39 Insulation Resistance Tester Manufacturers in 2024

This section provides an overview for insulation resistance testers as well as their applications and principles. Also, please take a look at the list of 39 insulation resistance tester manufacturers and their company rankings. Here are the top-ranked insulation resistance tester companies as of July, 2024: 1.SCHLEICH, 2.Klein Tools, Inc., 3.Tempco Electric Heater Corp..

Table of Contents

What Is an Insulation Tester?

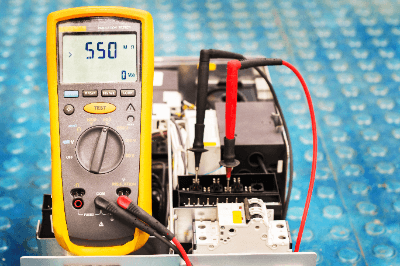

An insulation tester is a device used to diagnose insulation conditions. Insulation resistance testers capable of applying high voltages of about 1,000 VDC according to the system voltage are also available.

It is essential for any equipment that uses electricity to be well insulated. If the insulation deteriorates, it can cause electrical leakage, fire, or electric shock. To prevent the above accidents from occurring, it is necessary to evaluate the insulation performance periodically with an insulation resistance tester.

Usage of Insulation Testers

Insulation testers are used to quantify insulation capability. It is rarely seen in ordinary households.

In production, they are used for the final testing of electrical products at the factory where they are shipped. In addition, maintenance personnel of electrical equipment often have it as a measuring instrument for maintenance.

Resistance measurement involves the application of a voltage, and the applied voltage varies according to the system voltage.

Insulation Tester Principle

Insulation testers include wiring terminals, switches, DC power supplies, ammeters, and current protection elements.

The wiring terminal uses two terminals: the ground terminal and the line terminal. The ground terminal is grounded, and the line terminal is connected to the measuring section for measurement.

By pressing the switch, a DC voltage created by a DC power supply is applied. The minute current flowing to the earth is called leakage current, and the insulation resistance is obtained by measuring the leakage current when the voltage is used with an ammeter.

Since a high-voltage is applied, the impedance is increased with a current protection element to prevent overcurrents from flowing in the circuit. Due to the existing protection element, the internal impedance of the insulation resistance tester is designed to be very high.

The insulation performance is better with a higher the insulation resistance value. The insulation resistance value will be extremely low if an insulation breakdown occurs.

Other Information on Insulation Testers

Insulation resistance testers measure the insulation condition of electric lines and electrical components installed in factories and homes.

Causes of insulation defects may include poor installation of electrical circuits, poor insulation between charging and non-charging parts, deterioration over time, deterioration of internal wiring, damage due to shorts in parts used, and damage to the housing. If left unattended, these problems can lead to extremely dangerous electrical leakage, fires, and electrocution.

To prevent such problems, shut off the power supply system and measure insulation resistance as soon as the leakage breaker trips or an electric shock occur during operation appears.

List of 39 Insulation Resistance Tester Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- United States of America

- China

- Denmark

- Germany

- Japan

- Poland

- Taiwan

- United Kingdom

-

-

-

Associated Research

Hypot

Manufacturer Overview

Associated Research is a manufacturer of electrical safety products and equipment that was established in Illinois, USA, in 1936 before becoming a brand of the Chinese company Ikonix in 2023. The company’s product lineup includes ground bond testers for measuring resistance of protective ground circuits, hipot testers for dielectric withstand tests in the safety certification process, insulation resistance testers for measuring the resistance of insulating materials for enclosures. The company’s products are commonly used in medical device manufacturing, consumer appliance testing, and electric vehicle production operations.

-

-

-

-

-

Ikonix

Hypot

Manufacturer Overview

Associated Research (an Iknnix brand), established in 1936 and headquartered in Taoyüan, Taiwan, is a R&D manufacturer of test and measurement solutions for the electrical safety compliance industry. The company's products include the Hypot Series for Hipot testing, DC Hipot test, or Insulation Resistance testing, multiplexers that provide some of the largest productivity improvements for the electrical safety compliance industry, and the proprietary WithStand Software as a Service (SaaS) platform for cloud storage of tests and data. Services provided to clients include instrument calibration, repairs, and online software download updates.

-

-

-

-

-

FLUKE Corporation

Megohmmeter insulation testers

Manufacturer Overview

Headquartered in Everett, Washington, Fluke is an American-born company operating since 1948. Fluke offers a variety of testing equipment including digital multimeters, thermal cameras, solar PV testing equipment, thermometers, oscilloscopes, leak detection devices, as well as testing-equipment related accessories. Fluke offers direct online sales.

-

-

-

-

-

Tempco Electric Heater Corp.

Insulation Resistance Testers

Manufacturer Overview

Tempco is based in Wood Dale, Illinois and has been in business since 1972. Tempco is a manufacturer of many types of heating elements and thermocouples with design variations. Tempco is ISO 9001:2015 certified. Temco’s electric heaters and elements include band heaters, cartridge heaters, cast-in heaters, ceramic fiber heaters, coil and cable heaters, drum heaters, enclosure heaters, flexible heaters, heat trace cable, heated hose and tubing, infrared heaters, process heaters, shroud systems, strip heaters, tank heaters, and tubular heaters. Tempco also sells various application accessories and wiring accessories.

-

-

-

-

-

Keysight Technologies

U1450A/60A Series

Company Overview

Keysight Technologies, Inc. was founded in 1939 and headquartered in Santa Rosa, California. Keysight is a global developer and manufacturer of electronic design and test solutions to communications, networking, aerospace, defense, and government, automotive, energy, semiconductor, electronic, and education industries. Keysight’s communications solutions group solutions include electronic design automation software; radio frequency and microwave test solutions, hardware and virtual network test platforms and software applications, as well as optical laser source solutions. Keysight’s electronic industrial solutions group offers various design tools and verification tools. Keysight offers product support, technical support, and training and consulting services. It sells its products through direct sales force, distributors, resellers, and manufacturer's representatives.

-

-

-

-

-

-

-

SONEL S.A.

Insulation Resistance Meters

Manufacturer Overview

SONEL S.A. is a Polish manufacturer of high-quality measuring instruments for power, industry, and telecommunications. The company manufactures test equipment such as meters for measuring current, voltage, short-circuit loop impedance, insulation resistance, residual current protection, and ground resistance. It also offers power quality analyzers, equipment safety testers, thermal imaging cameras, wire and cable locators, as well as multimeters, clamp meters, low resistance meters, lux meters, and more.

-

-

-

-

Manufacturer Overview

SCHLEICH, established in 1935, is headquartered in Schwäbisch Gmünd, Germany, as a manufacturer of toy figurines and playsets. The company's product includes a diverse range of meticulously designed figurines spanning various themes such as wildlife, dinosaurs, farm animals, and mythical creatures. The company has won awards such as the Toy of the Year Award in 2018 for its detailed Horse Club sets. In addition, the company's diverse target market encompasses children, parents, educators, and enthusiasts, while international collaborations extend to partnerships with retailers and educational institutions.

-

-

-

-

-

-

-

HV Hipot Electric Co., Ltd.

INSULATION & EARTH RESISTANCE TESTER

Manufacturer Overview

HV Hipot Electric Co., Ltd., established in 2003 and based in Wuhan, China, is a manufacturer of electrical safety testing equipment. The company specializes in high voltage testing equipment and tests various kinds of electrical products, such as transformers, circuit breakers, surge arresters, generators and insulators. It also produces products like transformer, switch-gear, electric energy and battery test equipment, partial discharge measurement device and relay protection tester. The company provides OEM and customization services as well as inspection, maintenance and calibration services for its test equipment.

-

-

-

-

-

HV Hipot Tester Electric Co., Ltd.

Ground/Insulation Resistance Tester

Manufacturer Overview

HV Hipot Tester Electric Co., Ltd., founded in 2003 and based in China, is a manufacturer of electrical safety testing equipment, especially high voltage testing equipment. The company is a national high-tech organisation that has a 2000-square-meter 8S contemporary management and manufacturing facility and around 1500 square metres of high-tech, intelligent office space. Products from the company are utilised in the diagnostic assessment, proof testing, and preventive maintenance testing of electrical cables. It evaluates various electrical equipment, including GIS systems, transformers, circuit breakers, surge arresters, and generators. The company holds ISO and CE certification.

-

-

-

-

-

HD Power Test Equipment Co.ltd

Insulation Resistance Tester

Manufacturer Overview

HD Power Test Equipment Co., Ltd., established in 2001 and headquartered in Dongxihu District, Wuhan City, is a manufacturer specializing in electronic instruments and electrical safety testing equipment. The company offers an array of products, including the battery discharge load tester hdfd-2220, hdsd automatic open cup flash point tester, and hdgc3970 battery charge tester for 110v battery packs. These products find applications in various industries, such as motive power battery testing, power utility battery testing, and battery testing for lithium technology.

-

-

-

-

-

TECPEL CO.,LTD.

Megohm / Insulation Tester

Manufacturer Overview

TECPEL CO.,LTD. was established in 1990 and is a manufacturer of test and measurement devices based in Xindian, New Taipei City, Taiwan. The company manufactures various devices such as digital thermometers, temperature humidity transmitters, digital pH meters, digital handheld multimeters, and light meters datalogger. The products are manufactured under the CE requirements standards. The company was awarded the Asia-Pacific e-Business Champions of the Year 2008 from Alibaba. The company participated in various exhibitions such as Taitronix Exhibition, The 9th Taipei International Instrument Exhibition, and The Automotive Electronics Show 2018.

-

-

-

-

-

Haida International Equipment Co., Ltd.

Insulation resistance tester

Manufacturer Overview

Haida International Equipment was founded in 2004 as a manufacturer and supplier of Testing Equipment in China. The company deals in various precision testing instruments, machines, and services such as Batteries, Furniture, Textiles, Leather and Shoes, and Rubber and Plastic test equipment. There is also Adhesive tape, Cookware, Luggage, Optical, and Vibration test equipment along with Accelerated Environment Test Chamber (AES) that executes QC inspection on electronic appliances, paper products, metals, research institutes, and lots more. The other testing machines cater to industrial and mining enterprises, colleges and universities, engineering quality supervision stations, and other departments.

-

-

-

-

-

Good Will Instrument Co., Ltd

Safety tester

Manufacturer Overview

GW Instek or Good Will Instruments is a Taiwanese instrument maker founded in 1975. GW Instek has over 300 product lines, which include Oscilloscopes, Spectrum Analyzers, Signal Sources, Basic Tests and Measurement Instruments, Safety Monitoring Systems, and more. Leading manufacturers choose them as their test and measurement provider. GW Instek has become the leading brand in the electronic test and measurement industry. They help electronic industries reduce testing costs and increase competitiveness. GW Instek has subsidiaries in five countries and is sold to more than 80. Their mission is to reduce total costs and create customers value from cost savings.

-

-

-

-

-

Sanwa Electric Instrument Co., Ltd.

Insulation tester

Manufacturer Overview

Sanwa Electric Instrument Co., Ltd. was established in 1941, in Tokyo as a manufacturer of measuring instruments. Their product portfolio consists of Digital Multimeters, Analog Multitesters, Insulation, Earth testers, speedometers, and related instruments. Calibrators, detectors, LCR, and clamp meters are also part of the production. The equipment helps with measuring AC/DC voltages, and current, along with resistance and insulation, and for specific measuring applications. Many various industries benefit from Sanwa's products such as speedometers for the measurement of escalator emergency stop distance and detectors to test the direction of Motor rotation before connection of the power supply.

-

-

-

-

-

Kikusui Electronics Corporation

Insulation resistance tester

Manufacturer Overview

KIKUSUI ELECTRONICS CORP., founded in Yokohama, Kanagawa in 1951 is a manufacturer od electronic measuring instruments, electronic loads, and safety test equipment. The company's product portfolio includes Electrical Safety Testers, EMC Testers, Harmonics and Flicker Testers, Battery/Capacitor Testers, and AC Electronic Loads. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and Power Generation. The company provides services such as Product Selection Guidance, Engineering Support, and Custom Manufacturing.

-

-

-

-

-

Yokogawa Test & Measurement Corporation

Insulation tester

Manufacturer Overview

Yokogawa Test & Measurement Corporation was founded in Japan in 1954. Yokogawa currently serves a wide array of industries including the aerospace, automotive, consumer electronics, semiconductor and telecommunications industries with both hardware and software solutions. Among Yokogawa’s suite of products are oscilloscopes, voltage probes, power analyzers and meters, data acquisition tools, optical test equipment, a wide variety of handled meters, calibrators, and testers; analog instruments, and manometers.

-

-

-

-

-

Kyoritsu

Insulation tester

Manufacturer Overview

Founded in 1940, Kyoritsu has an 80 year history as a customer-focused organization specializing in multimeters. Kyoritsu provides analog multimeters as well as digital multimeters with and without clamps offering many varieties of measurement.

-

-

-

-

-

Amprobe Instrument Corporation

Ground Resistance & Insulation Testers

Manufacturer Overview

Amprobe Instrument Corporation, began life in Long Island, NY in 1948 under the name Pyramid Instrument Company, later renamed in1960, is a manufacturer and builds rugged test and measurement tools. The company was acquired by the Danaher Corporation and moved its worldwide headquarters to Everett, Washington in 2006. It designs, manufactures and distributes products from an extensive line of clamp meters and digital multimeters to industry-specific tools for residential/commercial electricians, HVAC/R technicians, utilities and industrial maintenance professionals. Its tools undergo rigorous and intensive testing to ensure compliance with the latest regulations in Fluke's CSA-recognized lab for safety and accuracy.

-

-

-

-

-

Teledyne FLIR LLC

Resistance Testers

Manufacturer Overview

Teledyne FLIR LLC, originally known as FLIR Systems and founded in 1978, is an American manufacturer headquartered in Wilsonville, Oregon, specializing in thermal imaging cameras and sensors, now operating as a subsidiary of Teledyne Technologies Incorporated. FLIR (Forward-Looking Infrared) offers handheld and fixed mount thermal cameras, thermal security cameras, thermography cameras, machine vision cameras, and gas detection cameras. They provide airborne systems, unmanned aerial and ground systems, land and maritime systems, and traffic management software. These products find applications in various fields and industries, such as airborne law enforcement, border and maritime patrol, critical infrastructure and force protection, search and rescue operations.

-

-

-

-

-

Chauvin Arnoux Metrix

Insulation tester

Manufacturer Overview

Chauvin Arnoux began in 1893 in France and took off in 1905 with the invention of the magneto ohmmeter. Chauvin Arnoux is an integrated manufacturer of portable test and measurement instruments used in the electrical sector, education, laboratories, and maintenance. A sample of Chauvin Arnoux’s products include calibrators, electrochemical measurements, relays, analystical software, and accessories. Chauvin Arnoux also offers industrial subcontracting, leveraging its large network of independently operating yet functionally integrated subcontractors’ abilities to manufacture and install PCBs, specialty items, sheet metal, tooling, and more.

-

-

-

-

-

Sansion Power Electric

Insulation Resistance Tester

Company Overview

Sansion Power Electric Co. Ltd. is a manufacturer and supplier of power testing equipment that was founded in 2005 in Wuhan, Hubei, China. The company produces systems and equipment for testing voltage, line safety, and current leakage. These include transformer test equipment, insulation resistance testers, and HV switchgear test sets. The company’s products are used in a range of industries including transportation, power generation, and aerospace manufacturing. Some of its notable clients include the China Railway Corporation, China National Offshore Oil Corporation, and China Southern Power Grid Corporation.

-

-

-

-

-

KAISE CORPORATION.

Insulation Testers

Company Overview

Kaise Corporation, established in 1955 and headquartered in Ueda City, Nagano Prefecture, Japan, is a manufacturer and supplier of electronic measuring instruments. Its product lineup includes battery checkers, jump starters, code readers, as well as oscilloscopes, and circuit testers, primarily used in automotive maintenance. Additionally, the company offers digital multimeters, clamp meters, and insulation resistance meters. Its SK-8550 Battery Checker received the 2016 Maintenance Support Award at the Automotive Newspaper Accessories Awards.

-

-

-

-

-

MULTI MEASURING INSTRUMENTS Co., Ltd.

Split Type AC Current Sensor

Company Overview

Multi Measuring Instruments Co., Ltd. was founded in Chiba, Japan in 1986 and is headquartered in Tokyo. As per its namesake, Multi offers a vast array of measuring and testing equipment used across a number of industries. Some of their offerings include voltage meters, network testers, lux meters, cable locators, sound meters, various thermometers, gas analyzers, and water quality meters. Multi Measuring Instruments has a mission for its products to improve the global environment by detecting inefficiencies and leaks, developing products that will be useful for solar and wind power generation.

-

-

-

-

-

EP Hipot Electric Co., Ltd.

Insulation Resistance Meter

Company Overview

EP Hipot Electric Co., Ltd., established in 2005 and headquartered in Wuhan, China, is a manufacturer and supplier of high-voltage test equipment. The company's product portfolio includes transformer ohmmeters, impulse voltage test systems, circuit breaker analyzers, AC resonance test systems, and other high-voltage test equipment. These products have applications in various sectors, including electrical utilities, power generation, electrical equipment manufacturing, industrial facilities, and research and development. The company is ISO 9001 certified, and it provides services including technical support, maintenance, repair, and training and workshops.

-

-

-

-

Company Overview

Gen3, founded in 1969 and headquartered in Farnborough, Hampshire, is a manufacturer and distributor of test and measurement equipment. The company offers a diverse product catalog, including a 3D digital microscope, flexible vision microscopes, and surface insulation resistance testing equipment. These products find applications in various industries, including telecommunications, oil and gas refineries, and aerospace engineering. It also provides a rent-to-buy plan for its software, test services, training, and consultancy services.

-

-

-

-

-

PCE Instruments UK Ltd

Insulation tester

Company Overview

PCE Instruments UK Ltd., started in 199 and headquartered in Manchester, UK, is a manufacturer and supplier of test instruments, equipment, and tools for weighing, measuring, and control systems. The company offers more than 500 test equipment, including analyzers, inspection cameras, meters, detectors, and sensors, with applications in various fields like data acquisition, electrical engineering, environmental science, building inspection, and food processing. Its manufacturing and development division is ISO 9001 certified, all its test instruments, equipment, and tools are factory calibrated, and the company also provides services for custom test instrument design, installation, and maintenance.

-

-

-

-

-

AOIP

Insulation tester

Company Overview

AOIP was established in 1896 and is a manufacturer and distributor of test instrumentation and electrical motor control products based in Ris Orangis, Essonne, France. The company offers various products in the portofolio, such as precision documented multifunction calibrator, handheld thermometer for thermocouples, leakshooter camera, field pressure process calibrator, and programmable digital panel meter. The products are used in various industries such as cement, mining, water plants, manufacturing, and quarries. The company has been certified with ISO 9001:2015 on the design, production engineering, marketing, services, and trade of the instrumentation and motor starters products.

-

-

-

-

-

Klein Tools, Inc.

ET600

Company Overview

Klein Tools is a fifth-generation family-run producer of hand tools founded in 187 and headquartered in Lincolnshire, Illinois. Klein Tools sells worldwide directly and through distributors. Klein Tools has a family of companies under its brand including Alco, Civitella, Mumme Tools, Tulmex, and Wattmaster. Klein Tools serves several industries including construction, HVAC/R, plumbing, telecom, municipal, and industrial. Some of the tools Klein Tools produces include non-contact voltage tester bens, multi-bit screwdrivers, digital circuit breaker finders, advanced circuit tracer kits, and multi-bit electronics screwdrivers.

-

-

-

-

-

Dr. Brockhaus Messtechnik GmbH & Co. KG

Franklin Tester

Company Overview

Dr. Brockhaus Messtechnik GmbH & Co. KG is a manufacturer of instrumentation systems and devices for magnetic materials established in 1975 and headquartered in Lüdenscheid, Germany. The company offers magnetization devices for soft as well as hard magnetic materials, and magnetic field measurement devices such as magnetometers and Tesla meters. It also offers magnetization and measurement services, as well as calibration of its portfolio products. The company mainly serves clients in the electrical, engineering, and R&D industries.

-

-

-

-

-

TEXIO TECHNOLOGY CORPORATION

Safety Testers

Company Overview

TEXIO TECHNOLOGY CORPORATION has been in operation in Japan for over 60 years. TEXIO specializes in custom orders of a variety of different products including power supplies. TEXIO also specializes in DC power supplies, oscilloscopes, multimeters, function generators, and safety testers.

-

-

-

-

-

Soken Electric Co.,Ltd.

High voltage insulating tester

Company Overview

Soken Electric Co., Ltd. (Tokyo, Japan), founded in 1974, is a maker of premium electronic measuring instruments that produce distinctive and beneficial products for a large industrial field. The company supplies measuring instruments used in the industrial fields, including research, development, quality control, and maintenance for power transmission/distribution infrastructure, and domestic electrical appliances as well as insulating electrical materials. They manufacture products that are “standard” measuring equipment which employed worldwide.

-

-

-

-

-

HIOKI E.E. CORPORATION

Insulation tester

Company Overview

Hioki E.E. Corporation was founded in 1935 and headquartered in Ueda, Nagano. Hioki provides testing & analysis, manufacturing & inspection, and equipment maintenance to industries including mobility, battery, motor, energy, electronic components, and infrastructure. Hioki’s has 10 primary product categories which are: recorders and data loggers including oscilloscopes, LCR/Resistance Meters, safety testing including signal generators and calibrators, power meters including power quality analyzers, probes & sensors, optical & PV maintenance & telecommunication, environmental measuring, DMM & testers & field measuring, IoT & new solutions & meter relay, and bare board & package testing.

-

-

-

-

-

Polyguard

Insulation

-

-

-

-

-

Chauvin Arnoux, Inc.

Megohmmeters - Insulation Testers

-

-

-

-

-

Gossen Metrawatt GmbH

Insulation measuring instrument

Company Overview

GMC Instruments is the result of a merger in 1993 from companies originally dating back to 1906. Under the Gossen Metrawatt and Camille Bauer brands, the company provides hardware, software, and services to several industries including medical devices and manufacturing. The company’s hardware division provides electrical safety devices, photometry equipment, energy management systems, and vital signs measurement devices. The company’s software lineup includes database management software, power analysis software, and medical device software.

-

-

-

-

-

DEIF A/S

Insulation monitor

Distributor Overview

DEIF A/S, founded in 1933 and headquartered in Skive, Denmark, is a supplier of safe power control products for decentralized power generation on land and sea. The company offers products such as single genset controllers, protection relays, HMI control panels, and pitch battery chargers. The company's products are used in land power, whitepapers, webinars, wind power, and marine sectors. It has ISO 9001:2015 and ISO 14001:2015 quality management certifications and also offers training, repair, and consultancy services.

-

-

-

-

-

Sifam Tinsley UK

Insulation Testers

Distributor Overview

Sifam Tinsley UK is based in London, England, United Kingdom, and is a supplier of electrical control and monitoring products for industrial automation that was established in 1946 as a subsidiary of Sifam Tinsley Instrumentation. The company’s product inventory includes digital and analog panel meters for measuring AC and DC voltages or currents, power quality analyzers for gauging parameters such as harmonics or flicker, and transducers for converting electrical signals into digital or analog inputs. The company’s products are commonly used by clients in Europe’s marine, power generation, and mining industries.

-

-

Insulation Resistance Tester Manufacturer Ranking

*Including some distributors, etc.Ranking as of July 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Klein Tools, Inc. |

8.4%

|

| 2 | SCHLEICH |

7.2%

|

| 3 | Tempco Electric Heater Corp. |

7.2%

|

| 4 | Soken Electric Co.,Ltd. |

7.2%

|

| 5 | Associated Research |

6.0%

|

| 6 | HIOKI E.E. CORPORATION |

4.8%

|

| 7 | Keysight Technologies |

4.8%

|

| 8 | FLUKE Corporation |

4.8%

|

| 9 | SCI An Ikonix Brand |

3.6%

|

| 10 | HV Hipot Electric Co., Ltd. |

3.6%

|

Derivation Method

The ranking is calculated based on the click share within the insulation resistance tester page as of July 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

- HIOKI E.E. CORPORATION: 1,009

- Yokogawa Test & Measurement Corporation: 250

- MULTI MEASURING INSTRUMENTS Co., Ltd.: 200

Newly Established Company

- TEXIO TECHNOLOGY CORPORATION: 2012 (12 years ago)

- Sansion Power Electric: 2005 (19 years ago)

- Haida International Equipment Co., Ltd.: 2004 (20 years ago)

Company with a History

- Associated Research: 1936 (88 years ago)

- Kyoritsu: 1940 (84 years ago)

- Yokogawa Test & Measurement Corporation: 1954 (70 years ago)

Insulation Resistance Tester Manufacturers in United States

*Including some distributors, etc.

- Associated Research

- Ikonix

- FLUKE Corporation

- Tempco Electric Heater Corp.

- Keysight Technologies

- SCI An Ikonix Brand

Global Distribution of Insulation Resistance Tester Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

Japan

Japan

|

10 | 33.3% |

United States of America

United States of America

|

6 | 20.0% |

China

China

|

6 | 20.0% |

Germany

Germany

|

2 | 6.7% |

Taiwan

Taiwan

|

2 | 6.7% |

United Kingdom

United Kingdom

|

2 | 6.7% |

Poland

Poland

|

1 | 3.3% |

Denmark

Denmark

|

1 | 3.3% |

List of Insulation Resistance Tester Products

1 product is listed.

Custom Co., Ltd.

Industrial equipment measuring instrument analog insulating resistor MG-02U

10+ people viewing

To confirm the insulation deterioration of electric equipment. ■ 125V/250V/500V compatible analog insulation resistance meter ・ With convenient l...