All Categories

History

This section provides an overview for spiral conveyors as well as their applications and principles. Also, please take a look at the list of 15 spiral conveyor manufacturers and their company rankings. Here are the top-ranked spiral conveyor companies as of March, 2026: 1.Alliance Industrial Corporation, 2.Innovative manufacturing services,Inc., 3.Millard Manufacturing Corp..

Table of Contents

Categories Related to Spiral Conveyors

Engaged in research on nitride semiconductor growth using the MBE method at Waseda University Graduate School. After graduating from graduate school in 2016, he joined a non-ferrous metal manufacturer.

Engaged in equipment maintenance and engineering work at metal smelting plants. Moved to a chemical manufacturer in 2022. Engaging in similar tasks.

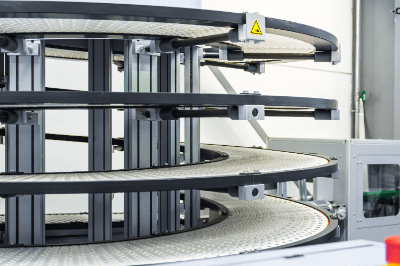

A spiral conveyor is a conveyor (transport device) with a circular, curved shape.

Compared to a normal belt conveyor, a spiral conveyor makes more efficient use of space and saves floor space. Since it can transport either upward or downward, it can carry a large volume of goods in a limited space, even when space is restricted. Because they can transport various types of cargo, from small packages to large products, they are used in a wide range of applications.

Spiral conveyors are used in many applications in the logistics and food processing industries.

In logistics, spiral conveyors are used in automated warehouses. They are highly space efficient and can transport a wide variety of products at high speed. Automated warehouses equipped with spiral conveyors may automatically pick up packages when an order is received and prepare them for shipment.

They may also be used in distribution centers. They can receive and sort large volumes of goods. Since space can be used efficiently, it is ideal for urban areas and places with high land prices.

Food processing lines can transport a variety of foods. Vacuum-packed foods and drinking water in PET bottles are examples. The system can be designed according to the type and shape of food products.

The belts of spiral conveyors are mainly made of resin or stainless steel.

It consists of rectangular resin or stainless steel slats that are connected in a bellows-like structure. They are harder to the touch than belts made of softer materials such as those used in rubber belt conveyors.

The conveyor is equipped with a set of left and right guide rails at both ends to prevent products from falling. Chains are laid vertically at equal intervals between the left and right guide rails, and the belt is mounted on top of the chains to maintain the conveyor's shape. A drive motor transmits rotation to the chain, which drives the belt in the same way as a normal conveyor.

The chain used in spiral conveyors is called a curved chain and has the property of making large lateral bends. This is why the conveyor can maintain its spiral shape. A slat structure is laid on top of the curved chain, and the product is placed on the slat structure and conveyed.

For products with heat sterilization and cooling functions, the perimeter of the conveyor is covered with heat-insulating panels. By exposing the panel-covered interior to steam or cold air, the products on the belt can be heated or cooled.

There are different types of spiral conveyors, such as drum spindle type and drumless type, which can be used depending on the layout. Products with additional functions such as heating sterilization and cooling are also available.

The drum spindle type has a rotating shaft called a drum at the center axis of the spiral conveyor. It has a high conveying capacity and can efficiently convey large loads. It is also relatively easy to maintain and generates little vibration and noise during operation.

The drumless type does not require a drum on the central shaft, and sprockets connected to the shaft control conveyor operation. Compared to the drum spindle type, the drumless type is more compact and can be operated in locations where space is limited. In addition, the speed of the spiral conveyor can be easily adjusted by controlling the number of sprocket rotations.

A spiral conveyor with a cooling function is called a spiral freezer, while one with a heat sterilization function is called a steamer specification, etc. This function is indispensable in the food manufacturing industry and enables food poisoning prevention measures to be taken in accordance with HACCP standards. In addition, products equipped with the CIP automatic cleaning function are widely used in food factories where the growth of food poisoning bacteria must be controlled, since the parts inside the chamber can be easily cleaned.

*Including some distributors, etc.

Sort by Features

Sort by Area

Alliance Industrial Corporation, established in 1973 with headquarters in the USA, is a manufacturer of conveyor systems, material handling equipment, and spare parts. The company's products include spiral conveyors, case conveyors, case and pack elevators, case depalletizers, and trash handling machines. It offers a range of services that include factory acceptance testing, control systems to complement material handling systems, troubleshooting, upgrades, maintenance, and repairs. The company's manufacturing and packaging solutions are used in industries that include process manufacturing and logistics.

Innovative Manufacturing Services, Inc., established in 2003 with headquarters in the UK, is a custom manufacturer of conveyor systems, material handling equipment, and packaging equipment. The company only produces custom turnkey conveyor, material handling, and packaging equipment solutions. Its services include planning, machine and system design, production, installation, and maintenance to meet the manufacturing, handling, or packaging-specific needs of each client. The company's manufacturing and packaging solutions are used in industries that include process manufacturing and logistics.

Millard Manufacturing was founded in 1971 and is based in Omaha, Nebraska. The company designs builds, and installs custom machinery, equipment, and parts, primarily for the food processing industry, to help customers achieve production yields, maintain sanitary environments, reduce costs, and improve safety. The company’s design and engineering are achieved with 3D modeling software from scratch or based on customers’ designs. Manufacturing is achieved with metals ranging from light gauge aluminum to stainless steel plate. Following installation, parts and raw materials are offered as after-market support.

Ryson International Inc. is a company founded in 1995 and is based in Yorktown, Virginia as a manufacturer and supplier of vertical conveying systems. Their product portfolio includes a range of spiral/slat conveyors and bucket elevators. The spiral conveyors and bucket elevators are available in different models and configurations which is the special expertise of the company. The products are used in multiple industries including warehouse and logistics, food and beverage, industrial and manufacturing, consumer packaged goods, and more.

Span Tech LLC., founded in 1988 and based in Glasgow, Kentucky, is a manufacturer of plastic chain conveyors that are capable of vertical, horizontal, and helical bends. The company stocks several types of conveyors like helical, wedge, and twist conveyors, and it also sells the accompanying components like drives, support structures, and chains. It serves industries like food production, manufacturing, and packaging and also offers services that include breakdown repairs, regular conveyor inspections, and service training. The company has its university with training programs to teach users about its conveyor systems.

Bastian Solutions was established in 1952 and is headquartered in Indianapolis, Indiana as a supplier of technological solutions. The company is a system integrator that offers seamless turnkey solutions by combining various equipment, controls, and software products. These solutions are implemented for designing, installing, and commissioning various procedures that are practiced in small-scale or large-scale manufacturing, and distributing industries and at warehouses of suppliers such as material handling, order fulfillment, distribution, etc. From single-component integration to the setting up of completely new systems, the company is equipped to fulfill all sorts of demands.

Atmos is a manufacturer of Warehouse Automation Robotic Systems based in Faridabad, India. They deal in various systems like Dimensioning Weighing Scanning Systems (DWS System) that can automatically capture the dimensions and weight of packages along with Diverting and Sorting Systems that help move from single lane conveyor line to a multiple one. The Robotic Palletizing system provides a solution to load and unload objects and the various types of conveyors provided by Atmos help serve the Transport, Aerospace, Food, Mining, and Pharmaceutical industries and the Warehouse and Distribution sectors.

C-Trak Conveyors Limited, established in 1979 with headquarters in the UK, is a manufacturer of conveyor systems and material handling equipment. The company's products include roller conveyors, inclined conveyors, mild steel gravity rollers for bulk handling, vertical lifts, and rotary tables, among many others. It also provides turnkey conveyor and material handling systems, and its bespoke production services include planning, machine and system design, installation, and maintenance to meet the specific needs of each client.

Astec Conveyors Limited, established in 1998 and with headquarters in the UK, is a manufacturer of conveyor systems, stand-alone belt conveyors, roller conveyors, case conveyors, and pallet conveyors. The company's products include gravity conveyor systems, powered roller accumulation conveyor systems, directional conveyor systems, pallet handling equipment, and modular belt conveyor systems that are used in industries that include manufacturing, packaging, and logistics. It also provides project management, conveyor system control systems, installation, and maintenance services. The company also offers bespoke conveyor production to meet client-specific requirements.

Apollo Group B.V. is a Dutch manufacturer of material handling components and systems established in 1847 and headquartered in Coevorden, Modem. The company's product list includes vertical transport systems (VTS) with optional product twisters, as well as spiral or bucket conveyors, balers and debalers, and pallet handling systems. These are primarily used for material handling operations in warehouses and transport installations for goods sold in bulk. The company's products are commonly used in feed and biomass production, food and beverage packaging, chemical processing, and recycling operations.

Kanetec CO. LTD., founded in 1949 and headquartered in Nagano, Japan, is a designer, manufacturer, and supplier of magnet application equipment. Some of its products include permanent magnetic chucks, electro-magnetic chucks, tesla meters, magnetic holders, and lifting magnets. The magnet products have various uses in several areas, including milling, grinding operations, refrigerators, conveyors, and food processing. All of the motors of 0.75kW or more used in the company’s products are IE3 motors that comply with the Energy Conservation Act in Japan, and the company can also issue a calibration certificate for its measuring instruments upon request.

Intralox, established in 1971 and with headquarters in the USA, is a manufacturer of conveyor belts and conveyor systems. The company's product line includes modular plastic belting, thermodrive conveyor belting, spiral conveyor systems, activated roller belt equipment, and active integration motion equipment used in industries that include manufacturing, packaging, and logistics worldwide. The company's after-sales services include planning, installation, and remote and onsite maintenance. It also offers custom conveyor production to meet client-specific requirements from design to installation.

Nitta Corporation is an Osaka-based manufacturer and distributor of various industrial products founded in 1885. The company offers power transmission and mechatronic products, as well as intermediate components like tubings and fittings. These are used in conveyor machines, hydraulic systems, and medical devices. The company also produces industrial parts, such as molded rubber products like gaskets or diaphragms, as well as air filters and monitoring equipment like particle counters or decontamination devices. Nitta Corporation maintains a network of manufacturing facilities and sales locations in 22 countries across four continents.

CONOVEY, established in 2009 and with headquarters in the USA, is a manufacturer and distributor of conveyor systems and automated packaging machines. The company's product line includes process conveyors, spiral conveyors, packaging belt conveyor systems, shrink wrap machines, and automatic bag inserting machines. Apart from its machines, the company distributes major conveyor and packaging system brands, including QC Conveyors, Gurki Pack, Spantech, and Kenwei. The company also provides a customization service to design, engineer, and produce machines to meet client-specific requirements.

Ranking as of March 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Alliance Industrial Corporation |

13.1%

|

| 2 | Innovative manufacturing services,Inc. |

10.0%

|

| 3 | Millard Manufacturing Corp. |

9.6%

|

| 4 | Intralox |

8.8%

|

| 5 | Ryson International, Inc. |

8.0%

|

| 6 | C-Trak Conveyors |

6.8%

|

| 7 | Atmos System |

6.0%

|

| 8 | Bastian Solutions, LLC |

6.0%

|

| 9 | Astec Conveyors Ltd |

5.6%

|

| 10 | Conovey |

4.8%

|

Derivation Method

The ranking is calculated based on the click share within the spiral conveyor page as of March 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

6 | 60.0% |

United Kingdom

United Kingdom

|

2 | 20.0% |

India

India

|

1 | 10.0% |

Japan

Japan

|

1 | 10.0% |

30 products found

30 products

ITS Co., Ltd.

1160+ people viewing

Last viewed: 15 hours ago

Long-distance, long-distance transportation processes such as cooling, freezing, and fermenting products can be accomplished with a single belt. Ad...

Taniguchi Co., Ltd.

370+ people viewing

Last viewed: 23 hours ago

This is a spring material (spiral) used in vending machines that sell food such as bread. We manufacture various sizes and pitch numbers, so please...

AC Foodtech Co., Ltd.

490+ people viewing

Last viewed: 1 day ago

Spiral freezer GYRoCOMPACT®70 ■Leads the industry as a world standard for technology. Latest model of FrigoscandiaGYRoCOMPACT series GYRoCOMPACT®70...

K's Belltech Co., Ltd.

490+ people viewing

Last viewed: 1 day ago

This conveyor takes advantage of its three-dimensional layout to save space and achieve high throughput. It can be combined with equipment such as ...

AEM Co., Ltd.

340+ people viewing

Last viewed: 1 day ago

A spiral conveyor that just needs to be placed under the cutting machine. Conveys cut pieces such as milling chips using a magnet-equipped conveyor...

ITS Co., Ltd.

530+ people viewing

Last viewed: 6 hours ago

■Spiral system ・Control system: PLC touch screen allows easy operation by the customer. In addition, the operating status and temperature history ...

GEA Japan Co., Ltd.

230+ people viewing

Last viewed: 1 day ago

■GEA Scan Vibro Spiral Elevator GEA Scan Vibro Spiral Elevators are designed for use in various areas of the food, feed, chemical technology and ph...

Matsuo Co., Ltd.

780+ people viewing

Last viewed: 8 hours ago

In order to save labor for farmers, sugarcane is cut and impurities such as leaves and mud are removed.

ITS Co., Ltd.

910+ people viewing

Last viewed: 1 day ago

AccuVeyor AVh is a first-in, first-out system and is our unique dynamic accumulator that can be transported without pressure. The belt guided by th...

Meiwa Co., Ltd.

600+ people viewing

Last viewed: 1 day ago

This equipment performs everything from post-sterilization to cooling of filled and capped products. We also have cooling machines only. We have a ...

Takahashi Galilei Co., Ltd.

590+ people viewing

Last viewed: 1 day ago

Features ■Flexible conveyor layout The conveyor layout can be customized according to the customer's products and requests. You can move freely fro...

Samini Co., Ltd.

450+ people viewing

Last viewed: 7 hours ago

■Unit price by order quantity (yen) ・1-9: 16,500 ・10-19: 15,500 ・20:14,500

Meiwa Co., Ltd.

440+ people viewing

Last viewed: 1 hour ago

This equipment performs everything from post-sterilization to cooling of filled and capped products. We also have cooling machines only. We have a ...

Samini Co., Ltd.

540+ people viewing

■Features There are no seams due to continuous molding, and the surface is smooth and abrasion resistant.

Samini Co., Ltd.

360+ people viewing

■Unit price by order quantity (yen) ・1-9: 8,700 ・10-20: 7,900