission components. The company's product range includes Brakes, Clutches, Couplings, Limit Switches, and SIOT Monitoring and control. These components are used in various machinery ensuring smooth operation and efficiency. It serves industries such as Amusement Rides and ski Lifts, Cranes and hoists, Elevators and escalators, and Farms and agriculture. Additionally, the company provides services such as customized solutions, technical support, and product maintenance.

Cyner Industrial Co. Ltd. was founded in 1978 in Taichung, Taiwan, and is a manufacturer, developer, and designer of various OEM parts. The company manufactures gears, shafts, and transmission parts for automobiles, motorcycles, electric cart parts, tractors, and machinery. It is a supplier for several major OEM factories in the global market, including in the USA, Europe, the Middle East, and Asia. The company also designs high-precision products, including 250cc to 8,000cc gasoline and diesel engine parts, and is ISO-9001 certified.

Summit Racing Equipment, founded in 1968 and located in Tallmadge, Ohio, is a distributor of automotive parts. The company’s diverse range of products includes cooling and heating, engines and components, exhaust, exteriors and accessories, and fasteners and hardware. These products have specific applications, including engine temperature regulation, performance enhancement, exhaust flow improvement, exterior and interior customization, and secure assembly through fasteners and hardware. These applications are used in the automotive industry to address the diverse needs of vehicle owners. The company's offerings cater to sectors within the automotive industry, including maintenance, restoration, and the aftermarket.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Quigley Motor Company, Inc. |

12.7%

|

| 2 | Mark Williams Enterprises Inc. |

10.4%

|

| 3 | Johnson Power, Ltd. |

10.0%

|

| 4 | The Driveshaft Shop |

7.9%

|

| 5 | Precision Shaft Technologies |

7.4%

|

| 6 | USA Standard Gear |

7.2%

|

| 7 | Sunnen Products Company |

6.0%

|

| 8 | Drive Shafts Incorporated |

5.7%

|

| 9 | Orlandi Gear Co. |

5.4%

|

| 10 | Modern DriveLine |

5.1%

|

Derivation Method

The ranking is calculated based on the click share within the driveshaft page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

11 | 91.7% |

Italy

Italy

|

1 | 8.3% |

89 products found

89 products

Honda Technos Co., Ltd.

300+ people viewing

■We respond to customer requests with our extensive experience in processing materials including iron, stainless steel, aluminum, and cast metals. ...

Maeda Iron Works Co., Ltd.

560+ people viewing

Last viewed: 20 hours ago

This gear shaft is machined with 4 module spur gears and involute serrations, and is finally polished in-house.

Hamakita Kogyo Co., Ltd.

190+ people viewing

Last viewed: 1 day ago

■Features ・Ensuring wear resistance through chilling ・Cantilever hollow products also available

Honda Technos Co., Ltd.

510+ people viewing

Last viewed: 1 hour ago

■We respond to customer requests with our extensive experience in processing materials including iron, stainless steel, aluminum, and cast metals. ...

Suzu Seiki Co., Ltd.

370+ people viewing

Last viewed: 1 hour ago

NC automatic lathe Material: Iron, stainless steel, brass, etc. Lot: from 1 piece The NC automatic lathe is an NC machine for mass production, but ...

Fuji Seiki Co., Ltd.

320+ people viewing

This is an internal component of the device (transmission) that converts the rotational speed of the transmitted power, and is a high-quality, high...

Showa Hatsujo Manufacturing Co., Ltd.

500+ people viewing

■SunS Flex Shaft Flexible shafts are used in industry as an excellent means of transmitting rotational power to distant locations. It has a simple...

Kyushu Hasek Co., Ltd.

490+ people viewing

■Features BS couplings are elastic couplings that use barrel springs (barrel-shaped coil springs) as elements. As for its characteristics, it has e...

Ernest Co., Ltd.

660+ people viewing

Last viewed: 20 hours ago

The drive shaft, which is a representative part of the drive system, is the ``keystone of power transmission'' that transmits the power of the car'...

Yamamoto Neji Kohan Co., Ltd.

300+ people viewing

Last viewed: 6 minutes ago

Kinokuniya Co., Ltd.

180+ people viewing

■Features This is a shaft processed by Kyushu Parts Processing Center.com. There is a thread in the center for attaching a bearing nut. Since the b...

Ernest Co., Ltd.

620+ people viewing

Last viewed: 4 hours ago

The drive shaft, which is a representative part of the drive system, is the ``keystone of power transmission'' that transmits the power of the car'...

Nano Precision Co., Ltd.

470+ people viewing

Last viewed: 22 hours ago

We also manufacture various parts used in the motorcycle. It supports cutting, polishing, and composite processing of various shapes and materials.

YSK CO.,LTD.

430+ people viewing

Last viewed: 1 day ago

■Summary YSK's high-frequency heat treatment technology has successfully refined the shaft surface structure. This microstructure has resulted in t...

Hamakita Kogyo Co., Ltd.

160+ people viewing

Last viewed: 1 day ago

■Features ・Ensuring hardenability through material adjustment - Irregular hollow, induction hardening, processing, and sub-Assemblies also available

Kinokuniya Co., Ltd.

170+ people viewing

■Features This is a shaft manufactured by Kyushu Parts Processing Center.com. Regarding the material, it is manufactured using a steel material cal...

Nano Precision Co., Ltd.

490+ people viewing

Fortune Cross (Thailand) also supplies motor shafts to the air conditioner and electrical field. It supports all kinds of metal shafts, from thick ...

Sanwa Creation Co., Ltd.

400+ people viewing

By combining functions by multilayer film, it achieves high hardness, has excellent burning resistance, abrasion resistance, and corrosion resistan...

Sanwa Creation Co., Ltd.

620+ people viewing

Last viewed: 2 hours ago

Try the pin shaft born from our micron -Submicron accuracy technology. It is used in various fields such as cars, communication, semiconductors, an...

CHAMPION CORPORATION Co., Ltd.

210+ people viewing

This shaft is used to hold the workpiece inside the automatic machine used for plug welding.

Nano Precision Co., Ltd.

620+ people viewing

For automobiles, the axis of the in -vehicle motor is supplied. We supply precision shafts for various in -vehicle motors that require high -precis...

Kinokuniya Co., Ltd.

180+ people viewing

■Features This is a shaft manufactured by Kyushu Parts Processing Center.com. It is stepped, and the second and third steps are manufactured with H...

Accurate Co., Ltd.

320+ people viewing

■Series common specifications ・Material: SUS304 (JIS G4303) ・Hardness: Hv300 or more ・Surface roughness: 1S or less

YSK CO.,LTD.

400+ people viewing

Last viewed: 2 hours ago

■Features The SUS304 rotating shaft is used as the central shaft for rotational motion. By using austenitic stainless steel SUS304, it has a rust p...

YSK CO.,LTD.

400+ people viewing

Last viewed: 1 day ago

■Summary Rust-resistant and wear-resistant stainless steel shaft The new material "YSU-1" has corrosion resistance equivalent to SUS303/304. In add...

Seiichi Kiko Co., Ltd.

1020+ people viewing

A compact solution for easily and accurately transmitting power in equipment with long center distances ■Tightening bolt replacement service If yo...

2 models listed

NK Works Co., Ltd.

200+ people viewing

Last viewed: 1 day ago

■Product overview MAPAL's hydro chuck "High Torque Chuck" has a 3° tapered slim tip model (interference prevention type) and a short heavy duty (he...

10 models listed

Wilco Co., Ltd.

230+ people viewing

Last viewed: 12 hours ago

■Features - Stainless steel shaft with high processing precision. - Suitable for use on bearings, pulley shafts, etc. - EU-RoHS2 compliant product.

8 models listed