All Categories

History

This section provides an overview for skin pass rollings as well as their applications and principles. Also, please take a look at the list of 10 skin pass rolling manufacturers and their company rankings. Here are the top-ranked skin pass rolling companies as of February, 2026: 1.GAZİ METAL, 2.Hertz Controls India Pvt. Ltd., 3.Clecim.

Table of Contents

Categories Related to Skin Pass Rollings

A skin pass rolling is one of the processing methods used to process metal materials such as steel sheets.

The purpose is to correct the distortion caused by cold rolling and to smooth the surface of the sheet material to make the surface shiny. Since skin pass rollings may reduce the strength of the sheet, heat treatment may be applied after skin passings to reinforce the strength of the sheet. Skin pass rollings are widely used in the processing of steel plates and other metal materials.

Exterior wall and roofing materials, treads and frame parts for elevators and escalators, and steel structural parts for water supply facilities and river bridges are examples.

Automobile exterior panels and frame parts, railroad car exterior panels and frame parts, ship exterior panels and structural parts, etc.

Housings and frame parts for home appliances, housings, and frame parts for medical equipment, housings and frame parts for vending machines and ATMs, housings and frame parts for machine tools and measuring instruments, etc.

Enclosures and frame parts for lighting fixtures and ceiling fans, and frame parts for golf clubs and tennis rackets are examples.

Skin pass rolling is a light rolling process to smooth the surface of a sheet material, which corrects the distortion of the material and evens out the unevenness of the surface, resulting in even light reflection and luster. Flatness and surface hardness can also be improved.

Skin pass rollings are used as a final finish before more precise processing because they are simple, light rolling or drawing, and do not cause significant deformation of the material after processing.

There are three main types of skin pass rollings. The names may differ.

Skin rollings are used to adjust the surface condition and correct rolling distortion. The material is processed while light pressure is applied to correct the distortion of the material. The pressure is adjusted according to the strength and hardness of the sheet.

Skin pass rollings for cut sheets are less productive and time-consuming because the sheets are processed one at a time, but it is highly flexible because the sheets to be processed are small and can be formed into a variety of shapes. It is also often used as a final finish before precision machining, since the surface of the plate after machining is smooth and flat.

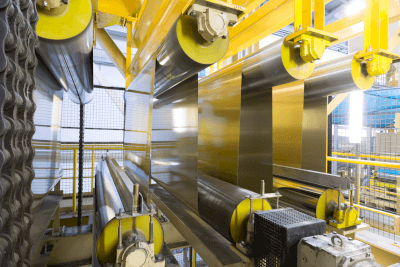

Continuous skin pass rolling is one method to continuously process metal materials. A large amount of sheet metal in coil form can be processed at once in a short time, and as the coiled sheet material passes through the skinpass mill, the surface condition of the sheet material is adjusted and distortions are corrected.

Continuous skin pass rollings are a processing method suitable for high-volume production, and their high productivity reduces processing costs. The high processing speed allows for the processing of a large number of sheets in a short time. The processing force can be adjusted according to the thickness of the sheet material, making it possible to process a wide variety of metal materials.

Tension leveling is a type of skin pass rolling, which is a process of removing surface irregularities by applying tension to the steel sheet and utilizing the reaction of the tension to make the surface flat.

Tension levelers are processing machines that correct rolling distortion and remove warpage by repeatedly bending coiled plates. Tension levelers use the tension (tensile force) inside the coil to bend the sheet material and process it in a bent state.

It is more precise than skinpass mills and can effectively remove rolling distortion. In addition, the repeated bending of the plate material allows the surface irregularities to be evened out, which is a characteristic feature of this process. It is also effective in improving the hardness of plates and is one of the indispensable processing machines for manufacturing high-quality plates.

There are two types of tension levelers: roller levelers with rolls at the front and rear, and top and bottom levelers with rolls at the top and bottom. The former corrects rolling distortion while moving the plate back and forth, while the latter corrects rolling distortion while moving the plate up and down. It is important to select the appropriate tension leveler according to the shape of the sheet material to be used and the purpose of processing.

Skin pass rollings are a processing technique mainly used for processing metal materials but are also sometimes used for processing plastic materials. In the case of plastic materials, Skin pass rollings on transparent plastic materials, such as polycarbonate and acrylic resins, can be used to even out surface irregularities and produce a beautiful finish.

Skin pass rollings make the surface of transparent plastic materials uniform and beautifully finished. Small scratches and flaws on the surface of the plastic material can also be polished away in the process.

*Including some distributors, etc.

Sort by Features

Sort by Area

NIPPON STEEL ENGINEERING CO. LTD., established in 1974 and based in Shinagawa, Tokyo, is a manufacturer of industrial plant equipment and steel products. The company engineers and produces equipment for industrial plants such as gas turbines, blast furnaces, and robots for automated lines. Its steel products and materials include steel pipes, welded steel frames, and composite deck slabs. The company also offers R&D, construction, and engineering services for manufacturing facilities, waste-to-energy plants, and clients in the civil engineering sector.

JP Steel Plantech Co. is a manufacturer of steel plant engineering established in 2001 and based in Yokohama, Japan. It specializes in manufacturing iron-making machine equipment like CDQ, water-sealed circular coolers, and continuous castings like slab and billet casters. It also manufactures rolling mills, RH vacuum degassers, electric furnaces, plate shears, and tension levelers. The company is a joint venture of four companies, namely JFE Engineering, Kawasaki Heavy Industries, Hitachi Zosen, and Sumitomo Heavy Industries, and has acquired the ISO 9001:2015 certification. Its products serve steel manufacturing, construction, and metalworking industries across India, China, and Japan.

SMS group GmbH, founded in 1871 and headquartered in Düsseldorf, Germany, is a provider of plant construction and mechanical engineering services in the world of metals. The company’s comprehensive offerings include machinery solutions for various applications, including casting, cold rolling, forging, hot rolling, metallurgy, mini mills, and tube and pipe manufacturing services. It designs new plants, modernizes existing ones, implements digitalization, and offers life cycle services. It provides various services, such as electrics and automation, technical support, consulting, and training, all emphasizing sustainability.

Fives, founded in Paris, France, in 1812 is a of manufactures machines and process equipment. The company's product portfolio includes CNC machines, milling machines, lathes, and grinders that are used in reactors, heat exchangers, filtration systems, mixers, and other bespoke solutions. The company serves markets including Medical and Healthcare, Aerospace and Defense, Consumer Goods, Industrial Manufacturing and Construction and Building. The company provides services such as Product Selection Guidance, Engineering Support, New Product Design and Development and Custom Manufacturing.

REDEX Group, established in 1949 and based in Pforzheim, Germany, is a supplier of machine drives, precision rolling mills, and strip processing technologies. The company has 3 service centres, 8 subsidiaries, and partners worldwide. It also has 30 active patents and offers services in designing, manufacturing sales, and technical support. The R&D and design centres are in different countries, such as France, Germany, and Slovakia, whereas the production plants are located in France and Germany. The company offers fully commissioned support globally to engineering teams in Europe, Asia, and American service centres.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | GAZİ METAL |

16.4%

|

| 2 | Hertz Controls India Pvt. Ltd. |

16.4%

|

| 3 | Clecim |

11.9%

|

| 4 | Esmech Equipment Pvt. Ltd. |

11.9%

|

| 5 | NIPPON STEEL ENGINEERING CO., LTD. |

10.4%

|

| 6 | Fives |

9.0%

|

| 7 | JP Steel Plantech Co. |

9.0%

|

| 8 | SMS group GmbH |

6.0%

|

| 9 | REDEX Group |

4.5%

|

| 10 | Primetals Technologies Limited |

4.5%

|

Derivation Method

The ranking is calculated based on the click share within the skin pass rolling page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

Japan

Japan

|

2 | 40.0% |

France

France

|

1 | 20.0% |

India

India

|

1 | 20.0% |

United Kingdom

United Kingdom

|

1 | 20.0% |