51 Vibration Sensor Manufacturers in 2024

This section provides an overview for vibration sensors as well as their applications and principles. Also, please take a look at the list of 51 vibration sensor manufacturers and their company rankings. Here are the top-ranked vibration sensor companies as of October, 2024: 1.Electro-Sensors, Inc., 2.Grace Technologies, 3.Banner Engineering Corporation.

Table of Contents

Categories Related to Vibration Sensors

What Is a Vibration Sensor?

Vibration Sensors are sensing elements used to measure the vibration state of a machine or object.

Vibration Sensors are necessary to understand and monitor the vibration state of a machine. There are three indices that represent the vibration of an object: acceleration, velocity, and displacement. Vibration Sensors measure these physical quantities and convert them into electrical quantities such as voltage and current.

In general, Vibration Sensors are available in two configurations: contact and non-contact. Depending on the physical quantity being measured (acceleration, velocity, displacement) and the conditions of the object, these two types of Vibration Sensors must be used in different ways. In addition, the magnitude and frequency range of the object being measured, as well as the measurement environment, must be taken into consideration when selecting a detailed Vibration Sensor to improve measurement accuracy.

Applications of Vibration Sensors

Vibration Sensors are used in production facilities and research and development. In production facilities, Vibration Sensors are useful for preventive maintenance to detect equipment failures and damage at an early stage. The use of sensors can prevent the occurrence of huge repair costs and loss of production efficiency due to breakdowns and damage.

In recent years, small Vibration Sensors have been used in production facilities, mostly for the purpose of machine diagnostics and predictive maintenance using IoT technology. An example of the use of Vibration Sensors in the field of research and development is the measurement of vibrations in product testing and durability testing.

Vibration Sensors are also used to evaluate passenger comfort, particularly in the automotive industry. Other applications in the field of industrial equipment range from electrical equipment and automobiles to production robots.

Principle of Vibration Sensors

As mentioned above, there are two types of Vibration Sensor configurations: contact and non-contact. Contact Vibration Sensors are used to measure acceleration, while non-contact Vibration Sensors are used to measure velocity and displacement.

This section introduces the principle of each type of Vibration Sensor suitable for various vibration (acceleration, velocity, and displacement) measurements.

1. Contact Type: Acceleration-Sensing Piezoelectric Sensors

Piezoelectric sensors utilize the piezoelectric effect that occurs in piezoelectric materials. The piezoelectric effect is a phenomenon in which a piezoelectric material (piezoelectric element), such as a single crystal of quartz, generates an electric charge on its surface when subjected to a force. The piezoelectric effect produces an electrical signal corresponding to the acceleration.

2. Non-Contact: Laser-Doppler Sensor with Velocity Detection

Laser-Doppler sensors are sensors that utilize the Doppler effect. A laser beam is emitted from the Vibration Sensor to a vibrating object, and the frequency change of the laser beam reflected from the vibrating object is converted into a voltage as a change in velocity.

3. Non-Contact Type: Displacement-Detecting Capacitive Sensor

Capacitive sensors are sensors based on the principle of measuring the capacitance between the sensor and the object to be measured and calculating the distance. When the distance between the sensor and the object to be measured changes, the capacitance value changes, thereby measuring the displacement of Vibration Sensor.

Other Information on Vibration Sensors

1. Detecting Elements of Vibration Sensors

The detection element of mechanical vibration is the temporal change in the magnitude of a quantity representing the motion or displacement of a mechanical system. In many cases, the vibration alternates between a state that is greater than or less than the average or reference value. In general, this vibration is composed of three elements: amplitude, frequency, and phase.

In particular, vibration that repeats at regular intervals is called harmonic vibration and consists of a single frequency. In such cases, displacement, velocity, and acceleration are as follows. By differentiating the displacement, the velocity can be derived, and by differentiating the velocity, the acceleration can be derived.

- Displacement d = Dsin (ωt + Φ)

- Velocity v = Vcos (ωt + Φ)

- Acceleration a = - Asin

D: single amplitude, ω: each velocity ω=2πf, f: frequency f=1/T, T: period (seconds), Φ: initial phase.

The types of Vibration Sensors used to detect this harmonic vibration include Acceleration Sensors (piezoelectric type), Velocity Sensors (electrokinetic type), and Non-contact Displacement Sensors (eddy current type). Among these, the piezoelectric type acceleration sensor in particular is characterized by its ability to cover a wide frequency range.

2. Usage of Vibration Sensors

As an example, we will explain how to use a piezoelectric Vibration Sensor, which is used for vibration monitoring. Piezoelectric Vibration Sensors utilize the piezoelectric effect, and when an external force is applied, they generate and output an electric charge proportional to that force. Piezoelectric Vibration Sensors with charge output are particularly advantageous for miniaturization.

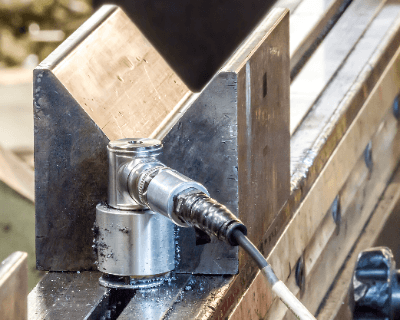

It is important to fix the sensor firmly with stud bolts to ensure it closely adheres to the non-measured object. If the sensor is not firmly attached, it may exhibit distinctive filter characteristics with peculiar attenuation patterns in the frequency response, thus making accurate measurements impossible. Other methods include using adhesives or magnets to fix the sensor.

Frequency analysis is widely used to analyze data detected by Vibration Sensors. Frequency analysis is a method of examining the frequency components and intensity of the measured waveform, and can provide an indicator to determine whether the vibration of an object is in normal operating condition or not.

List of 51 Vibration Sensor Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- United States of America

- China

- Finland

- France

- Germany

- Italy

- Spain

- United Kingdom

-

-

-

Aaronia AG

Vibration Sensors

Manufacturer Overview

Founded in 2003, Aaronia AG is a German manufacturer based in Strickscheid, specializing in measuring, tracking, and monitoring technology. Initially focusing on spectrum analyzers, including the first portable handheld model introduced in 2008, the company expanded its product line to include antennas, preamplifiers, signal generators, shielding materials, and related accessories. In 2013, Aaronia developed AARTOS, a drone detection system, most recently used in the security infrastructure of the 2022 G20 Summit in Bali, Indonesia. With real-time analysis software, Aaronia offers customized integration of hardware components for diverse applications. The company also provides GPS logger software to collect data from the antennas.

-

-

-

-

-

TECAT Performance Systems

strain sensor system

Manufacturer Overview

TECAT Performance Systems LLC, established in 2014 and headquartered in Ann Arbor, Michigan, United States, is a developer and manufacturer of commercial wireless sensor systems. The company's products include the WISER 4000, which has the ability to measure 3-axis acceleration, barometric pressure, and ambient temperature, and the WISER 8000 dual strain measurement and monitoring system that can measure both thrust and torque loads simultaneously. It also provides a base OEM platform with optional measurement parameters for easy client customization. Its products are used in beam oil pumping units, motorsport vehicles, and downhole drilling.

-

-

-

-

-

Electro-Sensors, Inc.

Vibration Sensor

Manufacturer Overview

Electro-Sensors, Inc. operates as a manufacturer of precision sensors and monitoring systems, established in 1968 and headquartered in Minnesota. The company specializes in providing products and services for industries such as industrial manufacturing, agriculture, and material handling.Its offerings include speed sensors, temperature sensors, and hazard monitoring systems. These products are used for precision monitoring and safety assurance, enhancing operational efficiency and safety measures in the industries it serves through its precision sensor and monitoring solutions.

-

-

-

-

-

Dytran Instruments, Inc.

Airborne

Manufacturer Overview

Founded in 1980, Dytran manufactures high-quality dynamic testing solutions from its 45,000-square-foot facility in Chatsworth, California. Dytran designs and manufactures innovative sensors, accelerometers, and associated electronics for measuring dynamic force, pressure, and vibration. The company offers a wide range of product lines, with full in-house customization capabilities to provide customers with a one-stop shop for test and measurement requirements. Dytran's specializations include designing single-axis and triaxial IEPE accelerometers, ultra-high temperature charge mode sensors, pressure sensors, and digital bus-based sensors. Dylan is reputed for its sensor technologies for both product development testing and embedded solutions.

-

-

-

-

-

Banner Engineering Corporation

TEMPERATURE & VIBRATION SENSORS

Manufacturer Overview

Banner Engineering Corporation, established in 1966 and headquartered in Minneapolis, Minnesota, is a manufacturer and supplier of industrial automation products. They offer an extensive range of sensors, including proximity sensors, photoelectric sensors, and limit switches, for detecting object presence, position, and speed. Additionally, Banner provides a different types of switches, such as pushbuttons, toggle switches, and rotary switches, to control electricity flow and offer system feedback. Their wide array of controls includes PLCs, HMIs, and motion controllers, enabling automation of industrial processes.

-

-

-

-

Manufacturer Overview

SpotSee, founded in 1976 and headquartered in Dallas, Texas, is a manufacturer of condition-indicating and monitoring solutions. The company offers a range of products, including ShockWatch, ShockLog, and WarmMark, which are designed to monitor and record shock, temperature, and other environmental conditions. These products are used in industries such as life sciences, transportation, aerospace, and manufacturing to protect sensitive products during transport and storage. Its solutions provides connected, mechanical, and chemical solutions that enable its customers and partners in 62 countries to detect changes in the condition of everything from vaccines to spaceships.

-

-

-

-

-

Motionics, LLC

VIBRATION ANALYSIS AND ROTOR BALANCING

Manufacturer Overview

Motionics, LLC is a developer and manufacturer of software for wireless metrology that was established in Austin, Texas, USA, in 2011. The company offers devices for wireless power monitoring such as voltage probes and power clamps, and tools for wireless measurements of dimensional parameters, such as laser distance meters and bore gauges. It also offers software for diagnosing rotational machinery utilizing electrical signals or vibrations. The company’s products are mainly used by manufacturers of heavy machinery, machine tools, and precision instrumentation.

-

-

-

-

-

Pepperl+Fuchs Inc.

Vibration Sensors

Manufacturer Overview

Pepperl+Fuchs, Inc. was founded in Mannheim, Germany in 1945 developing the forerunner of the proximity switch. Pepperl+Fuchs continues to develop proximity sensors as well as other industrial sensors including ultrasonic sensors, rotary encoders, positioning systems, display and signal processing, vibration monitoring, industrial communication, and signal processing as well as related accessories and software. Explosive protection products include safety barriers, surge protection, wireless solutions, HMI systems, power supplies, electrical explosion protection equipment, level measurement, and related software.

-

-

-

-

-

SignalQuest

Vibration Sensor

Manufacturer Overview

SignalQuest, a company founded in 1997, and based in New Hampshire USA, is a manufacturer, supplier and designer specialized in the production of innovative electronic sensing machines. The company offers a diverse range of products, including zero power tilt, inclinometers, shock and vibration sensors. These sensors find applications in industries such as aerospace, automotive, industrial automation, and robotics. Their sensors provide critical data for monitoring and control systems, enabling accurate measurements of inclination, and acceleration. The company also offers technical support to assist customers with product selection, integration, and troubleshooting.

-

-

-

-

-

CEC Vibration Products LLC

4-131 Vibration Sensor

Manufacturer Overview

CEC Vibration Products LLC, established in 1987 in the United States, is a manufacturer of vibration sensors and condition monitoring equipment. The products of the company include vibration sensors, accelerometers, data acquisition systems, and software. These products are used in several applications, including machinery condition monitoring, rotating equipment monitoring, and structural health monitoring. It is certified by ISO 9001:2015. The company has been providing quality products and services to customers like the United States, Canada, Australia, Brazil, and China.

-

-

-

-

-

Tokin America, Inc

vibration sensor

Manufacturer Overview

Tokin America Inc., headquartered in San Jose, California, is a supplier of passive electronic components in North, South, and Central America and is a subsidiary of Tokin Corporation. Its diverse product range includes capacitors, noise countermeasure components, and sensors used in several industries, including telecommunication, automotive electronics, and digital home appliances. The company also provides specialized design support and works with several distributors within the United States, including Future Electronics, WPG Americas, and Bravo Electronics.

-

-

-

-

-

Machine Saver Inc.

TriVibe Vibration Sensor

Manufacturer Overview

Machine Saver Inc. is a manufacturer and supplier of vibration monitoring and protection systems. Established in 2013, the company is headquartered in Houston, Texas, USA. The company develops, manufactures, and markets a wide range of vibration monitoring products including Vibration Sensors, Proximity Probes, Proximitors or Probe Drivers, Reliability and Machine Health Software as well as offering Reliability Services. Its solutions are designed to help industries prevent equipment failures and downtime. Machine Saver Inc’s main services encompass designing and implementing customized vibration monitoring solutions, catering to a wide range of industries including oil and gas, power generation, and manufacturing.

-

-

-

-

-

Grace Technologies

Vibration Sensors

Manufacturer Overview

Grace Technologies is a manufacturer of electrical safety devices and predictive maintenance tools originally founded as Grace Engineering in 1993 before rebranding in 2020. Based in Davenport, Iowa, the company offers various panel interface connectors, voltage indicators or permanent electrical safety devices (PESDs), and IIoT smart sensor devices under the brand names GracePort, GracePESDs, and GraceSense. Grace Technology products are primarily used by clients in the manufacturing, energy, and infrastructure sectors, including by metal fabricators, water treatment facilities, and power plants.

-

-

-

-

-

PCB Piezotronics

Vibration sensor

Manufacturer Overview

PCB Piezotronics, founded in 1967 and headquartered in North Carolina, is a manufacturer of sensors for design engineers and predictive maintenance. They design and manufacture various sensors such as microphones, vibration, pressure, force, and torque sensors. Their products are used for testing, measurement, monitoring, and control requirements in automotive, aerospace, military, and other industries in order to gather accurate data, ensure safety, enable predictive maintenance, and facilitate advancements across multiple industries. PCB Piezotronics is a subsidiary of Amphenol Corporation.

-

-

-

-

-

ifm efector, inc.

System for vibration monitoring and diagnostics

Manufacturer Overview

ifm efector (ifm) is a subsidiary of ifm electronic, founded in Germany in 1969. ifm has developed, manufactured and marketed sensors and controls technology to industries that include assembly and robotics, automotive, material handling, metal forming, mobile equipment, plastics, and food and beverage. Ifm produces sensors, condition monitoring equipment, image processing, safety technology, industrial communication, IO-link, systems for mobile machines, displays, software, connection technology, voltage supplies, as well as other accessories.

-

-

-

-

-

Resensys, LLC.

Wireless Vibration/Acceleration SenSpot Sensor

Company Overview

Resensys, LLC. is an American manufacturer and supplier of wireless sensor network technology products that was established in 2008 in College Park, Maryland. The company’s product portfolio includes its SENIMAX brand wireless gateway for collecting and transmitting sensor data, as well as its SENSPOT wireless sensors for measuring various physical parameters. It also offers its SENCLOUD brand web-based data visualization and analysis platform, along with its SENBRIDGE data integration software for third-party apps and systems. Aside from its products, the company provides installation, calibration, and personnel training services.

-

-

-

-

-

National Control Devices, LLC

Vibration Sensors

Company Overview

National Control Devices LLC, established in 1995 in Osceola, Missouri, is a manufacturer and designer of IoT-connected NCD devices and hardware for tech companies. The company makes IoT devices such as sensors, relay controllers, and accessories. It also provides services like customizing enclosures and boards and printing colors that help customers reduce wiring, power consumption and production costs. The company has partnered with PyComm, Particle, Losant, Blynk and Cayenne brands. Its authorized distributors include Relay Pros, Reboot Shop, Logic Bus, and Digi Key.

-

-

-

-

-

Jewell Instruments, LLC

Vibration Sensors

Company Overview

Jewell Instruments is headquartered in Manchester, New Hampshire. The company serves industries such as aerospace, geophysical, railroad, laboratory, and data acquisition with various measuring devices and sensors. The company has five product segments: Inertial & Tilt Sensors, GEO Instruments & Sensors, Meters & Avionics, Data Acquisition Hardware, and Triplett Test Equipment Tools. Inertial & Tilt Sensors include accelerometers, inclinometers, and inertial measurement unit devices. GEO Instruments & Sensors includes economical high-precision and ultra-precision sensors. Meters & Avionics include panel meters, avionics, and solenoids.

-

-

-

-

-

Shanghai MOONS' Electric Co., Ltd.

Wireless Supervisor

Manufacturer Overview

MOON’s is headquartered in Shanghai, China. MOON’s is a manufacturer or motion control products. Among these products are stepper drives and motors, brushed and brushless DC motors, servo drives and motors, integrated motors, BLDC drives, lighting drivers and control products, and condition monitoring products. MOON’s has achieved ISO 14001 and ISO 9001 certification.

-

-

-

-

-

Sensotec Group

Vibration

Manufacturer Overview

Sensotec, founded in 1985, is a manufacturer and application service supplier of sensors and transmitters specializing in pressure, level, and force measurements in Cornella de Llobregat, Barcelona. Sensotec offers pressure, level, and force transmitters. Its products cater to various industries and OEM manufacturers, providing sensors, transducers, and transmitters with output signals compatible with diverse measurement equipment. The company owns four brands: Lexitron, Leveltec, Nivomat, and Sensotec. The company serves customers from Africa, Asia, America, Europe, and Oceania.

-

-

-

-

-

Auxitrol Weston

Moderate Temperature Vibration Sensors

Manufacturer Overview

Auxitrol Weston is a manufacturer of sensors for aerospace applications that was established in Bourges, France, in 1888 before its acquisition by TransDigm Group Incorporated in 2019. The company primarily offers speed sensors for testing and simulation scenarios, high-accuracy temperature sensors for performance testing, and pressure sensors for a range of industrial applications. The company is ISO 14001, CAA Part 21, and NADCAP certified. It primarily serves clients in the commercial aerospace, military aerospace, and gas turbine industries.

-

-

-

-

-

Bruel & Kjaer Vibro America, Inc.

Sensors & Vibration Transmitters

Manufacturer Overview

Bruel & Kjaer Vibro America, Inc., established in 1994 as a subsidiary of German company Brüel & Kjær Vibro GmbH is an American service provider and manufacturer of condition monitoring products. Based in Gardnerville, Nevada, the company produces various VIBRO brand devices that collect, analyze, and/or display vibrational data. The devices include VC-8000 rack-based continuous monitoring system, VIBROPORT & VIBROTEST portable onsite measurement instruments, and the VCM-3 wireless connectivity & cloud-based data management system. It also offers accessories and spare parts for various application in the petrochemical, renewable energy, and mining industries.

-

-

-

-

-

TWK-Elektronik Gmbh

Vibration sensor

Manufacturer Overview

TWK-ELEKTRONIK GmbH, established in 1962, is based in Düsseldorf, Germany, and is a manufacturer and supplier of quality industrial sensors and position transducers. The company’s product portfolio includes rotary encoders, linear position sensors, draw-wire sensors, inclination sensors, and electronic modules. These sensors are utilized in a wide range of applications across industries such as automation, robotics, and machine tools.TWK-ELEKTRONIK's sensors provide precise and ideal position feedback, ensuring efficient motion control and accurate positioning in various industrial processes. With an aim to excellence, TWK-ELEKTRONIK continues to deliver state-of-the-art sensor solutions that cater to the demands of the industrial automation sector.

-

-

-

-

-

BDC Electronic S.r.l.

Vibration sensor

Manufacturer Overview

BDC Electronic, established in 1970 and situated in Grugliasco, Italy, is a manufacturer specializing in proximity sensors. The company provides an extensive array of industrial sensors, including ATEX sensors, inductive sensors, capacitive sensors, magnetic sensors, speed sensors, and acceleration sensors. Additionally, they offer supporting products like amplifiers and connectors. BDC Electronic adheres to quality standards certified under ISO 9001:2008, and their products undergo testing in accordance with the EN 60947-5-2 standards.

-

-

-

-

-

Lenord, Bauer & Co. GmbH

Tower oscillation monitor

Manufacturer Overview

Lenord + Bauer (LB) is a German developer and manufacturer of motion sensing solutions and integrated drive technologies originally founded in 1965 as a think tank in Oberhausen. The company produces various analog and digital motion sensors using magnetic and optical principles, motion control systems for managing actuators, drives or motors, and software solutions for parameterization and analysis of LB portfolio products. These supply client manufacturers of critical infrastructure such as Bombardier and Standler railway vehicles, Enercon and Nordex wind turbines, and DMG Mori machine tools.

-

-

-

-

-

Advantech

LoRaWAN Wireless Vibration Sensor

Manufacturer Overview

Advantech was established in 1981 and is a manufacturer and supplier of embedded computing and intelligent connectivity system solutions based in Taiwan. The company offers various IoT hardware and software solution products, including arm-based computing platforms, industrial display systems, advanced video appliances, wireless industrial automation sensors, and industrial ethernet switches. The products created by the company have been certified with REACH Compliance certificate. The company has partnered in the WISE-Marketplace Ecosystem with other businesses, including Anewtech Systems, Ibcon, Mirai Electronics, Lubi Electronics, and BioEnergy Projects Sdn Bhd.

-

-

-

-

-

TE Connectivity

Vibration Sensors - Accelerometers

Manufacturer Overview

TE Connectivity Ltd., started in 2007 and headquartered in Schaffhausen, Switzerland, is a designer and manufacturer of sensor and connectivity solutions for harsh conditions. It operates three primary segments, namely transport, industrial, and communication solutions, and its product portfolio includes automotive connectors, fiber optic connectors, analog power meters, RTD sensors, and circuit breakers. It serves customers in approximately 140 countries and several industries, including aerospace, automotive, rail, IoT connectivity, and E-mobility. The company manufactures 192 billion products annually and has invested over 610 million USD in research development and engineering.

-

-

-

-

Manufacturer Overview

Omron Corporation, started in 1933 and headquartered in Kyoto, Japan, is a manufacturer of automation components, equipment, and systems, and it developed the first contactless proximity switch in 1960. It has four domains, including industrial automation, electronic components, healthcare, and social systems, and it provides products and services in around 120 countries and regions. Some of its products include microsensing devices, access control systems, industrial robots, surveillance cameras, and blood pressure monitors. In 1971, it developed the first online cash machine, and in 1972, it established Japan’s first welfare factory.

-

-

-

-

AirPro Fan & Blower Company

Vibration Sensors

Manufacturer Overview

AirPro Fan & Blower Company was founded in 2002 and is headquartered in Rhinelander, Wisconsin. The company is a manufacturer of industrial fans and blowers that are typically used in industrial manufacturing applications. The company’s fan offerings include high-temperature fans, high-pressure blowers, radial fans, backward fans, and exhaust fans. Custom fan designs are made possible using an online fan selection tool. The company can design, build, and ship custom fans in as little as six days. The company offers several services including maintenance-ready design, installation, operation support, and maintenance services.

-

-

-

-

Manufacturer Overview

ALTHEN, established in 1978, headquartered in Kelkheim, Germany, is a manufacturer and supplier that specializes in providing precision sensors and measurement solutions. Their product range includes strain gauges, load cells, pressure transducers, and displacement sensors, catering to industries such as aerospace, automotive, renewable energy, and robotics. ALTHEN's sensors enable accurate data collection, testing, and monitoring of various parameters critical to the performance and safety of industrial processes and structures. They maintain ISO 9001 and ISO 14001 certifications, ensuring the quality of their products for precise measurements across diverse industrial applications.

-

-

-

-

T&S Communication Co, Ltd.

FBG VIBRATION SENSOR

Company Overview

T&S Communication Co., Ltd., established in 2000 and based in Shenzhen, China, is a manufacturer and supplier of optical communication components. The company's optical products include pre-terminated cable assemblies, connectivity accessories (WDM), PLC splitters, and MT ferrules. It is famous in OEM and ODM services for optical fibre termination products. The company offers optic connectivity products and FBG sensing products to clients from over 50 countries and regions and it holds ISO 9001:2015 certification.

-

-

-

-

-

PCE Instruments UK Ltd

Vibration Sensors

Company Overview

PCE Instruments UK Ltd., started in 199 and headquartered in Manchester, UK, is a manufacturer and supplier of test instruments, equipment, and tools for weighing, measuring, and control systems. The company offers more than 500 test equipment, including analyzers, inspection cameras, meters, detectors, and sensors, with applications in various fields like data acquisition, electrical engineering, environmental science, building inspection, and food processing. Its manufacturing and development division is ISO 9001 certified, all its test instruments, equipment, and tools are factory calibrated, and the company also provides services for custom test instrument design, installation, and maintenance.

-

-

-

-

-

Metra Mess- und Frequenztechnik

Vibration sensor

Company Overview

Metra Mess- und Frequenztechnik, founded in 1944 and based in Radebeul near Dresden, Germany, is a manufacturer and supplier of Piezoelectric vibration sensors and associated instruments. The company's product range includes piezoelectric accelerometers, charge amplifiers, vibration calibrators, and machine monitoring equipment. These solutions find application across diverse industries such as automotive, aerospace, machine building, electrical and more. Metra's services encompass comprehensive vibration measurement solutions, supported by decades of experience. The company’s devotion to quality is evidenced by ISO 9001:2015 certification, while their DAkkS accreditation according to DIN EN ISO/IEC 17025:2018 reinforces their technical competence.

-

-

-

-

-

Electromen Oy

Vibration transducer

Company Overview

Electromen Oy Ltd., founded in 1988 and based in Turku, Finland, is a manufacturer of electronic devices for industrial environments and automation solutions. Its product portfolio includes galvanic isolators, signal converters, motor controllers, transducers, and monitoring devices, mainly serving automation subcontractors and machinery and equipment manufacturers. While its main clients are based in Finland, the company works with international distributors from several countries, including Australia, France, Portugal, Romania, Singapore, and the United Kingdom. It also works directly with the customer to design and develop the product.

-

-

-

-

-

Phonoptics

SENSORS

Company Overview

Phonoptics, established in 2014 and headquartered in Paris, France, is a fiber optic sensor start-up designer, fabless manufacturer, and supplier. The company's products include vibration sensors, acoustic sensor microphones, and vibration sensor accelerometers. It also offers reflectometric pyrometers capable of measuring real-time temperatures, SLD (super luminescent diodes), and boxes providing the optical signal to use Phonoptics fiber optic sensors. The company specializes in developing new measurement solutions for hostile environments and offers custom sensor designs on demand.

-

-

-

-

-

PassatInnovations Ltd.

3-axis Vibration and Temperature Sensor

Company Overview

PassatInnovations Ltd., established in 2013 and headquartered in Mira, Belarus, is a supplier and manufacturer of electrical and control equipment. The company offers an extensive product portfolio featuring microprocessor devices, conveyor control systems, vibration diagnostics systems, and sensors, as well as systems for monitoring the smoothness of conveyance movement. These products have applications across various industries, including electrical, electronic, communication, automation, and metrology, and are instrumental in enhancing control, automation, and precision in processes.

-

-

-

-

-

-

-

-

-

Cable & Supplies, Inc.

VHL3 Component

-

-

-

-

-

Midé Technology Corporation

enDAQ Sensors

-

-

-

-

-

OmniSensing Photonics, LLC

COMPACT LASER VIBRATION SENSOR

-

-

-

-

-

RITTER Starktstromtechnik GmbH & Co. KG

Switchgear

-

-

-

-

-

White Bream

vibration sensor

-

-

-

-

-

Shenzhen QR Technology Development Corporation Ltd

Vibration Sensors

-

-

-

-

-

Sitron

VIBRATION

Company Overview

Sitron, started in 1978 and headquartered in Sao Paulo, Brazil, is a manufacturer of industrial measurement and control solutions used in temperature, pressure, and vibration applications, among others. Its products include hydrostatic level transmitters, flow switches, and pressure transmitters. The company’s CN series of conductive level switches come with integrated internal electronic relays within the housing, eliminating the need for a separate remote controller. In addition, the company’s HFS high-frequency limit level sensor, made using an all-stainless-steel housing, detects the level of fluids or paste-like media while being immune to build-up on the electrodes.

-

-

-

-

-

BalTech Co., Ltd

BT - 3104

-

-

-

-

Distributor Overview

CEMB, founded in Italy in 1946, is a supplier of vertical axis and horizontal axis balancing machines. The company's product portfolio includes equipment designed to balance various rotating components like fans, rotors, turbines, and more. These machines are used when the primary imbalance is along the horizontal axis. Applications include balancing crankshafts, car wheels, and other components where horizontal balance is critical. It also offers fer additional services, including installation, training, and maintenance for the equipment.

-

-

-

-

-

autosen gmbh

Vibration sensors

Distributor Overview

Autosen, located in Essen, Germany, is a supplier of a large selection of sensors, automation technology, and Internet of Things solutions. The company provides position sensors, process sensors, motion control products, and control and signaling devices. It also offers mounting accessories, Internet of Things gateways, and sensor cables. The variants of its process sensors, inductive sensors, have noise immunity and can withstand extremely harsh environments. It has 250,000 devices in stock and over 20,000 customers are satisfied with its products.

-

-

-

-

-

Monitran

vibration sensors

Distributor Overview

Monitran, a London-based supplier of advanced monitoring and measuring systems established in 1986, specializes in vibration and displacement sensors. They offer a wide range of solutions for industries such as manufacturing, energy, and transportation. Monitran's sensor options include accelerometers and velocity sensors, serving diverse applications in industrial processing, power stations, water treatment, wind turbines, mining, and the oil and gas industry. Additionally, Monitran provides project management services, delivering turnkey solutions that seamlessly integrate vibration sensors with monitoring and display hardware, complementing other sensor types and customer control systems.

-

-

-

-

-

Embedded Data Systems

Point Sensor Vibration

Distributor Overview

Embedded Data Systems is a distributor of embeddable systems and sensors that was established in 2001 in Lawrenceburg, Kentucky, USA. The company stocks products from a number of brands including Western Reserve Controls, MeshNet, and MicroDL. These products include portable iButtons for storing and transferring data, data loggers for recording and uploading data, and wireless communication products utilizing Bluetooth or radio frequency protocols. The company also offers discontinued or surplus products to its customers at “closeout” or discounted prices.

-

-

-

-

-

Classic Automation

Vibration Measurement Kit

Distributor Overview

Classic Automation based in Webster, New York is a parts distributor and repair servicer for installed controlled systems, drives, and servo motors, as well as a purchaser of well-maintained surplus systems. Parts that Classic Automation distributes and repairs include DcS, PPLC, and CNC control systems, panel controllers, HMI panels, display panels, drives, encoders, resolvers, and power supplies. Classic automation also offers hard drive repair services and support for customizing functionality in Panelicity controllers.

-

-

Vibration Sensor Manufacturer Ranking

*Including some distributors, etc.Ranking as of October 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Electro-Sensors, Inc. |

6.6%

|

| 2 | Grace Technologies |

6.2%

|

| 3 | ALTHEN |

5.0%

|

| 4 | Pepperl+Fuchs Inc. |

3.7%

|

| 5 | Bruel & Kjaer Vibro America, Inc. |

3.5%

|

| 6 | Dytran Instruments, Inc. |

3.3%

|

| 7 | Banner Engineering Corporation |

3.3%

|

| 8 | Aaronia AG |

3.3%

|

| 9 | SpotSee |

3.1%

|

| 10 | Tokin America, Inc |

3.1%

|

Derivation Method

The ranking is calculated based on the click share within the vibration sensor page as of October 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

- Pepperl+Fuchs Inc.: 7,100

Newly Established Company

- Machine Saver Inc.: 2013 (11 years ago)

- Motionics, LLC: 2011 (13 years ago)

- Resensys, LLC.: 2008 (16 years ago)

Company with a History

- Auxitrol Weston: 1888 (136 years ago)

- CEC Vibration Products LLC: 1937 (87 years ago)

- Bruel & Kjaer Vibro America, Inc.: 1942 (82 years ago)

Vibration Sensor Manufacturers in United States

*Including some distributors, etc.

- TECAT Performance Systems

- Electro-Sensors, Inc.

- Dytran Instruments, Inc.

- Banner Engineering Corporation

- SpotSee

- Motionics, LLC

- Pepperl+Fuchs Inc.

- SignalQuest

- CEC Vibration Products LLC

- Tokin America, Inc

- Machine Saver Inc.

- Grace Technologies

- PCB Piezotronics

- ifm efector, inc.

- Resensys, LLC.

- National Control Devices, LLC

- Jewell Instruments, LLC

Global Distribution of Vibration Sensor Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

17 | 50.0% |

Germany

Germany

|

7 | 20.6% |

Italy

Italy

|

3 | 8.8% |

China

China

|

2 | 5.9% |

United Kingdom

United Kingdom

|

2 | 5.9% |

Spain

Spain

|

1 | 2.9% |

France

France

|

1 | 2.9% |

Finland

Finland

|

1 | 2.9% |

List of Vibration Sensor Products

14 products are listed.

K engineering

Osciroscope vibration sensor KEM-VIB5A

60+ people viewing

Last viewed: 23 hours ago

It is a product with a piezoelectric acceleration sensation and preamplifier. Product features ・ ・ M 1 1 1 1 1 1 1 1 1 1 1 ・ ・ ・ ・ 8 -bit oscillos...

K engineering

Microcomputer ADC vibration sensor KEM-VIB3A

60+ people viewing

It is the best vibration sensor for microcomputers and A/D converters with a signal output of 3.3V. Product features ・ This product is a set of pi...

Malcom

Measurement vibration sensor unit RCM-V with two sensors for gravity acceleration

50+ people viewing

Easy to understand by gravitational acceleration measurement, each X, Y, and Z are displayed with profiles. ■ Features ・ Profile measurement of v...

Logical product Co., Ltd.

Ideal for measurement of shaking 920MHz series high accuracy 3 axis wireless acceleration sensor

40+ people viewing

Last viewed: 13 hours ago

It is a wireless vibration sensor that is ideal for measuring the shaking of bridges, buildings, etc. equipped with a high-precision acceleration s...

Krone Co., Ltd.

Accurate measured water level sensor (depth meter) 8000 series with a depth of 7,000m

80+ people viewing

The digital oats water level sensor enables accurate measurement at a depth of 7,000m, ideal for motion and static pressure observations using the ...