All Categories

History

This section provides an overview for polyurethane as well as their applications and principles. Also, please take a look at the list of 14 polyurethane manufacturers and their company rankings. Here are the top-ranked polyurethane companies as of February, 2026: 1.Gallagher Corporation, 2.IMA Srl, 3.FSI.

Table of Contents

Categories Related to Polyurethane

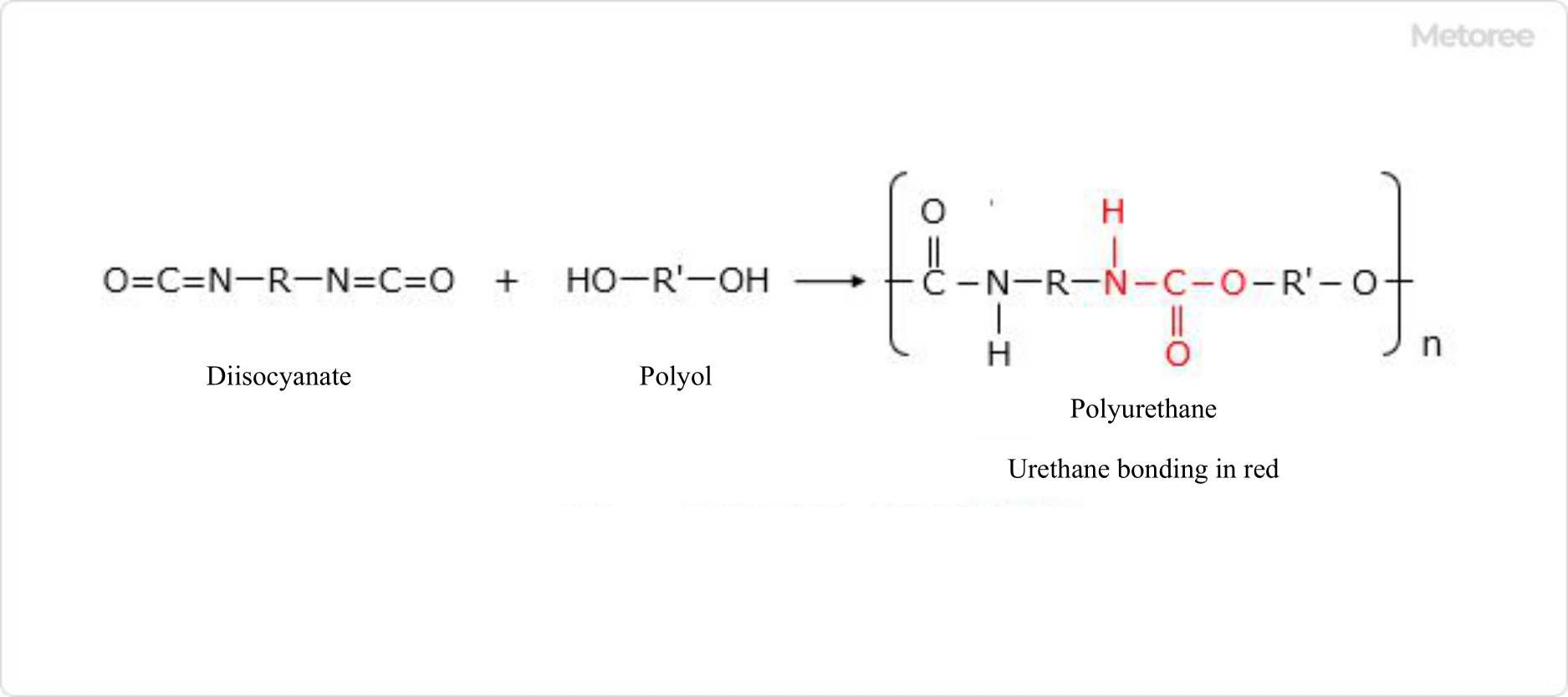

Polyurethane is a polymer with urethane bonds obtained by reacting isocyanate groups with hydroxyl groups.

By changing the type and composition of the primary raw materials and the molding method, polyurethane can be made spongy, flexible like rubber, or hard like rubber tires.

Figure 1. Polyurethane synthesis reaction formula

Polyurethane can be divided into two broad categories in terms of appearance: foam-based, which is porous, and non-foam-based, which is rubber-like. Since the uses for each are quite different, they are described separately below.

Foam-based polyurethane comes in two types: soft foam and hard foam. Soft foam, in particular, is used in various applications, from everyday items to industrial uses. Soft foam applications include sponges used in kitchens, cushions for headphones and other devices, rollers for industrial equipment, and soundproofing materials.

Rigid polyurethane foam applications are often used in construction sites as heat insulators.

Non-foamed polyurethane has high elasticity and toughness and is used as elastic structural materials such as rubber and elastomers, as well as fibers, paints, and adhesives.

As elastomers, they are used in tires, belts, gaskets, rollers, machine parts, and automobile bumpers. Polyurethane fibers, called spandex, are also widely used in clothing such as jackets, pants, swimwear, sportswear, etc., due to their high elasticity.

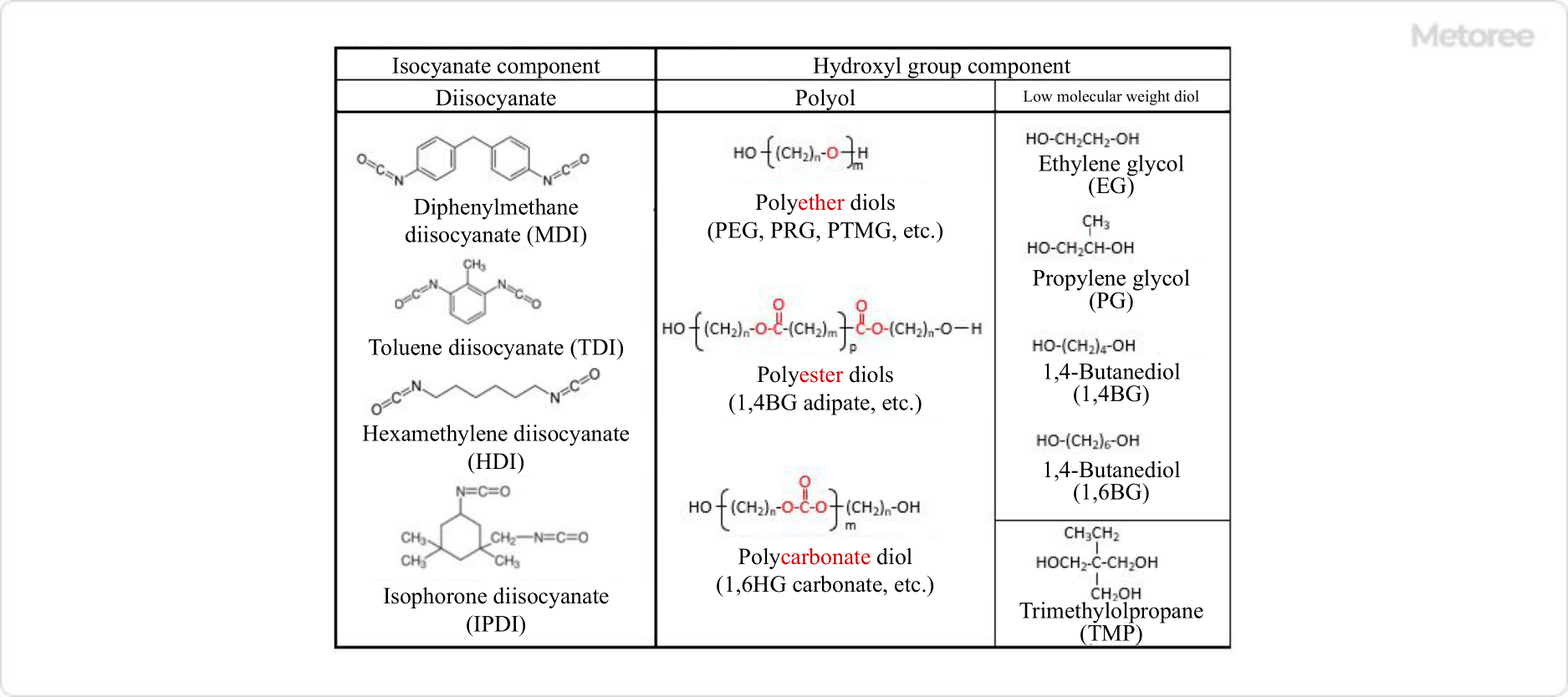

Figure 2. Typical examples of raw materials that make up polyurethane

The raw materials used to make polyurethane include diisocyanates, which have bifunctional isocyanate groups in their molecules, polyols, which have hydroxyl groups in their molecules, and low molecular weight diols.

While there are only a few types of diisocyanates used in polyurethane, there is a very wide range of polyols, which are the raw materials for the hydroxyl group component. This is because polyols themselves are polymers with molecular weights ranging from several hundred to several thousand, and they are composed of a wide range of monomer combinations.

The low molecular weight diols are typical examples of hydroxyl group components, and their dimers are also used as low molecular weight diols. Triols with three hydroxyl groups and alcohols with a single hydroxyl group are also used to adjust the molecular weight.

The characteristics of polyurethane vary greatly depending on the type of raw material used in the mixture. In general, polyurethanes have excellent mechanical strength (elasticity and toughness) and the following characteristics:

These characteristics vary greatly depending on the combination of raw materials used. For example, hardness and strength differ greatly depending on the ratio of polyol and low molecular weight diol used. In addition, the polyol component contributes significantly to weather resistance and hydrolysis resistance. Therefore, it is important to design molecules that match the required performance.

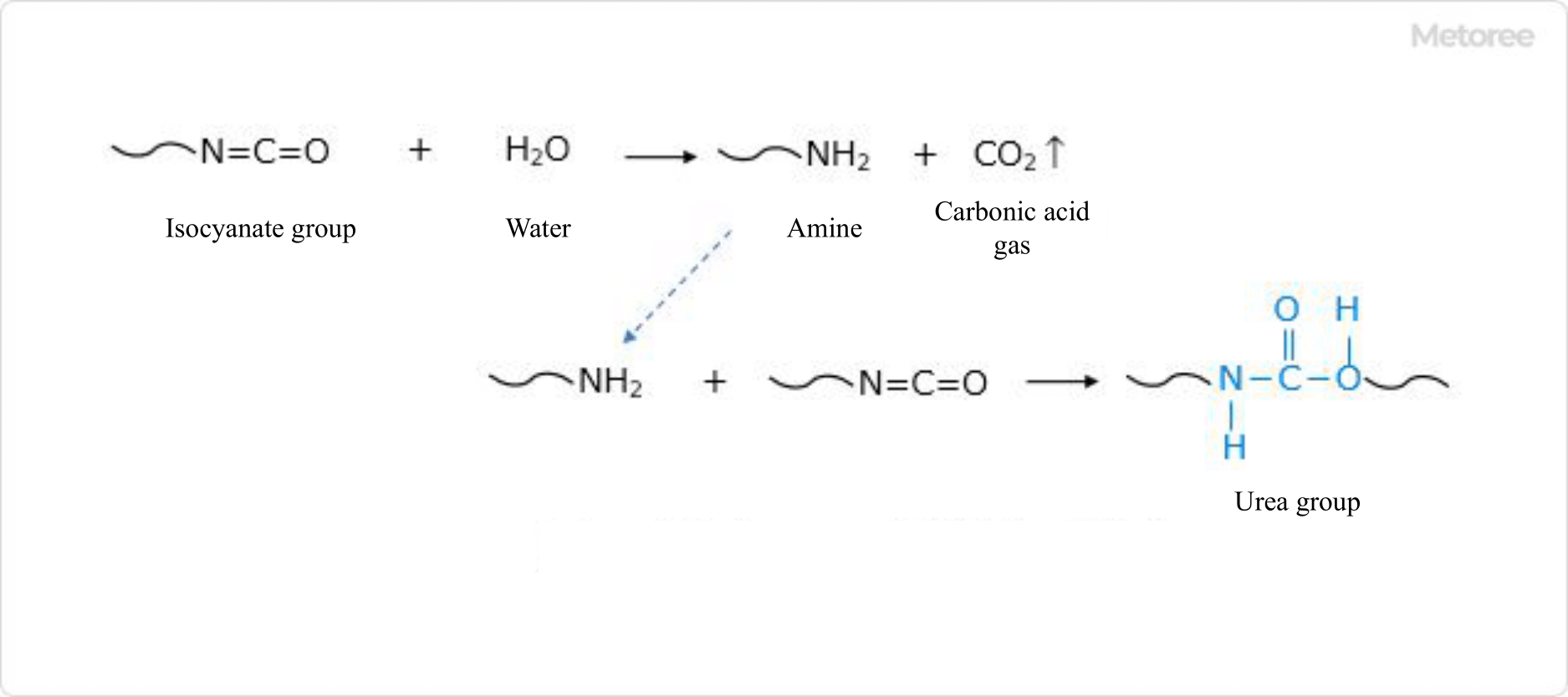

Figure 3. Reaction Formula for Urethane Foam Foaming

Polyurethane foam is a sponge-like molded product produced by foaming polyurethane during the molding process. There are multiple methods of manufacturing polyurethane foam, including slab molding, in which a mixture of raw materials is foamed without being placed in a mold and then cut into the shape of the product. Other methods are mold molding, where a mold is used to form the product into the required shape, and laminate molding, which is useful for producing large insulation boards.

1. Soft Foam-Based Polyurethane

In soft foam polyurethane, water is added as a foaming agent to the raw material polyol, and the isocyanate groups react with the water to produce carbon dioxide gas. At the same time, resinification by the reaction of polyol, low molecular weight diol, and isocyanate proceeds, so that each bubble of carbon dioxide gas cures in a continuous state to form a porous foam.

During the reaction with water, the isocyanate becomes an amine. However, due to the extremely high reactivity of amines, it immediately reacts with another isocyanate group to form a urea bond. For this reason, the composition of soft foam-based polyurethane contains not only urethane bonds but also many urea bonds.

2. Rigid-Foam Polyurethanes

Rigid-foam polyurethane uses a low-boiling physical foaming agent that evaporates from the reaction heat during urethane conversion. The bubbles of rigid foam are independent bubbles to obtain a high thermal insulation effect.

*Including some distributors, etc.

Sort by Features

Sort by Area

FSI, located in Earth City, Missouri, and established in 1972, is a manufacturer of polyurethane foam system solutions. The company offers an array of products, such as heat-seal coatings, elastomers, geotechnical polyurethane foams, pour-in-place polyurethane foam systems, and rigid molding foam. These products are used in various sectors, including manufactured housing, automotive, boating and marine, commercial refrigeration, and construction. In 2002, the company patented Ecomate blowing agent technology to replace harmful CFCs, HCFCs, and HFCs.

American Polyfilm, Inc., founded in Branford, CT in 1998, is a manufacturer of custom polyurethane films. The company's product portfolio includes adhesive polyurethane films, anti-scratch polyurethane films, decorative polyurethane and release films. Their products are used for interior and exterior automotive applications, electrical insulation and environmental protection, and medical devices and equipment for biocompatibility and protection. The company provides services such as Product Selection Guidance, Engineering Support, customer service and Custom Manufacturing.

General Plastics Manufacturing Company, established in 1941 in the United States, is a manufacturer of polyurethane foam and built-to-print composite parts. General Plastics manufactures custom-mold parts using flexible and semi-flexible polyurethane foam materials. The company also can support sub-assembly, part and tool design, and custom foam services. General Plastics provides build-to-print standard and custom laminates for myriad parts and assemblies, and on-site testing laboratories, including an FAA-certified burnt test facility. Their products have various military, industrial, and commercial applications.

Gallagher Corporation, founded in 1965 in the United States, is a polyurethane manufacturer of custom products. The company provides custom polyurethane molding services, collaboratively designs, precisely mold, and dependably delivers polyurethane components that improve customer product’s performance. Whether customer project is build-to-print or new development, is mass production or low quantity, or demands maximum performance, it controls the science of polyurethane to give the customer an advantage. It formulates and processes the polyurethane chemistry to provide performance parameters that meet customers' requirements. It is an end-to-end product manufacturer, with in-house capabilities to make customer polyurethane product from start to finish.

Anderson Development Co., founded in 1968 and located in Adrian, Michigan, is a manufacturer of chemicals. The company offers a diverse range of products that include acrylic resins, polyurethane dispersions, custom toll manufacturing, urethane elastomer systems, and boron compounds. These products find applications in industries including coatings and paints, adhesives, textiles, agriculture, and chemical manufacturing. The company’s chemicals are essential components in the formulation of coatings, adhesives, sealants, textiles, and agricultural products that are used in the development of a range of solutions across multiple sectors.

Capital Resin Corporation is a custom resins, coatings, and chemicals manufacturer established in 1976 and based in Columbus, Ohio. The company specializes in production operations for client companies in the agriculture, adhesives, personal care, and composites markets. The company’s product lineup includes phenolic and resorcinol resins, alkylated phenols, aromatic sulfonic acids, and polyurethanes used in industries like aerospace, defense, automotive, and electronics. As an ISO 9001 and SOCMA ChemStewards certified company, Capital Resin Corporation is equipped to provide technical integration services including research and development, as well as chemical storage, packaging, and transportation.

PSI Urethanes, Inc. was established in 1966 and is a manufacturer of custom-molded urethane products and sheet stock for die cutting, process automation, food processing, and metal forming. The products include multi-durometer urethanes and bespoke molds for the military, fluid cell remold, marine, automotive, and OEM industries, as well as polyurethane rollers, tubes, rods, shock absorbers, washers, and rings. The business is a member of the Association of Austin Regional Manufacturers member and has its headquarters in Austin, Texas.

Polyurethane Products was founded in the early 1980s and is headquartered in Addison, Illinois. The company is a manufacturer of polyurethane products, polyurethane metal fabrication tooling, and steel brake tooling for any both individual and industrial-scale projects. The company’s polyurethane metal fabrication tooling line includes radius tooling, press brake tooling, and urethane springs subdivisions which encompass custom radius tooling, hemming dies, and compression springs. Stock and standard products include urethane bumpers, coil storage, custom machining, mold making, and food-grade polyurethane.

Dow Inc. was originally incorporated in 1897 and is headquartered in Midland, Michigan. The company is a manufacturer and distributor of numerous advanced materials and chemicals used in packaging, infrastructure, and consumer industries by other companies around the world. The company’s product divisions include Packaging & Specialty Plastics, Industrial Intermediates & Infrastructure, and Performance Materials & Coatings. Packaging & Specialty Plastics include ethylene, rubbers, and wire and cable products. Industrial Intermediates & Infrastructure include ethanol amines, adhesives, sealants, and other composites. Performance Materials and Coatings provides paints and industrial coatings for metal packing.

Ima SRL, founded in 1956 and headquartered in Florence, Tuscany, Italy, is a manufacturer specializing in friction materials and industrial brake systems. The company's products include rigid plates, centrifugal brakes, and caliper brakes. It also produces braking material for rotors, boats, and wind turbines, brake blocks for drawworks, and conical clutch and drilling friction materials used for equipment systems used in the oil and gas industries. The company also offers custom product and friction material production in high or low volumes.

BASF SE, a manufacturer of polyurethane solutions, has been in business since 1865 and is headquartered in Ludwigshafen, Germany. They offer polyurethane products such as polyester polyols for CASE and footwear applications. The company delivers cutting-edge products while prioritizing environmental sustainability. With decades of expertise, they continue to drive creativity in the polyurethane sector, meeting the evolving needs of customers worldwide. With a long-standing history of success, BASF SE remains engaged on advancing technology and shaping the future of polyurethane applications.

Forrest Technical Coatings is a manufacturer and supplier of industrial coatings established in 1973 and located in Eugene, Oregon, USA. The company primarily produces its Stove Bright branded paints for pellet, wood, and gas stoves designed for high temperatures. It also offers its Infernex branded high temperature paints designed for use in exhaust and HVAC systems. The company is ISO 9001:2015-certified, and mainly serves clients in oil refining, biomass processing, and semiconductor manufacturing operations.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Dow Corporate |

16.9%

|

| 2 | Gallagher Corporation |

12.2%

|

| 3 | IMA Srl |

8.7%

|

| 4 | FSI |

8.5%

|

| 5 | PSI Urethanes, Inc. |

8.4%

|

| 6 | American Polyfilm, Inc. |

6.9%

|

| 7 | Polyurethane Products Corp. |

6.7%

|

| 8 | Anderson Development Company |

6.6%

|

| 9 | Capital Resin Corporation |

6.1%

|

| 10 | General Plastics Manufacturing Company |

6.0%

|

Derivation Method

The ranking is calculated based on the click share within the polyurethane page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

10 | 90.9% |

Italy

Italy

|

1 | 9.1% |

124 products found

124 products

Hyosei Japan Co., Ltd.

640+ people viewing

Last viewed: 6 hours ago

Creola, the global No. 1 spandex brand with the No. 1 market share in the world, has been selected by the Korean government as a world-class produc...

Gelb Japan Co., Ltd.

350+ people viewing

Last viewed: 1 day ago

■High quality elastic support made by GERB NOVODAMP® is also one of GERB's innovative products that meets the highest quality demands and the most ...

Yonei Co., Ltd.

490+ people viewing

■Super Polyforte (urethane roll) - Due to the special formulation, there is little change in surface roughness, and there is less adhesion of sizin...

Daiki Sangyo Co., Ltd.

480+ people viewing

Last viewed: 6 hours ago

■Realizes four benefits. A new lineup of belts suitable for high-load (high-speed/high-torque) applications. We would like to introduce you to the ...

KB Seiren Co., Ltd.

520+ people viewing

Last viewed: 5 hours ago

■Espansione FF has broken the conventional wisdom of hot melt type nonwoven fabrics. Espansione has a reputation as a polyurethane nonwoven fabric ...

Gelb Japan Co., Ltd.

360+ people viewing

Last viewed: 5 hours ago

■High quality elastic support made by GERB NOVODAMP® is also one of GERB's innovative products that meets the highest quality demands and the most ...

Gelb Japan Co., Ltd.

420+ people viewing

Last viewed: 1 day ago

■High quality elastic support made by GERB NOVODAMP® is also one of GERB's innovative products that meets the highest quality demands and the most ...

OS Polymer Co., Ltd.

380+ people viewing

Last viewed: 3 hours ago

Hayashi Co., Ltd.

310+ people viewing

Last viewed: 1 day ago

■Series overview Chemical products are materials that respond to customers' concerns with a variety of functionality. Use chemical products to solv...

Gelb Japan Co., Ltd.

330+ people viewing

Last viewed: 1 day ago

■High quality elastic support made by GERB NOVODAMP® is also one of GERB's innovative products that meets the highest quality demands and the most ...

Gelb Japan Co., Ltd.

310+ people viewing

Last viewed: 1 day ago

■High quality elastic support made by GERB NOVODAMP® is also one of GERB's innovative products that meets the highest quality demands and the most ...

Gelb Japan Co., Ltd.

250+ people viewing

Last viewed: 1 day ago

■High quality elastic support made by GERB NOVODAMP® is also one of GERB's innovative products that meets the highest quality demands and the most ...

Gelb Japan Co., Ltd.

270+ people viewing

Last viewed: 1 day ago

■High quality elastic support made by GERB NOVODAMP® is also one of GERB's innovative products that meets the highest quality demands and the most ...

Gelb Japan Co., Ltd.

300+ people viewing

Last viewed: 1 day ago

■High quality elastic support made by GERB NOVODAMP® is also one of GERB's innovative products that meets the highest quality demands and the most ...

Gelb Japan Co., Ltd.

390+ people viewing

Last viewed: 8 hours ago

■High quality elastic support made by GERB NOVODAMP® is also one of GERB's innovative products that meets the highest quality demands and the most ...

Gelb Japan Co., Ltd.

400+ people viewing

Last viewed: 1 day ago

■High quality elastic support made by GERB NOVODAMP® is also one of GERB's innovative products that meets the highest quality demands and the most ...

Mars Co., Ltd.

400+ people viewing

Last viewed: 1 hour ago

■Features Handy Foam is a compact cushioning material that does not require any equipment and can be easily made by anyone, anywhere. The polyureth...

KB Seiren Co., Ltd.

470+ people viewing

Last viewed: 17 hours ago

■Urethane nonwoven fabric Espansione is a melt-blown nonwoven fabric made from thermoplastic polyurethane elastomer developed using KB Seiren's pro...

Kunii Co., Ltd.

210+ people viewing

Last viewed: 1 day ago

■Features ・Polyurethane is a polymeric material that is highly stretchable and elastic. - Due to its good elasticity, it is often used as a synthe...