All Categories

History

This section provides an overview for rare earth metals as well as their applications and principles. Also, please take a look at the list of 7 rare earth metals manufacturers and their company rankings. Here are the top-ranked rare earth metals companies as of February, 2026: 1.NEO, 2.Texas Mineral Resources Corp, 3.Materion Advanced Materials Group.

Table of Contents

Categories Related to Rare Earth Metals

Senior Researcher, Policy Research Institute, Inc.

Graduated from the Graduate School of Advanced Science and Engineering, Waseda University (Department of Applied Chemistry) in 2007. He has been in his current position since August 2020 and a part-time lecturer at Josai International University since April 2020.

He specializes in data analysis and machine learning on the health risks associated with chemical substances.

(1)website

https://www.doctoral.co.jp/doctoral_staff/shimizu.php

(2)linkedin

https://www.linkedin.com/in/yoshiharu-shimizu-ba083b163/

(3)Thesis

https://scholar.google.co.jp/citations?user=GWVJYvkAAAAJ&hl=en&citsig=AMD79op_vFERPKFpVCIH_fkCxeNDGTy-Ug

(4)researchmap

https://researchmap.jp/prolead/

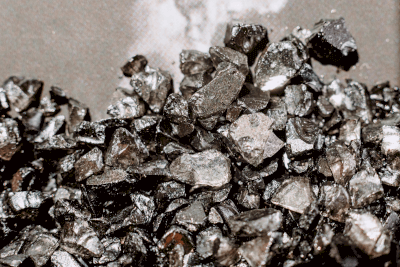

The definition of a Rare Earth Metal is not clear, but it is a general term for metals that are scarce in the earth's crust, difficult to extract for economic or technological reasons, or important to secure in a stable manner in industry.

The major Rare Earth metal-producing countries are Australia, China, Russia, and South Africa, and the global competition for rare metals is heating up.

Other metals that are produced in large quantities and used in various materials, such as iron, copper, and aluminum, are called base metals. Eight elements, including gold, silver, platinum, and palladium, are rare, corrosion resistant, and are called precious metals.

Rare earth metals are employed to enhance the corrosion resistance, melting point, and strength of materials due to their unique properties such as corrosion resistance, heat resistance, ferromagnetism, and superconductivity.

Lithium, cobalt, and nickel are used as cathode materials in batteries. Neodymium and dysprosium are used as powerful permanent magnets in PC HDDs, electric vehicle drive motors, and home appliances. Tantalum is used in capacitors for circuit boards inside electrical appliances, and tungsten is used in tools due to its hardness.

Indium is an essential element in making transparent electrodes for LCD panels. Niobium is used in superconducting magnets for linear motor cars, where extremely low temperatures are involved, and in alloys for engine nozzles in rocket satellites, which are subjected to very high temperatures. Gallium has led to improvements in energy conversion efficiency through the development of LEDs and power transistors.

Rare earth metals have a variety of applications but are rarely used alone. They are usually added to base metals and alloyed to achieve their functions.

Rare earth metals have the common characteristics of strengthening structures and adding new functions to materials by adding them to base metals.

Tantalum is a metal with high dielectric constant, excellent corrosion and acid resistance, and good workability, and is therefore used in capacitors inside electrical appliances.

Tungsten has excellent properties such as hardness and heat resistance at high temperatures, so it is processed into metal parts for tools that are expected to be used in harsh environments.

Although tungsten is an extremely useful Rare Earth Metal, it also poses the problem of frequent imbalances between supply and demand. When the supply/demand balance is disrupted, prices fluctuate wildly and have a significant impact on industrial activities.

Like petroleum, rare earth metals are also resources that are at risk of depletion; by 2050, many types of metals will have exhausted their existing reserves, and there are concerns that demand for some rare metals, such as indium, will far exceed the amount of reserves available.

In recent years, to address this supply/demand balance, recycling technologies have been developed to extract rare earth metals from the urban mining resources accumulated above ground.

There are growing expectations for technologies to extract rare earth metals from urban mines. Advantages of recycling include the following:

Extraction of metals from urban mines generally involves the process of "dismantling and component separation" → "extraction of target materials and materialization".

Urban mine development has great potential and is becoming an important issue for Japan, a country with limited natural resources. Efforts are being developed to recover used cell phones and small electronic devices and extract rare earth metals from them. However, the following challenges persist:

Cell phones and other billion small electronic devices are dispersed throughout the hands of individual consumers, making it difficult to put them in the recycling process unless they are collected efficiently.

Even if rare earth metals are contained in small electronic devices in high purity, a large part of them are other materials such as plastics, and effective use of materials other than rare earth metals must be considered.

One cell phone contains only about 75 cents of rare earth metals, and we must develop a technology (mechanism) to separate, extract, and recover rare earth metals at a lower cost than this.

*Including some distributors, etc.

Sort by Features

Sort by Area

Materion Advanced Materials Group, established in 1931, is a manufacturer of advanced materials based in the United States. The company specializes in producing a diverse range of quality materials tailored to industries such as aerospace, defense, electronics, and healthcare. The materials play a pivotal role in enabling cutting-edge technologies and applications. La Materion's aim is to empower industries with advanced materials that enhance performance, reliability, and sustainability. The company has a comprehensive portfolio and provides technical support.

NEO, headquartered in Toronto, Canada, is a manufacturer and supplier specializing in advanced industrial materials for modern technologies. The company’s product range includes magnetic powders, magnets, specialty chemicals, metals, and alloys, crucial to everyday and emerging technologies. These materials find applications in modern technologies such as hybrid vehicles, pollution control systems, energy-efficient appliances, and water purification. With divisions in Magnequench, Auto Catalysts, Chemicals and Oxides, Rare Metals and Water Purification, Neo serves global markets in automotive, renewable energy, consumer electronics, aerospace, and other sectors.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | NEO |

29.9%

|

| 2 | Texas Mineral Resources Corp |

24.3%

|

| 3 | Materion Advanced Materials Group |

14.9%

|

| 4 | MP MATERIALS |

11.0%

|

| 5 | NORTHERN MINERALS |

7.9%

|

| 6 | Iluka Resources Ltd |

6.0%

|

| 7 | Lynas Rare Earths Ltd |

6.0%

|

Derivation Method

The ranking is calculated based on the click share within the rare earth metals page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

3 | 42.9% |

Australia

Australia

|

3 | 42.9% |

Canada

Canada

|

1 | 14.3% |

112 products found

112 products

Higuchi Economic Planning Institute LLC

340+ people viewing

Last viewed: 7 hours ago

■Summary - Tantalum materials exhibit excellent performance in high pressure, high temperature, and anti-corrosion work environments in the aerospa...

Router Co., Ltd.

250+ people viewing

Last viewed: 1 day ago

■Summary Tungsten (W) metal has a melting point of 3,422℃ and a specific gravity of 19.25g/cm3, which is the highest melting point of any metal.It ...

8 models listed

Higuchi Economic Planning Institute LLC

350+ people viewing

Last viewed: 1 day ago

Tantalum Ta-111 alloy and tantalum Ta-122 alloy are made from a tantalum base with certain amounts of tungsten and hafnium added. Developed based o...

Higuchi Economic Planning Institute LLC

290+ people viewing

Tantalum Ta-111 alloy and tantalum Ta-122 alloy are made from a tantalum base with certain amounts of tungsten and hafnium added. Developed based o...

Higuchi Economic Planning Institute LLC

370+ people viewing

Last viewed: 1 day ago

Titanium Ti-15V-3Cr-3Sn-3Al alloy is a kind of stable β-type titanium alloy. The alloy's cold rolling and cold forming properties are excellent, as...

Higuchi Economic Planning Institute LLC

340+ people viewing

Last viewed: 36 minutes ago

Titanium Ti-10V-2Fe-3Al alloy is characterized by high strength, good fracture toughness, low forging temperature, and strong corrosion resistance....

Higuchi Economic Planning Institute LLC

320+ people viewing

Titanium Ti-6Al-2Sn-4Zr-6Mo alloy is a high aluminum content martensitic α+β two-phase thermal titanium alloy based on the composition of titanium ...

Higuchi Economic Planning Institute LLC

320+ people viewing

Titanium Ti-6Al-4V alloy exhibits outstanding advantages in high performance and technical properties. It has excellent creep resistance, thermal s...

Higuchi Economic Planning Institute LLC

400+ people viewing

Last viewed: 9 hours ago

Titanium Ti-3Al-2.5V (grade 9) alloy is a titanium alloy close to the alpha type. The composition is Ti-3Al-2.5V. Processed into cold-worked tubes....

Shinyo Co., Ltd.

450+ people viewing

Last viewed: 10 hours ago

Tungsten and molybdenum are widely used as materials for crucibles and peripheral parts for crystal growth and rare metal melting because of their ...

Yamanaka Advanced Material Co., Ltd.

350+ people viewing

Last viewed: 1 day ago

We provide high purity gallium and gallium compounds.

Higuchi Economic Planning Institute LLC

410+ people viewing

Last viewed: 1 day ago

In 1965, niobium C-103 alloy was first produced in America and used in the nozzle extension segment of the Apollo Lunar Module rocket engine. China...

Higuchi Economic Planning Institute LLC

330+ people viewing

Last viewed: 1 day ago

Niobium C129Y alloy has high temperature resistance and high strength, and is mainly used in aerospace equipment. These alloys are suitable for man...

Yamanaka Advanced Material Co., Ltd.

360+ people viewing

Last viewed: 12 hours ago

We provide high purity indium and indium compounds.

Higuchi Economic Planning Institute LLC

310+ people viewing

Last viewed: 1 day ago

Niobium Cb752 alloy has high temperature resistance and high strength, and is mainly used in aerospace equipment. These alloys are suitable for man...

Higuchi Economic Planning Institute LLC

340+ people viewing

Last viewed: 53 minutes ago

Niobium FS-85 alloy is a high strength niobium alloy. Using niobium as the base material, a large amount of metal elements such as tungsten, molybd...

A.L.M.T. Corp.

480+ people viewing

Last viewed: 1 day ago

■Product overview For lighting, electrodes, and high temperature furnace parts. In addition to tungsten wire, we can also provide bar material. It ...

Kuno Sangyo Co., Ltd.

190+ people viewing

Last viewed: 5 hours ago

*Other model numbers are available.

10 models listed

Kuno Sangyo Co., Ltd.

100+ people viewing

Last viewed: 23 hours ago

*Other model numbers are available.

10 models listed

Kuno Sangyo Co., Ltd.

150+ people viewing

Last viewed: 1 hour ago

*Other model numbers are available.

10 models listed

Kuno Sangyo Co., Ltd.

160+ people viewing

Last viewed: 23 hours ago

*Other model numbers are available.

10 models listed

Kuno Sangyo Co., Ltd.

140+ people viewing

Last viewed: 1 day ago

*Other model numbers are available.

10 models listed

Kuno Sangyo Co., Ltd.

170+ people viewing

*Other model numbers are available.

10 models listed

Kuno Sangyo Co., Ltd.

90+ people viewing

Last viewed: 1 day ago

*Other model numbers are available.

10 models listed