25 Urethane Foam Manufacturers in 2024

This section provides an overview for urethane foams as well as their applications and principles. Also, please take a look at the list of 25 urethane foam manufacturers and their company rankings. Here are the top-ranked urethane foam companies as of April, 2024: 1.RUBBERLITE, INC., 2.FSI, 3.Smooth-On, Inc..

Table of Contents

1987~1991: Engaged in research on wire covering materials at Polymer Materials Laboratory.

1991~1997: Worked as a patent Engineer at Koike International Patent Office.

1997~2005 Worked as an intellectual property member at GE Yokogawa Medical System, currently working as a writer.

Linkedinhttps://www.linkedin.com/in/%E8%A3%95%E5%AD%90-%E9%88%B4%E6%9C%A8-92b21a234/

researchmap

https://researchmap.jp/0315rs2017

What Is Urethane Foam?

Urethane Foam (formal name: polyurethane) is a polymer containing urethane bonds, which is obtained by mixing and reacting two main raw materials.

Urethane Foam (formal name: polyurethane) is a polymer containing urethane bonds, which is obtained by mixing and reacting two main raw materials.

It is widely used in various applications depending on the blending of the main raw materials and the molding method, and can be classified into foamed foam products (hereinafter referred to as Urethane Foam) and non-foamed products.

Foamed foam products and non-foamed products are broadly classified. Urethane Foam is classified into soft and hard, depending on the application. Non-urethane foam products range from soft and flexible like rubber to tough and resilient like those used in tires.

Uses of Urethane Foam

Among urethane foam products, soft urethane foam is the most commonly seen product used in everyday items such as cushions, sofas, and other furniture, bedding, clothing, and daily necessities.

Rigid Urethane Foam is also used in a wide range of industrial products such as building materials as a heat insulator and sound absorber due to its excellent heat insulation properties, lightness, and ease of molding. Both flexible and rigid foams can be molded at will, making it possible to create parts with a high level of design.

Non-form products, on the other hand, are used as raw materials for tires, tubes, and rollers. In addition, urethane is used in a wide variety of fields, such as paints and waterproofing materials that take advantage of its high weather resistance and waterproofing properties, as well as textiles and synthetic leathers.

Principle of Urethane Foam

The raw materials, polyisocyanate and polyol, form polymers by urethane bonding, and the type and additives are selected to produce urethane foam according to the purpose.

Polyisocyanate is a compound that has two or more isocyanate groups in one molecule. Typical examples are toluene diisocyanate (TDI) and diphenylmethane diisocyanate (MDI).

These polyisocyanates react with polyols having two or more hydroxyl groups in a single molecule to form urethane foam bonds. If a cross-linking agent is added as needed, burette and allophanate bonds can be formed. The elasticity varies depending on the density of the crosslink, with higher density resulting in harder properties.

Types of Urethane Foam

Urethane Foam and non-foam product forms are available.

1. Urethane Foam

Urethane Foam includes soft urethane foam, hard urethane foam, and semi-hard urethane foam, which has characteristics in between the two. Both types are manufactured by adding catalysts, blowing agents, foaming agents, and flame retardants to the raw materials polyisocyanate and polyol.

Flexible Urethane Foam

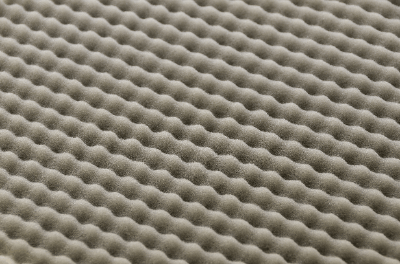

The foam of flexible urethane foam is produced by carbon dioxide gas generated during mixing and reaction of isocyanate and polyol, and is a continuous series of bubbles. The foam is soft, cushiony, and resilient, and is used in cushions and sofas, as mentioned above.

Rigid Urethane Foam

In rigid urethane foam, the foaming agent is vaporized by the reaction heat of isocyanate and polyol, in addition to stirring and mixing, and each foam in rigid urethane foam is a small independent foam. Each independent foam of rigid urethane foam is filled with gas derived from the blowing agent, thus achieving a high thermal insulation effect.

For this reason, as mentioned earlier, it is used as a building material for heat insulation and sound absorption. Since the curing reaction proceeds quickly, the raw materials are often mixed and sprayed at the work site to produce a foam form.

Semi-Rigid Urethane Foam

Semi-hard Urethane Foam is a material with hardness somewhere between that of soft urethane foam and hard urethane foam. It is characterized by high resilience and high elasticity and is used in mattresses.

2. Non-Foam

There are two types of non-foam materials: thermosetting and thermoplastic.

Thermosetting ones are used in car and motorcycle tires, while thermoplastic ones are used as materials for molded items such as car bumpers and synthetic leather. Other uses include paints, elastic fibers, adhesives, and waterproofing materials.

How to Select Urethane Foam

When selecting urethane foam, it is important to confirm the following points:

1. Airtightness

Rigid urethane foam used as a construction material is easy to cut, but if you make a mistake when filling a wall, there is a possibility that there will be a gap. Depending on the level of the installer, airtightness may be low, so it is important to confirm that airtightness can be secured.

2. Flammability

Urethane foam itself is highly flammable. As mentioned above, fire-retardant gypsum board is generally applied on top of the urethane foam, so it is not likely to catch fire directly. However, if fire is a concern, it is safer to use rock wool or similar materials.

3. Safety

There is a disease called "sick building syndrome," which has become common nowadays. This is a symptom of allergic reactions caused by toxic gases emitted from building materials used.

List of 25 Urethane Foam Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- United States of America

- India

- Japan

- United Kingdom

- United states of America

-

-

-

FSI

Flexibles

Manufacturer Overview

FSI, located in Earth City, Missouri, and established in 1972, is a manufacturer of polyurethane foam system solutions. The company offers an array of products, such as heat-seal coatings, elastomers, geotechnical polyurethane foams, pour-in-place polyurethane foam systems, and rigid molding foam. These products are used in various sectors, including manufactured housing, automotive, boating and marine, commercial refrigeration, and construction. In 2002, the company patented Ecomate blowing agent technology to replace harmful CFCs, HCFCs, and HFCs.

-

-

-

-

-

Graco Inc.

Polyurethane Foam

Manufacturer Overview

Graco Inc. Was incorporated in 1926 and is headquartered in Minneapolis, Minnesota. The company is a designer, marketer, and manufacturer of systems and equipment for the movement, control, dispensing, and spraying of fluid and powder materials to global customers. The company operates in three segments: industrial, process, and contractor. The industrial segment designs proportioning systems for pumping sealants, adhesives, and other coating materials. The process segment designs pumps used in water, wastewater, and petroleum industries. The contractor segment offers paint and viscous coating sprayers.

-

-

-

-

-

Specialty Products Inc.

Polyurethane Foam

Manufacturer Overview

Specialty Products Inc, is part of the Versaflex Companies since 2021, and is known as a manufacturer and supplier of polyurea, polyurethane, and custom plural-component spray foam equipment. Founded in 1974 and headquartered in Washington, United States, the company provides solutions for various industries, including construction and infrastructure, energy, environmental, and industrial applications. Their products include spray foam rigs, spray guns, and spray foam insulation equipment. The company aims at delivering solutions for protective coatings, waterproofing, and insulation needs in many industries.

-

-

-

-

-

Foam Products Corporation

Urethane Foam

Manufacturer Overview

Foam Products Corporation., founded in Calhoun, Georgia, in 1978 is a manufacturer of acoustical underpayments for LVT, vinyl plank, laminate and wood floors. The company's product portfolio includes double stick commercial carpet cushions for hospitality and commercial applications, wood wall planks and kitchen backsplashes, breathable waterproof protective films and coated fabrics and cushioning products. The company serves markets including Medical and Healthcare, Aerospace and Defense, Consumer Goods, Industrial Manufacturing and Construction and Building.

-

-

-

-

-

Smooth-On, Inc.

Mix and Pour Expanding Foams

Manufacturer Overview

Smooth-On, Inc. is a manufacturer of materials for various applications including molds and industrial parts. The company was established in 1895 and is now located in Macungie, Pennsylvania, United States. Smooth-On manufactures materials including rigid and flexible urethane foams, silicone rubbers, and coating and release agents. The company's products are used in various applications including sculpture and art casting, candle making, and architectural restoration. The company also offers training on basic and advanced molding and casting techniques at their facility.

-

-

-

-

-

Mearthane Products Corporate

urethane-based technology

Manufacturer Overview

Mearthane Products Corporate, established in Western Industrial Drive Cranston, RI is a manufacturer of a wide range of thermoplastics by combining the materials used in cast molding to achieve stronger, tailored, lightweight products, and components. The company offers fitness & recreation, military devices, food processing, packing, and many more products. Reaction Injection Molding (RIM) and compression molding are two distinct manufacturing processes that offer different advantages for producing parts made from thermoset materials. Reaction Injection Molding lets the designers envision things without compromising the structural integrity of the product. Whereas compression molding is related to cast molding system.

-

-

-

-

-

Quality Foam Packaging, Inc.

Rigid Urethane Foam

Manufacturer Overview

Quality Foam Packaging, Inc. is a manufacturer of custom foam cushions and components established in 1990 and headquartered in Lake Elsinore, California. The company produces foam components from polyurethane, polyethylene, polystyrene, etc. These materials are used for aircraft seating, shipping containers, military weapon cases, product packaging, bedding furniture, etc. The company can produce its own design and customers’ drawings with its CNC routing, wire cutting, hot wire profiling, and other equipment in its 90,000-square-foot facility. On January 2004, the company received Supplier of The Year Award from Raytheon Management.

-

-

-

-

-

General Plastics Manufacturing Company

LAST-A-FOAM POLYURETHANE FOAM PRODUCTS

Manufacturer Overview

General Plastics Manufacturing Company, established in 1941 in the United States, is a manufacturer of polyurethane foam and built-to-print composite parts. General Plastics manufactures custom-mold parts using flexible and semi-flexible polyurethane foam materials. The company also can support sub-assembly, part and tool design, and custom foam services. General Plastics provides build-to-print standard and custom laminates for myriad parts and assemblies, and on-site testing laboratories, including an FAA-certified burnt test facility. Their products have various military, industrial, and commercial applications.

-

-

-

-

-

RUBBERLITE, INC.

Polyurethane Foams

Company Overview

Rubberlite, Inc., established in 1988, and headquartered in West Virginia, is a distributor of converted cellular rubber and plastic products, and a manufacturer of custom polyurethane foams, and technical composites. The company converted Neoprene, EPDM, PVC Nitrile, Cross-link polyethylene, etc., into roll and sheet goods using skiving, buffing, PSA lamination, and slitting process and technologies. These goods can be utilized for seat covers, visors, prosthetic padding, shoe insoles, etc. Industries that benefited from its products are footwear, medical, automotive, aerospace, and industrial applications.

-

-

-

-

-

American Converters, Inc.

High Density Polyurethane Foam

Company Overview

American Converters Inc. (AMCON) manufactures polyurethane, polyethylene, polypropylene, and neoprene foams, is headquartered in Minnesota, and was established in 1976. The company offers over 80 classifications of foams with various densities and for any purpose. Foam materials are used for custom packaging, foam mattresses, military gun cases, medical cushioning, etc. The company has facilities to meet customers' demands, including water jet cutting, high-speed die cutting, CNC routing, abrasive wire cutting, etc.

-

-

-

-

-

EZFlow Foam Packaging Systems

Foams

Company Overview

EZ Flow, established in 1995, and headquartered in San Diego, California, manufactures polyurethane foam, foam chemicals, equipment, and accessories in any density and for any purpose. The company produces foam packaging, flotation foam, structural foam, thermal insulating foam, etc. It also offers molded foam products that can be contoured to any shape or angle. Flotation foam is used in maritime and coastguard jobs to fill buoys, pontoons, floating docks, barges, etc. Meanwhile, structural foam can be a great building material due to its strong structure.

-

-

-

-

-

Reynolds Advanced Materials

Urethane Foams – Flexible

Distributor Overview

Reynold Advance Material, established in 1963, is a distributor of retail art supplies, mold-making supplies, etc., headquartered in Pennsylvania, US. The company distributes latex, gypsum, clays, rubber, concrete, etc. It also offers urethane foam and urethane resin for various applications and industries. Application of its products can be seen in film special effects, sculpture, hyper-realistic decorations, etc. Besides offering art materials, the company also provides art classes and courses for the public. It has 12 branches in the US, including Los Angeles, Chicago, Detroit, Seattle, etc.

-

-

-

-

-

AGC Inc.

Polyurethanes Business

Manufacturer Overview

AGC Inc., founded in Amagasaki, Japan, in 1907 is a supplier of flat, automotive, display glass, chemicals, ceramics and other high-tech materials and components. The company's product portfolio includes Architectural glasses, Automotive glasses, Architectural Materials, performance chemicals and Biopharmaceuticals. Their products are used in markets such as Automotive and Transportation, Telecommunications, Industrial Automation, Healthcare and Medical Devices and Aerospace and Defense. They also offer custom packaging, warehousing, customer service and distribution services.

-

-

-

-

-

The Rubber Company

Polyurethane Foam

Manufacturer Overview

The Rubber Company, established in 2013 and headquartered in Romsey, Hampshire, is a British manufacturer and supplier of rubber products. Some of the company’s products are rubber and polyvinyl chloride (PVC) extrusions used for sealing, noise control, vibration control, and decorative trim. Product variants include seals and extruded rubber profiles, flame retardant neoprene and silicone, conductive extrusions and coatings, as well as miniature profiles. These products find applications in various industries such as automotive, construction, engineering, marine, and lighting. Additionally, The Rubber Company offers specialist products like anti-slip flooring and mats used in agricultural, commercial, gym, residential, and leisure settings.

-

-

-

-

-

Alanto Ltd.

Polyurethane Foam

Manufacturer Overview

Alanto Ltd. was established in Walsall, UK, and is a manufacturer of foam and rubber products for body armor, domestic appliances, electrical and lighting, heating, and ventilation Industries. The company uses raw materials such as neoprene, polyethylene foam, solid rubber, and silicone to make the following products: rubber coils, rubber gaskets, foam tapes, foam rolls, and rubber seals. The applications of the equipment include safeguarding machines from dust and water and combating operatives.

-

-

-

-

-

Kinetic Polymers

Polyurethane Foam

Manufacturer Overview

Kinetic Polymers, established in Rangareddy, Telangana, India, is a manufacturer of multiple conductive compounds and anti static products and solutions since 2000. The company offers ESD safe products like anti static, conductive products also fabricates the ESD furniture like work stations/ tables, ESD chairs, trolleys, shelves, matching stringent technical demands and customized products. It also produces conductive products for explosives, chemicals and pharma industries for fire safety. It is equipped with the latest technologies for testing and calibration of different instruments, and latest machineries and R&D infrastructure to meet certification demands from customers.

-

-

-

-

-

Trelleborg AB

Confor cushioning and impact absorbing safety foam

Manufacturer Overview

Trelleborg AB, a company founded in 1905 and headquartered in Trelleborg, Sweden, is a manufacturer that provides solutions for extreme cold, heat, pressure, or the tremendous power of nature. The company offers a wide range of products, including Cassette Seal CSL 1500, Pneumatic seals, O-rings, and more. It also has a shop called Seals-Shop that offers various products, such as Rod and Piston Seals. It provides rubber wear liners with synthetic rubber and chemical resistance. It has received the Excellence in Quality 2018 Award and Certificate of Merit from Hyster-Yale Group. It serves various industries, including Aerospace, Agriculture, and more.

-

-

-

-

-

Saint-Gobain Tape Solutions

Polyurethane Gasketing Foams

Manufacturer Overview

Saint-Gobain Tape Solutions, established in 1963, is a manufacturer of tapes, including adhesive, bonding, gaskets, and spacer tapes targeting the automotive, energy, building & construction, industrial, and electrical markets. Saint-Gobain Tape Solutions offer custom solutions, with 139 projects opened in the last twelve months and three new projects each week. The company in Bengaluru, Karnataka, India, has gasketing foams that eliminate the sticky problems that come with sealants, elastomeric foam tapes are also available with or without adhesive.

-

-

-

-

-

INOAC CORPORATION

Polyurethane

Manufacturer Overview

INOAC CORPORATION, founded in 1954 and headquartered in Nagoya, Aichi, is a manufacturer and supplier of functional materials based on composites. The company's product lineup includes polyurethane, rubber, plastics, and composites. These materials serve various functions such as sound insulation, vibration dampening, shock absorption, and heat resistance. They predominantly serve sectors like transportation, IT equipment, housing & construction, medical & welfare, and consumer products. Beyond its core products, the company also ventures into distribution, packaging, and electric product domains.

-

-

-

-

-

Aerovac Composites One

Urethane Foam Core

Company Overview

Aerovac Composites One, established in 2021 and headquartered in Illinois, USA, is a manufacturer and supplier of vacuum bagging and process material. The company’s products include bagging films, breather fabrics, release films, peel plies, sealant tapes, etc. These products are important for producing composites used in aerospace, wind energy, marine, motorsports, and more. As a part of Composites One, Aerovac has a strategic position to distribute its products from its 44 distribution centers across North America.

-

-

-

-

-

-

-

-

-

-

-

Acoustics First Corporation

Acoustical Foam Absorbers

-

-

-

-

-

QualityTrade

Polyurethane Foam

-

-

Urethane Foam Manufacturer Ranking

*Including some distributors, etc.Ranking as of April 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | RUBBERLITE, INC. |

8.4%

|

| 2 | FSI |

7.0%

|

| 3 | Smooth-On, Inc. |

7.0%

|

| 4 | American Converters, Inc. |

5.9%

|

| 5 | General Plastics Manufacturing Company |

5.3%

|

| 6 | Graco Inc. |

5.3%

|

| 7 | Foam Products Corporation |

5.1%

|

| 8 | Reynolds Advanced Materials |

5.1%

|

| 9 | Specialty Products Inc. |

5.1%

|

| 10 | Quality Foam Packaging, Inc. |

4.8%

|

Derivation Method

The ranking is calculated based on the click share within the urethane foam page as of April 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

- AGC Inc.: 7,412

- INOAC CORPORATION: 1,846

Newly Established Company

- Technomak: 2010 (14 years ago)

- EZFlow Foam Packaging Systems: 1995 (29 years ago)

- RUBBERLITE, INC.: 1986 (38 years ago)

Company with a History

- Smooth-On, Inc.: 1895 (129 years ago)

- General Plastics Manufacturing Company: 1941 (83 years ago)

- Grand Rapids Foam Technologies: 1949 (75 years ago)

Urethane Foam Manufacturers in United States

*Including some distributors, etc.

- FSI

- Graco Inc.

- Specialty Products Inc.

- Foam Products Corporation

- Smooth-On, Inc.

- Mearthane Products Corporate

- Quality Foam Packaging, Inc.

- General Plastics Manufacturing Company

- RUBBERLITE, INC.

- American Converters, Inc.

- EZFlow Foam Packaging Systems

- Reynolds Advanced Materials

Global Distribution of Urethane Foam Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

12 | 63.2% |

India

India

|

3 | 15.8% |

United Kingdom

United Kingdom

|

2 | 10.5% |

Japan

Japan

|

1 | 5.3% |

United states of America

United states of America

|

1 | 5.3% |