All Categories

History

This section provides an overview for electromagnetic switches as well as their applications and principles. Also, please take a look at the list of 1 electromagnetic switch manufacturers and their company rankings.

Table of Contents

Categories Related to Electromagnetic Switches

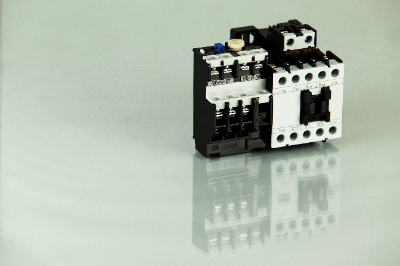

An electromagnetic switch is a switch that combines an electromagnetic contactor, which opens or closes an electric circuit by the action of an electromagnet, and a thermal relay, which interrupts the circuit when overloaded.

An electromagnetic switch is a switch that combines an electromagnetic contactor, which opens or closes an electric circuit by the action of an electromagnet, and a thermal relay, which interrupts the circuit when overloaded.

Most electromagnetic contactors have three main contacts corresponding to a three-phase power supply. In addition, there are several auxiliary contacts, which have a lower current rating than the main contacts. They are used to energize lamps and buzzers to indicate open/closed states or overloads, and for self-maintaining circuits.

Thermal relays detect the overcurrent that flows in the event of an overload and output a signal, but do not themselves have the function of interrupting the circuit. Therefore, they are used in combination with electromagnetic contactors that have a circuit-breaking function.

Electromagnetic switches, unlike circuit switches, are used as a switching function for circuits with relatively large load currents, such as motors. They are mainly used in control panels. When selecting a switch, it is necessary to consider the allowable current, durability of switching, and ease of maintenance.

The most common application is in motor switching circuits. The method of providing an on/off button on the control panel is often used. Auxiliary contacts are used in circuits for self-hold circuits, lamp on/off, overload protection, etc.

For lighting applications, switching functions and overcurrent protection mechanisms are built into the control panel that manages all the lighting in a building.

Three-phase induction motors can be operated in forward and reverse by changing the phase order.

A reversible electromagnetic switch is available to switch between forward and reverse operation using two electromagnetic contactors; a mechanical interlock is incorporated to prevent the two contactors from being turned on at the same time. They are used when forward and reverse rotation is required.

Electromagnetic switches consist of an electromagnetic contactor and a thermal relay.

The electromagnetic contactor consists of an electromagnet, a movable contact, a fixed contact, a coil, and a spring.

When the power is off, the movable and fixed contacts are separated by a spring. When the power is turned on, an electric current flows through the coil and a magnetic field is generated. The electromagnet is pulled by the magnetic field, the movable and fixed contacts contact each other, and current flows into the main circuit.

A thermal relay consists of a bimetal, which is a combination of two metals with different expansion rates, a heater, a push plate, and two connection terminals. When an electric current flows through the thermal relay, heat is generated from the heater in proportion to the magnitude of the current.

The heat causes the bimetal to bend and the push plate to be pushed. If a current greater than the set amount of current flows, the euphemism of the bimetal increases and the circuit is interrupted. This principle protects electrical equipment from overcurrents. For motor loads, it is common practice to set the current setting at 1.73 times the normal value or less.

When the thermal relay is activated, the operating circuit through the auxiliary contact of the electromagnetic contactor is interrupted. The current flowing through the electromagnet coil of the electromagnetic contactor is then turned off, interrupting the main contact circuit and stopping the motor, etc.

The difference between electromagnetic switches and relays is the value of current that can flow through the contacts. Relays are generally used only in control circuits. Relays are generally used only in control circuits, and even when they are used to operate a load, it is limited to a small motor or solenoid valve. The maximum contact capacity of a relay is about 5A.

Electromagnetic switches consist of a main contact that can carry a large current and an auxiliary contact that is used in a control circuit. The current that can flow through the main contact depends on the capacity of the electromagnetic switch, which can be 400 to 1,000A at maximum.

Electromagnetic switch failures can be broadly classified into two types. One is contact failure, which occurs when the contacts fail to make contact due to arcing caused by opening and closing, and the other is contact welding, which occurs when an excessive current flows through the contacts, causing them to stick together.

Contact failure occurs mainly due to deterioration over time. The higher the open/close current and the greater the frequency, the higher the probability of occurrence. Dust between contacts can also cause contact failure, which can be prevented by periodic cleaning.

Contact welding is often caused by forced deterioration and occurs when the load is too large or the wiring is faulty and rare shorts occur.

There are also coil failures. Coil failures include coil disconnections, shorts, and unfastening of the fixed iron core. Disconnection or short-circuit occurs when the control power supply voltage is wrong in the design stage. Coil failure can also occur due to age-related deterioration and can be avoided by periodic replacement, etc.

*Including some distributors, etc.

Sort by Features

Omron Corporation, started in 1933 and headquartered in Kyoto, Japan, is a manufacturer of automation components, equipment, and systems, and it developed the first contactless proximity switch in 1960. It has four domains, including industrial automation, electronic components, healthcare, and social systems, and it provides products and services in around 120 countries and regions. Some of its products include microsensing devices, access control systems, industrial robots, surveillance cameras, and blood pressure monitors. In 1971, it developed the first online cash machine, and in 1972, it established Japan’s first welfare factory.

Number of Employees

Newly Established Company

Company with a History

15 products found

15 products

Kiriyama Manufacturing Co., Ltd.

420+ people viewing

Last viewed: 21 hours ago

It opens and closes the fractionation head, and the opening/closing time can be set automatically using the reflux regulator to set the reflux ratio.

Shimonishi Giken Co., Ltd.

640+ people viewing

Last viewed: 1 hour ago

■Summary An open/close detection sensor uses a magnet to integrate open/close detection function and door holding function. It is also called a mag...

3 models listed