27 Negative Temperature Coefficient (NTC) Thermistor Manufacturers in 2024

This section provides an overview for negative temperature coefficient (ntc) thermistors as well as their applications and principles. Also, please take a look at the list of 27 negative temperature coefficient (ntc) thermistor manufacturers and their company rankings. Here are the top-ranked negative temperature coefficient (ntc) thermistor companies as of July, 2024: 1.Vishay Intertechnology, Inc.,, 2.Urbans Aqua Inc., 3.Electronic Controls Corp. (ECC), Div. of Selco Products.

Table of Contents

Engaged in research on nitride semiconductor growth using the MBE method at Waseda University Graduate School. After graduating from graduate school in 2016, he joined a non-ferrous metal manufacturer.

Engaged in equipment maintenance and engineering work at metal smelting plants. Moved to a chemical manufacturer in 2022. Engaging in similar tasks.

What Is a Negative Temperature Coefficient (NTC) Thermistor?

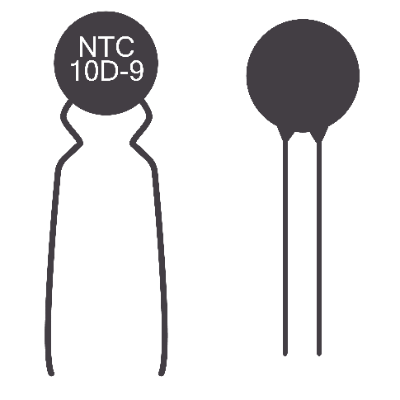

Negative temperature coefficient (NTC) thermistors are electronic components whose resistance decreases as the temperature increases.

Negative temperature coefficient (NTC) thermistors are electronic components whose resistance decreases as the temperature increases.

NTC stands for negative temperature coefficient, meaning that there is a negative correlation between temperature and resistance. Thermistor is derived from "thermal sensitive resistor". A thermistor is a component that can measure temperature from the difference in electrical resistance when a resistive element is brought into contact with the object to be measured. It is characterized by the use of a metal oxide semiconductor as the resistive element.

Negative temperature coefficient (NTC) thermistors are the most versatile of all thermistors because the material is inexpensive and easy to process. They are high-precision thermistors because their resistance value changes even with minute changes in temperature. They are widely used in familiar home appliances and industrial equipment.

They are used as temperature sensors by detecting differences in resistance. Lead type, chip type, disk type, and thin-film type are available.

Uses of Negative Temperature Coefficient (NTC) Thermistors

Negative temperature coefficient (NTC) thermistors are used in a wide range of applications, from industrial applications to home appliances, due to their inexpensive characteristics. They are mainly used as temperature sensors.

- Internal temperature detection in smartphones

- Inrush current reduction in electronic circuit boards

- Temperature measurement in electronic thermometers

- Motor temperature monitoring in vacuum cleaners

- Temperature detection in refrigerators

1. Application to Smartphones

Smartphones use heat-sensitive components and components that lose accuracy due to heat, so it is important to prevent heat buildup. Therefore, the negative temperature coefficient (NTC) thermistor detects internal temperature changes and conveys the information to the IC. In addition to measuring room temperature, NTC thermistors are also used as temperature protection elements to protect circuits from overheating in order to stabilize circuits and prevent failures.

2. Inrush Current Reduction

In electrical and electronic equipment, a large current exceeding the steady-state current value may temporarily flow at power-on. This current is called inrush current. The reason for inrush current may be the initial charging of a large-capacity capacitor.

Negative temperature coefficient (NTC) thermistors are sometimes used to suppress inrush current at power-on by taking advantage of their high resistance value at low temperatures. As the temperature of the thermistor rises due to current loading, the resistance value decreases and power decreases as well.

Since the resistance value decreases as the temperature rises due to energization, power loss can be reduced compared with the use of fixed resistors. Therefore, negative temperature coefficient (NTC) thermistors are used as ICLs (Inrush Current Limiters) to protect circuits of electrical and electronic equipment by easily and effectively limiting inrush currents.

3. Temperature Measurement Circuits

Negative temperature coefficient (NTC) thermistors are widely used in temperature measurement circuits. Since this component detects temperature change by resistance change, it is often used in combination with other resistors. The most commonly used circuit configuration is to use a thermistor connected to a constant voltage source via a pull-up or pull-down resistor.

Principle of Negative Temperature Coefficient (NTC) Thermistors

The main component of the negative temperature coefficient (NTC) thermistor is ceramics, which is a semiconducting ceramics made by mixing and sintering oxides of manganese, nickel, cobalt, etc., with electrodes attached. There are N-type and P-type semiconductors depending on the doping substance.

Normally, the transfer rate of free electrons and holes decreases as the temperature rises. However, in negative temperature coefficient (NTC) thermistors, electrons in the valence band are transferred to the conductor by thermal energy, and the rate of increase of free electrons and holes in the conductor is greater than the rate of increase of free electrons and holes, resulting in lower resistance. Negative temperature coefficient (NTC) thermistors are characterized by a gradual decrease in resistance.

To make negative temperature coefficient (NTC) thermistors, raw oxides are mixed to make a uniform mixture and temporarily baked at 800°C to 1,000°C. They are then pulverized and the grains are sized. After crushing them, the grain size is increased to a size suitable for molding, and then they are formed into their final shape and fired at 1,300-1,500°C. Finally, electrodes are formed and the product is finished by coating with epoxy resin.

How to Select Negative Temperature Coefficient (NTC) Thermistors

Negative temperature coefficient (NTC) thermistors are selected according to application, dimensions, B constant, and resistance value. The application is the use for which negative temperature coefficient (NTC) thermistors are used. These include automotive and electronic board mounting applications. Select a thermistor according to its dimensions and the situation in which it is to be mounted.

The larger the B constant, will create a greater change in resistance with temperature. Therefore, products with a large B constant have high sensitivity, while those with a small B constant have low sensitivity.

The resistance value is the normal resistance value at room temperature (25°C). Generally, a product with a small resistance value should be selected for low-temperature environments, while a product with a large resistance value should be selected for high- temperature environments.

List of 27 Negative Temperature Coefficient (NTC) Thermistor Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- United States of America

- China

- France

- Germany

- Japan

-

-

-

Mitsubishi Materials Corporation

Our NTC-thermistors can accurately measure temperature due to Our unique raw materials

Manufacturer Overview

The Company operates diverse businesses, ranging from nonferrous metals and other fundamental materials to cemented cardide tools/metalworking solutions, the manufacturing of semiconductor-related and electronic components/materials, resource recycling, and renewable energy power generation. In each business, the Company holds the No.1 position in production volume, sales volume, etc.

-

-

-

-

-

ifm efector, inc.

Temperature plugs

Manufacturer Overview

ifm efector (ifm) is a subsidiary of ifm electronic, founded in Germany in 1969. ifm has developed, manufactured and marketed sensors and controls technology to industries that include assembly and robotics, automotive, material handling, metal forming, mobile equipment, plastics, and food and beverage. Ifm produces sensors, condition monitoring equipment, image processing, safety technology, industrial communication, IO-link, systems for mobile machines, displays, software, connection technology, voltage supplies, as well as other accessories.

-

-

-

-

-

Brandywine Communications

FREQUENCY DISTRIBUTION UNITS

Manufacturer Overview

Brandywine Communications is a time and frequency products manufacturer that was established in Tustin, California in 1995. The company’s product lineup includes clock timers and displays, GPS time servers, network time protocol devices, and time code equipment for converting or distributing time codes. It also offers PTP grandmaster clocks for precision time protocol operations, along with custom design and engineering services for unique projects. The company’s products are commonly used by clients in the transportation, space exploration, and armed forces sectors, including by the United States Navy, Army, and Air Force.

-

-

-

-

-

Electronic Controls Corp. (ECC), Div. of Selco Products

NTC Thermistors

Manufacturer Overview

Selco Products was founded in 1958 and is headquartered in Reno, Nevada. The ISO 9001:2008-certified company is a global manufacturer of customized electronic components. The company serves several markets including medical, HVAC, electronics, and aerospace OEMs and end-user companies, leveraging JIT delivery, Kansan, and engineering support. Electronics offerings include thermistors, temperature controls, panel instruments, and signal converters. Non-electronics include buttons, knobs, and other accessories used in digital and analog electronics controls.

-

-

-

-

-

Vishay Intertechnology, Inc.,

THERMISTORS - NTC THERMISTORS

Manufacturer Overview

Vishay Intertechnology, Inc. (Vishay) was incorporated in 1962 and is headquartered in Malvern, Pennsylvania. The company serves the industrial, automotive, telecommunications, consumer products, and medical end markets and sells its products under numerous brand names inlcuding Siliconix, Draloric, Beyschlag, UltraSource, and Applied Thin-Film Products. The company manufactures and sells discrete semiconductors and passive electronic components in globally while operating in six market segments: MOSFETs, diodes, optoelectronic components, resistors, inductors, and capacitors.

-

-

-

-

-

Amphenol Thermometrics, Inc.

THERMOMETRICS | NTC THERMISTORS

Manufacturer Overview

Amphenol Advanced Sensors, established in 1999 and headquartered in St. Marys, Pennsylvania, is a manufacturer and supplier of sensing technologies. Their diverse product portfolio includes temperature sensors like RTDs, thermocouples, and thermistors, serving applications in industrial automation, medical devices, and environmental monitoring. Furthermore, they offer a wide range of pressure sensors, such as absolute pressure, differential pressure, and vacuum sensors, utilized in industrial automation, medical devices, and automotive industries. They also provide an extensive array of air quality sensors, including CO2, VOC, and particulate sensors, serving applications in environmental monitoring, building automation, and healthcare sectors.

-

-

-

-

-

Resin Tech Inc.

NTC Thermistors

Manufacturer Overview

Resin Tech Inc. is an American-made water treatment products manufacturer established in Camden, New Jersey since 1986. The company offers multiple items in its product catalogue. For example, its Ion Exchange Resin aimed for removing ionic impurities in small and large watser systems. It also produces cartridges, fiberglass tanks and testing kits to detect several kinds of water pollution. The venture also offers various services like custom product engineering, resin regeneration or RO membrane restoration. In addition, it serves all kinds of industries, including mining, municipal water, power generation, radwaste treatment, and more.

-

-

-

-

-

Littelfuse

NTC and PTC Thermistors

Manufacturer Overview

Littelfuse founded in 1927, is an industrial manufacturing company empowering a sustainable, connected, and safer world, headquartered in Chicago, Illinois, United States. The company's product portfolio includes the solutions for both individual and entire systems, as a global manufacturer of technologies in circuit protection, power control, and sensing. Across more than 20 countries, and with approximately 18,000 global associates, partner with customers to design and deliver advanced solutions. Serving over 100,000 end customers, their products are found in industrial, transportation, and electronics end markets.

-

-

-

-

-

Ametherm, Inc.

Inrush Current Limiter

Company Overview

Ametherm, Inc., established in 1994 is a manufacturer and supplier of inrush current limiting solutions headquartered in Carson City, Nevada, U.S.A. Its product portfolio is segmented into inrush current limiters and sensing thermistors such as Disc & chip NTC thermistors, thermistor probes, surface mount thermistors, NTC probes, and end-band surface mount thermistors. The company is ISO:9001:2015 certified, and it offers power thermistors that meet the UL and CSA standards. It offers products used in various electrical devices in residential & commercial, industrial, healthcare, renewable energy, and electric vehicle applications.

-

-

-

-

-

Mini-Circuits

Voltage Controlled Oscillators VCOs

Company Overview

Mini-Circuits, founded in 1968 and headquartered in Brooklyn, New York, is a designer, manufacturer, and distributor of RF and microwave components and integrated assemblies. The company’s range of products includes adapters, amplifiers, attenuators, cables, and frequency multipliers. Mini-Circuits' products are used to provide essential components and solutions for RF and microwave communication, signal processing, and testing across industries such as telecommunications, aerospace, defense, research, and manufacturing. Their offerings enable efficient signal transmission and manipulation in diverse applications where RF and microwave technologies play a role. The company also holds ISO 9001, AS 9100, and ISO 14001 certifications.

-

-

-

-

-

NIC Components Corp.

Thermistors

Company Overview

NIC Components Corp., and Nippon Industries Co. Ltd. have collaborated for over 37 years to design and manufacture passive components, including capacitors, resistors, and magnetics. Established in the USA in 1982, NIC has expanded its business to the custom speciality that meets the demands of today’s emerging and latest technology. Their regional offices can be found in Canada, Malaysia, India, Mexico, China, etc. All of their products are built with more features and are certified with different ISO certifications. They also assist their customers in component selection through live support.

-

-

-

-

-

Magengine Co.,ltd

Soft Ferrite

Manufacturer Overview

Magengine Co.,ltd was founded in 2005 and is a manufacturer of neodymium iron boron, samarium cobalt, ferrite, aluminum nickel cobalt, and magnetic tools based in Xicheng, Beijing, China. The company manufactures various products such as linear motor, casting steel, bonded magnets, soft ferrite, and EV charger products. The products have been used in various industries such as automobile, wind power, servo motors, rail transit, and medical equipments. The company has passed the ISO 9001:2015 certification for the quality management system.

-

-

-

-

-

Neosid Pemetzrieder GmbH & Co. KG

EMI ferrite cores

Manufacturer Overview

NEOSID., Ltd., founded in Germany, in 1923 is a manufacturer of custom ferrites, inductances and RFID transponders. The company's product portfolio includes Shielded Inductors, Air core coils, Rod core chokes, Transponder coils and Filter and Coil Kits. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and Power Generation. The company provides services such as Product Selection Guidance, Engineering Support, New Product Design and Development and Custom Manufacturing.

-

-

-

-

-

TDK Electronics

Sensors and Sensor Systems

Manufacturer Overview

TDK Electronics, established in 1935 and headquartered in Tokyo, Japan, is a developer, manufacturer of electronic components and systems. Its product portfolio spans capacitors, ferrites, and inductors, including piezo and protection devices. The company also offers sensors and sensor systems, covering temperature, pressure, magnetic, and MEMS sensors. Furthermore, TDK provides power supplies, energy devices, magnetic heads, and more, all branded under TDK, EPCOS, InvenSense, Micronas, Tronics, and TDK-Lambda, catering to diverse electronic needs. The company operates about 20 development and manufacturing sites, along with a network of design, manufacturing locations, and sales offices situated in Asia, Europe, North America, and South America.

-

-

-

-

-

Auxitrol Weston

Thermistors

Manufacturer Overview

Auxitrol Weston is a manufacturer of sensors for aerospace applications that was established in Bourges, France, in 1888 before its acquisition by TransDigm Group Incorporated in 2019. The company primarily offers speed sensors for testing and simulation scenarios, high-accuracy temperature sensors for performance testing, and pressure sensors for a range of industrial applications. The company is ISO 14001, CAA Part 21, and NADCAP certified. It primarily serves clients in the commercial aerospace, military aerospace, and gas turbine industries.

-

-

-

-

-

KOA Corporation

Thermistors

Manufacturer Overview

KOA Corporation, established in 1940 in Minowa-machi, Japan, is a manufacturer of electronic components. The company provides an extensive product range including resistors, current sense shunt resistors, fuses, thermal sensors, and inductors. These quality components find applications in industries such as automotive, ecology, energy conservation, telecommunications, power supply units, and home appliances. Operating under the guiding principles of circulation, finite resources, harmony, and enrichment, it continues to provide sustainable electronic solutions to cater to the ever-changing demands of global industries.

-

-

-

-

-

HOKURIKU ELECTRIC INDUSTRY CO.,LTD

NTC Thermistor

Manufacturer Overview

Hokuriku Electric Industry Co. LTD., founded in 1943 and headquartered in Toyama, Japan, is a manufacturer and supplier of electronic components. Some of its products include circuit modules, fixed resistors, printed circuit boards, variable resistors, and NTC Thermistors, and it has eight domestic affiliate companies and 11 overseas affiliate companies, including HDK America Inc., and HDK China Ltd. The company is ISO 14001 certified, and it is working on producing products that are RoHS compliant. Its net sales for the 2022 fiscal year were 45.46 billion Japanese Yen, which was a 5.01 billion YoY increase from 2021.

-

-

-

-

-

Murata Manufacturing Co., Ltd.

NTC Thermistors

Manufacturer Overview

Murata Manufacturing Co., Ltd. (Murata Manufacturing) was founded in 1944 and is headquartered in Nagaokakyo, Japan. Murata Manufacturing designs, manufactures, and sells ceramic-based passive electronic components and solutions globally. The company operates through components, modules, and others segments, serving communications, mobility, industrial, healthcare, and personal electronics customers. They company's product offerings include noise suppression products, quartz devices,RFID devices, phase shifters, and wireless connectivity platforms. Services such as webinars and video library are also available for existing and potential customers alike.

-

-

-

-

-

Acme Chip Technology Co.

NTC THERMISTORS

Manufacturer Overview

Acme Chip Technology Co. Ltd., founded in 2008 and based in Shenzhen, China, is a distributor of electronic components that is ISO 9001 certified. Its products include sensors, power supplies, and optical inspection equipment sourced from several manufacturers, including Advanced Linear Devices Inc., Central Semiconductor Corp., and Fluke. The company also offers a large stock of electronic components, including obsolete components and old code chips that are always available for immediate shipment.

-

-

-

-

-

Kemtron Ltd.

Ferrites for EMI Suppression

Manufacturer Overview

Kemtron Ltd., founded in 1980 and currently a subsidiary of TE Connectivity, is a British manufacturer headquartered in Braintree, Essex, producing valves and fluid control equipment. The company's valve range includes ball, butterfly, and check valves. It also offers other variants including control, needle, and safety relief valves. In addition, the company produces manual, electric, and pneumatic actuators to operate valves. Pipe fittings, like flanges, elbows, and couplings, are also available for fluid handling systems. These products find applications in various fields, including food and beverage production, chemical and pharmaceutical processing, and water treatment plants.

-

-

-

-

-

Xiamen SET Electronics Co.,Ltd.

Inrush Current Limiting NTC Thermistor NTC

Manufacturer Overview

Xiamen SET Electronics Co. Ltd., established in 2000 and headquartered in Xiamen, China, is a manufacturer of circuit protection components. The company provides technology that includes over-temperature protection, over-voltage protection, and over-current protection. Its products include cartridge fuse-links, surge protection fuses for low-power systems, and gas discharge tubes. These components are used in various applications, including for home appliances, personal computing, and lighting products. It serves industries that include telecommunications, new energy, and automotive.

-

-

-

-

-

TE Connectivity

NTC THERMISTORS

Manufacturer Overview

TE Connectivity Ltd., started in 2007 and headquartered in Schaffhausen, Switzerland, is a designer and manufacturer of sensor and connectivity solutions for harsh conditions. It operates three primary segments, namely transport, industrial, and communication solutions, and its product portfolio includes automotive connectors, fiber optic connectors, analog power meters, RTD sensors, and circuit breakers. It serves customers in approximately 140 countries and several industries, including aerospace, automotive, rail, IoT connectivity, and E-mobility. The company manufactures 192 billion products annually and has invested over 610 million USD in research development and engineering.

-

-

-

-

-

Duracell

NTC Thermistor

Manufacturer Overview

Duracell is a battery manufacturer that finds its origin in 1924 in Burlington, Massachusetts. The company's long lasting presence in the field shows it as a key party in historical events, like its development of long lasting batteries needed in hot climates during World War II, or its part in the production of Kodac film cameras in the 1960s. The venture's product catalogue ranges from coppertop batteries to hearing aid batteries, offering lithium coins, rechargeable units and power stations along the way. In addition, it's is partnered with reputable brands in North America, including XBOX, OMRON, envidia, and Coleman.

-

-

-

-

-

Trigon Components

NTC

-

-

-

-

-

shengyuic

NTC Thermistors

Company Overview

Shenzhen Shengyu Electronics Technology Ltd., founded in 2008 and headquartered in Shenzhen, China, is an electric component distributor that is ISO 9001 certified. The company stocks several components, including switches, capacitors, and resistors, which it sources from multiple manufacturers like Seiko Instruments, Inc., Renesas Electronics America, and Nuvoton Technology Corporation America. Depending on the size and configuration of the customer’s components, the company provides a full range of packaging services. It accepts single or multiple-part quotations, and its website allows customers to search hundreds of products ranging from ICs to computer accessories.

-

-

-

-

-

TEWA TEMPERATURE SENSORS Sp. z o.o.

NTC thermistor

-

-

-

-

-

Urbans Aqua Inc.

NTC Temperature Sensor

Distributor Overview

Urbans Aqua Inc., founded in 2017, and headquartered in Lima, Pennsylvania, is a supplier and distributor of water treatment solutions. The company offers a range of products to solve water treatment challenges, and some of its products include Ion Exchange Resins, Activated Carbon, Filter Media, Parts & Pumps, and Systems. Its products are designed to keep water clean and drinkable. As members of Water Quality Association (WQA) the company offers products which have been tested against ANSI standards and are NSF or WQA Gold Seal certified.

-

-

Negative Temperature Coefficient (NTC) Thermistor Manufacturer Ranking

*Including some distributors, etc.Ranking as of July 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Vishay Intertechnology, Inc., |

11.9%

|

| 2 | Urbans Aqua Inc. |

8.7%

|

| 3 | Resin Tech Inc. |

7.9%

|

| 4 | Electronic Controls Corp. (ECC), Div. of Selco Products |

7.9%

|

| 5 | Duracell |

6.3%

|

| 6 | Amphenol Thermometrics, Inc. |

5.6%

|

| 7 | HOKURIKU ELECTRIC INDUSTRY CO.,LTD |

5.6%

|

| 8 | NIC Components Corp. |

4.8%

|

| 9 | Murata Manufacturing Co., Ltd. |

4.0%

|

| 10 | ifm efector, inc. |

4.0%

|

Derivation Method

The ranking is calculated based on the click share within the negative temperature coefficient (ntc) thermistor page as of July 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

- Murata Manufacturing Co., Ltd.: 77,581

- Mitsubishi Materials Corporation: 5,450

- HOKURIKU ELECTRIC INDUSTRY CO.,LTD: 1,907

Newly Established Company

- Magengine Co.,ltd: 2005 (19 years ago)

- Brandywine Communications: 1995 (29 years ago)

- Urbans Aqua Inc.: 1984 (40 years ago)

Company with a History

- Auxitrol Weston: 1888 (136 years ago)

- Littelfuse: 1927 (97 years ago)

- Duracell: 1940 (84 years ago)

Negative Temperature Coefficient (NTC) Thermistor Manufacturers in United States

*Including some distributors, etc.

- ifm efector, inc.

- Brandywine Communications

- Electronic Controls Corp. (ECC), Div. of Selco Products

- Vishay Intertechnology, Inc.,

- Amphenol Thermometrics, Inc.

- Resin Tech Inc.

- Littelfuse

- Ametherm, Inc.

- Mini-Circuits

- NIC Components Corp.

Global Distribution of Negative Temperature Coefficient (NTC) Thermistor Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

10 | 58.8% |

Japan

Japan

|

4 | 23.5% |

China

China

|

1 | 5.9% |

Germany

Germany

|

1 | 5.9% |

France

France

|

1 | 5.9% |