All Categories

History

This section provides an overview for alloy tool steel as well as their applications and principles. Also, please take a look at the list of 35 alloy tool steel manufacturers and their company rankings. Here are the top-ranked alloy tool steel companies as of February, 2026: 1.Precision Marshall, 2.Harris Product, 3.Dayton Lamina Corporation.

Table of Contents

Categories Related to Alloy Tool Steel

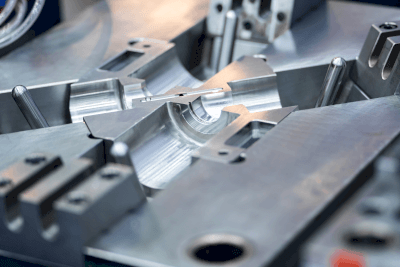

Alloy Tool Steel is a steel material generally characterized by high hardness, wear resistance, heat resistance, corrosion resistance, and strength.

It is used in the manufacture of tools and machine parts, and its properties are generally improved by adding various metallic elements (chromium, vanadium, molybdenum, etc.) to carbon tool steel.

Alloy Tool Steel can be heat treated to adjust its hardness and strength. It is usually heated to high temperatures and cooled rapidly in a process called quenching, which increases hardness and at the same time makes them brittle, so moderate forging, machining, and heat treatment are necessary to control the hardness.

Alloy Tool Steels such as high speed steel (HSS), and molybdenum steel are used.

Tool steel and tungsten steel are used for dies. Examples include molds for plastic molding and molds for casting.

Alloy Tool Steel such as high speed steel and molybdenum steel are used for machine tools. Machine tool blades, machine tool drive parts, and bearings are examples.

Alloy Tool Steel, such as high-speed steel and chrome vanadium steel, is used for automotive parts. Examples include engine valves, chassis, and gears.

Alloy Tool Steels such as high speed steel, tungsten steel, and molybdenum steel are used for aircraft parts. Examples include jet engine parts, fuel system pipes, and control system parts.

Alloy Tool Steels such as high speed steel and chrome vanadium steel are used in a variety of industries. Examples include construction materials, precision machinery, electronics, and sporting goods.

Alloy Tool Steel for cutting tools are characterized by high hardness and heat hardenability, and can be used for high-speed cutting. They are highly durable and can withstand prolonged use.

Alloy Tool Steel for impact resistant tool steels have higher impact resistance than carbon steel, and is less likely to be deformed or broken even when subjected to blows or vibrations.

Alloy Tool Steel for cold dies are suitable for molds used at room temperature.

Alloy Tool Steel for hot work tooling have properties suitable for molds used at high temperatures.

The main factors to consider when selecting alloy tool steel are as follows:

The required hardness and wear resistance vary depending on the cutting conditions, such as cutting speed, feed rate, machining depth, cooling method, etc. Therefore, it is necessary to check the cutting conditions and select an appropriate alloy tool steel.

Alloy Tool Steel has various performances such as hardness, wear resistance, corrosion resistance, fatigue resistance, machinability, and heat treatment performance. Depending on the required performance, the appropriate alloy tool steel should be selected.

Depending on the shape and size of the alloy tool steel material, its machining and heat treatment performance will vary. For example, alloy tool steel with a finer grain size is suitable for small blades and tools.

Procurement cost should also be considered when selecting an appropriate alloy tool steel. High quality alloy tool steel can be expensive.

Specifically, alloy tool steel has the following properties:

Common alloying elements and their effects are described below. The alloying elements listed below affect the properties of the steel depending on the proportion added to the steel and other addition conditions. The amount of alloying elements added has a significant effect on the properties of the steel, and therefore the optimum amount should be established.

1. Chromium (Cr)

Chromium is added to improve corrosion resistance. By forming oxides and protecting the surface, it also improves resistance to corrosion, as well as the hardness and strength of the steel.

2. Vanadium (V)

Vanadium is added to increase strength. It is characterized by the formation of fine particles that strengthen the crystalline structure of the steel, thereby increasing its strength. It is also used to improve wear resistance.

3. Molybdenum (Mo)

Molybdenum is added to steels to make them suitable for use at high temperatures. It improves resistance to oxidation and corrosion at high temperatures and also increases the strength and hardness of the steel.

4. Manganese (Mn)

Manganese is an alloying element added to increase hardness and strength. It also oxidizes the surface of steel during heat treatment and promotes surface hardening.

5. Nickel (Ni)

Nickel is added to improve corrosion resistance. Like chromium, it improves resistance to corrosion by forming oxides and protecting the surface. It also contributes to the strength of steel through heat treatment.

6. Cobalt (Co)

Cobalt is added to steels to make them suitable for use at high temperatures. It improves resistance to oxidation and corrosion at high temperatures and also increases the hardness and strength of the steel.

Various other alloying elements are also used, such as tungsten (W), which improves hardness, strength, and machinability. Silicon (Si) is used to increase strength and control deformation during heat treatment.

Combinations of alloying elements produce alloy tool steels with a variety of properties. For example, alloy tool steel combining chromium and vanadium can improve both corrosion resistance and strength. Alloy tool steel combining chromium and nickel is also suitable for use at high temperatures.

*Including some distributors, etc.

Sort by Features

Sort by Area

JFE Steel America, Inc., a subsidiary of JFE Steel Corporation and established in 1994, is located in North Kingstown, Rhode Island, and is a manufacturer and supplier of flat-rolled steel products. Their product offerings include galvanized steel with a zinc coating for corrosion protection, cold-rolled steel with improved strength and smoother surface, hot-rolled steel used for beams, plates, and bars, stainless steel resistant to corrosion and high temperatures, and alloy steel with enhanced strength, toughness, and corrosion resistance. JFE Steel America's products find applications in diverse industries like construction, automotive, and manufacturing.

Precision Marshall, established in 1948 and headquartered in Washington, USA, is a manufacturer and supplier of decarb-free tool steels and specialty alloys. The company offers tool steel and alloy plates, steel and alloy bars, and printable product line cards. These products are used in mold and die-making, aerospace, automotive components, and other industries. The company also provides plate and sheet conversion, bar cutting, and quick turnaround on converting your sheet or plate to milled, vertical ground services to its diverse customers.

Dayton Lamina is a subsidiary of MISUMI Group Inc. formed in 2014 in Ohio and is the manufacturer and supplier of a diverse range of metal stamping products, dies, punches, and more. Dayton Lamina is subsumed by other brands namely, Lempco, Danly IEM, Lamina, and Dayton Progress. Each of these brands has its own production line such as Lempco serves the canning, electronics, and automotive industry with its die set guidance system. Danly IEM manufactures die and mold components along with Lamina. Dayton Progress designs catalogs and brochures for the die and punch market.

Harris Product, established in 2006 and based in Ohio, United States, is a manufacturer of metalworking products such as brazing and soldering alloys and welding consumables. The company produces products such as brazing alloys, fabricated tubes, welding alloys and fluxes, and equipment for soldering, cutting, and welding for the gas distribution industries. The gas and welding equipment are manufactured in 11 manufacturing facilities across 6 countries – USA, Brazil, Mexico, Portugal, Italy, and Poland. The company has ISO 9001 quality management certification to manufacture the products by abiding by the quality standards.

TMS Titanium was established in 2006 and is located in Poway, California, and is a supplier and distributor of titanium mill products for various industrial applications. The company's product folio includes titanium sheets, rods, blocks, transition reducers, and, exhaust accessories that have a wide range of applications in the aerospace, medical, racing, and commercial industries The company has acquired ISO9001:2008 and AS9100C quality assurance certifications and also offers fabrication, precision grinding, water jet cutting, welding, and, saw cutting services.

Hadco Metal Trading is a service center and distributor of semi-finished metals and plastics, founded in 2006 and headquartered in Bensalem, Pennsylvania. The company’s wide-ranging stock encompasses sheet, plate, tube, pipe, structural, and architectural shapes made from aluminum, magnesium, stainless steel, engineering plastics, copper, and brass, catering to the diverse needs of numerous industries. With strategically placed branches across locations such as New York, Pennsylvania, Connecticut, Florida, and New Hampshire, the company serves all of North America through its suppliers, including Arconic, Kaiser, Constellium, Hydro, and North American Stainless.

Diamond Metals Distributor, LLC, founded in 1995 and based in Cleveland, United States of America, is a supplier of industrial tools as well as some pertinent services like saw-cutting service The company provides powdered metals, hot rolled steel, and tool steel. It also offers pre-squared finishing, flame-cutting, grinding and milling, and saw-cutting services. The powdered metals leverage crucible particle metallurgy technology, leading to superior quality tool steels. It serves customers in the Midwest, trans-Atlantic, and southeastern states.

Alloys Unlimited and Processing, LLC, established in 1990 in Austintown, Ohio, is a distributor of tool steels, alloys, and carbon round bars. The company’s 88,000-square-foot facility, situated in Mineral Ridge off I-80, caters to a range of industries. Beyond distribution, the company offers various services, including the supply of semi-finished parts, machining options, and specialized heat-treating solutions. Alloys Unlimited and Processing LLC products are based on ASTM, AISI, or SAE specifications.

New Mexico Metals LLC, established in 2022, is a metal supplier based in New Mexico, USA. The company provides services like metal shearing, sawing, punching and notching, metal and steel bending, and drilling. The company specializes in delivering metals cut to size without minimum order requirements. This unique approach allows customers to purchase precisely the amount of metal needed without concerns about leftover scrap. With a service-oriented approach, the company caters to wholesale and retail customers. Its clientele spans from large industrial maintenance departments to local DIY enthusiasts.

TAH CHUNG STEEL CORP, founded in 1968, is a Taiwan-based manufacturer and trader of wire, special steel, bars, coils, welded steel wire mesh, brackets, and 3D lightweight wall panels used in the steel market. The company’s product portfolio comprises 3D panels, welded wire reinforcement, and a wide range of steel types, including carbon, alloy, and free-cutting steel in a full range of sizes, with specifications ranging from 0.2 to 100mm. The company adheres to stringent requirements on quality and working environment allowing it to achieve the ISO 9001 certification and also provides professional OEM and ODM services.

Shimomura Tokushu Seiko Co., Ltd. (STS) is an Osaka, Japan-based cold finished steel bar manufacturer founded in 1946. The company produces specialized steels such as stainless steel for medical equipment, alloy steels for gears and springs, free cutting steel for nuts and bolts, and tool steel used in dies and molds. They also provide steel type simulation and shaping to help clients select suitable steels for unique use cases. STS is a member of Daido Steel Group, and has clients in various industries including in the manufacturing, automotives, and food processing sectors.

Fushun Special Steel Co. Ltd. is an ISO 9001-certified manufacturer of steel products and alloy materials founded in 1937 and based in Fushun, Liaoning, China. The company produces steel products for structural components, tools, and sensitive components for medical devices. It also produces nickel-based alloys for aerospace components and parts requiring resistance to extreme temperatures. The company offers manufacturing services for steel and alloy materials, including forging using hydraulic or precision machinery, melting with arc or vacuum furnaces, and heat treatment. It primarily serves clients in the aerospace, energy, and petrochemical markets.

NACHI-FUJIKOSHI CORP. is a Japanese manufacturer of industrial machinery and tools, such as bearings, hydraulic equipment, robots, and cutting tools. They also provide services such as machine maintenance and repair. The company's products are used in automotive, aerospace, construction, and electronics. One of NACHI-FUJIKOSHI's renowned products is their robotic arm, the "MZR series," which is designed for precision assembly and inspection tasks in industries. They received several awards for their technological advancements and contributions to the industry, including the 2021 Japan Society of Mechanical Engineers Medal for new hydraulic equipment technology and the 2020 Nikkan Kogyo Shimbun Grand Technology Award.

Daido Steel Co., Ltd., originally founded in 1916 in Japan, is a manufacturer of alloy and tool steels. The company offers a wide range of products that include mechanical construction steels, superalloys used in engine components, welding wires, alloy powders, and permalloy foil. Daido Steel Co., Ltd.'s specialty steel products are used in the automotive parts, industrial machinery parts, electrical machinery parts, and welding markets. The company has diversified to include businesses in real estate, insurance, and the provision of welfare services and has expanded operations outside of Japan in North America, Asia, and Europe.

Struers is a manufacturer of materialographic equipment and consumables based in France since 1875. The company designs equipment used for cutting, mounting, grinding, polishing, and verifying materials for enhancing and streamlining the processes of sample preparation, from manufacturing and quality assurance to failure investigation and research. There are cut-off machines such as Magnutom-5000, Mounting accessories, machines, and consumables along with automated solutions for grinding and polishing. These products cater to automobile and airplane manufacturers including mobile phone producers and aerospace sectors.

Virgamet is a manufacturer of engineering materials that was founded in 1995 and is headquartered in Toruńska, Koło, Poland. Its main activity is the production of steel, including carbon steel, stainless steel, and alloy steel. The company also offers a wide range of services, such as cutting, bending, and welding. Other areas of specialization include the supply of materials that require special mechanical and physical properties, resistance to difficult working conditions, abrasion, critical temperatures and a corrosive environment. Virgamet's products are used by many customers, including the automotive, construction, and machinery industries.

Patriot Forge Co., founded in Canada is a manufacturer of Bars and Shafts, Sleeves, and Open Die Rings. The company's product portfolio includes Precision Ground Bars, Forged Cylindrical Sleeves, Bushings and Bearings, Precision Bore Sleeves, and Forged Rings of Various Diameters. It also provides services such as Heat Treatment and Stress Relief, Machining and Precision Finishing, Surface Treatments and Coatings, and Just-in-Time Manufacturing and Inventory Management. it serves industries such as Renewable Energy, Industrial Equipment, and Mining and Construction.

SC Tools, founded in 1967, is a manufacturer of solid carbide cutting tools headquartered in Michigan, USA. The company provides various end mills, drills, reamers, and burrs. The company's end mills are made from solid carbide, which provides longevity and performance. The company also offers custom tool design and manufacturing services to meet the specific needs of its customers. The company caters to metalworkers who require high-precision cutting tools for machining multiple materials.

TOKUSHU KINZOKU EXCEL Co. Ltd. is an ISO 9001-certified manufacturer of precision metal materials that was established in 1940 in Tokyo, Japan. The company produces various performance alloys designed for flexibility, durability, or magnetism. These include electrical heating alloys, soft magnetic iron steel, and shape memory alloys. The company also offers contract manufacturing for custom or industry-specific material orders. It primarily serves clients in the aerospace, digital consumer products, and semiconductor manufacturing sectors.

METALBALL, founded in 2004 and headquartered in Grisolles, France, is a manufacturer of precision steel balls and ceramic balls. The company makes balls and beads according to class 1 of ASTM standards from stainless steel, plastic, carbon, tungsten carbide, and glass. The products are applied in aeronautics, medical, industrial, pharmaceutical, and cosmetic industries. It has received the award for Best Performance Aeronautical Supplier from UMBRA Group. The company is EN 9001 certified and Napcard accredited, administered by PRI.

Hudson Tool Steel Corporation, founded in the United States in 2002, is a supplier of tool steels, high speed steels, carbon steels, and alloy steels. The company's product portfolio includes an extensive selection of tool steels designed to meet the demanding requirements of cutting, machining, and forming applications. Its products are used for manufacturing industries, from automotive and aerospace to machinery and tooling and for precision machining and metalworking processes.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Precision Marshall |

9.5%

|

| 2 | Harris Product |

7.9%

|

| 3 | Dayton Lamina Corporation |

5.3%

|

| 4 | JFE Steel America, Inc. |

4.8%

|

| 5 | Trident Company |

4.2%

|

| 6 | TMS Titanium |

4.2%

|

| 7 | Virgamet |

3.7%

|

| 8 | Alloys Unlimited and Processing, LLC |

3.7%

|

| 9 | Struers |

3.7%

|

| 10 | METALBALL |

3.2%

|

Derivation Method

The ranking is calculated based on the click share within the alloy tool steel page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

11 | 45.8% |

Japan

Japan

|

4 | 16.7% |

Taiwan

Taiwan

|

2 | 8.3% |

China

China

|

1 | 4.2% |

Denmark

Denmark

|

1 | 4.2% |

Poland

Poland

|

1 | 4.2% |

France

France

|

1 | 4.2% |

| Romania | 1 | 4.2% |

India

India

|

1 | 4.2% |

Germany

Germany

|

1 | 4.2% |

30 products found

30 products

Matsuse Steel Co., Ltd.

390+ people viewing

Last viewed: 1 day ago

■Features ・Hardness 40HRC ・Emphasis on specularity ・High-grade plastic steel - Heat treated to 37~43HRC (surface guaranteed) under optimal condi...

Matsuse Steel Co., Ltd.

390+ people viewing

■Features ・Hardness 40HRC ・Emphasis on workability ・High-grade plastic steel - Heat treated to 37~43HRC (surface guaranteed) under optimal condi...

Matsuse Steel Co., Ltd.

540+ people viewing

Last viewed: 1 day ago

■Features PXA30 (PX Ace 30) is a general-purpose plastic mold steel that is based on the conventional AISI P20 improved steel and has improved spec...

Moritec Steel Co., Ltd.

650+ people viewing

Last viewed: 30 minutes ago

■Summary Moritec Steel proposes the most suitable metal materials by utilizing the experience and knowledge we have cultivated over the years as a ...

Matsuse Steel Co., Ltd.

370+ people viewing

Last viewed: 1 day ago

■Features ・Hardness 30HRC ・General-purpose plastic steel

Moritec Steel Co., Ltd.

340+ people viewing

■Summary Moritec Steel proposes the most suitable metal materials by utilizing the experience and knowledge we have cultivated over the years as a ...

Matsuse Steel Co., Ltd.

500+ people viewing

Last viewed: 1 day ago

■Features GHX is a high-grade steel for plastic molds that combines excellent specularity and high corrosion resistance. ■Excellent specularity Th...

Matsuse Steel Co., Ltd.

580+ people viewing

Last viewed: 1 day ago

■Features KPM30 is a P20 improved steel type steel for general-purpose plastic molds that has excellent total balance from mold manufacturing to mo...

Matsuse Steel Co., Ltd.

500+ people viewing

Last viewed: 22 hours ago

■Features S50C forged steel

Matsuse Steel Co., Ltd.

440+ people viewing

StavaxESR is a high-grade stainless steel and plastic mold steel suitable for inserts and cores. It combines corrosion resistance and wear resistan...

Matsuse Steel Co., Ltd.

580+ people viewing

This is a new generation cold die steel that supports Japanese manufacturing. Features ■KD11MAX with excellent surface treatment characteristics A...

Matsuse Steel Co., Ltd.

430+ people viewing

Last viewed: 1 day ago

■Features frame hard steel ■Hardness Possible up to 60HRC

Matsuse Steel Co., Ltd.

500+ people viewing

Last viewed: 21 hours ago

■Features - Already tempered to 37~41HRC (surface hardness) and does not require heat treatment, making it suitable for manufacturing complex and p...

Matsuse Steel Co., Ltd.

580+ people viewing

Last viewed: 1 day ago

■Features ・By solidifying and molding metal powder produced by a combination of vacuum melting and inert gas atomization, highly clean powdered hi...

Matsuse Steel Co., Ltd.

680+ people viewing

Last viewed: 2 hours ago

■Features ・Through nitriding in powder form, it is solidified and molded to achieve uniform nitriding to the inside of the material. This is a ste...

Matsuse Steel Co., Ltd.

350+ people viewing

Features ■Improved galling resistance ・Achieved a steel structure that is ideal for PVD treatment. ・Since the surface treatment film is difficult...

Matsuse Steel Co., Ltd.

430+ people viewing

Last viewed: 1 day ago

■Features ・SKD61 ・Heat crack improved steel ・Die-casting material

Toyo Polishing Industry Co., Ltd.

340+ people viewing

Last viewed: 1 day ago

■Cemented carbide ・It is made by mixing powders of rare metals tungsten (WC) and cobalt (Co) and sintering them at a high temperature of approxima...