All Categories

History

This section provides an overview for terminal relays as well as their applications and principles. Also, please take a look at the list of 12 terminal relay manufacturers and their company rankings. Here are the top-ranked terminal relay companies as of February, 2026: 1.Wieland ELECTRIC GMBH, 2.Dinkle International Co. Ltd, 3.PHOENIX CONTACT.

Table of Contents

Categories Related to Terminal Relays

Engaged in research on nitride semiconductor growth using the MBE method at Waseda University Graduate School. After graduating from graduate school in 2016, he joined a non-ferrous metal manufacturer.

Engaged in equipment maintenance and engineering work at metal smelting plants. Moved to a chemical manufacturer in 2022. Engaging in similar tasks.

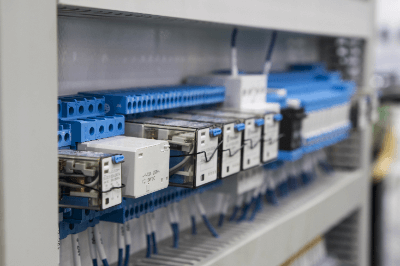

A terminal relay is an input/output signal processing device that integrates multiple relays and terminal blocks.

A terminal relay is an input/output signal processing device that integrates multiple relays and terminal blocks.

It is used as an interface device to relay I/O of programmable controllers and solenoid valves. The main structure of a terminal relay, which plays the role of I/O interface device, is a terminal block on a pedestal with a built-in printed circuit board, and multiple independent single-pole type small relays can be mounted on this pedestal according to the application, as a compact relay structure while excelling in maintainability, This contributes to downsizing of equipment and reduced wiring.

Terminal relays are mainly used in industrial applications.

The following are examples of terminal relay applications:

Generally, microcomputers, PLCs, and other control devices are used to control large industrial equipment in complex ways. While these control devices are capable of complex internal processing, the allowable output signal current is often small. Conducting large currents through these devices may have adverse effects, such as accelerating failure frequency.

Therefore, if you wish to control equipment with large load currents or inrush currents, such as solenoid valves, isolate the outputs of the control equipment by means of relays. However, installing multiple power relays and other relays side by side occupies space and complicates control wiring.

Terminal Relays are a device that combines a terminal block and relay into a single unit, allowing a lineup of small, single-pole relays. Therefore, space and wiring savings can be achieved.

Terminal relays are composed of terminal block components and relay components.

The terminal block component consists of a relay socket and a terminal block. The part that conducts electricity is made of copper or iron screws, and the casing is made of hard synthetic resin. Many products are fixed by tightening the external wiring, which is processed with round terminals, etc., with iron screws.

Generally, most products have sockets that can accommodate four relays, with two inputs and two output terminals per relay. 16-point products are also available. Terminal Relay is sometimes referred to as a relay terminal.

A relay is a component that insulates and relays signals. Terminal relays are generally small, single-pole relays. It is often installed by inserting it into a terminal block component with a pin on the back side. Relay specifications are often printed on the casing on the relay surface, and products with various power supply specifications and signal types are sold.

When selecting a terminal relay, the following considerations should be taken into account:

The number of output points is the number of points that can be output by the terminal relay. Most general-purpose products have 4 output points, but there are products with 16 or 32 output points for connection to PLCs. In the case of a system that controls many devices, the more output points, the less wiring is required.

The input specification is the type of signal input to the coil portion of the relay. 100 VAC, 24 VDC, and other specifications are available. Select the input specification according to the output specification of the control equipment.

Output specifications are the specifications of the signals output by the relay. Factors such as signal type and rated energizing current are included.

Signal types are mainly classified into contact and non-contact. With contacts, the signal is transmitted by mechanically operating a metal section with an electromagnetic coil. It tends to have a large allowable current and has the advantage of being heat resistant. However, it has the disadvantage that the contact parts gradually wear out due to opening and closing operations.

The non-contact method uses semiconductors or solid-state relays to transmit electrical signals. Since there is no physical drive, it can withstand high open/close frequencies and high speed open/close operations. However, they are susceptible to heat and have drawbacks, such as semiconductor components that can fail if currents exceeding their rated currents flow through them.

The rated current rating is the amount of current that can be conducted. The larger the current value, the more capable it is of controlling large loads, but the larger the relay often becomes. Generally, when used as terminal relays, most products have a current-carrying capacity of 1 to 5 A.

*Including some distributors, etc.

Sort by Features

Sort by Area

Honeywell International Inc. was founded in 1885 and headquartered in Charlotte, North Carolina. Honeywell is a diversified technology and manufacturing company to global customers in many industries such as aerospace, building technologies, performance materials, manufacturing, and safety. Honeywell produces hardware and software solutions for each industry it serves. In building technologies, Honeywell designs access controls, electrical and wiring, fire life safety, and employee training services. In aerospace, Honeywell designs cockpit systems and displays, engines, cabin management and cleaning, and health and usage monitoring.

Automation Systems Interconnect (ASI), founded in 1999, is a manufacturer and supplier of electrical and electronic components, universal printing systems, and custom-assembled products based in Mechanicsburg, Pennsylvania. The company’s product portfolio includes cables, cords and connectors, CAM and disconnect switches, and more. Their wide range of industrial components cater to various applications such as automation and control, power distribution and generation, and printed board assembly. The company’s suppliers and partners hold ISO, UL and ATEX certifications to ensure their industrial electrical and electronic components meet industry standards.

OMEGA Engineering Inc., founded in Norwalk, CT, in 1962 is a manufacturer of products used to measure temperature and humidity, flow and level, and pressure. The company's product portfolio includes thermocouple probes and assemblies, pressure gauges and switches, and air velocity measurement systems, wireless systems and portable optic sensors. The company serves markets including Automotive and Electric Vehicles, Renewable Energy and Energy Storage and Electronics and IT Infrastructure. The company also offers customer services that include support, custom research projects and customized services.

c3controls, founded in 1976 and based in Pennsylvania, is a leading manufacturer and supplier of electrical control products. Specializing in a wide array of offerings, c3controls delivers an extensive selection of push buttons, pilot lights, circuit breakers, motor starters, and control relays, encompassing crucial components for electrical control systems. Their product portfolio also encompasses switches, sensors, terminal blocks, and power supplies, catering to diverse applications within industrial environments such as machine control, motor control, power distribution, panel building, and industrial automation systems. Notably, c3controls holds certifications from the International Organization for Standardization (ISO) and Underwriters Laboratories (UL).

Toyogiken Co. Ltd (TOGI) is a manufacturer in electrical machinery and accessories. They design, develop and sell terminal blocks, transformers, cables, box terminals, PC board terminals and related accessories. TOGI headquartered in Nagano, Japan has set up their global operations in China, Taiwan, Korea, Thailand, Indonesia, Malaysia and Vietnam. The company is ISO:9001 2015 certified. In addition they are also involved in solar power business operations. TOGI holds 7 patents, 5 trademark patents and 48 utility model patents.

Wieland, established in 1910 and based in Bamberg, Germany, is a manufacturer and supplier of electrical connection technology. Their product range includes pluggable connections for seamless plug-and-play electrical device connections, insulated connectors that provide electrical insulation in device connections, cable glands for safeguarding cables and ensuring a watertight seal, terminal blocks used for connecting electrical wires, and contact systems facilitating connections between electrical components. Wieland's products find applications in diverse industries, such as building construction, electrical engineering, and automation.

TE Connectivity Ltd., started in 2007 and headquartered in Schaffhausen, Switzerland, is a designer and manufacturer of sensor and connectivity solutions for harsh conditions. It operates three primary segments, namely transport, industrial, and communication solutions, and its product portfolio includes automotive connectors, fiber optic connectors, analog power meters, RTD sensors, and circuit breakers. It serves customers in approximately 140 countries and several industries, including aerospace, automotive, rail, IoT connectivity, and E-mobility. The company manufactures 192 billion products annually and has invested over 610 million USD in research development and engineering.

Omron Corporation, started in 1933 and headquartered in Kyoto, Japan, is a manufacturer of automation components, equipment, and systems, and it developed the first contactless proximity switch in 1960. It has four domains, including industrial automation, electronic components, healthcare, and social systems, and it provides products and services in around 120 countries and regions. Some of its products include microsensing devices, access control systems, industrial robots, surveillance cameras, and blood pressure monitors. In 1971, it developed the first online cash machine, and in 1972, it established Japan’s first welfare factory.

Dinkle Group was established in 1983 and is headquartered in Taipei, Taiwan. Dinkle is a multi-national, ISO 9001-certified manufacturer and distributor of electronics and equipment for industrial sectors such as factory automation, transportation, new energy, telematics, and equipment manufacturing. Dinkle has 4 product lines: terminal blocks, electronics & interface, electronic housings, and tools. Terminal blocks include PCB terminal blocks, barrier terminal blocks, and NEMA terminal blocks. Electronics & interface include interface modules, surge protection devices, and industrial relays. Electronic housings include enclosures for bus systems, DMEB component housing, and PCB carriers. Tools include drivers, marking systems, ferrules, and others.

Phoenix Contact is headquartered in Blomberg, Germany, originally founded in 1923. Phoenix Contact’s Israeli subsidiary was founded in 2006 and located in Quadima Tzoran. Phoenix Contact provides tools and components for e-mobility, power, infrastructure, process industry, production manufacturing, system manufacturing, and others. Phoenix Contact’s product lines include automate including cloud computing, connect including PCB terminal blocks, “mark, assemble, and install” including hand tools, “supply, charge, and protect” including power distributors, and “switch, measure, and monitor” including relays and optocouplers.

Rockwell Automation, Inc. was founded in 1903 and is headquartered in Milwakee, WI. Rockwell Automation provides industrial automation and digital transformation solutions around the world. Rockwell Automation operates through their intelligent devices, software & control, and lifecycle services segments with both hardware and software products and services. The Intelligent Devices segment offers drives, motion, safety, sensing, industrial components, and configured-to-order products. The Software & Control segment provides control and visualization software and hardware, information software, and network and security infrastructure solutions. The Lifecycle Services segment provides consulting, professional services and solutions, and connected and maintenance services through independent distributors.

Beckhoff Automation LLC is the American branch of Beckhoff Automation GmbH & Co. founded in Verl, Germany. The United States headquarters is based in Savage, Minnesota. The company serves industries such as automotive, marine, semiconductors, and alternative energy with hardware and software-based solutions. The company’s five hardware product segments are industrial PCs, fieldbus components for I/O, motion drive systems, MX systems, and system-integrated machine vision products. The company also produces software for automation-related tasks.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Wieland ELECTRIC GMBH |

18.7%

|

| 2 | Dinkle International Co. Ltd |

13.2%

|

| 3 | PHOENIX CONTACT |

12.0%

|

| 4 | TOYOGIKEN CO.,LTD. |

11.6%

|

| 5 | c3controls |

9.9%

|

| 6 | Rockwell Automation |

9.9%

|

| 7 | Automation Systems Interconnect |

8.8%

|

| 8 | TE Connectivity |

8.1%

|

| 9 | Omron |

6.1%

|

| 10 | Beckhoff Automation GmbH & Co. KG |

0.7%

|

Derivation Method

The ranking is calculated based on the click share within the terminal relay page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

4 | 44.4% |

Germany

Germany

|

3 | 33.3% |

Japan

Japan

|

1 | 11.1% |

Taiwan

Taiwan

|

1 | 11.1% |

38 products found

38 products

IDEC Co., Ltd.

1150+ people viewing

Last viewed: 1 hour ago

■Features ・Eco & slim safety measures. 2-pole force-guided relay that reduces costs and saves space ・Forced guide type contact structure (EN50205...

IDEC Co., Ltd.

960+ people viewing

Last viewed: 1 day ago

■Features ・Small high capacity power relay ・It has a high capacity contact of 10A, and the external size of the 1c to 2c contact type is small an...

Shinden Technology Co., Ltd.

710+ people viewing

Last viewed: 1 day ago

16-point MIL connector terminal with 1A, 5A relay. Easy maintenance as only the load side terminal block can be attached and detached. Features ■I...

Shinden Technology Co., Ltd.

550+ people viewing

Last viewed: 1 day ago

32-point MIL connector terminal with 1A, 5A relay. Depending on the application, you can choose the presence or absence of a contact protection cir...

Shinden Technology Co., Ltd.

530+ people viewing

Last viewed: 1 day ago

32-point MIL connector terminal with 1A, 5A relay. Depending on the application, you can choose the presence or absence of a contact protection cir...

Shinden Technology Co., Ltd.

600+ people viewing

Last viewed: 12 hours ago

Case-integrated 1-point terminal equipped with PhotoMOS relay. Ultra slim type with a width of 10mm (Relay rated load capacity 2.7A/60V) Features ...

Shinden Technology Co., Ltd.

770+ people viewing

Last viewed: 1 day ago

A slim 1-point terminal that integrates a relay and a case, allowing you to choose between 1a/5A and 1c/6A. Features ■Slim 1-point relay terminal ...

Shinden Technology Co., Ltd.

530+ people viewing

Last viewed: 1 day ago

Case-integrated 1-point terminal equipped with PhotoMOS relay. Ultra slim type with a width of 10mm (Relay rated load capacity 6A/60V) Features ■P...

Shinden Technology Co., Ltd.

530+ people viewing

Last viewed: 1 day ago

General purpose MY type 4PDT relay Features ■General purpose MY type relay A general-purpose relay suitable for sequence control and power switchi...

Shinden Technology Co., Ltd.

500+ people viewing

Last viewed: 29 minutes ago

16-point relay terminal that allows you to select relays according to your application (relays sold separately) Features ■Can be equipped with var...

Shinden Technology Co., Ltd.

620+ people viewing

Last viewed: 11 hours ago

General purpose MY type DPDT relay Features ■General purpose MY type relay A general-purpose relay suitable for sequence control and power switchi...

Shinden Technology Co., Ltd.

490+ people viewing

Last viewed: 1 day ago

16-point MIL connector terminal with PhotoMOS relay. Two model lineup: NPN (+COM) /PNP (-COM) (Relay rated load capacity 2.7A/60V) Features ■PANAS...

Shinden Technology Co., Ltd.

520+ people viewing

Last viewed: 1 day ago

General purpose LY type 4PDT relay Features ■General purpose LY type relay A general-purpose relay suitable for power switching, capable of switch...

Shinden Technology Co., Ltd.

440+ people viewing

Last viewed: 15 hours ago

32-point MIL connector terminal with PhotoMOS relay. Two model lineup: NPN (+COM) /PNP (-COM) (rated load capacity 2.7A/60V) Features ■PANASONIC A...

Shinden Technology Co., Ltd.

590+ people viewing

Last viewed: 1 day ago

General purpose LY type DPDT relay Features ■General purpose LY type relay As a general-purpose relay suitable for power switching, it is possible...

Shinden Technology Co., Ltd.

420+ people viewing

Last viewed: 1 day ago

32-point MIL connector terminal with PhotoMOS relay. Easy maintenance as the load side terminal block is removable (rated load capacity 2.7A/60V) ...

Shinden Technology Co., Ltd.

560+ people viewing

Last viewed: 1 day ago

General purpose MY type 4PDT relay Features ■General purpose MY type relay A general-purpose relay suitable for sequence control and power switchi...

Shinden Technology Co., Ltd.

570+ people viewing

Last viewed: 21 hours ago

General purpose LY type DPDT relay Features ■General purpose LY type relay As a general-purpose relay suitable for power switching, it is possible...

Shinden Technology Co., Ltd.

630+ people viewing

Last viewed: 1 day ago

2-point terminal integrated into the case with 1A and 5A relays. Adopts OMRON G6B relay that is resistant to inductive loads Features ■Equipped wi...

Shinden Technology Co., Ltd.

670+ people viewing

Last viewed: 3 hours ago

4-point terminal with 1a, 5A relay. Comes with a replacement lever for convenient relay removal Features ■Achieving both compactness and work effi...

Shinden Technology Co., Ltd.

560+ people viewing

Last viewed: 1 day ago

4-point terminal with 1C, 10A relay. Adopts SAMWON SHN relay ideal for heavy load driving Features ■Equipped with SAMWON SHN power relay Ideal for...

Shinden Technology Co., Ltd.

600+ people viewing

Last viewed: 1 day ago

4-point terminal with 1C, 10A relay. Equipped with OMRON G2R relay, ideal for driving heavy loads Features ■Equipped with OMRON G2R relay ・Ideal ...

Shinden Technology Co., Ltd.

600+ people viewing

Last viewed: 2 hours ago

4-point relay terminal that allows you to select the relay according to the application (relay sold separately) Features ■Can be equipped with var...

Toho Technology Co., Ltd.

470+ people viewing

Last viewed: 1 day ago

■Features - Supports 16 and 32 I/O points. - Output signals can be directly controlled, making it suitable for equipment trial runs, debugging, and...

Toho Technology Co., Ltd.

410+ people viewing

Last viewed: 1 day ago

■Features - Supports 8 and 16 I/O points. - Standard valve circuit integrated into one unit. A system can be constructed simply by connecting valve...

Toho Technology Co., Ltd.

440+ people viewing

Last viewed: 1 day ago

■Features ・8 I/O points - Standard type that can be installed on the right side of the duct when placed vertically. ・Self-up type (PS), screw-up ...

Toho Technology Co., Ltd.

590+ people viewing

Last viewed: 1 day ago

■Features - Supports 8 and 16 I/O points. -Equipped with a 2-contact type power relay. Compatible with a wide range of voltage specifications. (DC2...

Toho Technology Co., Ltd.

450+ people viewing

Last viewed: 1 day ago

■Features - Compared to the conventional relay terminal PXGR series, the installation space can be reduced by approximately 40%. ・The lineup inclu...

Toho Technology Co., Ltd.

610+ people viewing

Last viewed: 1 day ago

■Features - Supports 16 and 32 I/O points. - Output signals can be directly controlled, making it suitable for equipment trial runs, debugging, and...

Toho Technology Co., Ltd.

610+ people viewing

Last viewed: 15 hours ago

■Features ・The lineup includes 8 and 16 I/O points. -Equipped with a relay with an arc barrier, which can cut off arcs when switching loads. ・Sin...