14 Thermal Conductivity Analyzer Manufacturers in 2024

This section provides an overview for thermal conductivity analyzers as well as their applications and principles. Also, please take a look at the list of 14 thermal conductivity analyzer manufacturers and their company rankings. Here are the top-ranked thermal conductivity analyzer companies as of May, 2024: 1.APT S.r.l., 2.Nova Analytical Systems, 3.C-Therm Technologies Ltd..

Table of Contents

Graduated with a master's degree in mechacanical engineering from the Department of Mechanical Engineering, University of Tokyo.

As a student, he was engaged in research on thermophysical properties and materials, such as thermal interface materials and heat insulating materials.

After that, he mainly engaged in the development of coating equipment and CAE work at a chemical manufacturing company. Currently, he is engaged in research and development related to CFD, molecular dynamics, chemical equilibrium, and gas-liquid equilibrium at a food manufacturing company.

What Is a Thermal Conductivity Analyzer?

A thermal conductivity analyzer is a device used to measure the thermal conductivity of a material.

There are various types, such as those that use a heat plate, hot wire, or laser. Thermal conductivity is the value of the ease of heat transfer within a material and is one of the points that characterize a material. For example, pots and pans can be heated faster if the thermal conductivity is high and retains heat better if the thermal conductivity is low.

Uses of Thermal Conductivity Analyzers

Thermal conductivity analyzers are used to evaluate product manufacturing methods and to develop new materials and products.

1. Evaluation of Heat Retention Performance

For example, the thermal insulation performance of a storage container is evaluated. The lower the thermal conductivity, the higher the thermal insulation and the longer it can keep warm. We measure thermal conductivity as an indicator of this performance.

2. Development of Heat-Dissipating Materials

Recently, thermal conductivity has been increasingly used in the development of heat-dissipating materials, as heat dissipation is an important factor in CPUs and other devices to prevent thermal runaway caused by heat generation.

For example, the higher the thermal conductivity of the thermal conductive grease used to improve heat dissipation, the higher the heat dissipation.

Principle of Thermal Conductivity Analyzers

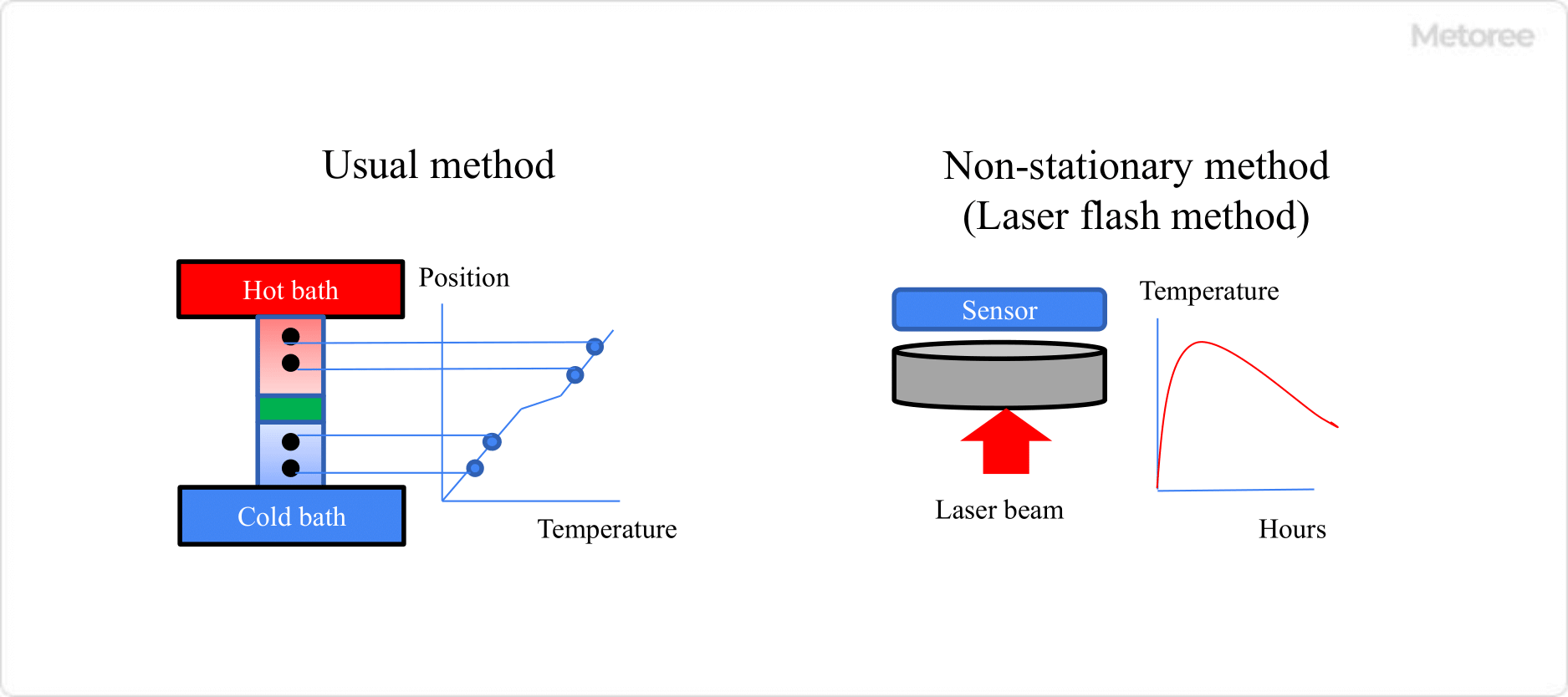

Figure 1. Steady-state and non-steady-state methods

Thermal Conductivity Analyzers can be broadly classified into the Steady-State Method and the Non-Steady-State Method.

1. Steady-State Method

The steady-state method directly measures thermal conductivity by generating a steady thermal gradient. A steady heat flow is generated by making one side of the sample hot and the other side cold.

By measuring the heat flux from a heat flux meter or a material of known thermal conductivity and temperature, the thermal conductivity can be measured from the temperature difference generated in the sample. The simple principle makes accurate measurements possible, but temperature control of the sample surface and heat dissipation to the surroundings can cause errors. Another disadvantage is that it takes a lot of time to reach a steady state.

2. Transient Method

The transient method is a method to measure thermal conductivity by applying non-steady heat to a sample. By measuring the change in sample temperature over time after heat is applied, the thermal conductivity can be calculated. There are two methods of applying heat: the laser flash method using a laser beam and the hot wire method using a heater wire, etc. The laser flash method uses a laser beam to apply heat to the sample.

In the laser flash method, the sample is heated using a laser beam and is detected by an infrared sensor. The disadvantage of this method is that it is difficult to detect samples with too small a thermal conductivity. In the hot wire method, the sample is heated by passing a hot wire inside the sample. This method can be used to measure without distinction between solids and liquids.

Other Information on Thermal Conductivity Analyzer

1. Difference From Thermal Diffusivity Measurement Device

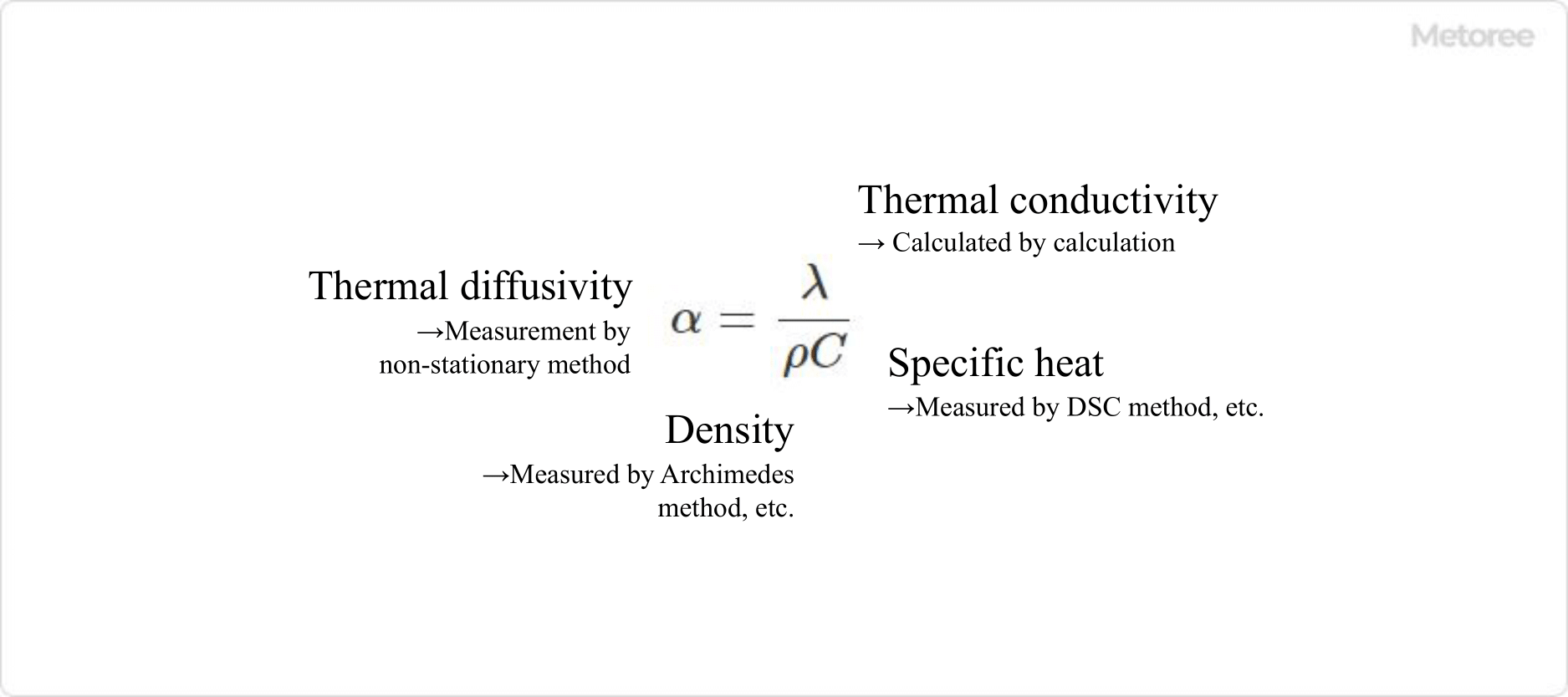

Figure 2. Thermal diffusivity and thermal conductivity

Thermal diffusivity is generally measured by devices using the laser flash method, but thermal conductivity cannot be measured directly. Thermal conductivity can be obtained by multiplying the thermal diffusivity obtained with a laser flash measurement device by the specific heat and density.

The specific heat is measured by a differential thermal analyzer (DSC), and the density is measured by a method such as the displacement method known as Archimedes' method in water. The laser flash method can be used to measure the thermal diffusivity of a wide range of materials, including rubber, plastics, and other polymers, ceramics, and even metals. On the other hand, there are restrictions on test conditions, and the materials to be measured are dense rather than porous.

The material must be free of defects, such as shrinkage porosity and cracking, which are common in metallic materials. Therefore, composite or laminated materials made of fibers or granular materials cannot be measured.

In addition to the laser flash method, the thermal diffusivity measurement system also includes a cyclic heating method. In this method, the temperature response or phase difference is determined from the temperature response or phase difference at a certain distance away when periodically varying thermal energy is applied. However, this method also cannot directly measure thermal conductivity.

2. Rapid Thermal Conductivity Meter (Non-stationary Fine Wire Heating Method)

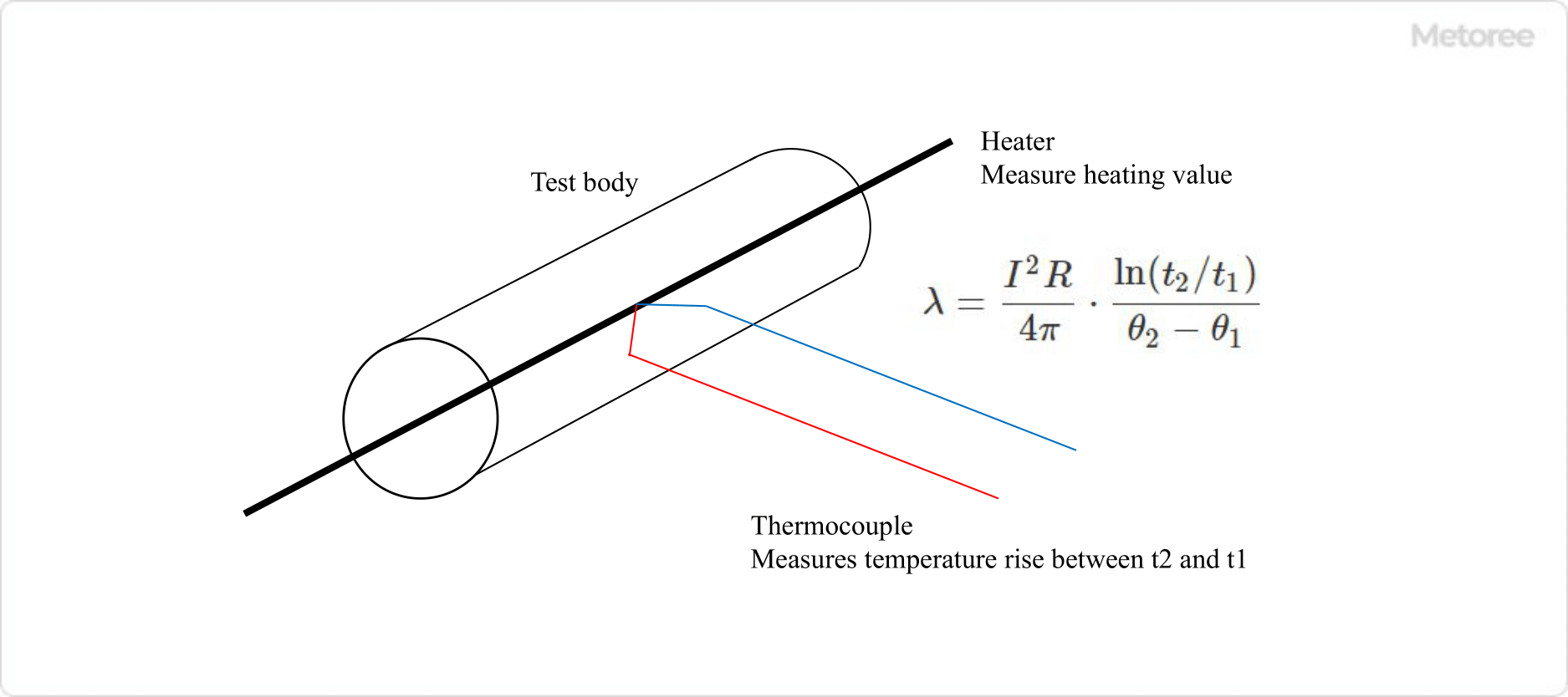

Figure 3. Non-steady-state fine wire heating method

For rapid measurement of the heat transfer coefficient, a rapid heat transfer coefficient meter using the unsteady thin-wire heating method is effective. The sensor part consists of a heating wire stretched in a straight line and a thermocouple, and a constant current is applied to raise the heating temperature.

For example, if the specimen has high thermal conductivity, such as ceramics, heat diffuses rapidly into the specimen and the temperature of the heating wire decreases. Conversely, for a specimen with low thermal conductivity, the temperature of the heating wire rises, and the thermal conductivity can be determined from the slope of the temperature rise graph at this time.

Thermal Conductivity Analyzer can quickly and easily measure the thermal conductivity of a uniform specimen, and the analyzer itself is small enough to be carried around. The measuring instrument itself is compact and portable, making it possible to take measurements immediately on site, another major advantage. It can be used for a wide range of applications, from industrial building materials to food and clothing.

Examples of test specimens that can be measured are as follows:

- Fiber-based and foamed plastic insulation materials, etc.

- Plastics, glass, wood, etc.

- Sheets, skins, thin plate samples, etc.

- Bread dough, paste, powder, etc.

- Refractory insulation materials at high temperatures, ceramics, etc.

List of 14 Thermal Conductivity Analyzer Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- United States of America

- Germany

- India

- Italy

- Japan

-

-

-

Honeywell International Inc

Thermal Conductivity Analyzer

Manufacturer Overview

Honeywell International Inc. was founded in 1885 and headquartered in Charlotte, North Carolina. Honeywell is a diversified technology and manufacturing company to global customers in many industries such as aerospace, building technologies, performance materials, manufacturing, and safety. Honeywell produces hardware and software solutions for each industry it serves. In building technologies, Honeywell designs access controls, electrical and wiring, fire life safety, and employee training services. In aerospace, Honeywell designs cockpit systems and displays, engines, cabin management and cleaning, and health and usage monitoring.

-

-

-

-

-

Thermophysical Properties Research Laboratory, Inc.

Thermal Conductivity Analyzers

Manufacturer Overview

Thermophysical Properties Research Laboratory, Inc., founded in 1972 and headquartered in West Lafayette, Indiana, is a manufacturer specializing in instruments and related products for measuring, displaying, and controlling industrial process variables. It offers a range of products and services, including thermal conductivity measurement, flash diffusivity measurement, specific heat measurement, thermal expansion measurement, and emissivity measurement. These instruments find applications in diverse industries, such as manufacturing, materials research, aerospace, and energy, aiding in optimizing heat transfer, analyzing material behavior, and improving energy efficiency. The company holds ISO 9001:2015 certification and has maintained ISO certification since 2003 through Perry Johnson Registrars.

-

-

-

-

-

-

-

-

-

Steam Equipments Pvt Ltd

Thermal Conductivity Analyzers

Manufacturer Overview

Steam Equipments Pvt. Ltd., established in 2004 and based in Pune, Maharastra, India is a manufacturer of Steam and Water Analysis Systems (SWAS), Continues Emission Monitoring System (CEMS). The company also produces Ambient Air Monitoring Systems (AQMS), water and waste water monitoring, flow metering, vibration monitoring systems (VMS), and moisture and dew point monitoring systems. It provides whole systems that comprise software, SCADA, PLC, and shelter or container-based solutions for safe or hazardous areas. The company has construction and/or testing facilities in Pune, Bangalore, South Africa, the UAE, the USA, and Singapore.

-

-

-

-

-

ADVANCE RIKO,Inc.

Thermal Conductivity Measurement System

Manufacturer Overview

Advance Riko Inc., founded in 1962 with headquarters in Yokohama, Japan, is a manufacturer of thermal analysis equipment and thermophysical properties measuring equipment. The company's product line includes atmospheric thermoelectric module evaluation systems, thermoelectric conversion efficiency evaluation systems, and laser flash method thermal constant measurement systems. These products are used for the research and development of thermoelectric materials such as ceramics, carbon, and metals, the evaluation of power generation amounts, and the heat flow of materials, among other applications of research and development to create new materials in many industrial fields, including new energy.

-

-

-

-

-

Toshniwal Industries Pvt. Ltd.

Thermal Conductivity Analyzer

Manufacturer Overview

Toshniwal Industries Pvt. Ltd. is a manufacturer of industrial instrumentation and security products. The company is headquartered in Ajmer, Rajasthan, India, and was established in 1959. Toshniwal offers a wide range of products, including Gas Analyzers, Dust Monitors, Environment Monitoring Systems, Test Measurements and Process Calibrators. The company’s services include Installation and Commissioning, Annual Maintenance Contract, Calibration, Ultrasound and Vibration. Its products find application in numerous industries, including the oil and gas, chemical, and power industries. The company also offers Surveillance CCTV Systems, Voice and Video Communication Systems, Laboratory Packages and Process Optimization Solutions.

-

-

-

-

-

APT S.r.l.

Thermal Conductivity Analyzer

Manufacturer Overview

APT S.r.l. is headquartered in Cesano Maderno, Italy as a designer, manufacturer, and supplier of integrated systems and instruments for gas and liquid analysis since 1995. The company offers numerous products, including sampling systems, gas and liquid analyzers, fire detectors gas detectors, as well as measuring and test instruments for industrial applications. Its products find application in areas such as oil & gas, chemical, and environmental industries. The company also provides customization services including feasibility study, site survey, preliminary inspection, as well as installation, training, and technical assistance.

-

-

-

-

-

Fuji Electric Co., Ltd.

Thermal Conductivity Gas Analyzer

Manufacturer Overview

Fuji Electric Co., Ltd., founded in 1923 and headquartered in Shinagawa-ku, Tokyo, is a manufacturer of electrical equipment and power electronics technologies. The company offers a range of electrical equipment such as motors, inverters, pressure transmitters, controllers, generators as well as power electronic components such as semiconductors, UPS, sensors and transformers. The services offered by the company include thermal, geothermal, and hydraulic power generation by building power plants and power generation equipment, electrical and air conditioning equipment installation and energy management solutions. Fuji works on system solutions using IoT by combining engineering, services and optimal control with components to maximise energy efficiency.

-

-

-

-

-

Process Insights

Thermal Conductivity Analyzers

Manufacturer Overview

Process Insights is a designer and manufacturer of water and gas analytical instrumentation that was established in 2012 as a portfolio company of the private equity firm Union Park Capital. Headquartered in Houston, Texas, the company produces detectors, sensors, monitors, and analyzers for measuring physical environmental parameters such as moisture, gas composition, or humidity. It also offers software and instrumentation for environmental compliance and process control applications. Process Insights also provides performance verification and factory acceptance testing for its clients in the petrochemical, power generation, semiconductor, and environmental protection sectors.

-

-

-

-

-

C-Therm Technologies Ltd.

Thermal Conductivity Analyzers

Manufacturer Overview

C-Therm Technologies Ltd. (formerly Mathis Instruments), founded in 2007, is a Canadian manufacturer based in Fredericton, New Brunswick, engaging in non-destructive thermal conductivity instruments. The company develops the Trident system with three transient methods, namely modified transient plane source (MTPS), transient plane source (TPS), and thermal laser stimulation (TLS). This system enables testing of various solids, liquids, powders, and pastes, such as heat transfer fluids, polymers, and nanomaterials. Such applications cover diverse industries, including automotive and electric vehicles (EV), building materials, insulation, metals, as well as oil and gas. The company serves notable clients like the National Aeronautics and Space Administration (NASA).

-

-

-

-

-

International Thermal Instrument Company, Inc.

Thermal Conductivity Analyzers

Manufacturer Overview

International Thermal Instrument Company Inc. (ITI Company Inc.), founded in 1969, is a thermal instrument manufacturer based in Del Mar, California, United States. The company’s range of instruments includes calorimeter-temperature sensors, intended for direct insertion into a flame front, geothermal heat flow transducers for measuring local heat fluxes, and heat flux transducers, used on surfaces to measure heat flow. The company also produces heat loss detection systems, thermal conductivity analyzers, and thermoelectric calorimeters. It offers custom instruments, some of which have been supplied to clients like the National Aeronautics and Space Administration (NASA) and National Institute of Standards and Technology (NIST).

-

-

-

-

-

Nova Analytical Systems

Thermal Conductivity Analyzers

Manufacturer Overview

Nova Analytical Systems is a part of Tenova Goodfellow Inc and is based both in Hamilton, Ontario and Niagara Falls, New York. The company is a designer and manufacturer of dependable gas analysis equipment serving customers in a diverse range of traditional and emerging industries around the world. The company’s gas analyzing equipment is used in flue gas & emissions, power generation & hydrogen purity, hazardous area gas quality, and oil & natural gas quality, measuring levels of carbon monoxide, sulfur dioxide, and other chemicals.

-

-

-

-

-

DKS GmbH Engineering und Vertrieb

Thermal Conductivity Analyzer

Distributor Overview

DKS GmbH Engineering und Vertrieb is a gas measurement technology and data visualization supplier that is headquartered in Großröhrsdorf, Bautzen, Saxony, Germany, and was established in 1990. The company develops intelligent solutions for gas measurements, especially in the area of trace moisture measurement in inert combustible and corrosive gases using the proven P2O5 measurement method. Its popular products and services, include Trace moisture in gas, CombiSens gas analysis platform, Dew point hygrometer and Gas analyzers - TCD. DKS also offer services, such as system design, engineering, and installation and its products find application in the food, pharmaceutical, chemical, and semiconductor industries.

-

-

Thermal Conductivity Analyzer Manufacturer Ranking

*Including some distributors, etc.Ranking as of May 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | APT S.r.l. |

15.4%

|

| 2 | Nova Analytical Systems |

15.4%

|

| 3 | Process Sensing Technologies Limited |

12.8%

|

| 4 | Toshniwal Industries Pvt. Ltd. |

10.3%

|

| 5 | C-Therm Technologies Ltd. |

10.3%

|

| 6 | Thermophysical Properties Research Laboratory, Inc. |

7.7%

|

| 7 | DKS GmbH Engineering und Vertrieb |

5.1%

|

| 8 | International Thermal Instrument Company, Inc. |

5.1%

|

| 9 | Process Insights |

5.1%

|

| 10 | ADVANCE RIKO,Inc. |

5.1%

|

Derivation Method

The ranking is calculated based on the click share within the thermal conductivity analyzer page as of May 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

- Fuji Electric Co., Ltd.: 26,757

- ADVANCE RIKO,Inc.: 62

Newly Established Company

- APT S.r.l.: 1995 (29 years ago)

- DKS GmbH Engineering und Vertrieb: 1990 (34 years ago)

- International Thermal Instrument Company, Inc.: 1969 (55 years ago)

Company with a History

- Fuji Electric Co., Ltd.: 1923 (101 years ago)

- International Thermal Instrument Company, Inc.: 1969 (55 years ago)

- DKS GmbH Engineering und Vertrieb: 1990 (34 years ago)

Thermal Conductivity Analyzer Manufacturers in United States

*Including some distributors, etc.

- Honeywell International Inc

- Thermophysical Properties Research Laboratory, Inc.

- Process Sensing Technologies Limited

- Teledyne Analytical Instruments

Global Distribution of Thermal Conductivity Analyzer Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

4 | 40.0% |

India

India

|

2 | 20.0% |

Japan

Japan

|

2 | 20.0% |

Italy

Italy

|

1 | 10.0% |

Germany

Germany

|

1 | 10.0% |

List of Thermal Conductivity Analyzer Products

1 product is listed.

Grotz Beckelt Japan

Contact cold-sensitive heat conductivity measuring machine C-THERM

10+ people viewing

The only measuring instrument based on ASTM D7984, which quantitizes the warmth and coolness of textiles and fabrics Heat conductivity measurement...