All Categories

History

This section provides an overview for high frequency welders as well as their applications and principles. Also, please take a look at the list of 5 high frequency welder manufacturers and their company rankings. Here are the top-ranked high frequency welder companies as of February, 2026: 1.Willems Industriële Producties b.v., 2.Yamamoto Vinita Co., Ltd., 3.Hexagon Electric Industrial Co., Ltd..

Table of Contents

Categories Related to High Frequency Welders

Engaged in research on nitride semiconductor growth using the MBE method at Waseda University Graduate School. After graduating from graduate school in 2016, he joined a non-ferrous metal manufacturer.

Engaged in equipment maintenance and engineering work at metal smelting plants. Moved to a chemical manufacturer in 2022. Engaging in similar tasks.

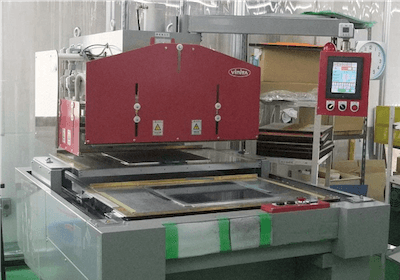

A high frequency welder is a device that welds materials using high frequency dielectric heating.

It is suitable for thermoplastic resins like polyvinyl chloride (PVC) and nylon. Welding with a high frequency welder offers higher weld strength and a cleaner finish compared to other external heating methods.

Unlike microwave heating, a high frequency welder can achieve targeted and deeper heating by using electrode plates to heat the material between them.

High frequency welders are utilized to bond sheet materials, including:

Due to its operating principle, the range of materials compatible with a high frequency welder is limited. However, the seamlessness of the welds results in a visually appealing finish, making it ideal for aesthetically sensitive products and ensuring airtightness and waterproofness for items like tents.

A high frequency welder generates heat through dielectric heating, where a high-frequency voltage agitates the material's molecules to create frictional heat, uniformly warming the material from inside. This method is effective only for dielectric materials such as vinyl chloride and polyethylene.

By applying high frequency voltage and pressure between electrodes, the material is heated to 248-266°F within seconds, reaching a semi-liquid phase. Cooling under pressure then allows the materials to fuse together.

This process is notable for not causing appearance defects like scorching, as it heats the weld area locally without affecting the surroundings. The process is smoke-free and does not emit harmful substances, offering a safe and environmentally friendly solution.

Main materials include:

Selection of power and frequency depends on the material and thickness of the object. Frequencies range from 40 MHz to 200 MHz for plastic sheets, and 10 MHz to 50 MHz for thermosetting plastics, with 2.45 GHz also being used for specific applications.

Prices vary widely based on size and output capacity, with smaller units starting around 3,000,000 yen and larger equipment for industrial use ranging from 5,000,000 to 10,000,000 yen.

*Including some distributors, etc.

Sort by Features

Sort by Area

Yamamoto Vinita Co., Ltd., established in 1953 and headquartered in Osaka, Japan, is a manufacturer that manufactures high-frequency dielectric heating equipment. The company offers a range of products, including THERMOTRON-RF8 EX Edition, Defroster, Hot Stamping Welder, Laminating Machine, and more. It also offers Dryers, Flash Joining Machine, Wood and Paper Box, and Transistor-oscillation type welders. Its high-frequency dielectric heating equipment can heat the adhesives, resulting in selective heating and laminating and cross-laminated timber joining. The company has achieved ISO 13485 for its quality of medical equipment. It serves the plastics industry, food industry, and medical industry.

Nippon Avionics Co., Ltd is a Japanese manufacturer of electronic aviation equipment and other office equipment. The incorporation is a result of merging NEC Corporation and Hughes Aircraft Company in 1960. Headquarters are located in Yokohama Japan. The company designs, manufactures, and sells items from three product lines: Information Systems, Joining Equipment, and Infrared Thermography. The products include communication devices used in aviation integrated circuit (IC) boards and media projectors for office use.

Willems Industriële Producties B.V., established in 1987 with headquarters in the Netherlands, is a manufacturer of process handling equipment and (or in combination with) high-frequency welding machines. The company’s new, fully high-frequency welding machines are individually designed for different types of products and production process applications. Its high-frequency welding electrodes and tool sets are used to produce various products, such as car seat covers, car mats, orthopedic bandages, and life jackets. The company’s after-sales support services include machine maintenance, repairs, spare parts, and accessories for HF welding.

Hexagon Electric Industrial Co., Ltd., established in 1985 with headquarters in China, is a manufacturer of high-frequency welding machines and industrial products. The company's welding machine product line includes plastic welding machines, blister packaging machines, canvas welding machines, sports shoe welding machines, and medical welding machines. Its products include helmet liners, car seats, inflatable products, protective clothing, and canopies used in the automotive, outdoor design, transport, and residential home accessories markets. The company's equipment can also be customized to suit client-specific requirements.

Balacchi Srl, established in 1964 and headquartered in Lombardia, Italy, is a manufacturer of HF welders for PVC and CNC cutting machines for plastic materials. The company’s products include welding equipment such as bars, electrodes, and welding blades, as well as cutting systems with consumables, feeding systems, and tools. Its cutting systems offer solutions for the precise cutting of textile fibers, synthetics, and fiberglass. The company’s HF welding technology ensures precise, secure, and durable joints for different materials, including PVC, polyurethanes, and PETG. Its products find applications in automotive, medical, and construction industries, including tensile structures and conveyor belts.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Willems Industriële Producties b.v. |

26.1%

|

| 2 | Hexagon Electric Industrial Co., Ltd. |

19.0%

|

| 3 | Yamamoto Vinita Co., Ltd. |

19.0%

|

| 4 | Balacchi srl |

14.8%

|

| 5 | Nippon Avionics Co., Ltd. |

14.8%

|

| 6 | Liaoning Unify High Frequency Equipment Co., Ltd. |

6.3%

|

Derivation Method

The ranking is calculated based on the click share within the high frequency welder page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

Japan

Japan

|

2 | 50.0% |

Netherlands

Netherlands

|

1 | 25.0% |

Taiwan

Taiwan

|

1 | 25.0% |

65 products found

65 products

Yamamoto Vinita Co., Ltd.

550+ people viewing

Last viewed: 9 hours ago

Air or motor machine with foot pedal. It can also handle complex machining using the foot pedal. Newly installed 4 system hybrid ■Safety system T...

Saito Koken Co., Ltd.

340+ people viewing

Last viewed: 9 hours ago

Automatically welds by applying heat.

Kobayashi CHORD & CO.

640+ people viewing

Last viewed: 7 hours ago

Vibrate the metal and weld with ultrasonic waves. Large products such as large clear books can also be welded.

Hiroshima Co., Ltd.

590+ people viewing

Last viewed: 4 hours ago

The appeal of Hiroshima-made laser resin welding equipment ■One control Control of the VL-W1 and the device is unified, and all operations can be c...

Asahi Sangyo Co., Ltd.

350+ people viewing

Last viewed: 9 hours ago

In May 2023, a battery type was added to the ultrasonic welder Kuppa. Welding can be done in an instant using the power of ultrasonic waves. It is ...

2 models listed

Ultrasonic Application Research Institute Co., Ltd.

450+ people viewing

Last viewed: 9 hours ago

■The handpiece has been made smaller by using a high-performance vibrator. ・300W, handpiece diameter φ35mm ・150W, handpiece diameter φ30mm ■Feat...

Ultrasonic Application Research Institute Co., Ltd.

510+ people viewing

Last viewed: 9 hours ago

Easy setup, simple structure, slim head, and high rigidity. ■Features ・High rigidity, slim body ・Easy settings ・Simple structure ・Achieves hig...

Kobayashi CHORD & CO.

530+ people viewing

Last viewed: 9 hours ago

The function is the same as the high -frequency welder machine, but the table moves and the weld is free, so you can work faster.