20 Non-Contact Temperature Sensor Manufacturers in 2024

This section provides an overview for non-contact temperature sensors as well as their applications and principles. Also, please take a look at the list of 20 non-contact temperature sensor manufacturers and their company rankings. Here are the top-ranked non-contact temperature sensor companies as of July, 2024: 1.Tempsens, Inc., 2.OMEGA Engineering inc., 3.Pixsys Electronics.

Table of Contents

Categories Related to Non-Contact Temperature Sensors

Engaged in research on nitride semiconductor growth using the MBE method at Waseda University Graduate School. After graduating from graduate school in 2016, he joined a non-ferrous metal manufacturer.

Engaged in equipment maintenance and engineering work at metal smelting plants. Moved to a chemical manufacturer in 2022. Engaging in similar tasks.

What Is a Non-Contact Temperature Sensor?

A non-contact temperature sensor is a sensor that can detect temperature without being directly attached to the object being measured.

A non-contact temperature sensor is a sensor that can detect temperature without being directly attached to the object being measured.

They use infrared rays emitted by an object or scattered by incident neutrons. Most non-contact temperature sensors on the market are infrared sensors. Infrared rays are detected using a sensing element, and the emissivity is used to calculate the temperature of the object being measured. Emissivity is the amount of infrared radiation relative to the surface temperature determined for each object, and is necessary when using non-contact temperature sensors.

Non-contact sensors have a specific range or distance over which they can measure, and the range over which they can measure is called the spot diameter. The smaller the spot diameter is compared to the object or person being measured, the more stable the temperature can be measured. In addition, when measuring high-temperature objects, it is necessary to take measures such as cooling the non-contact temperature sensor to prevent it from being damaged due to the heat generated by the sensor itself.

Uses of Non-Contact Temperature Sensors

Non-contact temperature sensors are used in a wide range of applications, from everyday life to industrial use. The following are examples of non-contact temperature sensor applications.

- Measuring the temperature of food during the baking process in food factories

- Temperature measurement to determine the degree of drying of industrial products after painting

- Measurement of product temperature distribution during lathing

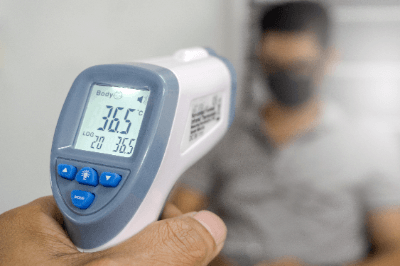

- Measurement of body temperature

Non-contact temperature sensors are used in situations where it is difficult or impossible to measure with contact-type temperature sensors. Specifically, they are used for moving or rotating objects.

It is also used to measure body temperature. They are used in numerous situations, such as in restaurants and when going to work in an office. Compared to contact thermometers that are inserted under the arm, the advantages of these thermometers are that they measure temperature faster and are more hygienic, eliminating the need to disinfect them after each use.

On the other hand, because they use infrared rays, they are greatly affected by external factors such as ambient temperature and sunlight. In addition, they are less accurate than contact sensors. It is necessary to adjust the temperature calculation method and improve the environment while taking into consideration the location where the non-contact temperature sensor will actually be utilized.

Principle of Non-Contact Temperature Sensors

A non-contact temperature sensor using infrared rays consists of a light-collecting lens, thermopile, amplifying amplifier, and arithmetic unit. Temperature is measured in the following sequence

1. Infrared Light Collection

Infrared light is invisible from 0.7 to 1,000 μm. Within this frequency range, only frequencies between 0.7 μm and 20 μm are used for practical temperature measurements.

This light is focused using an infrared condenser lens. By focusing infrared rays in the wavelength range detectable by the thermopile, measurement accuracy can be improved.

2. Conversion to Electrical Signals

Thermopiles are used to convert infrared rays into electrical signals for output. The thermopile is an infrared detection element that outputs an electrical signal in response to the temperature heated by infrared rays.

Within the thermopile, multiple thermocouples are connected in series with the warm junction facing the center, and an infrared absorbing film is placed at the center where the warm junction faces. Light collected by the lens hits only the warm junction, creating a temperature difference between the warm junction and the cold junction on the outside. This creates a voltage difference due to the Seebeck effect, enabling temperature measurement.

3. Amplification of Electrical Signals

An amplifying amplifier is used to amplify the electrical signal emitted from the thermopile. Amplification enables detection with higher accuracy.

4. Calculating Temperature From Emissivity

Corrections are made to calculate the temperature of the object to be measured. Emissivity is used for the correction. Emissivity is the ratio of the amount of infrared radiation emitted to the surface temperature of an object, which is a constant value for each object.

The temperature of the object to be measured is calculated using the amount of infrared radiation detected from the electrical signal converted by the thermopile and the emissivity of the object to be measured, which is measured in advance.

Types of Non-Contact Temperature Sensors

Non-contact temperature sensors can be classified into portable and installed types.

1. Portable Type

Portable sensors are held by a person and used to measure temperatures. Since it does not require a power supply, it can be easily carried around. They are lightweight, compact, and often inexpensive, ranging from several thousand yen to several tens of thousands of yen.

2. Installation Type

The target object passes in front of the device, and the temperature can be measured automatically without human intervention. Many of these products combine a thermographic camera and other equipment, and are often expensive, ranging from several hundred thousand yen to several million yen. The measurement does not require the user to touch the device, and depending on the device, measurements can be taken from a distance of 0.5 to 1.5 meters.

List of 20 Non-Contact Temperature Sensor Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- United States of America

- Germany

- Italy

- Japan

- United Kingdom

-

-

-

Banner Engineering Corporation

More Sensors, More Solutions.

Manufacturer Overview

Banner Engineering Corporation, established in 1966 and headquartered in Minneapolis, Minnesota, is a manufacturer and supplier of industrial automation products. They offer an extensive range of sensors, including proximity sensors, photoelectric sensors, and limit switches, for detecting object presence, position, and speed. Additionally, Banner provides a different types of switches, such as pushbuttons, toggle switches, and rotary switches, to control electricity flow and offer system feedback. Their wide array of controls includes PLCs, HMIs, and motion controllers, enabling automation of industrial processes.

-

-

-

-

-

Advanced Energy Industries, Inc.

FluorOptic Fiber Optic Temperature Sensors

Manufacturer Overview

Advanced Energy Industries, Inc., founded in 1981 and based in Denver, Colorado, is a manufacturer, distributor, and supplier of precision power conversion, measurement, and control solutions. Its products, include AC-DC power supply units, DC-DC conversion products, and high voltage amplifiers, which are used in mission-critical applications across various industries such as healthcare, telecommunications, and industrial equipment. The company offers on-site support, capable of securing and mounting products, managing electrical connections, and conducting tests as per specifications.

-

-

-

-

-

OMEGA Engineering inc.

Infrared thermocouple / Infrared thermometer

Manufacturer Overview

OMEGA Engineering was originally begun in 1962 as a manufacturer of thermocouples and has grown to over 100,000 products for measurement and control of temperature, humidity, pressure, strain force, flow, level pH, and conductivity as well as customer service including data acquisition, electric heating, and custom-engineered products. Additionally, OMEGA offers tools to serve as reference for engineers around the world. OMEGA Engineering serves the aerospace, automotive, wireless, sanitary, test & measurement, process control, power monitoring, environmental, and laboratory markets.

-

-

-

-

-

-

-

Optex Fee

Non-Contact Thermometers

Manufacturer Overview

Optex Fee Co., Ltd., was established in 2002 and based in Kyoto, Japan, is a manufacturer and supplier of factory automation sensors and solutions. The company offers an extensive and diversified product portfolio including photoelectric sensors, fiber-optic sensors, displacement sensors, non-contact thermometers, vision sensors, and other industrial automation products. These sensors and solutions play a pivotal role in enhancing manufacturing processes across a spectrum of industries, including automotive, electronics, and packaging.

-

-

-

-

Manufacturer Overview

Chino, headquartered in Tokyo, Japan, is engaged in the manufacture and sale of measurement and control equipment and instrumentation work. The company was founded in 1936 as Chino Seisakusho. Chino operates in the area of "measurement, control, and monitoring" and contributes to the development of all industrial fields. Major products include recorders, regulators, temperature sensors, data loggers, radiation thermometers, thermal image measuring devices/thermal cameras, composition meters, moisture meters, thickness meters, thyristor regulators, and fuel cell evaluation and testing devices.

-

-

-

-

-

HORIBA

Radiation Thermometer

Manufacturer Overview

HORIBA RADIO LABORATORY was established in Japan in 1945 and has spent the last three-quarters of a century growing as an R&D company and engaged in international operations. HORIBA Scientific offers 200 years of experience developing high-performance scientific instruments and analytical solutions. The HORIBA Group of worldwide companies provides an extensive array of instruments and systems for applications ranging from automotive R&D, process and environmental monitoring, in-vitro medical diagnostics, semiconductor manufacturing, and metrology to a broad range of scientific R&D and QC measurements. Operating in Asia, Europe, and North and South America, HORIBA scientific develops solutions that go beyond just products.

-

-

-

-

-

AMETEK Land

Non-contact thermometer

Manufacturer Overview

AMETEK Land was founded in the UK in 1947, and acquired by the Process & Analytical Instruments Division of AMETEK, Inc in 2006, is a manufacturer of monitors and analyzers for industrial infrared non-contact temperature measurement, combustion efficiency, and environmental pollutant emissions. The company is a supplier of product application solutions to world industries including steelmaking, glass making, minerals processing, hydrocarbon processing, and thermal power generation. Aligned with their expert knowledge, they meet the challenges of a wide range of applications, delivering process safety and process control that the customers depend on.

-

-

-

-

-

Proxitron GmbH

Pyrometer / Thermal camera

Manufacturer Overview

Proxitron GmbH, founded in 1979, and based in Elmshorn, Germany, is a manufacturer of optoelectronic systems for industrial color detection and measurement. Its product line includes inductive sensors, optical sensors, path and distance measurement systems, pyrometers, and flow sensors. These products are used for various applications like metal object detection, distance measurement, temperature measurement, and flow monitoring. The company maintains ISO 9001 certification, ensuring industry standards in its manufacturing processes and product quality.

-

-

-

-

-

Dr. Georg Maurer GmbH

Digital infrared pyrometer

Manufacturer Overview

Dr. Georg Maurer GmbH Optoelektronik (MAURER) is German manufacturer of infrared thermometers for non-contact temperature measurement founded in 1945 and based in Kohlberg. The company produces various thermal imaging cameras for capturing infrared radiation, pyrometers for measuring the temperature of an object or a surface, and line scanners that analyze an object or surface using a rotating mirror and thermal imaging camera. These have applications in metals, glass, plastics, and food manufacturing, as well as in research laboratories. MAURER also provides calibration, training, and repair services, as well as custom software development for clients with niche requirements.

-

-

-

-

-

SENSATEC Co., Ltd.

Temperature and humidity sensor

Manufacturer Overview

SENSATEC Co. Ltd., established in 1988 and based in Kyoto, Japan, is a manufacturer and supplier of OEM sensors. The company specializes in crafting electronic detection and control devices, medical tools, and beauty equipment, including various sensors, A/D/D/A converters, and optical fiber data systems. Its diverse product range also includes cable and coil winding processing, and it provides support for metal mask manufacturing. The company also offers tailored designs emphasizing miniaturization and handles everything from standard strips to soldering and assembly.

-

-

-

-

-

Omron

ES2-HB-N / THB-N

Manufacturer Overview

Omron Corporation, started in 1933 and headquartered in Kyoto, Japan, is a manufacturer of automation components, equipment, and systems, and it developed the first contactless proximity switch in 1960. It has four domains, including industrial automation, electronic components, healthcare, and social systems, and it provides products and services in around 120 countries and regions. Some of its products include microsensing devices, access control systems, industrial robots, surveillance cameras, and blood pressure monitors. In 1971, it developed the first online cash machine, and in 1972, it established Japan’s first welfare factory.

-

-

-

-

-

Tempsens, Inc.

Non Contact Temperature Sensors

Manufacturer Overview

Tempsens Instruments (I) Pvt. Ltd., established in 1990 and currently a subsidiary of Pyrotech Electronics Pvt. Ltd., is an Indian manufacturer headquartered in Udaipur, Rajasthan, specializing in thermal and cable products. The company offers a range of products encompassing cables and wires, contact temperature sensors, circulating chillers, heating cables and mats, and industrial heaters. Its portfolio also includes industrial and laboratory furnaces, mineral insulated cables, nickel and thermocouple alloys, non-contact temperature sensors, and temperature calibrators. Additionally, the company provides thermal profiling systems and thermocouples with molded connectors. These products find applications in various industries, including cement, glass, petrochemical, pharmaceutical, and steel sectors.

-

-

-

-

-

Micro-Epsilon

Infrared pyrometer

Manufacturer Overview

Micro-Epsilon was originally founded in Osaka and Micro-Epsilon America was founded in 1998, headquartered in Raleigh, North Carolina. Micro-Epsilon develops, manufactures, and distributes sensors to aerospace, battery production, glass production, wind power, precision optics, medical technology, transportation, semiconductor, and other industries. Micro-Epsilon’s sensor product categories include inductive, capacitive, laser, confocal, laser distance, magneto-inductive, draw-wire, rotation speed, color, paint thickness measurement, and fiber optic sensors in addition to interferometers and other sensor equipment.

-

-

-

-

-

Texense

Infrared temperature sensor

Manufacturer Overview

Texense, founded in Nevers, France is a manufacturer of embedded sensors. The company's product portfolio includes Inertial Boxes, IR Temperature Sensors, Lean Angle Sensors, Miniature pressure sensors, and Pitot Sensors. Their products are used by international racing teams from F1, NASCAR, and Moto GP. The company serves markets including Automotive and Electric Vehicles, aviation and Electronics and IT. The company also provides services including global distribution, preventative maintenance, troubleshooting, repair and customer service.

-

-

-

-

-

Fluke Process Instruments

Infrared linescanner

Manufacturer Overview

Fluke Process Instruments, founded in Everett, Washington, in 2017 is a manufacturer of Noncontact temperature measurement and profiling equipment. The company's product portfolio includes Industrial Temperature Sensors, Infrared Noncontact Temperature Measurement, Infrared Thermometry, Fiber Optic Temperature Measurement, and Thermal Imaging equipment. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and Power Generation. They also provide services including product selection, installation, preventative maintenance, troubleshooting, and repair.

-

-

-

-

-

Optris GmbH

Infrared thermometers & pyrometer

Company Overview

Optris GmbH, founded in 2003 in Germany, is a manufacturer and supplier of cutting-edge temperature measurement solutions. The company’s product portfolio encompasses a wide range of infrared cameras and pyrometers designed for non-contact temperature measurement in various applications. These technologies find applications across industries such as manufacturing, research, and industrial process monitoring. The company aims to provide quality and accurate temperature measurement solutions to optimize processes and enhance efficiency. With a passion for technological brilliance and customer satisfaction, Optris continues to enhance advancements in temperature measurement technology and its applications.

-

-

-

-

-

Japan Sensor

Non-Contact Temperature Sensor

Company Overview

Japan Sensor Corporation, founded in 1972, is a Japanese manufacturer based in Minato-ku, Tokyo, specializing in infrared measurement solutions. The company's product range includes fiber-type, fiber-less, and general-purpose infrared thermometers. These products feature quartz-permeable wavelengths, enabling measurement through glass, as well as the fastest response time of 0.001 seconds, facilitating rapid detection of temperature changes. Sensor heads, fiber cables, and temperature converters are also installed based on specific requirements. The company also offers indicating setters for infrared thermometers and emissivity meters.

-

-

-

-

-

SSS Corporation

Noncontact temperature sensors

Company Overview

SSS Corporation, founded in 2000 and based in Kuwana City, Japan, is a manufacturer and supplier specializing in custom non-contact thermometers. The company's product portfolio includes gas concentration measurement sensors, standard wide-field type noncontact thermometers, and standard point-focus type noncontact thermometers. These products are used in various sectors, including food processing, environmental monitoring, and oil and gas industry. The company offers online resources to educate customers on the proper use and maintenance of the products, as well as customization of its thermometers.

-

-

-

-

-

Pixsys Electronics

Non-contact temperature sensor

Company Overview

Pixsys Electronics was established in the early 1990s and is headquartered in Pianiga near Padua, Italy. The company services industrial sectors such as railway, water treatment, plastics, and refrigeration to customers globally. The company’s hardware components include controllers, terminals, converters, sensors, and others. The company also provides software tools for monitoring hardware performance. The company also sells a multizone monitoring and recording system called iModView and a graphic datalogger called iTrendView.

-

-

Non-Contact Temperature Sensor Manufacturer Ranking

*Including some distributors, etc.Ranking as of July 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Tempsens, Inc. |

11.8%

|

| 2 | OMEGA Engineering inc. |

8.8%

|

| 3 | Pixsys Electronics |

7.6%

|

| 4 | AMETEK Land |

7.1%

|

| 5 | Texense |

7.1%

|

| 6 | Proxitron GmbH |

6.5%

|

| 7 | Dr. Georg Maurer GmbH |

5.9%

|

| 8 | Fluke Process Instruments |

5.9%

|

| 9 | Micro-Epsilon |

4.7%

|

| 10 | Optris GmbH |

4.1%

|

Derivation Method

The ranking is calculated based on the click share within the non-contact temperature sensor page as of July 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

- HORIBA: 8,205

- CHINO: 994

- Optex Fee: 254

Newly Established Company

- Optris GmbH: 2003 (21 years ago)

- Optex Fee: 2002 (22 years ago)

- Tempsens, Inc.: 1976 (48 years ago)

Company with a History

- CHINO: 1936 (88 years ago)

- Shinko Technos Co., Ltd.: 1945 (79 years ago)

- HORIBA: 1945 (79 years ago)

Non-Contact Temperature Sensor Manufacturers in United States

*Including some distributors, etc.

Global Distribution of Non-Contact Temperature Sensor Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

Japan

Japan

|

4 | 33.3% |

United States of America

United States of America

|

3 | 25.0% |

Germany

Germany

|

3 | 25.0% |

United Kingdom

United Kingdom

|

1 | 8.3% |

Italy

Italy

|

1 | 8.3% |

List of Non-Contact Temperature Sensor Products

27 products are listed.

A and Day Co., Ltd.

Skin infrared body thermometer Saes Air (Cise AIR)

20+ people viewing

[Bluetooth®] Skin infrared thermometer CISE AIR (sesea Air) that can be measured in non -contact. The amount of body temperature (armpit temperatur...

Micro-Epsilon JAPAN K.K.

Non -contact temperature sensor for metal processing - Thermometer CTM2

30+ people viewing

The infrared temperature sensor of the Thermometer CT series is suitable for a wide range of applications in non -contact temperature measurements,...

SSS Corporation

Sensor product Non-contact temperature sensor SST Series Atractive type (for general use, 5V power supply, 0-5V output)

30+ people viewing

The "SST Temperature Sensor/SSS Temperature Switch Series" has a popular version for general applications and a low -priced version for specific ap...

SSS Corporation

Sensor product Non -contact temperature sensor SST series equipment Incorporation / small, low -cost, cylindrical type

30+ people viewing

The "SST Temperature Sensor/SSS Temperature Switch Series" has a popular version for general applications and a low -priced version for specific ap...

SSS Corporation

Sensor product Non -contact temperature sensor SST series Equipment, small, low -cost, cable horizontal type (metal / aluminum housing)

30+ people viewing

The "SST Temperature Sensor/SSS Temperature Switch Series" has a popular version for general applications and a low -priced version for specific ap...

SSS Corporation

Sensor product non -contact temperature sensor NSPXS, mounting bracket for NSM

30+ people viewing

Last viewed: 8 hours ago

Examples of use ・ For initial examination evaluation ・ Installation bracket for NSPXS and NSM (with youth screw, with hexagonal wrench) External...

SSS Corporation

Sensor product non-contact temperature sensor SST series wide-visual field type (popular version for general use, 0-5V output)

30+ people viewing

Last viewed: 8 hours ago

The "SST Temperature Sensor/SSS Temperature Switch Series" has a popular version for general applications and a low -priced version for specific ap...

SSS Corporation

Sensor product Non -contact temperature sensor SST series equipment Incorporation / small / low -priced type

30+ people viewing

The "SST Temperature Sensor/SSS Temperature Switch Series" has a popular version for general applications and a low -priced version for specific ap...

SSS Corporation

Sensor product Non-contact temperature sensor SST Series Intracignular type (for general use, 12-24V power supply, 0-5V output)

30+ people viewing

The "SST Temperature Sensor/SSS Temperature Switch Series" has a popular version for general applications and a low -priced version for specific ap...

SSS Corporation

Sensor product Non-contact temperature sensor SST Series Point Focus custom (popular version for general use, 0-5V output)

30+ people viewing

The "SST Temperature Sensor/SSS Temperature Switch Series" has a popular version for general applications and a low -priced version for specific ap...

Micro-Epsilon JAPAN K.K.

Non-contact temperature sensor for metal and composite materials-Thermometer CT-M3

30+ people viewing

Measured infrared temperature sensor of 2.3 μm of measurement wavelengths suitable for measurement of 50 ° C or higher The infrared temperature se...

Micro Control Systems Co., Ltd.

Brewing sensor temperature sensor R-bee

30+ people viewing

We support the "visualization" of the brewing process. Quickly grasp with a tablet and save data to the PC for each season. It is a local type of b...

Shinko Technos Co., Ltd.

Infrared sensor (non-contact) RD-600 series

30+ people viewing

■ Measurement of glossy metal surface is possible Small infrared temperature sensor of 2.3 meters wavelength. Glossy metal surface, secondary metal...

Shinko Technos Co., Ltd.

Infrared sensor (non-contact) RD-500 series

40+ people viewing

Last viewed: 3 hours ago

・ There is a visual angle type and a cross -focus type that can measure 5φ. ・ Easy selection with a simple lineup ・ Unified with the same size o...

Thank you Technos Co., Ltd.

Aiface non -contact face authentication type thermal measuring instrument

20+ people viewing

We will guide you to the non -contact face authentication type thermal measuring instrument AIFACE as a new colonavirus countermeasure product. Mea...

Shinko Technos Co., Ltd.

Infrared sensor (non-contact) RD-715-HA

30+ people viewing

Last viewed: 3 hours ago

・ Temperature measurement by non -contact ・ Fast response time: 14 ms (90 %response) ・ Compact detection end ・ Temperature range 0 to 500 ° C ...

SANKO ELECTRONIC LABORATORY CO.,LTD

Non-contact thermometer measurement "Deko Pitot" Management Medical Equipment Skin infrared body thermometer UT-701

20+ people viewing

■ Features ・ Non -contact type: Sanitary without touching the skin ・ Easy: Measurement of about 1 second just to hold over the forehead ・ Attach...